High damage-resistant aluminium alloy and preparation method thereof

An aluminum alloy and damage-resistant technology, which is applied in the field of non-ferrous metal materials, can solve the problems of narrow PFZ and achieve the effects of improving damage resistance, high resistance to fatigue crack growth, and reducing stress concentration at the tip of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

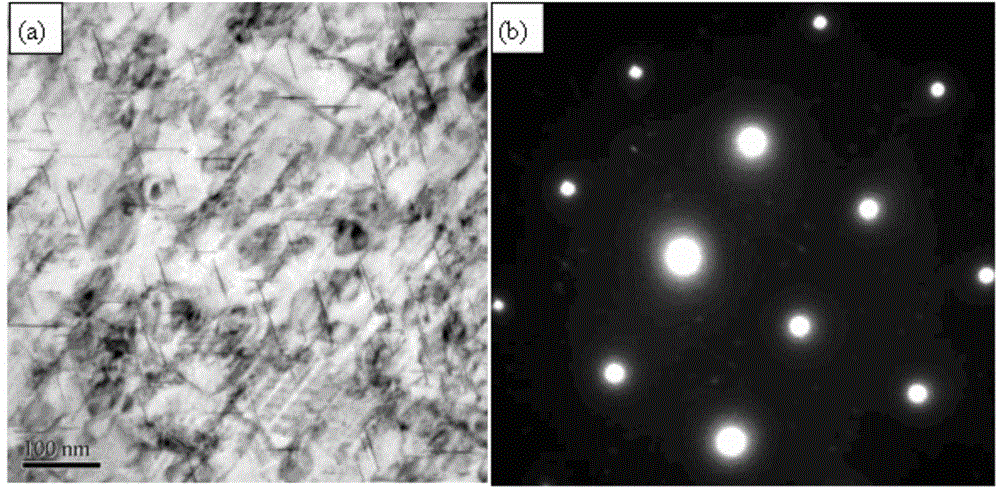

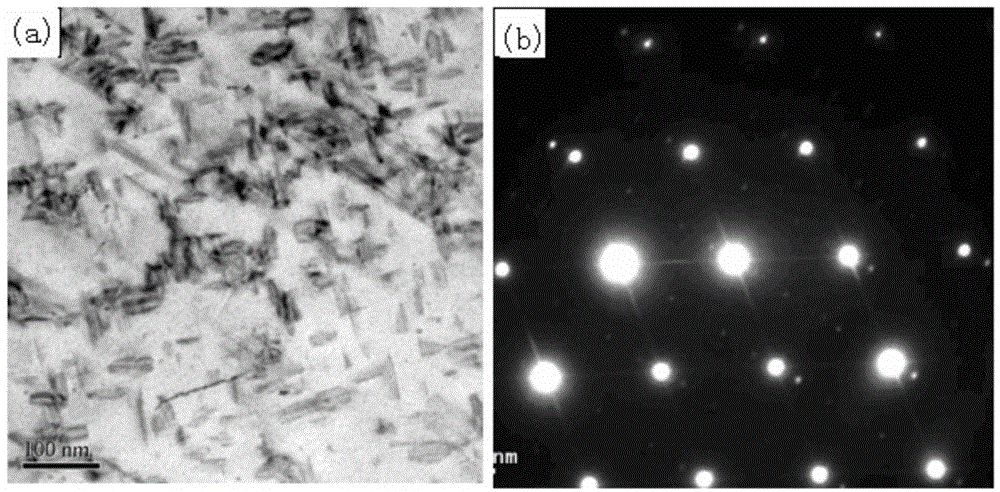

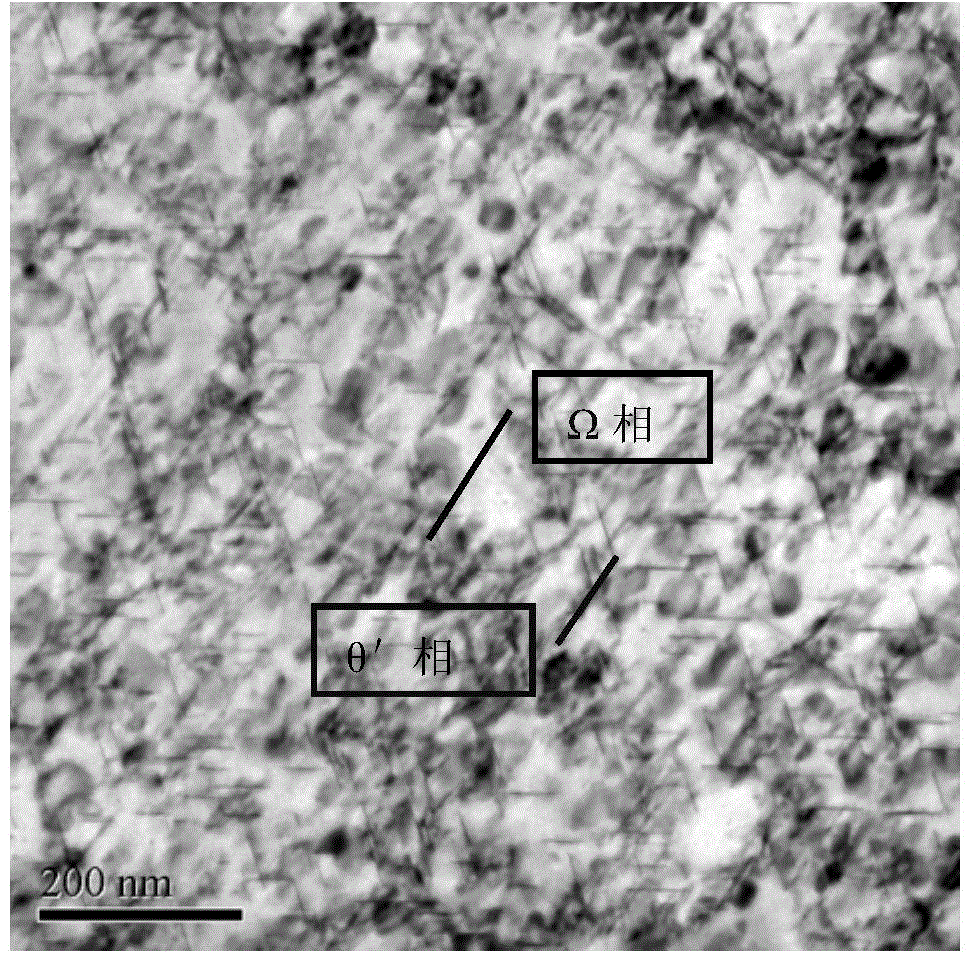

Image

Examples

Embodiment example 1

[0050] The composition of alloy 1 is 3.15% Cu, 0.84% Mg, 0.3% Mn, 0.48% Ag, 0.12% Zr, and the balance is unavoidable trace impurity elements and Al.

[0051] After the ingot billet is obtained, it is first kept at 480°C for 8 hours, and then at 520°C for 36 hours to obtain a homogenized ingot billet, which is hot-rolled, intermediate annealed, and cold-rolled to obtain a cold-rolled billet. State plate; the temperature of the hot rolling is 400-450 ℃, the deformation of the hot rolling pass is 15%; the total deformation of the hot rolling is 60%; the system of the intermediate annealing is: after annealing at 450 ℃ for 5 hours Cool to room temperature with the furnace; the pass deformation of the cold rolling is 10%, and the total deformation of the cold rolling is 60%.

[0052] The cold-rolled sheet is solution treated at 530°C for one hour, water quenched, and then pre-deformed by 4% cold rolling, aged at room temperature for 100 days, and the mechanical properties at room...

Embodiment example 2

[0055] The composition of alloy 1 is 3.15% Cu, 0.84% Mg, 0.3% Mn, 0.48% Ag, 0.12% Zr, and the balance is unavoidable trace impurity elements and Al.

