Pipe material used for transmission layer of flexible oil gathering and transportation pipeline in oil field and preparation method thereof

An oil pipeline and transmission layer technology, applied in the field of pipe materials and their preparation, can solve the problems of inability to meet the use requirements, poor high temperature oil resistance, etc., and achieve excellent hot melt processing performance, good high temperature resistance, and improve the effect of high temperature and low tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

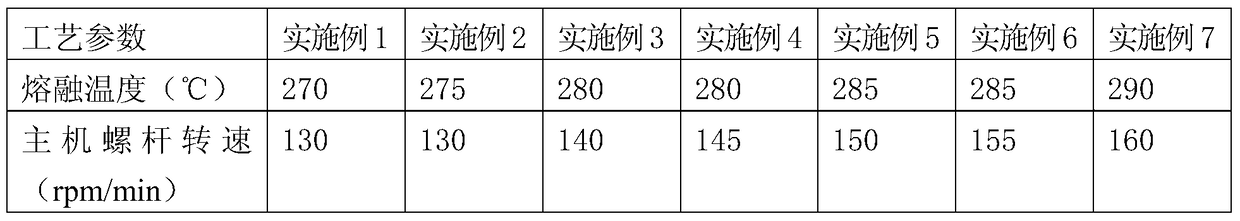

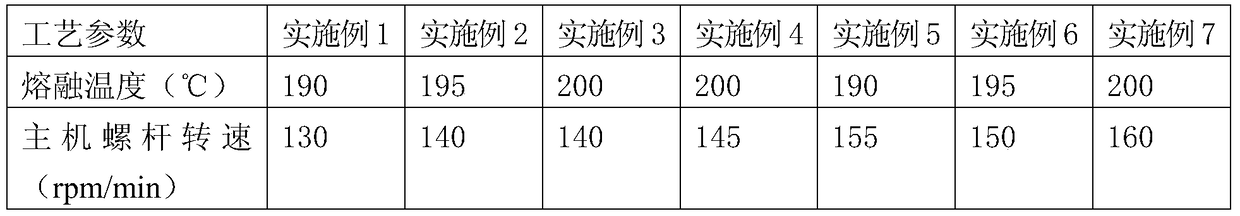

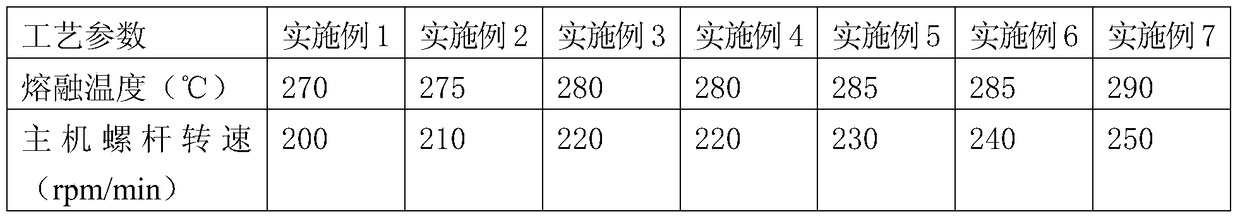

[0011] The pipe material used for the transmission layer of the oilfield flexible oil gathering and transportation pipe of the present invention comprises the following components in parts by mass, including 5-15 parts of ethylene vinyl alcohol copolymer EVOH, 10-30 parts of nylon, 20-60 parts of polyethylene Phenyl ether PPO, 5-15 parts of compatibilizer and 4-8 parts of toughening agent, the compatibilizer of the present invention is polystyrene / polyphenylene ether grafted maleic anhydride PS-PPO-g-MAH, The toughening agent is polystyrene / hydrogenated styrene butadiene styrene copolymer grafted maleic anhydride PS-SEBS-g-MAH. The ethylene vinyl alcohol copolymer EVOH of the present invention has excellent gas barrier properties and excellent hot-melt processing properties, and has strong oil resistance and organic solvent resistance, so that the transmission layer has good oil resistance. , the transmission layer will not be damaged, and the service life of the flexible oil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com