High strength self-lubricating iron-copper powder composite material and preparation method thereof

A technology of iron-copper powder and composite materials, which is applied in the direction of lubricating compositions, additives, petroleum industry, etc., can solve the problems of low tensile strength and hardness, and achieve the effects of improving mechanical properties, increasing relative density, and good self-lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

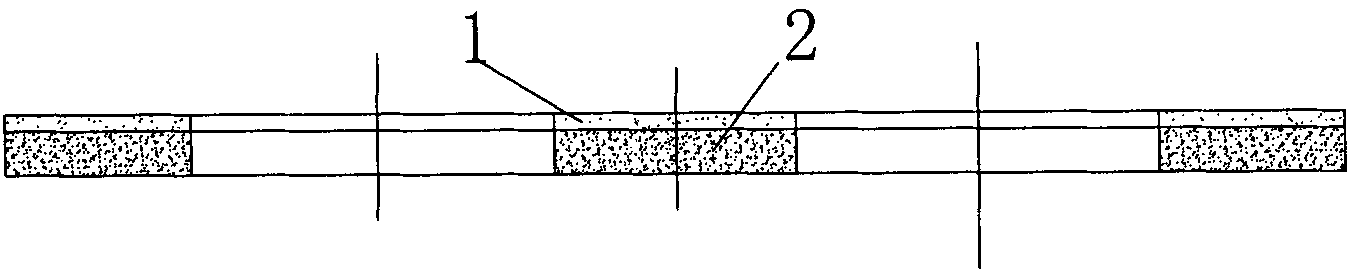

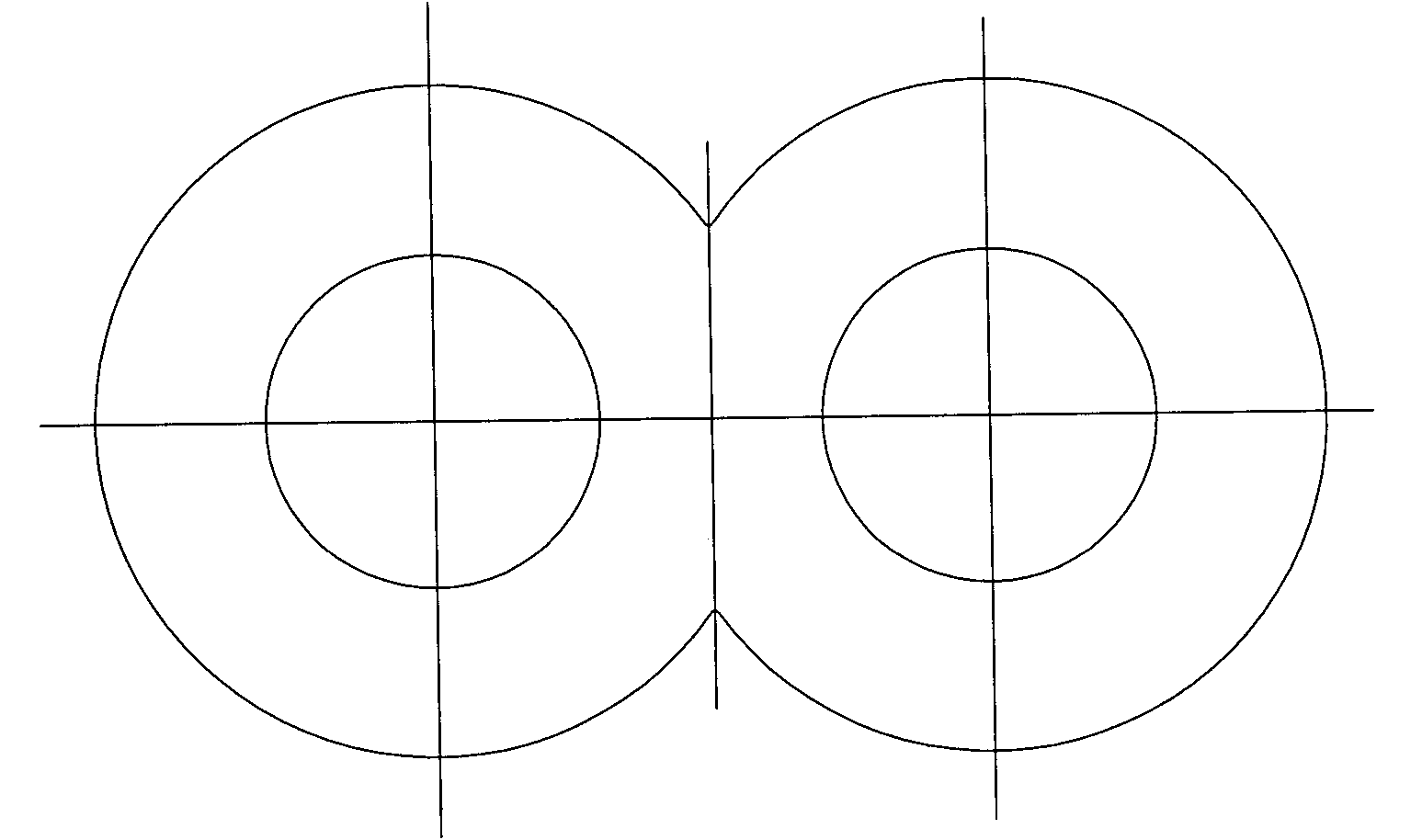

[0036] see figure 1 and figure 2 , figure 1 It is a sectional view of the side plate of the gear oil pump, figure 2 It is a top view of the side plate parts of the gear oil pump.

