Method for producing lithium iron phosphate

A lithium iron phosphate, precursor technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of adhesion to precursors, affecting product quality, low tap density, etc., to achieve easy scale The effect of chemical production, lower production cost and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

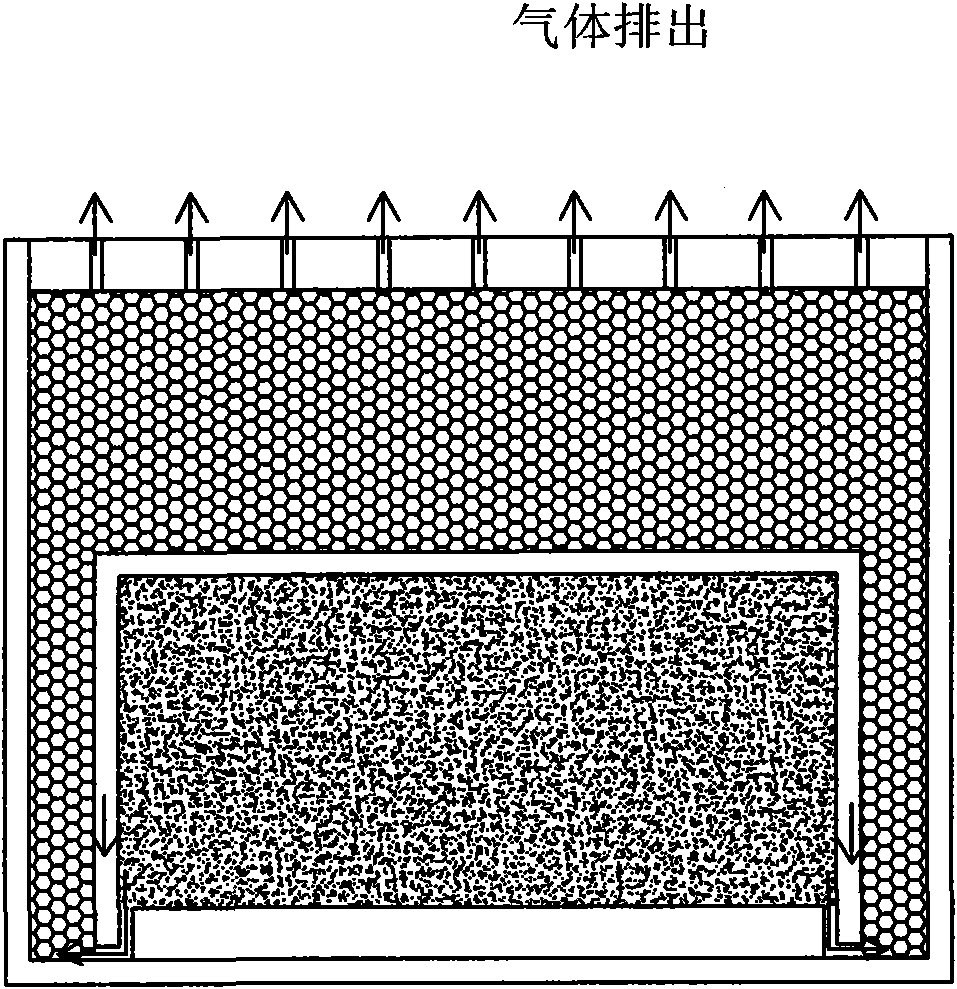

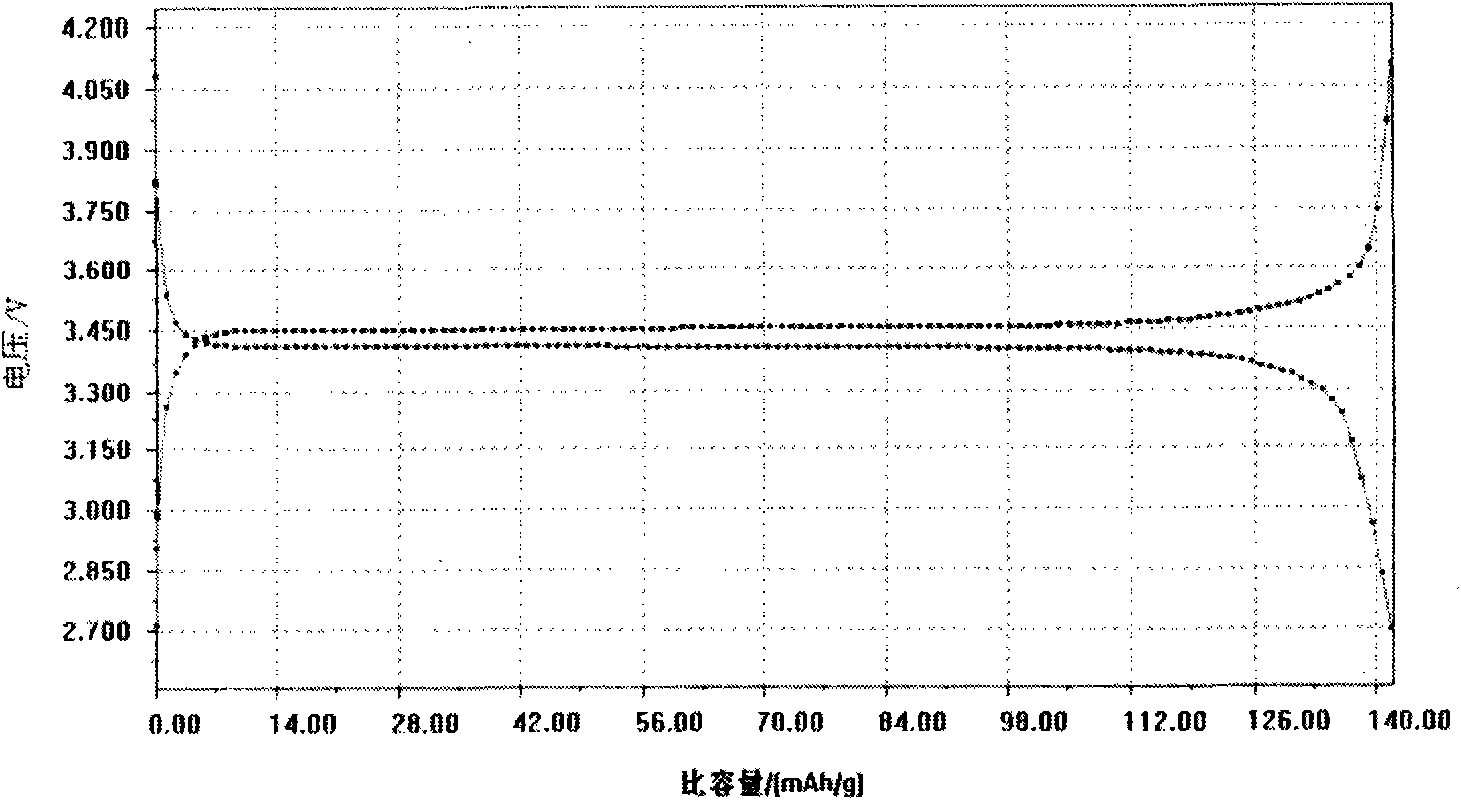

[0036] Such as figure 1 As shown, lithium hydroxide: ferrous oxalate: ammonium dihydrogen phosphate was mixed in a molar ratio of 1.1:1:1, and 5% carbon black was added by mass ratio, and placed in a stirring ball mill for mixing and grinding for 5 hours; The precursor prepared by mixing and grinding is put into a stainless steel box, the precursor powder is compacted with a hydraulic press, and the high temperature resistant plate that is higher than the box is pressed on the precursor material, leaving a gap between the high temperature resistant plate and the box, and then Put the stainless steel box and the high temperature plate upside down into a semi-closed container, add carbon powder to fill up the semi-closed box, and finally spread the high temperature plate with fine holes on the carbon powder; then put it in a vacuum The box was evacuated for 0.5 hours and then filled with high-purity nitrogen. Finally, the precursor was sent to a tunnel kiln for calcination. It w...

