Copper plating free welding wire containing nano ionic liquid lubricating coating and preparation method

A nano-ionic, liquid lubrication technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problem of affecting the accuracy, cost, efficiency and continuous operation of automatic robot welding, and can not meet the requirements of excellent lubrication, electrical conductivity and anti-rust performance at the same time. , low comprehensive performance of coatings or lubricants, to achieve good rust resistance and wire feedability, easy industrial promotion and production, and reduce arc ablation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A nano-ionic liquid lubricating oil for copper-free welding wire consisted of 2% modified nanocomposite, 37% ionic liquid, and 61% lubricating oil.

[0036] Preparation of modified nanocomposites:

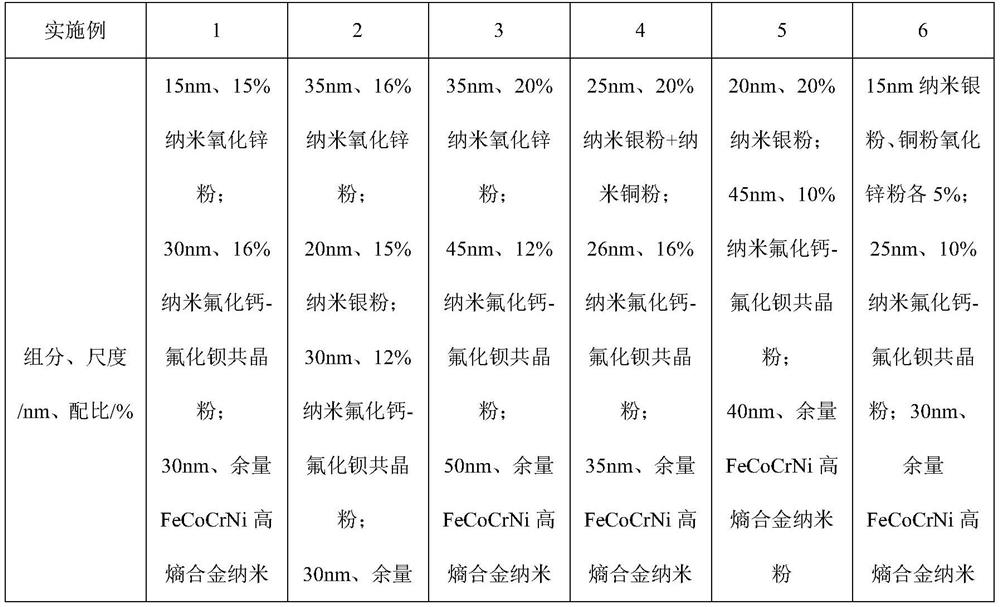

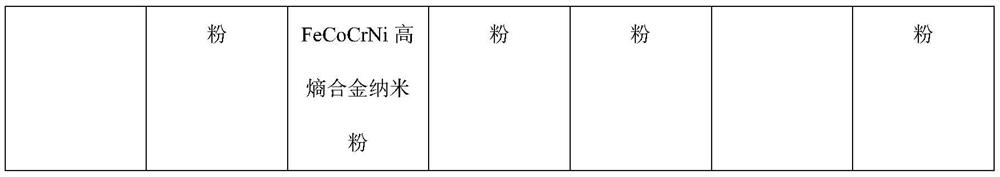

[0037] (1) Sintering and mixing: Put the nano-powders in the mass percentage shown in Table 1 into the MITR polyurethane ball milling tank successively, and roll wet, dry (rotary evaporator) and pre-press (graphite mold) according to the parameters in Table 2, Then together with the graphite mold of the powder pre-compaction block, it is spark plasma sintered (SPS, -FCT-HP D250), to obtain a nanocomposite block; (2) crushing powder: coarsely crushing by a crusher and finely pulverizing by a high-energy ball mill to obtain a nanocomposite powder, and the ground nanocomposite is placed in a blast drying oven (GFL-45) drying, setting temperature is 90°C, heating power 1.5kw, ambient temperature 25°C, humidity 60%; (3) Surface functionalization: Weigh a certain amount of nanoco...

Embodiment 2

[0049] A nano-ionic liquid lubricating oil for copper-free welding wire consists of 5% modified nanocomposite, 40% ionic liquid and 55% lubricating oil.

[0050] Preparation of modified nanocomposites:

[0051] (1) Sintering and mixing: Put the nano-powders in the mass percentage shown in Table 1 into the MITR polyurethane ball milling tank successively, and roll wet, dry (rotary evaporator) and pre-press (graphite mold) according to the parameters in the table, and then Spark plasma sintering (SPS, -FCT-HP D250), to obtain a nanocomposite block; (2) crushing powder: coarsely crushing by a crusher and finely pulverizing by a high-energy ball mill to obtain a nanocomposite powder, and the ground nanocomposite is placed in a blast drying oven (GFL-45) drying, setting temperature is 150°C, heating power 1.5kw, ambient temperature 35°C, humidity 75%; (3) Surface functionalization: Weigh a certain amount of nanocomposites, add surface functional agent and The solution prepared w...

Embodiment 3

[0063] A nano-ionic liquid lubricating oil for copper-free welding wire consists of 8% modified nanocomposite, 60% ionic liquid and 32% lubricating oil.

[0064] Preparation of modified nanocomposites:

[0065] (1) Sintering and mixing: Put the nano-powders in the mass percentage shown in Table 1 into the MITR polyurethane ball milling tank successively, and roll wet, dry (rotary evaporator) and pre-press (graphite mold) according to the parameters in the table, and then Spark plasma sintering (SPS, -FCT-HP D250) to obtain nanocomposite blocks; (2) crushing and powder making: coarsely crushing with a crusher and finely crushing with a high-energy ball mill to obtain nanocomposite powders, and drying the ground nanocomposites in blast Dry in a box (GFL-45), set the temperature at 65°C, the heating power is 3kw, the ambient temperature is 40°C, and the humidity is 50%; (3) Surface functionalization: Weigh a certain amount of nanocomposites, add surface functional agents and T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com