A kind of multi-element rare earth magnesium alloy and preparation method thereof

A rare earth magnesium and alloy technology is applied in the field of metal materials, which can solve the problems of insufficient heat resistance and low strength, and achieve the effects of stable high temperature performance, broad application prospects, and high high temperature tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

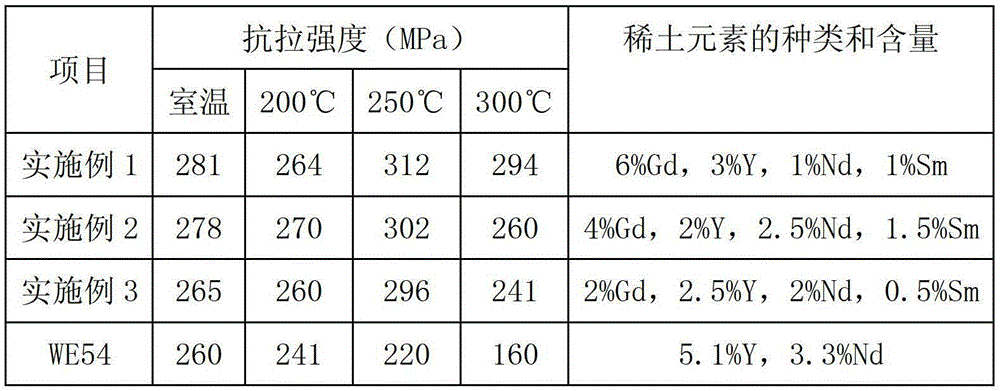

[0026] The multi-component rare earth magnesium alloy of this embodiment is composed of the following components in mass percentage: 6%Gd, 3%Y, 1%Nd, 1%Sm, 0.4%Sb, and the total amount of impurity elements Si, Fe, Cu and Ni is less than 0.02%, the balance is Mg. The sum of the mass percentages of Gd, Y, Nd, and Sm is 11%.

[0027] The preparation method of the multi-element rare earth magnesium alloy of the present embodiment comprises the following steps:

[0028] 1) Preheat Mg, Sb, master alloys Mg-Gd, Mg-Y, Mg-Nd and Mg-Sm to 190°C;

[0029] 2) Put Mg and Sb into a crucible preheated to 500 °C, in CO 2 +SF 6 Under the protection of mixed gas, heat and melt quickly with high power, continue to stir, add master alloys Mg-Gd, Mg-Y, Mg-Nd and Mg-Sm at 730°C, heat and melt slowly with low power;

[0030] 3) After the master alloy is melted, remove the scum on the surface, keep stirring, raise the temperature to 780°C and keep it for 10 minutes to obtain the mixed solution; ...

Embodiment 2

[0034] The multi-component rare earth magnesium alloy of this embodiment is composed of the following components in mass percentage: 4%Gd, 2%Y, 2.5%Nd, 1.5%Sm, 0.8%Sb, and the total amount of impurity elements Si, Fe, Cu and Ni is less than 0.02%, the balance is Mg. The sum of the mass percentages of Gd, Y, Nd, and Sm is 10%.

[0035] The preparation method of the multi-element rare earth magnesium alloy of the present embodiment comprises the following steps:

[0036] 1) Preheat Mg, Sb, master alloys Mg-Gd, Mg-Y, Mg-Nd and Mg-Sm to 220°C;

[0037] 2) Put Mg and Sb into a crucible preheated to 500 °C, in CO 2 +SF 6 Under the protection of mixed gas, heat and melt quickly with high power, continue to stir, add master alloys Mg-Gd, Mg-Y, Mg-Nd and Mg-Sm at 740 ° C, and slowly heat and melt with low power;

[0038] 3) After the master alloy is melted, remove the scum on the surface, keep stirring, raise the temperature to 770°C and keep it for 10 minutes to obtain the mixed s...

Embodiment 3

[0042] The multi-component rare earth magnesium alloy of this embodiment is composed of the following components in mass percentage: 2%Gd, 2.5%Y, 2%Nd, 0.5%Sm, 0.6%Sb, and the total amount of impurity elements Si, Fe, Cu and Ni is less than 0.02%, the balance is Mg. The sum of the mass percentages of Gd, Y, Nd, and Sm is 7%.

[0043] The preparation method of the multi-element rare earth magnesium alloy of the present embodiment comprises the following steps:

[0044] 1) Preheat Mg, Sb, master alloys Mg-Gd, Mg-Y, Mg-Nd and Mg-Sm to 150°C;

[0045] 2) Put Mg and Sb into a crucible preheated to 500 °C, in CO 2 +SF 6 Under the protection of mixed gas, heat and melt quickly with high power, continue to stir, add master alloys Mg-Gd, Mg-Y, Mg-Nd and Mg-Sm at 720 ° C, and slowly heat and melt with low power;

[0046] 3) After the master alloy is melted, remove the scum on the surface, continue to stir, raise the temperature to 775°C and keep it for 10 minutes to obtain the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com