Granular delta-phase uniformly distributed GH4169 alloy preparation method

A technology of uniform distribution of GH4169, which is applied in the preparation of high-temperature alloy materials and the field of GH4169 alloy preparation, can solve problems such as low efficiency, high energy consumption, surface oxidation of workpieces or billets, etc., to reduce oxidation degree, reduce material waste, and improve alloy strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] In a specific embodiment, the method for preparing a GH4169 alloy with a uniform distribution of granular δ phases of the present invention includes cold deformation and heat treatment of the GH4169 alloy, and the cold deformation and heat treatment include the following steps:

[0021] a) Firstly, the GH4169 sheet is subjected to solution treatment at 985°C±5°C for 1 hour to eliminate the residual stress, structure and phase inhomogeneity caused by the deformation history;

[0022] b) Carry out rolling deformation to the slab with a deformation amount of more than 30% (generally 40-70%), and pay attention to the cleaning of the slab and the lubricating effect of the roll during the deformation process;

[0023] c) Clean the slab after cold deformation with alcohol or acetone to remove the oil stain on the surface of the slab and prevent it from being severely oxidized during subsequent heat treatment;

[0024] d) Perform heat treatment on the cold deformed slab. The he...

Embodiment

[0028] The GH4169 sheet is subjected to solution treatment at 985°C for 1 hour to eliminate the residual stress, structure and phase inhomogeneity caused by the deformation history; the slab is subjected to rolling deformation with a deformation amount of 50%; the cold-rolled slab is used Wash with acetone to remove oil stains on the surface of the slab; heat-treat the cold-rolled slab, the heat treatment system is: 985°C for 1h, and quickly cool under the protection of vacuum argon; / h cooling to 620°C for 8h, rapid cooling under vacuum protection of argon.

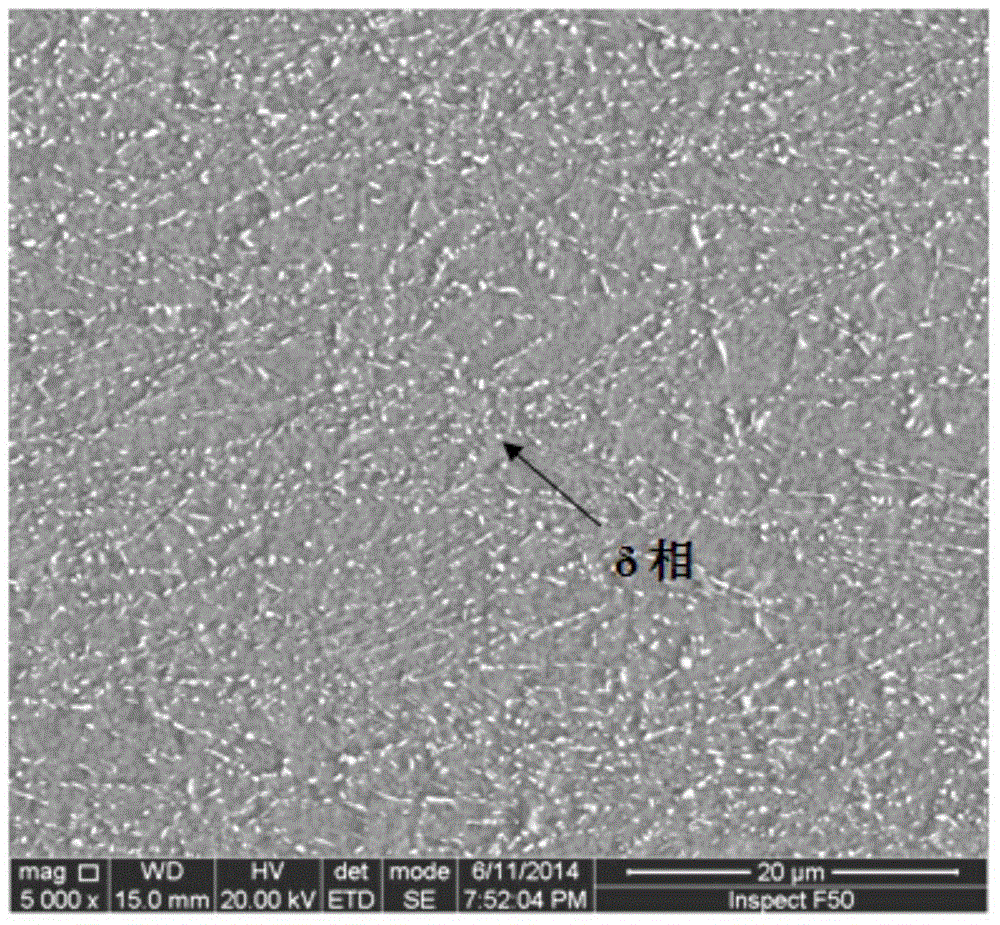

[0029] Such as figure 1 As shown, from the scanning electron microscope of the GH4169 alloy, it can be seen that uniformly distributed granular δ phases are precipitated in the grain boundaries and intragranular structures of the alloy.

[0030] The results of the examples show that when the granular δ phase is evenly distributed in the alloy grain boundary and in the grain, the crack growth rate can be effectively redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com