Aluminum alloy with high heat stability and fatigue resistance and heat treatment technology

A thermal stability and anti-fatigue technology, which is applied in the field of aluminum alloy and heat treatment process, can solve problems such as low elongation, inability to realize thermal stability and fatigue performance of structure performance, and inability to reach high temperature conditions of 200°C, and achieve thermal stability Improvement of resistance and fatigue performance, satisfying high strength and thermal stability, and excellent strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1(T8

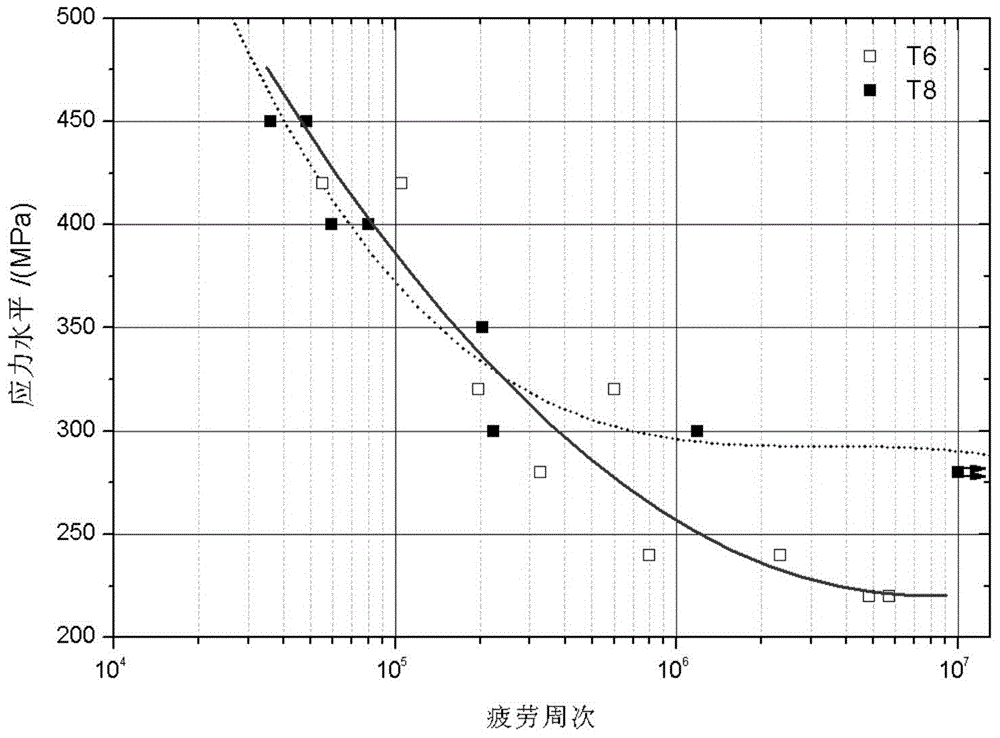

[0045] The alloy composition is: 4.10%Cu, 1.27%Mg, 0.47%Mn, 0.10%Ti, 0.2%Ni, 0.5%Fe, 0.5%Si, and the balance is Al at 490°C for 12 hours for homogenization After chemical treatment, the ingot was extruded into a material at 410°C with an extrusion ratio of 27, then solidified at 505°C for 1 hour and quenched in water, with a pre-stretch deformation of 4%, and aged at 185°C for 2 hours. The tensile mechanical properties at room temperature reach: the tensile strength is 555MPa, the yield strength is 472MPa, and the elongation is 14%. The elongation rate is 10%. Under the alternating load of 280MPa stress level and stress ratio of 0.1, the number of fatigue cycles reaches 1.25×10 7 .

Embodiment 2(T8

[0047] The alloy composition is: 3.80%Cu, 1.80%Mg, 0.90%Mn, 0.15%Ti, 0.10%Ni, 0.70%Fe, 0.70%Si, and the balance is Al at 460°C for 36 hours for uniform After chemical treatment, the ingot was extruded into a material at 380°C with an extrusion ratio of 20, then solidified at 510°C for 0.5 hour and water quenched, 4% pre-stretch deformation was applied, and then aged at 150°C for 12 hours The final mechanical properties reach: the tensile strength is 541MPa, the yield strength is 437MPa, and the elongation is 16%. The rate is 13%. Under the alternating load of 350MPa stress level and stress ratio of 0.1, the fatigue cycle reaches 5.0×10 5 .

Embodiment 3(T8

[0049] The alloy composition is: 4.90%Cu, 1.20%Mg, 0.30%Mn, 0.05%Ti, 0.35%Ni, 0.30%Fe, 0.30%Si, the balance is Al alloy ingot at 475℃ for 24 hours for uniform After chemical treatment, the ingot was extruded into a material at 360°C with an extrusion ratio of 27, then solidified at 515°C for 50 minutes and water quenched, 8% pre-stretch deformation was applied, and then aged at 120°C for 20 hours The final mechanical properties reach: the tensile strength is 542MPa, the yield strength is 463MPa, and the elongation is 15%. The rate is 9%. Under the alternating load of 280MPa stress level and stress ratio of 0.1, the number of fatigue cycles reaches 1.0×10 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com