Graphite crucible

A graphite crucible and crucible technology, applied in the direction of inorganic chemistry, non-metallic elements, silicon compounds, etc., can solve problems such as no integral graphite, and achieve the effect of improving lifespan and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

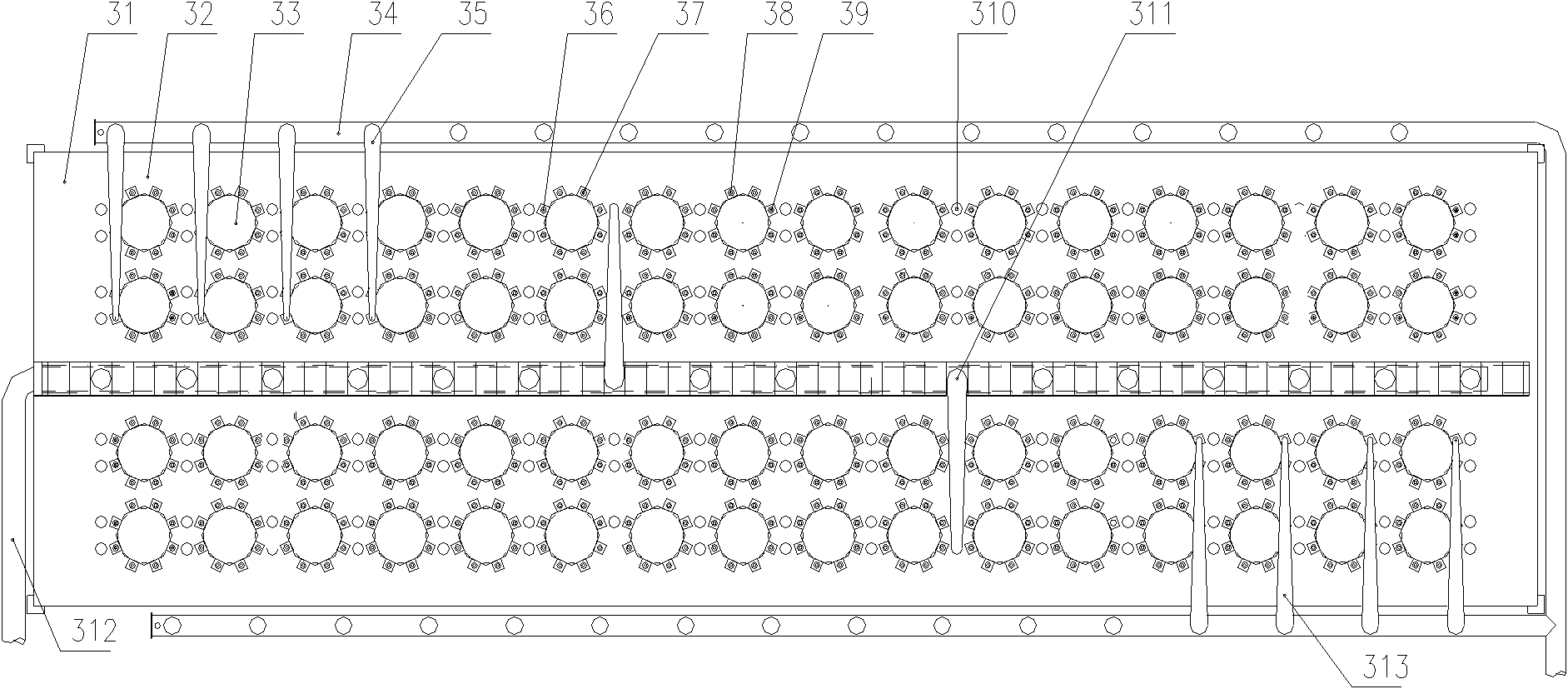

[0042] The preparation method of described graphite crucible comprises the following steps:

[0043] 1) Add auxiliary materials to the raw material of calcined petroleum coke granules, and sieve them into 4 kinds of granular materials after 3 stages of crushing; 8-4mm: 14%-16%; particle size 4-2mm: 11%-12%; particle size 2-0mm: 26%-25%; the remaining particle size is less than 0.075mm. The auxiliary material is selected from silica fume, etc. The amount of the auxiliary material can be 9% to 4% of the raw material of calcined petroleum coke particles by mass percentage, preferably 6%. The particle size of the auxiliary material is preferably less than 600 mesh.

[0044] 2) Add the prepared calcined petroleum coke particle raw materials and auxiliary materials into the kneading pot and stir, then add liquid pitch to the kneading pot, and continue stirring to make the pitch soak into the petroleum coke particles; the amount of the added liquid pitch can be expressed in mass perc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com