High-strength underwater welding electrodes

A high-strength, wet technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/materials, etc., can solve the problems of low strength of underwater electrodes and difficulty in adapting to the requirements of high-strength steel underwater welding, etc., and achieve good underwater Welding process performance, re-strike performance is good, and the effect of reducing engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The commercially available H08E steel wire is used as the welding core, and the outer layer of the coating is coated with waterproof material. The waterproof material can be commonly used lacquer, paraffin, etc., and the binder can be potassium sodium water glass or sodium water glass, which is generally used The binder. In this embodiment, the binder adopts blue lacquer, and potassium sodium water glass is used as the coating binder. The components and weight percentages of the coating are: rutile 42, potassium feldspar 20, talc 6, cellulose 8. Aluminum magnesium alloy 4, manganese iron 14, nickel powder 0, iron powder 6.

Embodiment 2

[0019] The commercially available H08E steel wire is used as the welding core, the outer layer of the coating is coated with waterproof material blue paint, and potassium sodium water glass is used as the coating binder. The components and weight percentages of the coating are: rutile 48 and potassium feldspar 15 , Talc 8, Cellulose 12, Aluminum Magnesium Alloy 2, Manganese Ferro 8, Nickel Powder 4, Iron Powder 3.

Embodiment 3

[0021] The commercially available H08E steel wire is used as the welding core, the outer layer of the coating is coated with waterproof material lacquer, and potassium sodium water glass is used as the coating binder. The components and weight percentages of the coating are: rutile 54 and potassium feldspar 12 , Talc 10, Cellulose 4, Aluminum Magnesium Alloy 0, Ferromanganese 6, Nickel Powder 2, Iron Powder 12.

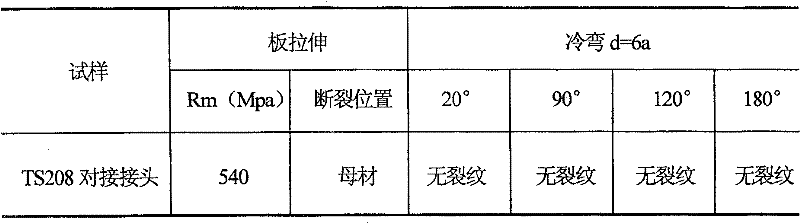

[0022] Example effect

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com