Apparatus and process for clarifying water efficiently

A treatment device and clarified water technology, applied in the field of water treatment, can solve the problems of low organic matter treatment capacity, unstable effluent water quality, complex automatic control, etc., to save water head loss, reduce sludge subsequent treatment process, and reduce chemical consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

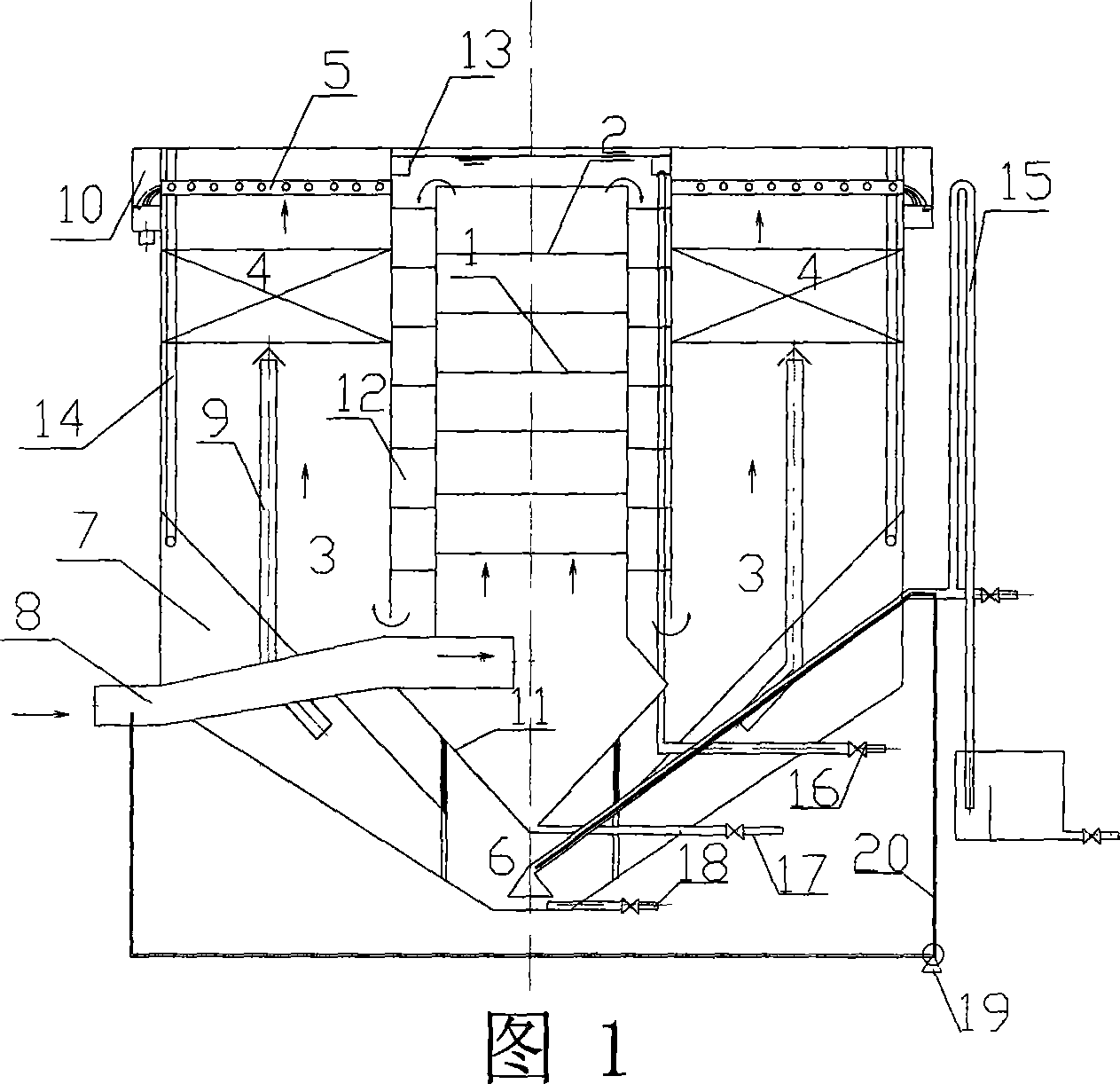

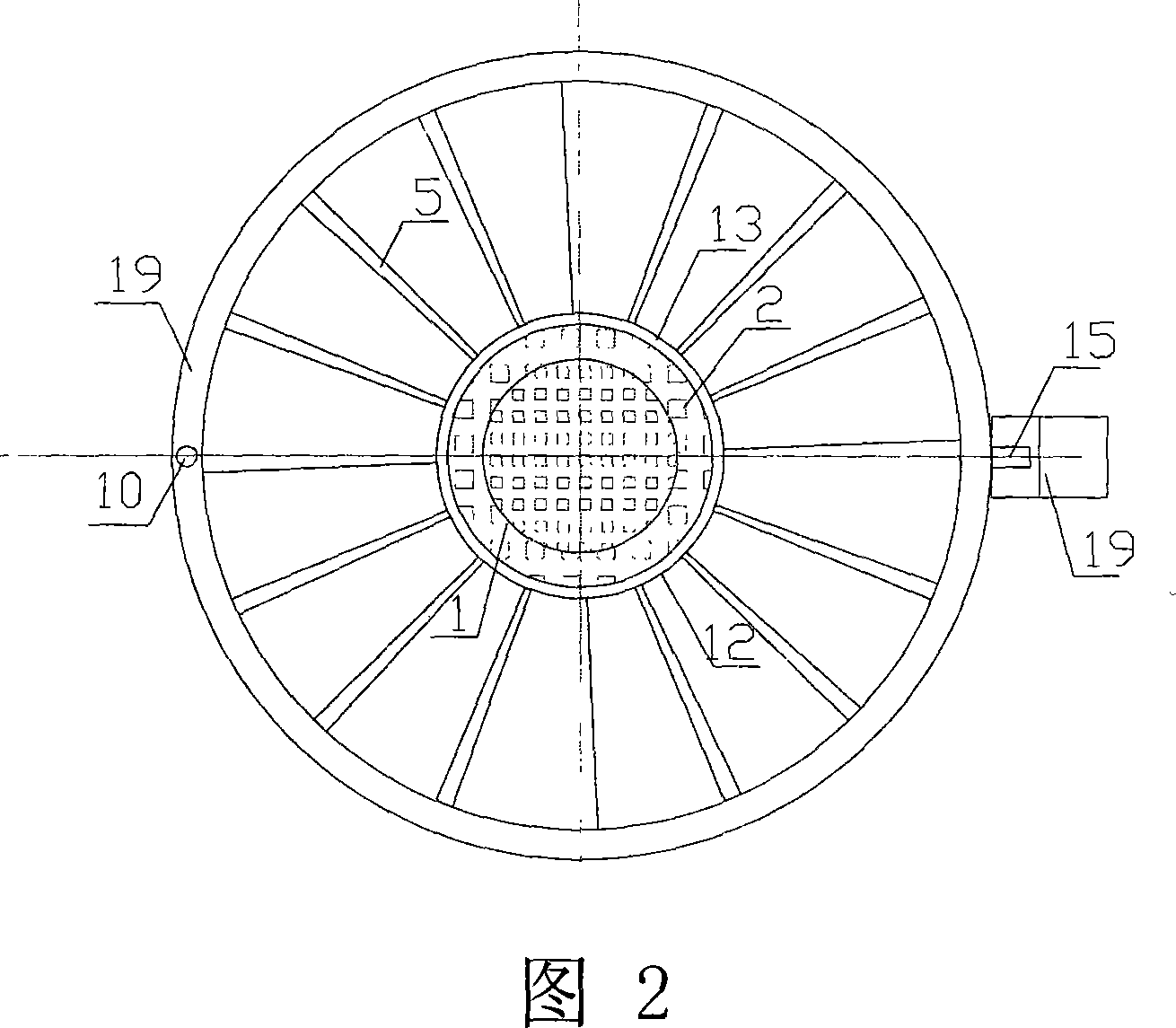

[0024] Embodiment 1, a newly-built waterworks, scale is 30,000 tons / day, adopts the water supply process of the present invention: adopt submersible pump to take water, after adding medicine before the pump, enter high-efficiency clarifier, its parameter is as follows:

