High-toughness hydrogel based on PHEMA as well as preparation method and application of the high-toughness hydrogel

A hydrogel and high-toughness technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problems such as the inability to induce tissue regeneration, and achieve adipogenic differentiation, high fracture toughness, and biophase good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1, the preparation of hydrogel of the present invention

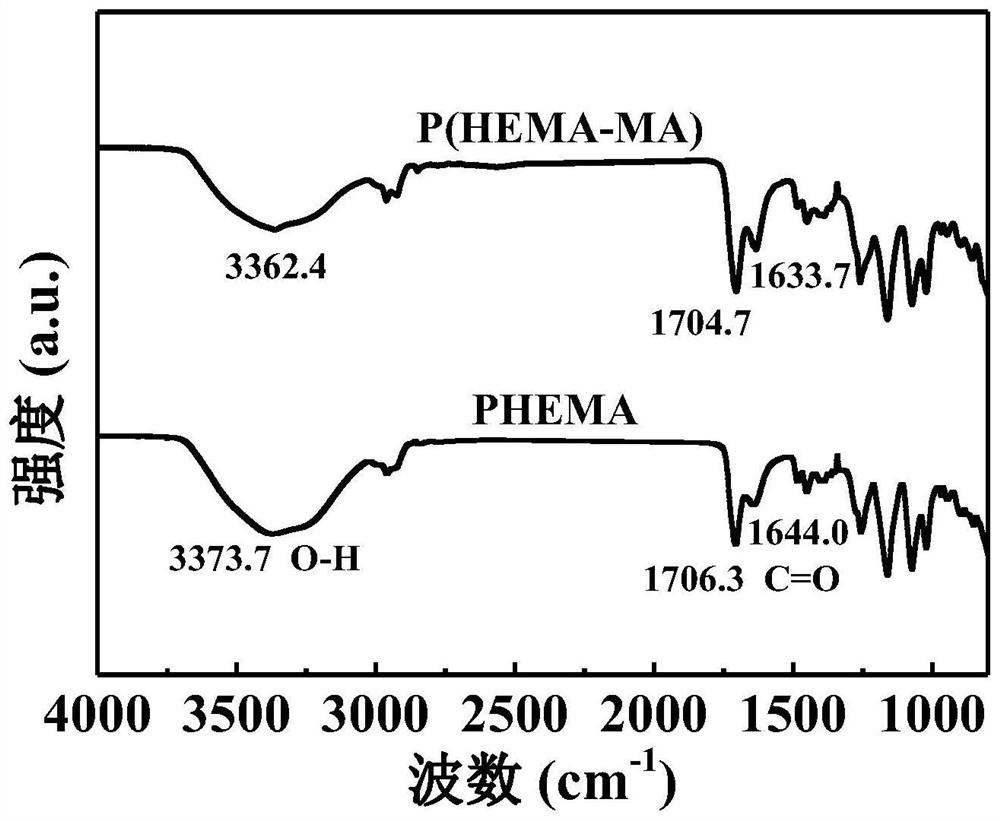

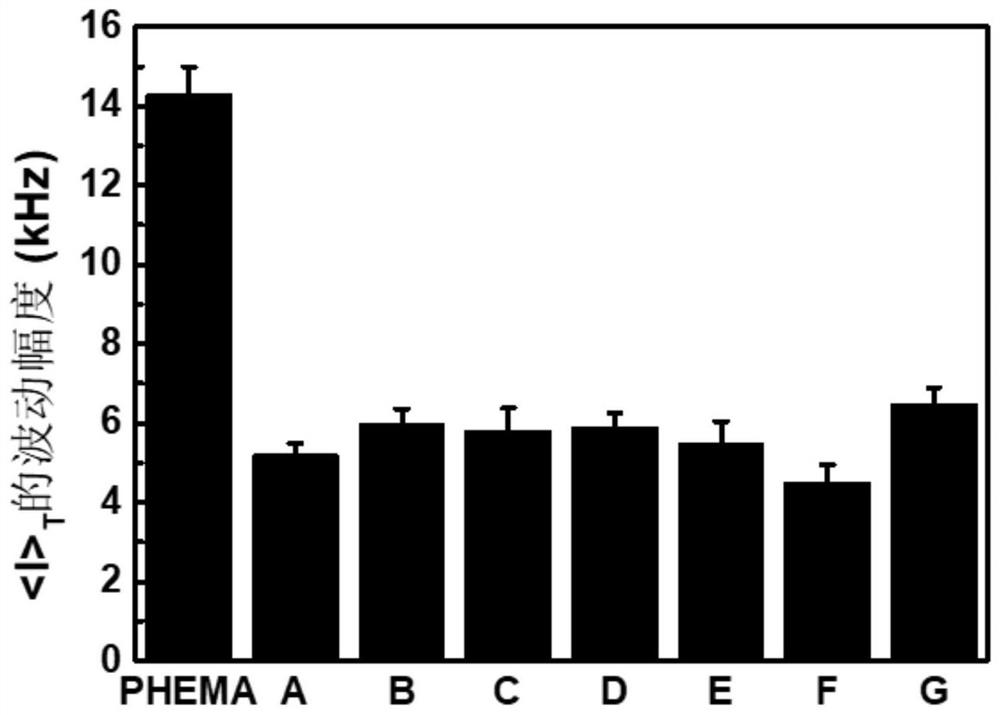

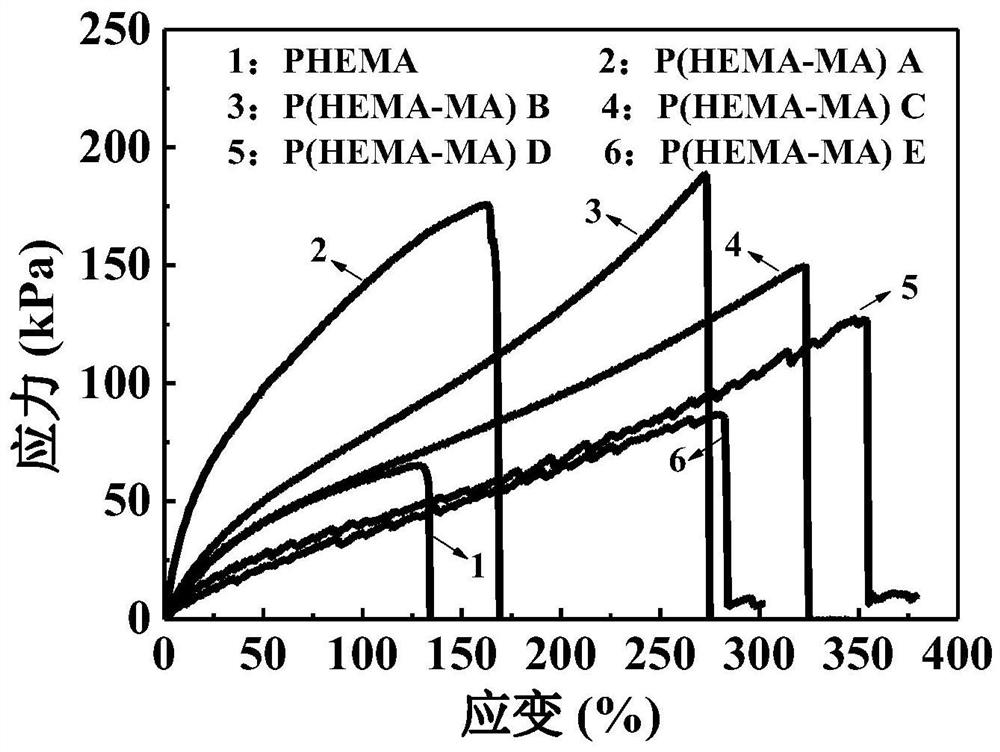

[0048] Dissolve hydroxyethyl methacrylate (HEMA) and maleic anhydride (MA) with a molar ratio of 8:1 in water, that is, dissolve 8 mol HEMA and 1 mol MA in 30 mL of water, and blow nitrogen into the solution for 10 min while stirring to remove the Oxygen, then add 0.0003mol photoinitiator 2-hydroxyl-2-methyl propiophenone (1173), light reaction 2h under the ultraviolet lamp that wavelength is 365nm, power is 300W, obtains P (HEMA-co-MA) water Gel A, denoted as P(HEMA-MA)A.

Embodiment 2

[0049] Embodiment 2, the preparation of hydrogel of the present invention

[0050] Dissolve hydroxyethyl methacrylate (HEMA) and maleic anhydride (MA) with a molar ratio of 8:2 in water, that is, dissolve 8 mol HEMA and 2 mol MA in 30 mL of water, and blow nitrogen into the solution for 10 min while stirring to remove the Oxygen, then add 0.0003mol photoinitiator 2-hydroxyl-2-methyl propiophenone (1173), light reaction 2h under the ultraviolet lamp that wavelength is 365nm, power is 300W, obtains P (HEMA-co-MA) water Gel B, denoted as P(HEMA-MA)B.

Embodiment 3

[0051] Embodiment 3, the preparation of hydrogel of the present invention

[0052] Dissolve hydroxyethyl methacrylate (HEMA) and maleic anhydride (MA) with a molar ratio of 8:3 in water, that is, dissolve 8 mol HEMA and 3 mol MA in 30 mL of water, and blow nitrogen into the solution for 10 min while stirring to remove the Oxygen, then add 0.0003mol photoinitiator 2-hydroxyl-2-methyl propiophenone (1173), light reaction 2h under the ultraviolet lamp that wavelength is 365nm, power is 300W, obtains P (HEMA-co-MA) water Gel C, denoted as P(HEMA-MA)C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com