Part surface temperature control device and control method in electric arc additive manufacturing process

A surface temperature and additive manufacturing technology, applied in the field of additive manufacturing, can solve problems such as prolonged residence time, aggravated oxidation, and influence on deposition efficiency, and achieve the effects of reducing waiting time between layers, preventing aggravated oxidation, and improving deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

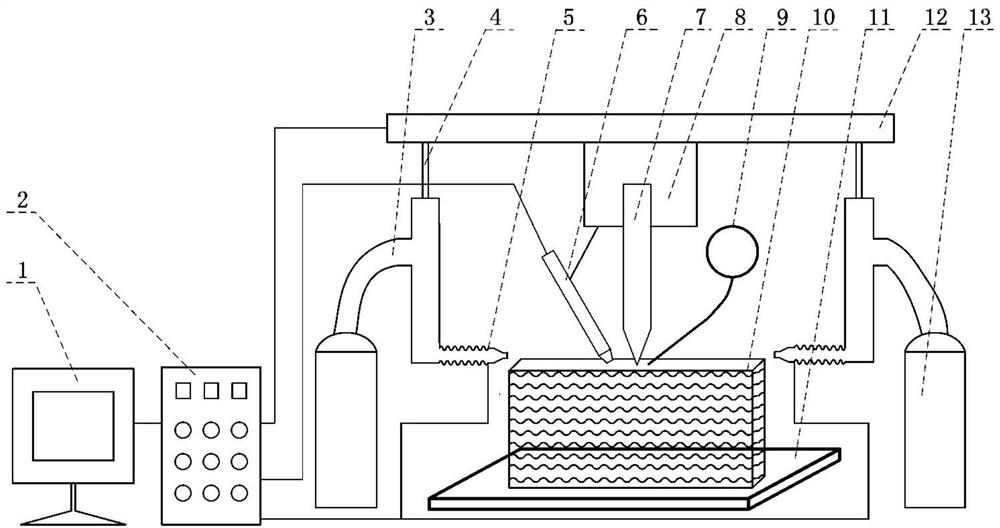

[0030] see figure 1 , the present invention provides a part surface temperature control device in the arc additive manufacturing process, which is the same as the prior art in that it includes a computer 1, a control system 2, a welding torch 7, a servo motor 8, a wire reel 9 and a machine tool moving system 12. The control system 2 is connected to the machine tool movement system 12; the machine tool movement system 12 is connected to the welding torch 7 through the servo motor 8; the difference from the prior art is: the part surface temperature control device in the arc additive manufacturing process provided by the present invention It also includes a blowing device that is connected with the machine tool moving system 12 and moves synchronously with the welding torch 7; the bottom of the blowing device is at the same level as the bottom of the welding torch 7. The control system not only controls the movement of the machine tool, but also controls the blowing device (such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com