Pneumatic actuator structure for cable production

A technology of pneumatic actuators and cables, applied in the field of actuators, to achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

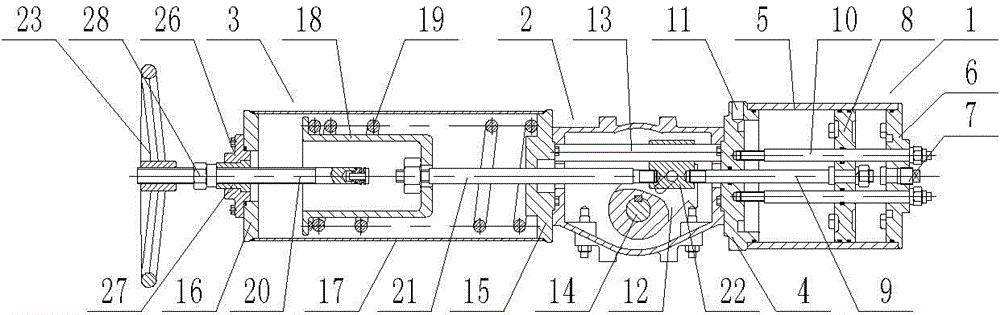

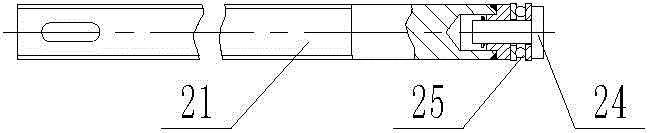

[0025] Such as figure 1 As shown, the pneumatic actuator structure used for cable production in the present invention includes a short cylinder body 1, a hollow box body 2 and a long cylinder body 3, and the two ends of the hollow box body 2 are respectively connected with the long cylinder body 3 and the short cylinder body 1 by screws connect.

[0026] The short cylinder block 1 includes an intake cylinder head 4 , a cylinder barrel 5 , a limit cylinder head 6 , a limit post 7 , a piston 8 , a piston rod 9 and two guide posts 10 penetrating the piston 8 . The two ends of the cylinder barrel 5 are respectively welded with the intake cylinder head 4 and the limit cylinder head 6. The piston rod 9 passes through the piston 8 and is fixed by a hex nut. The edge of the piston 8 is embedded with an O-ring, and the piston 8 is also There are two through holes for the guide column 10 to pass through the piston 8, and O-ring sealing rings are embedded on the walls of the through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com