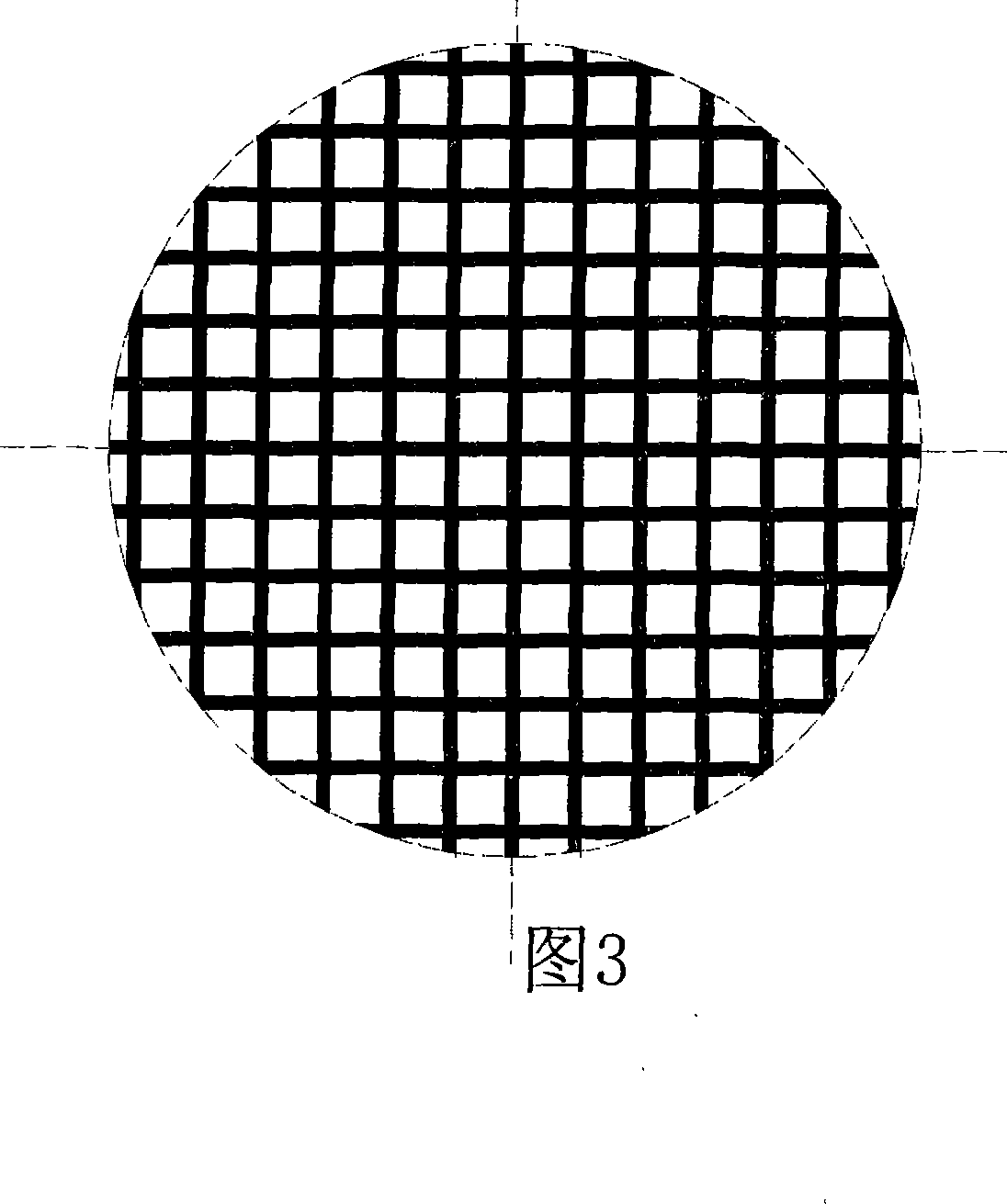

[0025] The effective diameter of the high-efficiency clarifier is 12.50m, the diameter of the volume flocculation chamber 1 is 3.00m, and the diameter of the volume flocculation chamber 12 is 4.20m; the flow velocity in the water inlet gradient pipe is reduced from 1.00m / s to 0.20m / s; the spoiler net The hole is two sections, the mesh size used is 25×25mm and 50×50mm respectively, the water flow velocity in the mesh is 0.25m / s, the rising flow velocity in the reaction chamber is 0.05m / s, the flow velocity and volume flocculation in the mesh The ratio of the flow rates in the chamber is 5:1. Six slag discharge pipes are arranged in the active sludge layer, evenly distributed, with a diameter of DN200. The risi...

Embodiment 2

[0027]Embodiment 2, this process is used for the transformation of certain waterworks, and the original technique of waterworks is the hydraulic circulation clarifier process of 125 tons / hour, under the situation of influent turbidity at 20~200NTU, effluent is generally at 10 ~15NTU. Through transformation, the original clarifier was equipped with mesh flocculation device, sludge layer filtration, inclined tube sedimentation, and a sludge discharge system and sludge return system were set up according to this process.

[0028] The parameters used in the design are as follows:

[0029] The effective diameter of the high-efficiency clarifier is 7.20m, the diameter of the volume flocculation chamber 1 is 1.80m, and the diameter of the volume flocculation chamber 12 is 2.82m; the flow velocity in the water inlet gradient pipe is reduced from 1.0m / s to 0.2m / s; the spoiler net The hole is two sections, the mesh size used is 25×25mm and 50×50mm respectively, the water flow velocity i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com