Fair-current and transverse-flow combined grain drying device

A grain drying and equipment technology, which is applied in grain drying, drying gas arrangement, lighting and heating equipment, etc., can solve the problems of low thermal efficiency and inability to work, and achieve the effect of improving drying quality, improving uniformity, and reducing crack growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

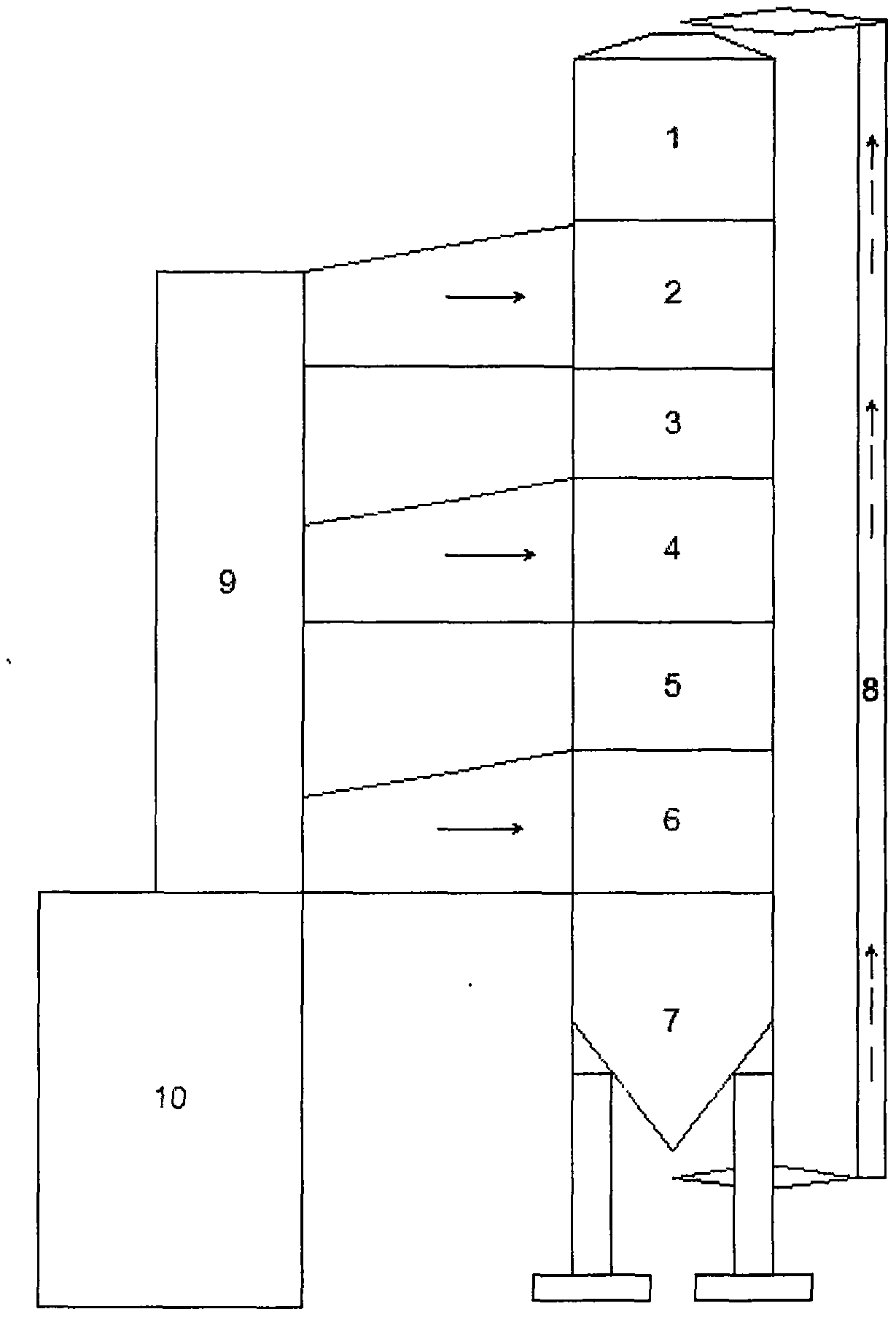

[0013] like figure 1 The grain drying equipment of a combination of co-current and cross-flow is shown, which is a grain drying equipment combined with co-current drying and cross-flow drying, which includes a dryer and a heating system; The grain drying equipment has a combined dryer and heating system, which can match the structure size of the dryer with the heating capacity of the heating system according to actual needs:

[0014] 1. Grain storage section, 2. First-level downstream drying section, 3. First-level slow drying section, 4. Secondary downstream drying section, 5. Secondary slow drying section, 6. Cross-flow drying section, 7. Grain row section, 8. Elevator, 9. Hot air ducts, 10 heating systems.

[0015] The grain drying equipment described in a combination of downstream and cross flow has a combined dryer and a heating system. The heating system is connected with the hot air pipeline of the combined dryer.

[0016] The working process of a kind of grain dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com