Method for improving thermal stability and fatigue resistance of Al-Cu-Mg-Yb alloy for aluminum alloy drill rod

An al-cu-mg-yb, aluminum alloy technology, which is applied in the field of heat treatment of aluminum alloys, can solve problems such as the inability to meet the requirements of ultra-deep wells, and achieve excellent room temperature tensile properties, high residual strength, and high fatigue strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

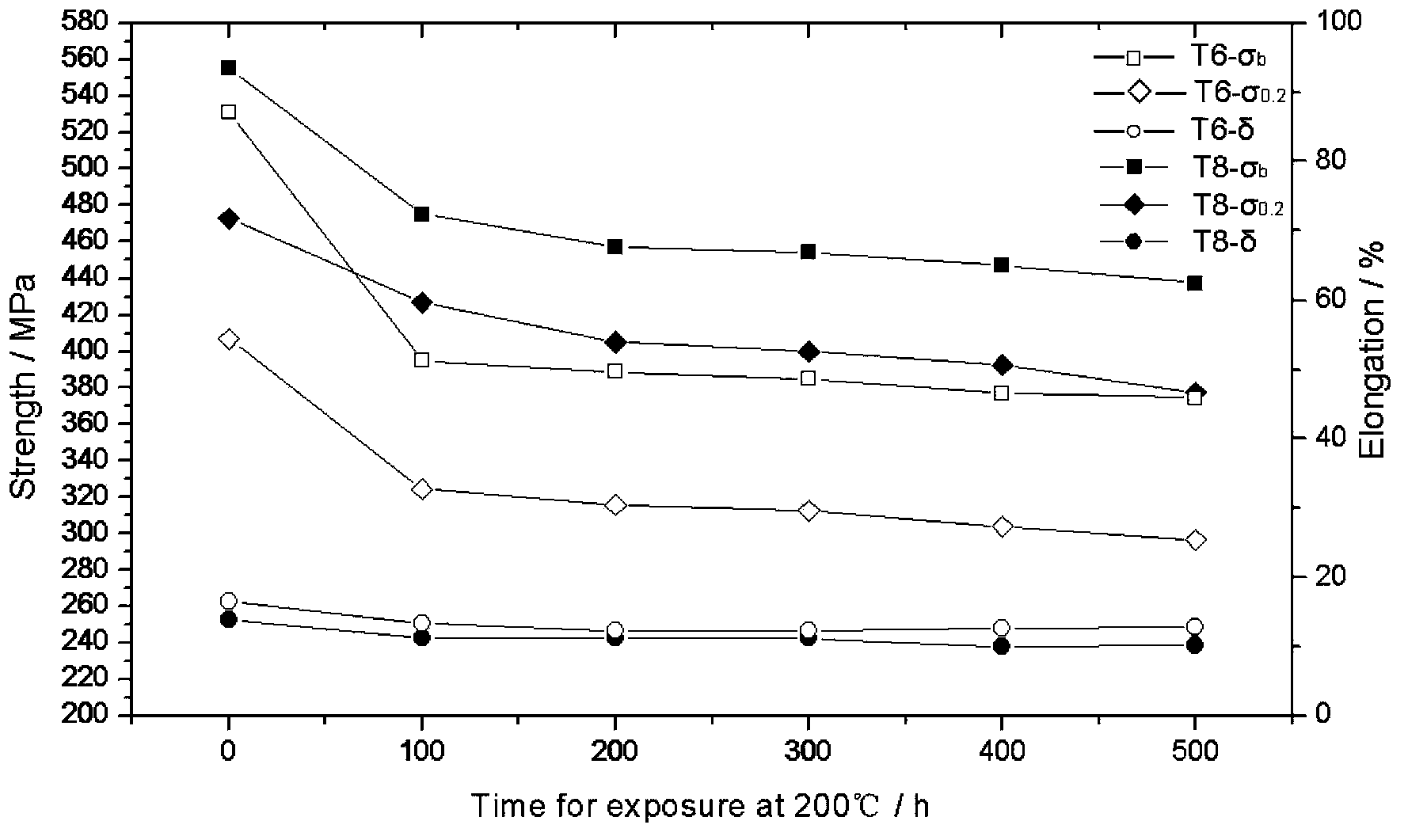

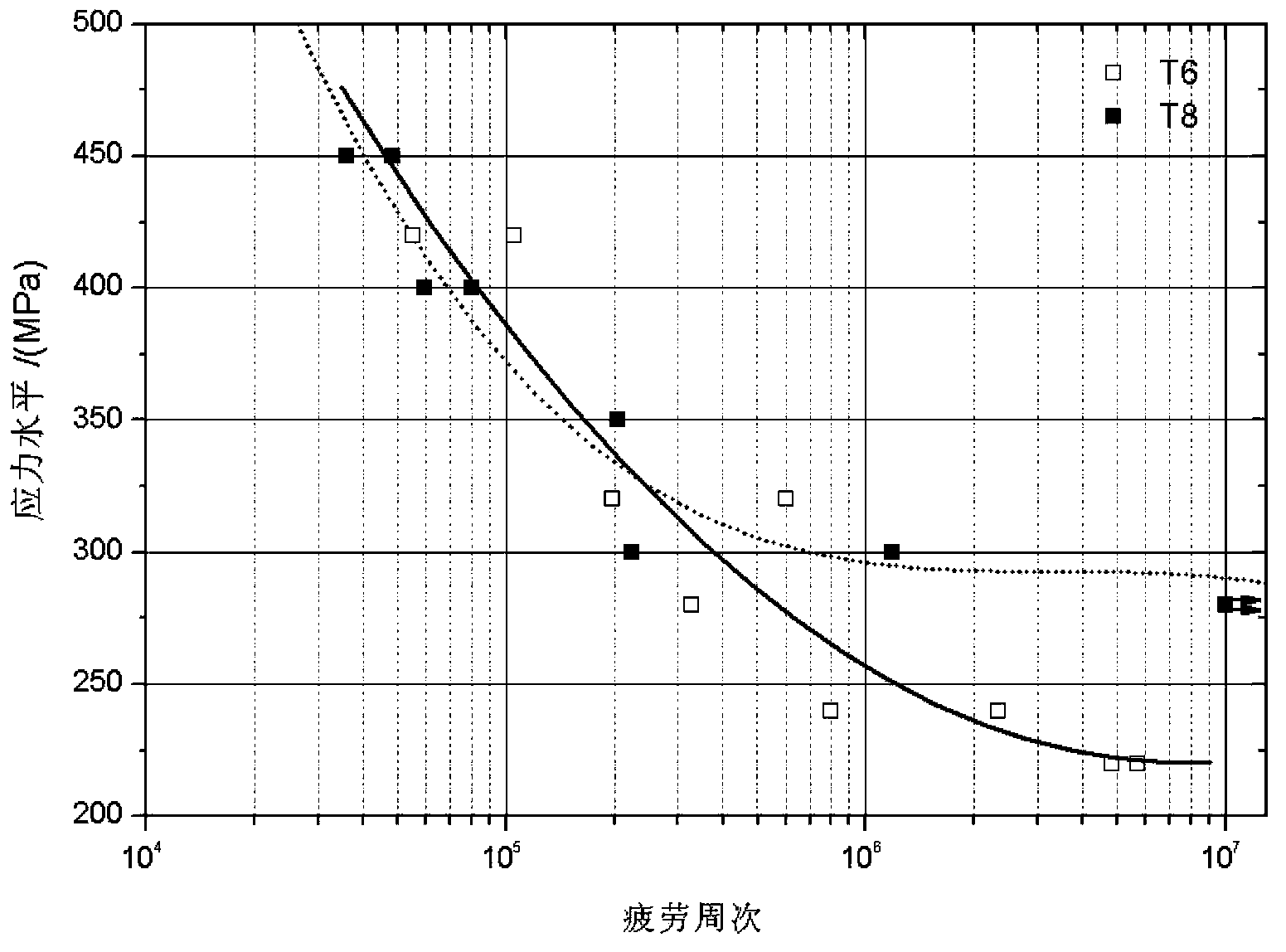

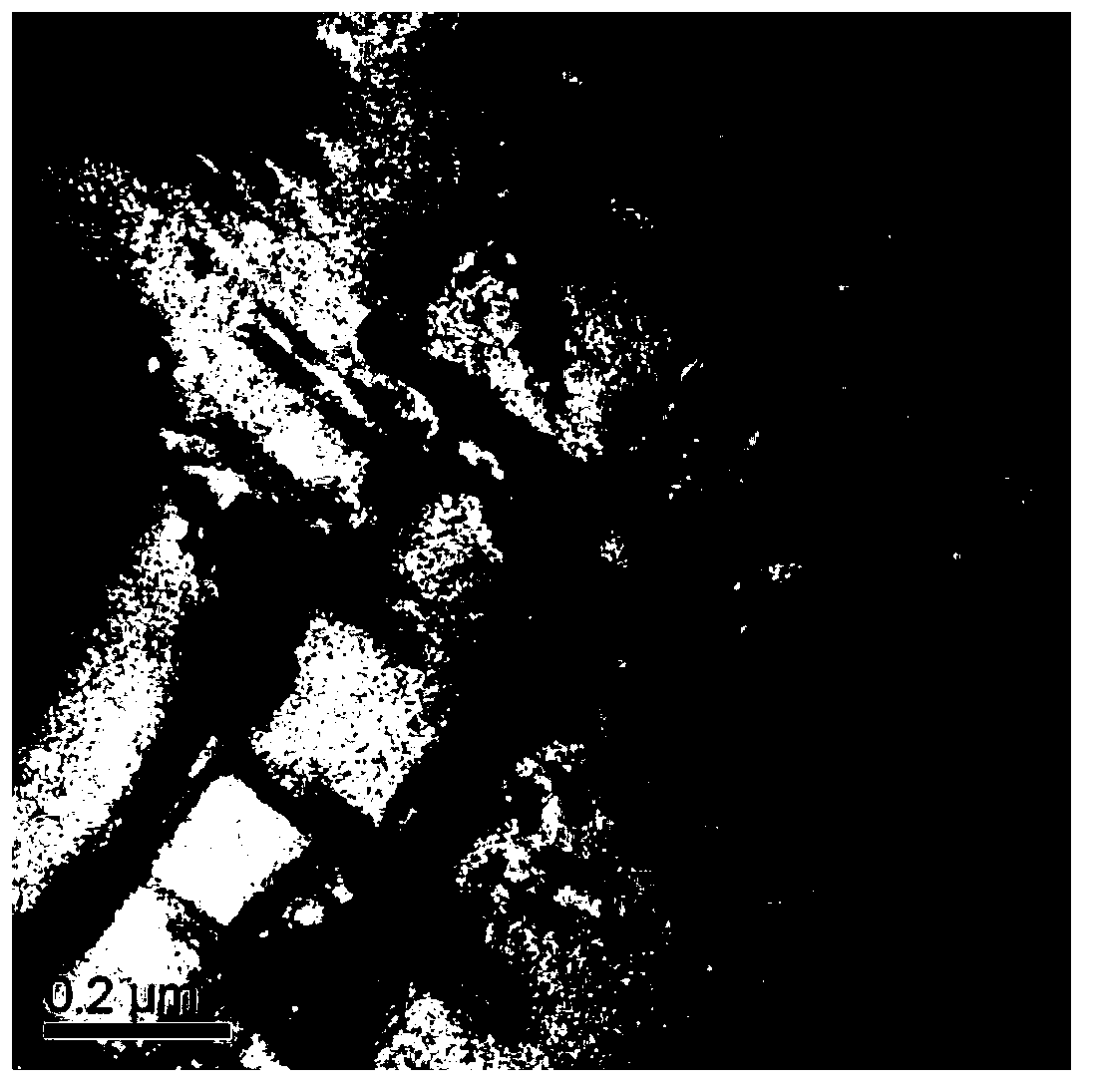

[0037] This embodiment provides a method for improving the thermal stability and fatigue resistance of Al-Cu-Mg-Yb alloys for aluminum alloy drill pipes, combined with reference Figure 1 to Figure 10 And Table 1, the method includes: after the Al-Cu-Mg-Yb alloy that has undergone solid solution is pre-stretched