A self-shielding flux-cored welding wire for welding in wading environment

A technology of flux-cored welding wire and self-protection, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem of excessive smoke and gas generation, affecting joint performance, etc., and achieve no arc extinguishing phenomenon, The arc combustion is stable and the shape is beautiful.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

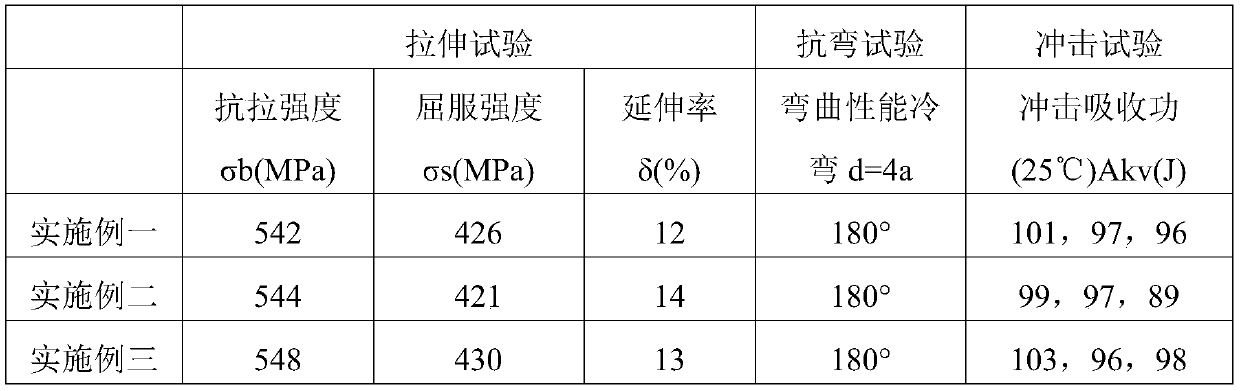

Embodiment 1

[0023] Embodiment one: the composition and weight percent of medicinal powder are: rutile 37%, iron oxide 18%, aluminum oxide 6%, calcium carbonate 8%, fluoride 4%, titanium powder 2%, nickel powder 6%, molybdenum powder 1% , Iron powder 18%.

Embodiment 2

[0024] Embodiment two: the composition and weight percent of medicinal powder are: rutile 44%, iron oxide 12%, aluminum oxide 8%, calcium carbonate 6%, fluoride 6%, titanium powder 3%, nickel powder 4%, molybdenum powder 1.5% , Iron powder 15.5%.

Embodiment 3

[0025] Embodiment three: the composition and weight percent of medicinal powder are: rutile 48%, iron oxide 10%, aluminum oxide 5%, calcium carbonate 7%, fluoride 5%, titanium powder 4%, nickel powder 8%, molybdenum powder 2% , Iron powder 11%.

[0026] Adjust the composition and content of the core powder according to the above ratio, prepare the core powder, and prepare three kinds of flux cored wires with different component contents. The particle size of the core powder is 80 mesh, and put the prepared core powder into the powder mixer for mixing Take it out for 5-6 hours and set aside.

[0027] The metal sheath of the flux-cored welding wire is made of low-carbon steel strip with a specification of 0.3mm×9mm. It is produced according to the ordinary flux-cored welding wire preparation process. The above-mentioned uniformly mixed flux core powder is added to the metal sheath to prepare a cross-section It is an "O" type flux-cored wire with a wire diameter of The filling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com