Damper, washing machine, and washer/dryer

A shock absorber and washing machine technology, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problems of increased damping force and increased frictional resistance, and achieve good density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

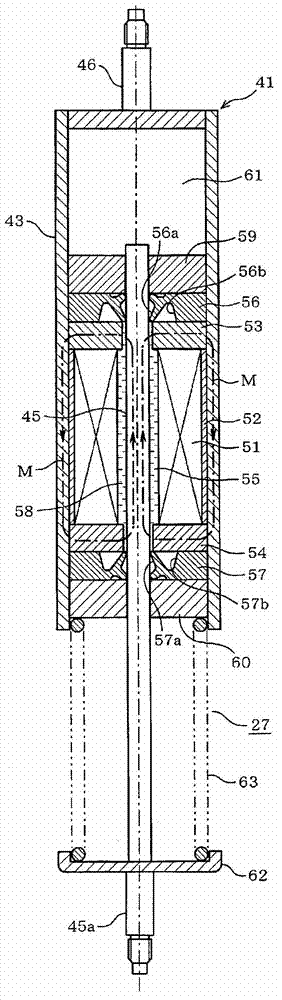

[0055] Hereinafter, regarding the first embodiment of the present invention, refer to Figure 1 to Figure 3 Be explained.

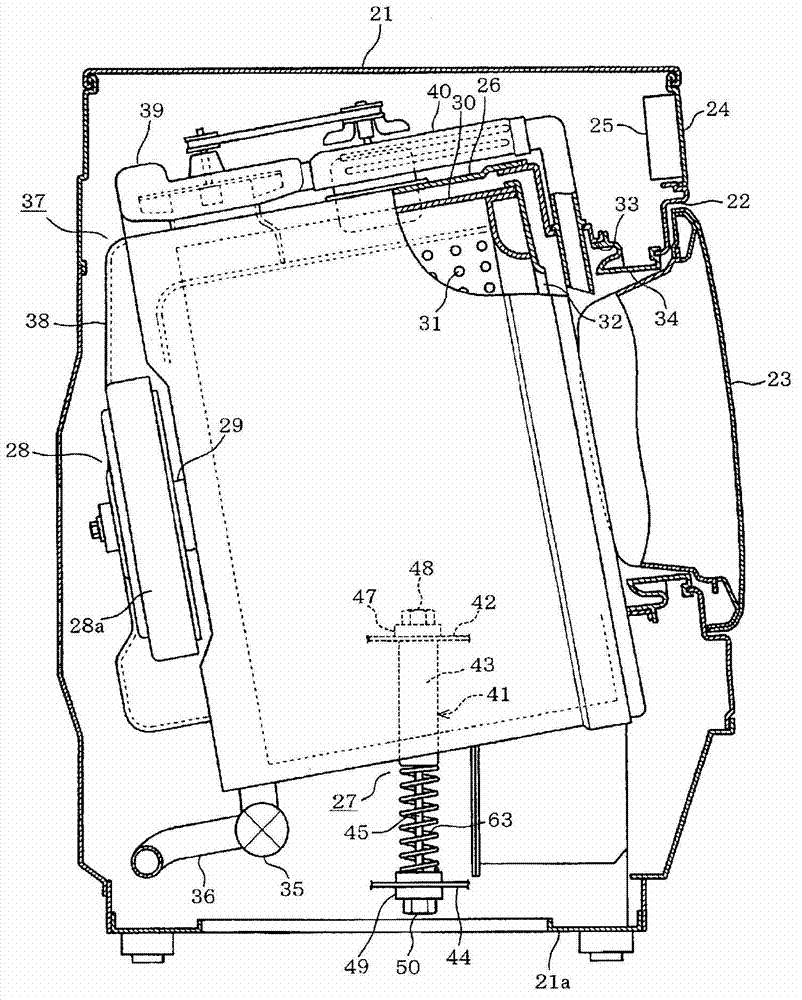

[0056] First, in figure 2 The middle figure shows the overall structure of the drum type washing machine, and the outer case 21 is used as an outer casing. In the front portion of the outer box 21 ( figure 2 In the substantially central portion of the middle right side), a laundry inlet and outlet 22 is formed, and a door 23 for opening and closing the inlet and outlet 22 is provided. In addition, an operation panel 24 is provided on the upper portion of the front portion of the outer case 21 , and a control device 25 for operation control is provided on the back side thereof (inside the outer case 21 ).

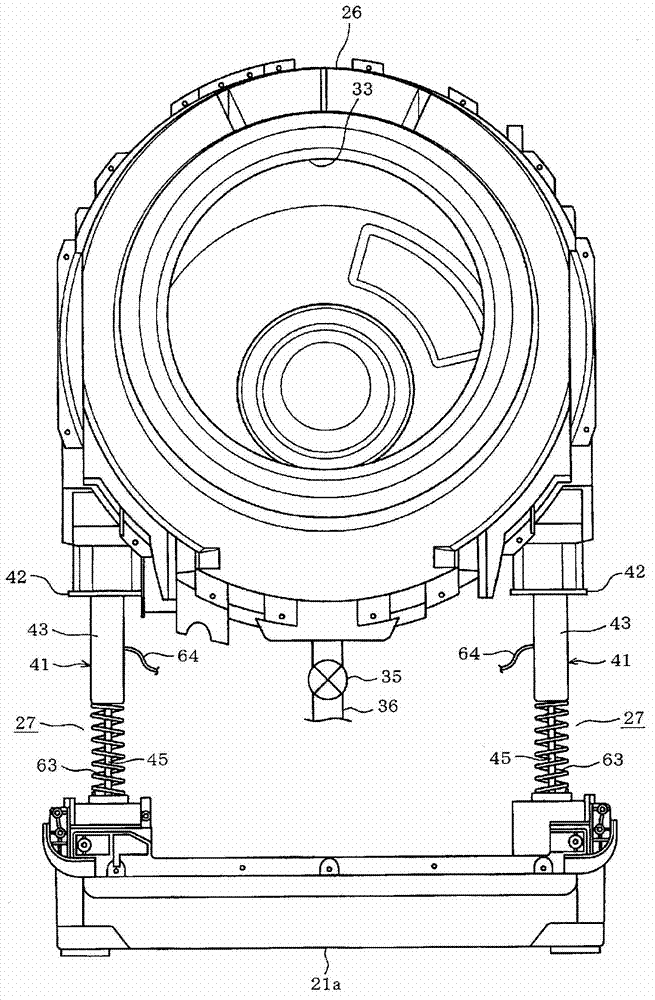

[0057] Inside the outer case 21, a water tank (tank) 26 is arranged. The water tank 26 is axially front and rear ( figure 2 Center right left) of the horizontal axis cylindrical shape, in this case, such as image 3 As shown, it is elastically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com