and deformed by 0 to 8%, it is heated to 150°C to 190°C, kept for 2 hours to 12 hours, and then air-cooled. The content ratio of copper and magnesium in the Al-Cu-Mg-Yb alloy is 2-4. The main components and weight percentages of the Al-Cu-Mg-Yb alloy are: Cu: 3.8%-4.8%, Mg: 1.2%-1.8%, Mn: 0.3%-0.9%, Ti: 0.05%-0.20%, Yb: 0.05% to 0.25%, the balance is Al. The solid solution temperature of the Al-Cu-Mg-Yb alloy is 505°C to 515°C, the solid solution time of the Al-Cu-Mg-Yb alloy is 0.5 hour to 1 hour, and the solid solution of the Al-Cu-Mg-Yb alloy is After melting, use water quenching to cool down. The Al-Cu-Mg-Yb alloy is made by adding 0.05% to 0.25% of Yb during th...

Embodiment 2

[0039] This embodiment provides a method for improving the thermal stability and fatigue resistance of Al-Cu-Mg-Yb alloys for aluminum alloy drill pipes, combined with reference Figure 1 to Figure 10 And Table 1, the method includes: after the Al-Cu-Mg-Yb alloy that has undergone solid solution is pre-stretched and deformed by 0 to 8%, it is heated to 150°C to 190°C, kept for 2 hours to 12 hours, and then air-cooled. The content ratio of copper and magnesium in the Al-Cu-Mg-Yb alloy is 2-4. The main components and weight percentages of the Al-Cu-Mg-Yb alloy are: Cu: 4.1%-4.3%, Mg: 1.2%-1.5%, Mn: 0.47%-0.75%, Ti: 0.10%-0.15%, Yb: 0.15% to 0.20%, the balance is Al. The solid solution temperature of the Al-Cu-Mg-Yb alloy is 505°C to 515°C, the solid solution time of the Al-Cu-Mg-Yb alloy is 0.5 hour to 1 hour, and the solid solution of the Al-Cu-Mg-Yb alloy is After melting, use water quenching to cool down. The Al-Cu-Mg-Yb alloy is made by adding 0.05% to 0.25% of Yb during ...

Embodiment 3

[0041] The embodiment of the present invention provides a method for improving the thermal stability and fatigue resistance of Al-Cu-Mg-Yb alloys for aluminum alloy drill pipes, combined with reference Figure 1 to Figure 10 And Table 1, the composition and composition of the Al-Cu-Mg-Yb alloy are: 4.10% Cu, 1.27% Mg, 0.47% Mn, 0.20% Ti, 0.05% Yb, and the balance is Al. The aluminum alloy plate of this composition is solid-dissolved at 505°C for 1 hour and quenched in water, the pre-stretch deformation is 0%, and the tensile mechanical properties at room temperature after aging at 190°C for 8 hours reach: the tensile strength is 531Mpa, the yield strength The tensile strength at room temperature after 500 hours of heat exposure at 200°C reaches: the tensile strength is 374Mpa, the yield strength is 296Mpa, and the elongation is 13%. Under the alternating load of 220MPa stress level and stress ratio of 0.1, the number of fatigue cycles reaches 5.7×10 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com