[0037] The side plate of the gear oil pump is made of the high-strength self-lubricating iron-copper powder composite material and the preparation method thereof of the present invention.

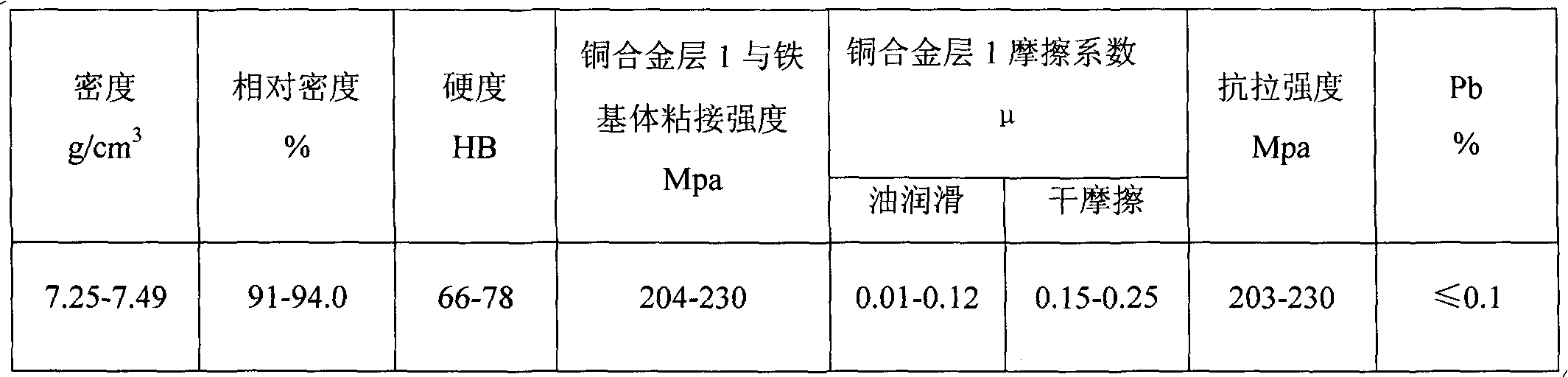

[0038] In this embodiment, the high-strength self-lubricating iron-copper powder composite material is composed of an iron alloy matrix 2 and a copper alloy layer 1 as a surface layer; wherein, the composition of the iron alloy matrix 2 by weight percentage is shown in Table 1; the material of the copper alloy layer 1 is shown in Table 1. The composition in weight percent is shown in Table 2; the thickness of the copper alloy layer 1 is set to 1.0 mm.

[0039] In this embodiment, the high-strength self-lubricating iron-copper powder composite material is prepared according to the following steps:

[0040] ...

Embodiment 2

[0058] In this embodiment, the parts manufactured from the high-strength self-lubricating iron-copper powder composite material and its preparation method are hydraulic pump oil distribution plates.

[0059] The high-strength self-lubricating iron-copper powder composite material of the hydraulic pump oil distribution plate parts and its preparation method are the same as in Example 1, except that:

[0060] The thickness of the copper alloy layer 1 in the present embodiment is designed to be 0.5 mm; the specific chemical composition of the copper alloy layer 1 is shown in Table 4; the specific chemical composition of the iron alloy substrate 2 is shown in Table 5;

[0061] Heat nickel powder, tin powder, iron powder and copper powder in vacuum at 180°C for 2.5 hours to relieve stress and temper;

[0062] The pressing pressure of warm pressing on the press with warm pressing device is 650MPa, the powder temperature of iron alloy substrate warm pressing powder and copper alloy l...

Embodiment 3

[0074] The parts manufactured by the high-strength self-lubricating iron-copper powder composite material and its preparation method in this embodiment are racks.

[0075] The high-strength self-lubricating iron-copper powder composite material and its preparation method described in the rack part are the same as in Example 1. The difference with embodiment 1 is:

[0076] In this embodiment, the thickness of the copper alloy layer 1 is 2 millimeters; the specific chemical composition of the copper alloy layer 1 is shown in Table 7, and the specific chemical composition of the iron alloy substrate 2 is shown in Table 8;

[0077] Heat nickel powder, tin powder, iron powder and copper powder respectively at 190°C for 3 hours in vacuum or protective atmosphere to relieve stress and temper;

[0078] The pressing pressure of warm pressing on the press with warm pressing device is 680MPa, the powder temperature of iron alloy substrate warm pressing powder and copper alloy layer warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com