Bridge plate

A technology for bridge slabs and bridge piers, which is applied to bridges, bridge parts, bridge construction, etc., can solve problems such as insufficient bonding force of concrete and insufficient tension force of steel skeleton, so as to reduce the possibility of transverse fracture and improve bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Do further description below in conjunction with accompanying drawing:

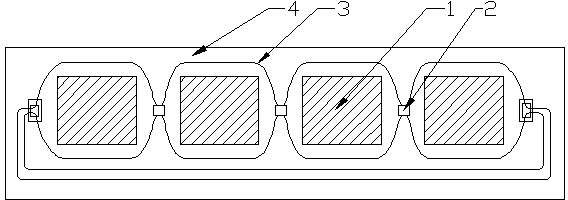

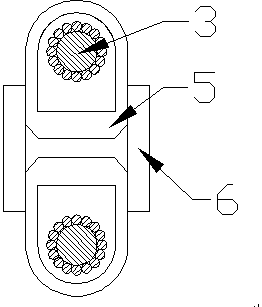

[0017] like figure 1 As shown, the bridge slab of the present invention is composed of several main girders poured and fixed, steel cables 3 are wound around the whole exterior of several main girders 1, and there is a certain gap between the several main girders 1 when they are placed on the beams. A steel cable connector 2 is arranged in the gap, such as figure 2 , the cable connector includes two connecting rods 5 provided with reverse threads, the connecting rods 5 are fixed by the thread and the joint block 6, when the steel cable 3 is wound, the steel cables 3 respectively pass through the steel cables arranged on the connecting rod 5 Through the through hole, after the steel cable 3 is wound, by rotating the joint block 6, the connecting rod 5 shrinks, thereby tensioning the steel cable 3, and the head of the steel cable passes through the steel cable connector 2, and the connecting rod 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com