Method and device for improving corrosion resistance of MIG welding Cr-Ni series stainless steel

A corrosion-resistant, stainless steel technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problem of decreased stress corrosion resistance of welds, increased stress corrosion cracking tendency, refractory oxide precipitation tendency, oxygen content Increase and other problems, to achieve the effect of reducing ferrite content, facilitating industrial application, and increasing nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

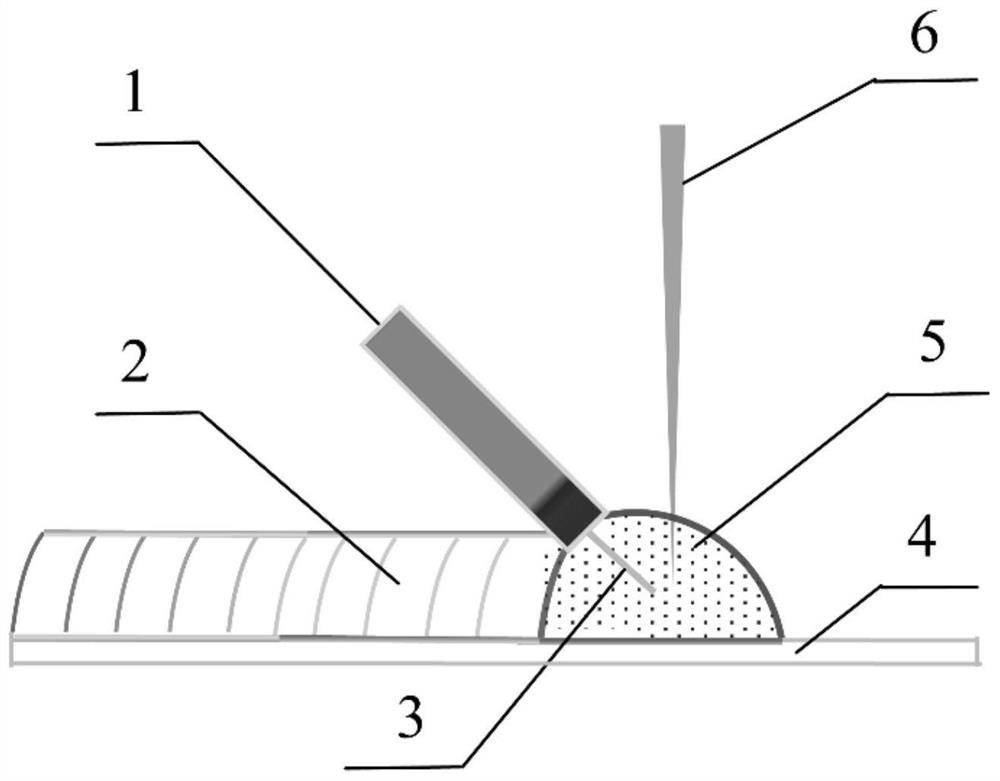

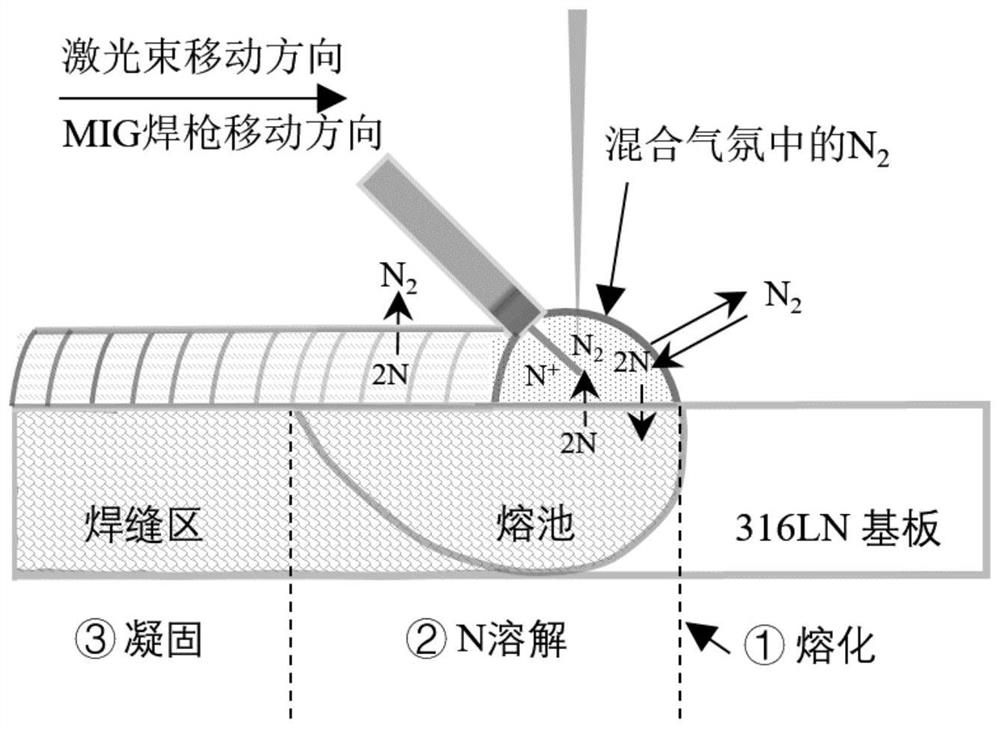

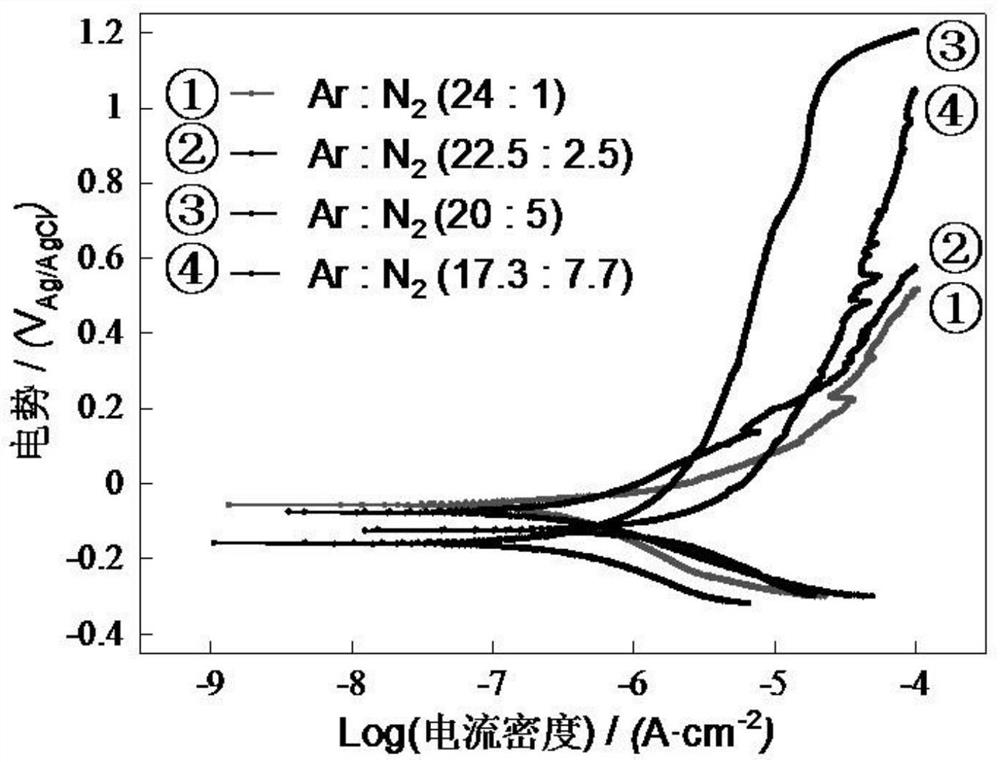

[0052] Grind the piece to be welded and clean it with alcohol or acetone, fix it on the workbench, and use a laser beam assisted welding torch to weld the piece to be welded in MIG welding under the atmosphere of protective gas. The composition of the protective gas is argon A mixture of gas and nitrogen, the gas flow ratio of argon and nitrogen is 22.5:2.5, the energy of the laser beam is 0.6KW, in the MIG welding process, the arc generated by the MIG welding torch is in front, and the laser beam is behind the welding method Do the welding. The material to be welded is Cr-Ni stainless steel.

Embodiment 2

[0054] Grind the piece to be welded and clean it with alcohol or acetone, fix it on the workbench, and use a laser beam assisted welding torch to weld the piece to be welded in MIG welding under the atmosphere of protective gas. The composition of the protective gas is argon A mixture of gas and nitrogen, the gas flow ratio of argon and nitrogen is 20:5, and the energy of the laser beam is 1.2KW. During the MIG welding process, the arc generated by the MIG welding torch is in the front, and the laser beam is behind the welding method Do the welding. The material to be welded is Cr-Ni stainless steel.

Embodiment 3

[0056] Grind the piece to be welded and clean it with alcohol or acetone, fix it on the workbench, and use a laser beam assisted welding torch to weld the piece to be welded in MIG welding under the atmosphere of protective gas. The composition of the protective gas is argon A mixture of gas and nitrogen, the gas flow ratio of argon and nitrogen is 17.5:7.5, the energy of the laser beam is 1.5KW, in the MIG welding process, the arc generated by the MIG welding torch is in the front, and the laser beam is behind the welding method Do the welding. The material to be welded is Cr-Ni stainless steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com