[0056] After the ingot billet is obtained, it is first kept at 480°C for 8 hours, and then at 520°C for 36 hours to obtain a homogenized ingot billet, which is hot-rolled, intermediate annealed, and cold-rolled to obtain a cold-rolled billet. State plate; the temperature of the hot rolling is 400-450 ℃, the deformation of the hot rolling pass is 15%; the total deformation of the hot rolling is 60%; the system of the intermediate annealing is: after annealing at 450 ℃ for 5 hours Cool to room temperature with the furnace; the pass deformation of the cold rolling is 10%, and the total deformation of the cold rolling is 60%.

[0057] The cold-rolled sheet is solution treated at 520°C for 1.5 hours, water quenched, and then subjected to 4% cold rolling pre-deformation, and artificially aged at 145°C for 60 hours to obtain mechanic...

Embodiment example 3

[0065]The composition of alloy 2 is 3.32% Cu, 0.91% Mg, 0.3% Mn, 0.48% Ag, 0.1% Zr, and the balance is unavoidable trace impurity elements and Al. After the ingot billet is obtained, it is first kept at 485°C for 12 hours, and then at 530°C for 30 hours to obtain a homogenized ingot billet, which is hot-rolled, intermediate annealed, and cold-rolled to obtain a cold-rolled billet. State plate; the temperature of the hot rolling is 400-450 ℃, the deformation of the hot rolling pass is 8%; the total deformation of the hot rolling is 64%; the system of the intermediate annealing is: after annealing at 420 ℃ for 4h Cool to room temperature with the furnace; the deformation of each pass of cold rolling is 8%, and the total deformation of cold rolling is 64%.

[0066] The cold-rolled sheet is solution treated at 530°C for one hour, water quenched, and then pre-deformed by 4% cold rolling, aged at room temperature for 100 days, and the mechanical properties at room temperature are ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com