Embodiment 2

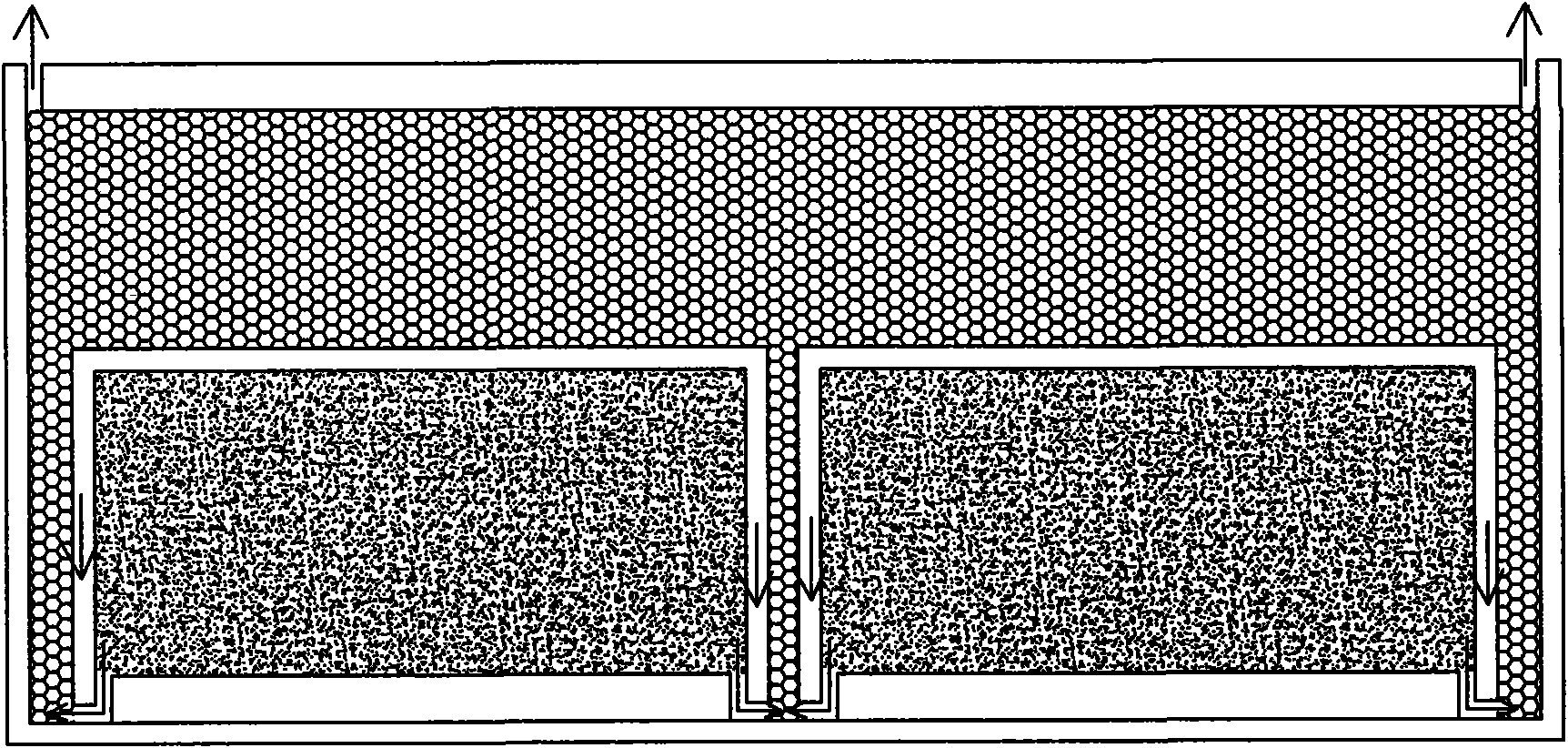

[0038] Lithium carbonate: ferrous oxalate: ammonium dihydrogen phosphate: Mg(OH) 2 Mix at a molar ratio of 0.5:0.95:1:0.05, add 8% glucose by mass ratio, place in a stirring ball mill for mixing and grinding for 5 hours; put the precursor prepared by fully mixing and grinding into a stainless steel box, and use a hydraulic press Compact the precursor powder, press the high temperature resistant plate above the box body on the precursor material, so that there is a gap of 5 wires between the high temperature resistant plate and the box body, and then turn the stainless steel box body together with the high temperature resistant plate upside down. Put it into a semi-closed container, add charcoal powder to fill up the semi-closed box, and finally spread the high-temperature plate on the charcoal powder, so that there is a gap of 5 wires between the high-temperature plate and the box; then place it in a vacuum The box was evacuated for 0.5 hours and then filled with high-purity n...

Embodiment 3

[0040] Lithium carbonate and iron phosphate were mixed in a molar ratio of 0.5:1, and 10% glucose was added in a mass ratio, and placed in a stirring ball mill for mixing and grinding for 5 hours; the precursor prepared by fully mixing and grinding was loaded into a stainless steel box, Use a hydraulic press to compact the precursor powder, and press the high temperature resistant plate out of the box body on the precursor material, leaving a gap between the high temperature resistant plate and the box body, and then put the stainless steel box body together with the high temperature resistant plate upside down into a In the semi-closed container, add charcoal powder to fill the semi-closed box around, and finally spread the high-temperature resistant plate with fine holes on the charcoal powder; finally send the precursor into the tunnel kiln for roasting, and start heating from room temperature , the heating rate is 10°C / min, heated to 700°C and roasted for 6 hours, then cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com