Method for preparing ceramic foams with pore gradient

A foamed ceramic and gradient technology, which is applied in the field of ceramic material preparation and processing, can solve problems such as unreported, and achieve the effects of uniform network structure, high product strength, and overcoming the fatal weakness.

Inactive Publication Date: 2011-06-15

SUZHOU UNIV

View PDF1 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, at present, there is no report on the preparation process of the pore-gradient foamed ceramic material in the strict sense of being economical, reasonable and easy to manufacture.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| solid fraction | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Login to View More

Abstract

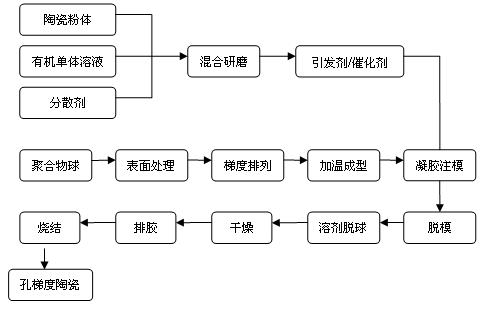

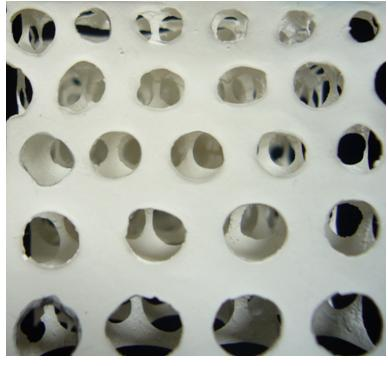

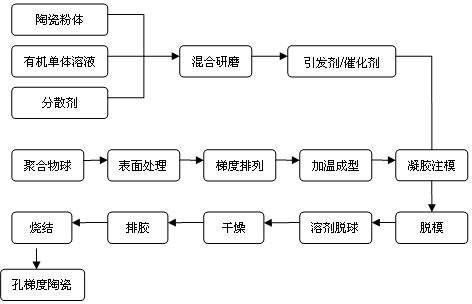

The invention relates to a method for preparing ceramic foams with pore gradient. The method comprises the following steps: arranging polymers or organic matter spheres to form a template in gradient distribution according to the design requirement, carrying out heating and pressurizing to ensure the spheres to adhere to each other to form a whole, filling the whole into a moulding mould and then injecting slurry for gel casting and removing the mould after drying the spheres to obtain a moulded green body integrating the spheres and solidifying slurry, immersing the green body after removing the mould into a solvent or warming the green body, removing the spheres to obtain a network-shaped body only with the solidifying slurry and obtaining the ceramic foams with pore gradient after binder removal and high-temperature sintering. The ceramic foams prepared according to the technical scheme adopted by the invention have the following advantages: the pore diameters are in gradient distribution; the pore gradient can be designed and controlled; the moulded green body has high strength and can be processed and cut into needed shapes; the sizes and shapes of the products are controllable; the problem that the shapes and sizes of the products as well as the sizes of the pores are usually limited by organic carriers in the process of preparing the ceramic foams is solved; and the shortcomings of less slurry absorbed for moulding, more blind pores and low product strength in the impregnation method are overcome.

Description

A kind of preparation method of pore gradient foam ceramics technical field The invention relates to a method for preparing a pore gradient foam ceramic material by using polymer balls with different particle diameters as molded body templates combined with a gel injection molding process, and belongs to the technical field of ceramic material preparation and processing. Background technique Foam ceramics (Ceramicfoams, also known as reticulated ceramics) is a kind of porous ceramics with a foam-like shape and a large pore size. It is the third generation of porous ceramics developed after ordinary porous ceramics and honeycomb porous ceramics. The open porosity of foam ceramics is as high as 70% to 90%, and it is a kind of porous structure ceramics with continuous network ceramic skeleton and three-dimensional continuous through holes. Gradient ceramic foams (Graded ceramic foams) refer to ceramics in which the pore size of the foam ceramic body decreases or increases reg...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B38/00

Inventor 王淑梅周竹发郭新爽赵松

Owner SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com