Preparation method of high-performance titanium/steel bimetallic composite plate

A bimetal and clad plate technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problem of inability to produce large-size, heavy-weight or thin-thickness titanium/steel bi-metal clad plates, and the interface bonding strength is not good. Stability, increase the cost of raw materials and other issues, to achieve the effect of low equipment requirements, simple and convenient pretreatment, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

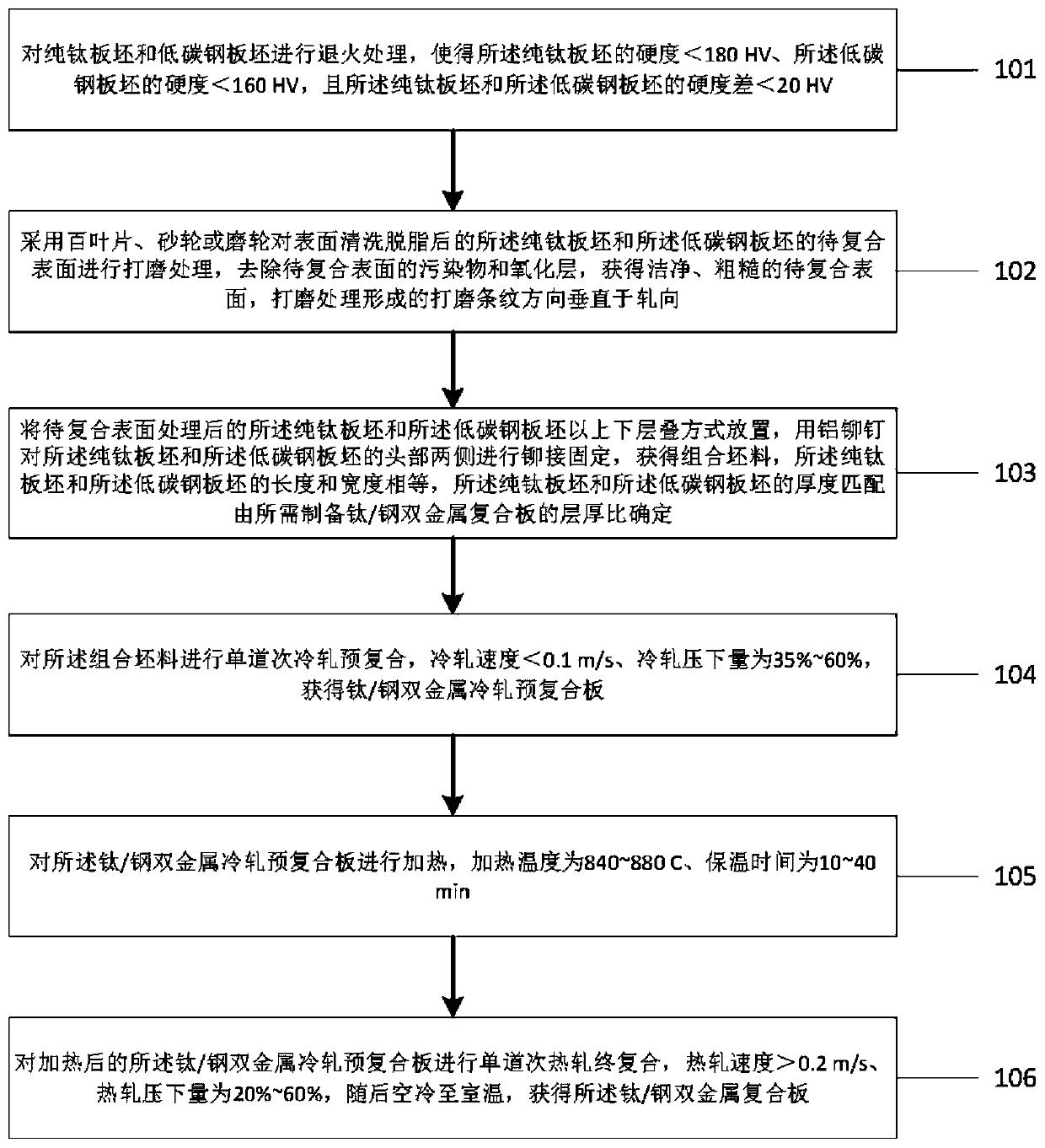

[0036] Such as figure 1 Shown, according to the preparation method of high-performance titanium / steel bimetal clad plate of the present invention, comprises the steps:

[0037] Step 101: Annealing the pure titanium slab and the low-carbon steel slab, so that the hardness of the pure titanium slab is <180HV, the hardness of the low-carbon steel slab is <160HV, and the pure titanium slab and the The hardness difference of the low carbon steel slab is less than 20HV;

[0038] Step 102: Use louvers, grinding wheels or grinding wheels to polish the surface to be compounded of the pure titanium slab and the low-carbon steel slab after surface cleaning and degreasing, to remove pollutants and oxide layers on the surface to be compounded, and obtain a clean , The rough surface to be compounded, the direction of the grinding stripes formed by the grinding treatment is perpendicular to the rolling direction;

[0039] Step 103: Lay the pure titanium slab and the low-carbon steel slab t...

Embodiment 1

[0047] Preparation of TA2 titanium / Q235 steel bimetal composite plate.

[0048] Anneal the 1mm-thick TA2 pure titanium slab and the 4.5mm-thick Q235 low-carbon steel slab. The annealing system of the TA2 pure titanium slab is 750°C for 0.5h and then furnace cooling. The hardness after annealing is 148HV, and the Q235 low-carbon steel slab The annealing system of the steel slab is 870°C for 0.5h and then furnace cooling, and the hardness after annealing is 136HV; the TA2 pure titanium slab and the surface of the Q235 low carbon steel slab to be compounded are mechanically polished with a louver treatment to remove pollutants and oxide layers on the surface to be compounded to obtain a clean and rough surface to be compounded, and the direction of the grinding stripes formed by the grinding treatment is perpendicular to the rolling direction; the TA2 pure titanium slab and the Q235 low-carbon The steel slabs are stacked up and down, and the two sides of the head of the TA2 pure ...

Embodiment 2

[0050] Preparation of TA1 titanium / Q235 steel bimetal composite plate.

[0051] Anneal the 2mm thick TA1 pure titanium slab and the 4mm thick Q235 low carbon steel slab. The annealing system of the TA1 pure titanium slab is 750°C for 0.5h and then furnace cooling. The hardness after annealing is 140HV. Q235 low carbon steel plate The annealing system of the slab is furnace cooling at 920°C for 0.5h, and the hardness after annealing is 132HV; the TA1 pure titanium slab and the Q235 low carbon steel slab to be composited are mechanically ground with a grinding wheel, Remove the pollutants and oxide layer on the surface to be compounded to obtain a clean and rough surface to be compounded. The direction of the grinding stripes formed by the grinding treatment is perpendicular to the rolling direction; the TA1 pure titanium slab and the Q235 low carbon steel slab after the compounded surface treatment Lay it up and down, and use aluminum rivets to rivet and fix the two sides of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com