Unsymmetric dimethylhydrazine resistant plugging and sealing material as well as preparation method and application

A technology of unsymmetrical dimethylhydrazine resistance and sealing materials, which is applied in the field of materials and processes, can solve the problems of increasing the amount of chopped glass fiber, low toughness, and reduced viscosity, etc., and achieves a wide range of bonding materials, good toughness, and reduced viscosity. The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The plugging and sealing material resistant to unsymmetrical dimethylhydrazine, including the mass parts of each component: 100 parts of WSR618 epoxy resin with an epoxy equivalent of 192g / mol, 3 parts of KH550 silane coupling agent, and 40 parts of chopped glass fiber 10 parts of imidazole, 10 parts of tetraethylenepentamine.

Embodiment 2

[0029] The preparation method of the unsymmetrical dimethylhydrazine-resistant plugging and sealing material described in Example 1, the preparation process is as follows: 100 parts of WSR618 epoxy resin and KH550 are fully stirred at room temperature (20-25°C) for 0.5h, and then added short Cut 40 parts of glass fiber, and after preliminary mixing, grind 3 times on a three-roll mill. After the glass fiber is evenly dispersed in the resin matrix, the component A of the unsymmetrical dimethylhydrazine-resistant plugging and sealing material is prepared; 10 parts of imidazole and tetraethylenepentamine are mixed evenly to prepare the unsymmetrical dimethylhydrazine-resistant plugging and sealing material. B component of the material.

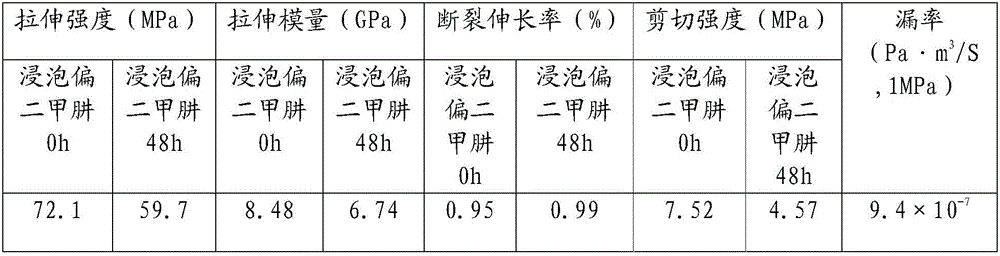

[0030] When using glue, mix A and B components evenly according to the mass ratio of 100:7.5, and then use it. The prepared dual-resistant unsymmetrical dimethylhydrazine plugging and sealing material aluminum-aluminum bonding has a tensile shear...

Embodiment 3

[0032] A plugging and sealing material resistant to unsymmetrical dimethylhydrazine, comprising the following components in mass parts: 100 parts of WSR618 epoxy resin with an epoxy equivalent of 189 g / mol, 3 parts of KH550 silane coupling agent, and 40 parts of chopped glass fiber Parts; 5 parts of imidazole, 5 parts of tetraethylenepentamine, 10 parts of mercaptan fast curing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com