Method for comprehensively recycling valuable minerals in rare-earth tailings

A technology of rare earth tailings and tailings, which is applied in the fields of niobium, fluorite, comprehensive recovery of rare earths and iron, can solve the problems of low recovery rate of valuable elements, low resource utilization rate, complex composition, etc. Simultaneous optimization of selectivity and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

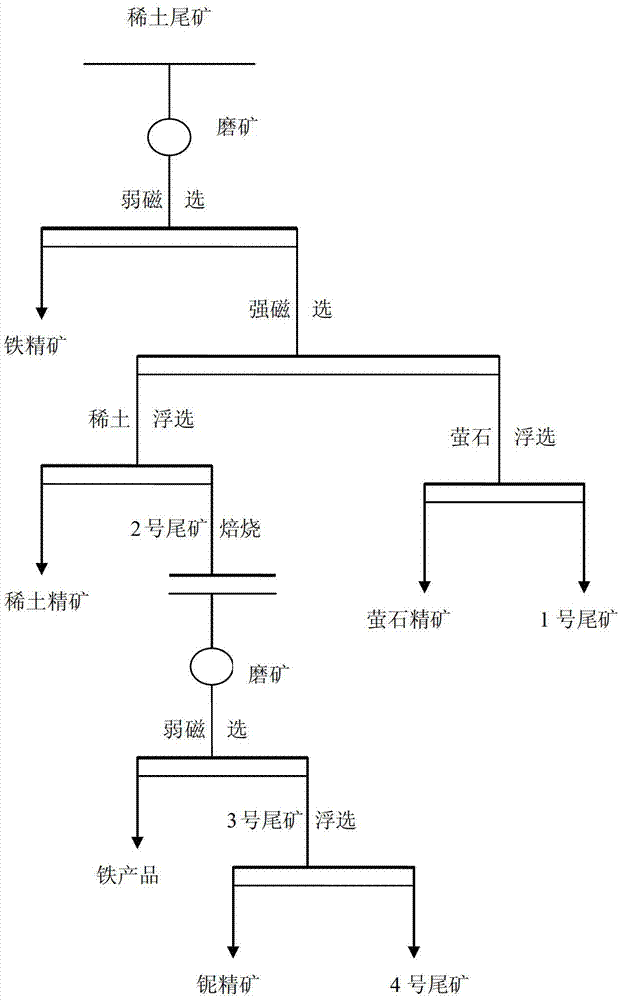

[0024] Raw materials are rare earth tailings from Baotou Steel tailings pond, in which iron minerals are mainly hematite and a small amount of magnetite, iron silicate and iron carbonate; rare earth minerals are mainly bastnaesite, bastnaesite and Monazite; niobium minerals are mainly niobite, niobium-iron rutile, yellow green stone and fractalite; other minerals are mainly silicate minerals, fluorite, carbonate minerals and a small amount of apatite, barite, quartz, Feldspar, pyrite, manganese minerals, etc. The total iron content in the rare earth tailings is 19.73%, and the grades of rare earth, niobium and fluorite are: 4.8%, 0.13%, and 26.42%, respectively. The particle size of rare earth tailings is -200 mesh 36.95%. According to the nature of minerals, the process of comprehensive recovery of valuable components is as follows:

[0025] Grind the raw materials until the content is 88.5% below 200 mesh, and then perform weak magnetic separation under the magnetic field ...

Embodiment 2

[0031] The raw material in this example is the tailings after flotation recovery of rare earth in a concentrator in the south, in which the total iron content is 15.56%, and the grades of rare earth, niobium and fluorite are: 5.6%, 0.19% and 24.57% respectively. Up to -200 mesh 69.78%.

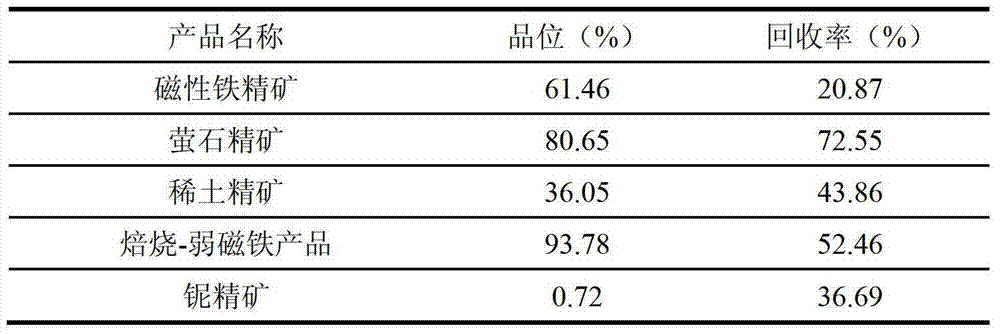

[0032] Grind the raw materials to 90% of the content below 200 mesh, and then perform weak magnetic separation under the magnetic field strength of 1600 Oersted to obtain iron concentrate products with an iron grade of 61.46% and a recovery rate of 20.87%; the tailings of weak magnetic separation The ore is subjected to strong magnetic separation at a magnetic field strength of 18,000 Oersted to obtain a strong magnetic separation concentrate containing iron, niobium and rare earths, and a strong magnetic separation tailings containing fluorspar.

[0033] Strong magnetic separation tailings are used for flotation enrichment and recovery of fluorite. First, adjust the slurry, the pulp concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com