Wear-resistant disk

A disc and disc carrier technology, applied in the field of brake grinding frame and wear-resistant disc, can solve the problems of consumption, complex processing and assembly procedures, high production cost, etc., and achieve low production cost, good structural density and good structural strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

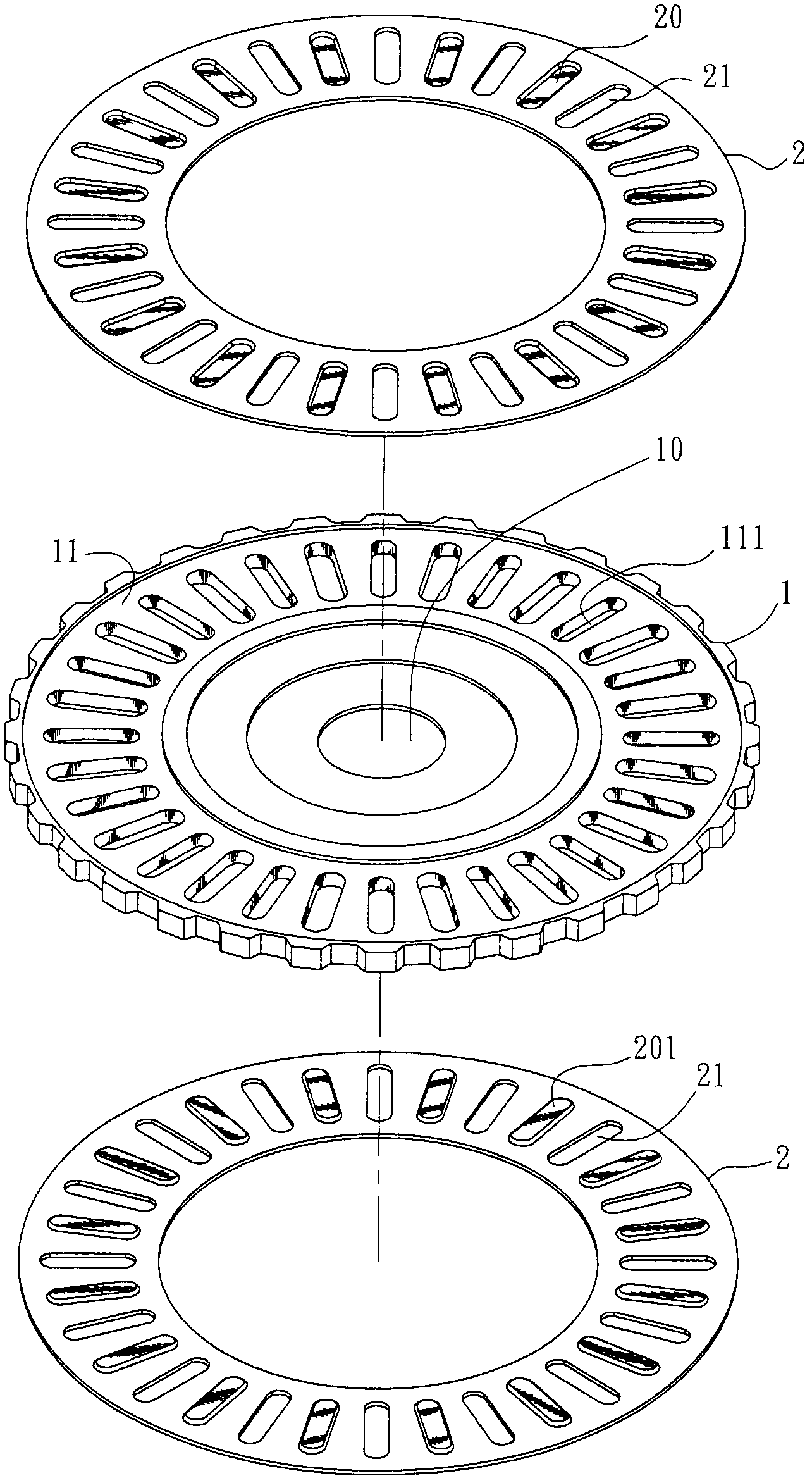

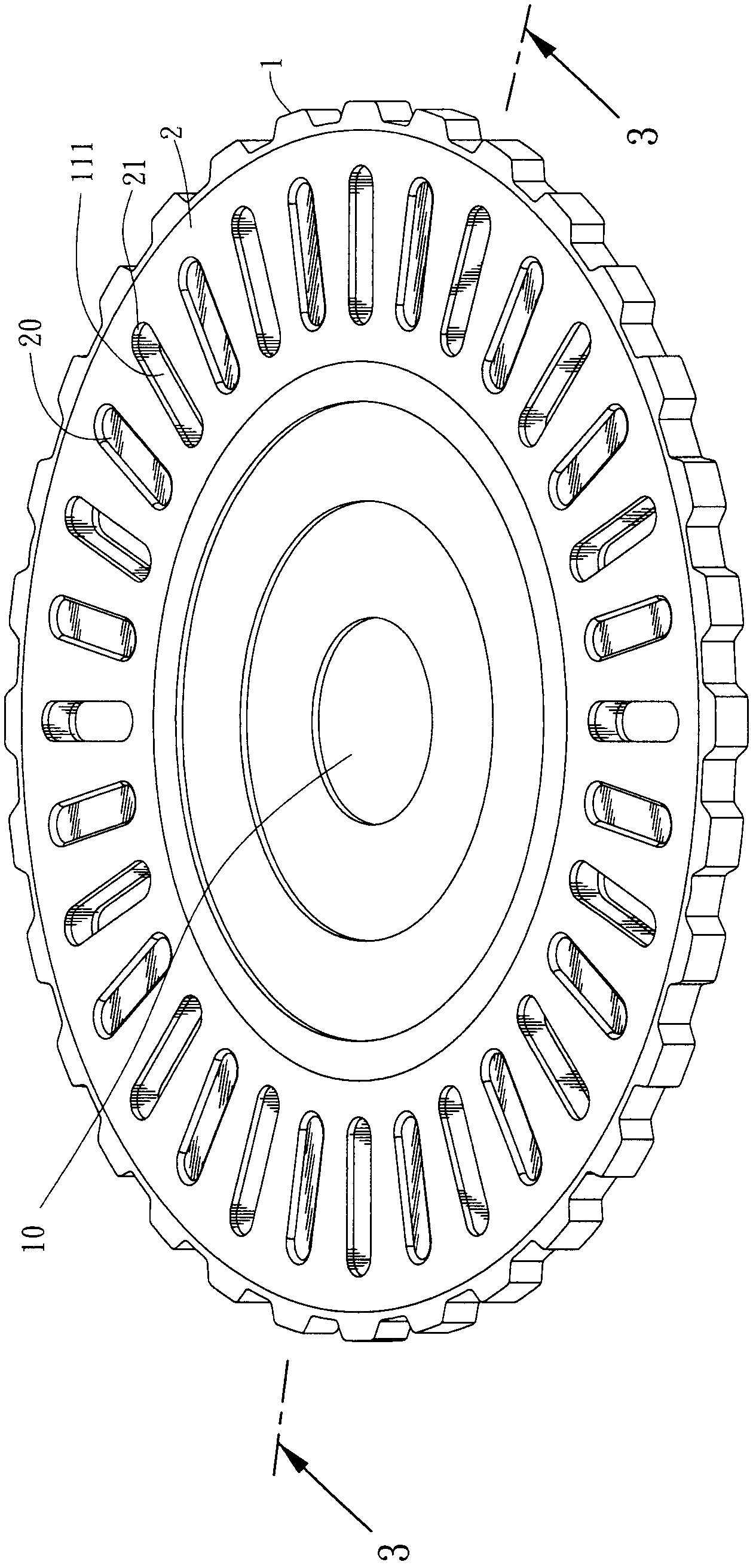

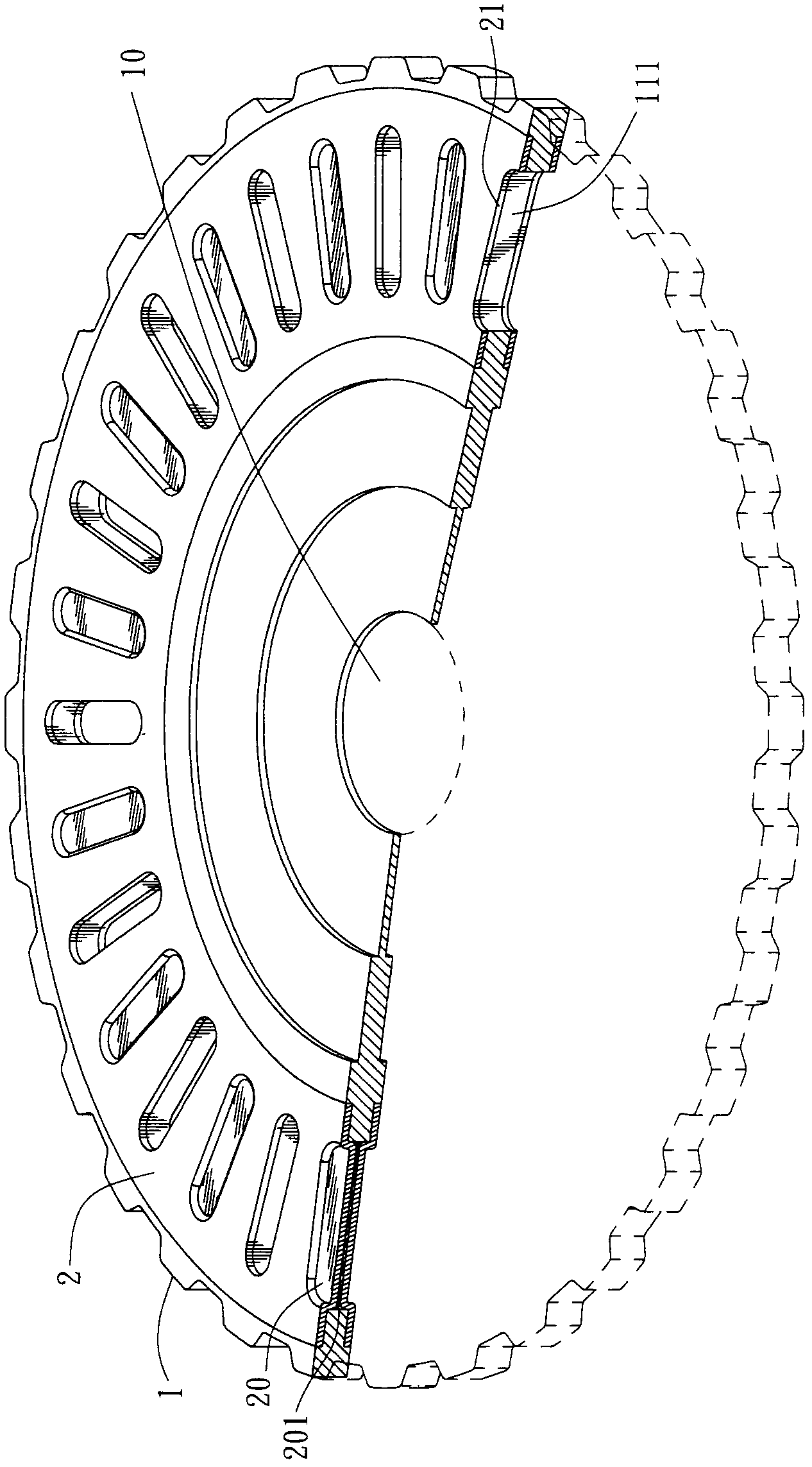

[0035] The invention relates to a wear-resistant disc, which includes a carrier plate 1 mounted on the hub of a wheel. A ring-shaped brake frame 2 is assembled on both sides of the carrier plate 1. The carrier plate 1 is made of aluminum alloy or the like. Light metal material is made, and these two brake grinding frames 2 are made of ferrous metal materials such as white iron or stainless steel.

[0036] For preferred embodiments of the present invention, please refer to Figure 1 to Figure 3 As shown, the center of the carrier plate 1 has a through-shaped shaft hole 10 for the wheel hub to be fixed, and the front and back of the carrier plate 1 have a concave ring groove 11 corresponding to the shape of the brake frame 2. The outer circumference of the disk 1 is provided with several ring holes 111 in the ring groove 11;

[0037] The thickness of each brake grinding frame 2 is less than or equal to 1 / 2 of the carrier plate 1, and each brake grinding frame 2 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com