Bearing bush with vacuum sputtering film and production method thereof

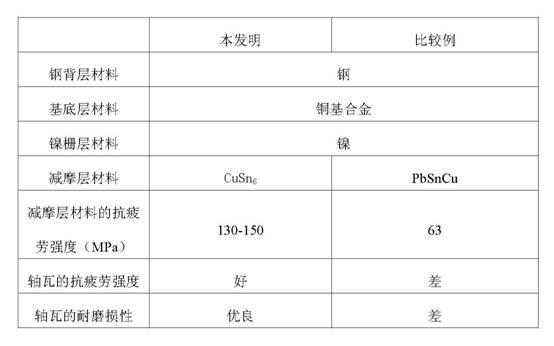

A bearing bush and vacuum technology, which is applied to bearing bushes with a vacuum sputtering coating and its production field, can solve the problems of environmental and personnel hazards, and achieve the effects of high fatigue resistance, excellent wear resistance and good environmental performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

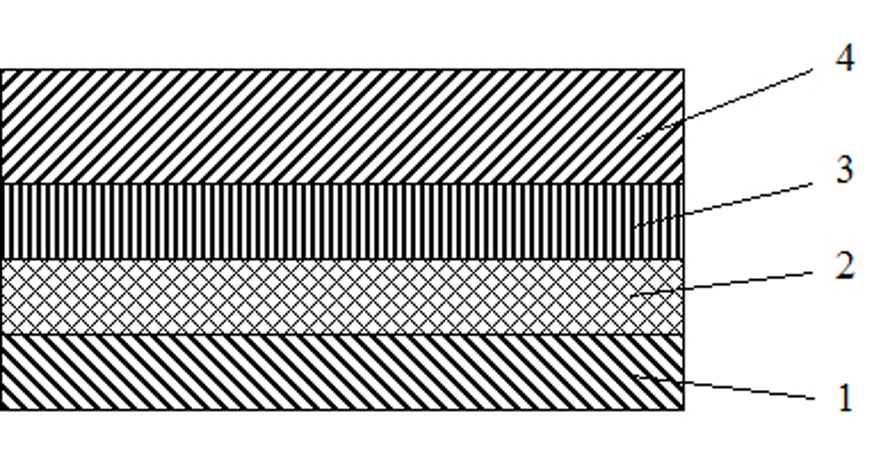

Image

Examples

Embodiment 1

[0031] The ratio of each element of the copper-tin alloy is: tin 5%, and the rest is copper.

Embodiment 2

[0033] The ratio of each element of the copper-tin alloy is: 6% tin, and the rest is copper.

Embodiment 3

[0035] The ratio of each element of the copper-tin alloy is: tin 7%, and the rest is copper.

[0036] A method for manufacturing the above-mentioned bearing bush with a vacuum sputtering coating, comprising the following steps:

[0037] 1) Install the bearing base into the sputtering equipment, and evacuate the inside of the sputtering equipment to the set value;

[0038] 2) Under the vacuum conditions set above, use ion power to clean the surface of the bearing bush;

[0039] 3) Establish a horizontal orthogonal electromagnetic field between the bearing base and the target, in which the electric field is provided by a DC bias power supply, the DC bias power supply is continuously adjustable from 50V-900V, and the pulse frequency is continuously adjustable from 10%-85% Adjustable, the magnetic field is provided by a magnetic control power supply, the magnetic control power supply is a DC magnetic control power supply and its value is continuously adjustable from 100V-900V;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com