Patents

Literature

74results about How to "Increased precipitation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing cryolite by alkaline leachate of cathode carbon block of aluminum electrolytic cell

The invention relates to a method for preparing cryolite by alkaline leachate of a cathode carbon block of an aluminum electrolytic cell, and belongs to a leachate preparation method. The method comprises the steps of grinding the cathode carbon block of the aluminum electrolytic cell to a certain particle size, mixing the ground cathode carbon block with alkaline liquid, carrying out size mixing, carrying out stirring leaching at a heating temperature of 20-90 DEG C, filtering to obtain first filtrate and a first filter residue, adding sodium fluoride and a small amount of Na3AlF6 solids into the first filtrate, controlling the introducing velocity of CO2-rich gas to generate precipitates while heating and stirring, after the reaction is finished, filtering to obtain second filtrate and a second filter residue, and drying the second filter residue at 100-150 DEG C, so as to obtain a cryolite product. According to the method, acidy leaching is replaced with alkaline leaching, so that the equipment requirements in the production process are reduced, processing processes such as flotation are omitted, an absorption process of hydrogen fluoride is omitted, and the processing process is simplified; a high-temperature processing process is saved, so that the energy consumption is reduced; and by adding crystal seeds, high-quality cryolite with the uniform particle size is generated when airflow rate is controlled. The method has the beneficial effects that the process is simple, a closed loop is utilized, the resource utilization rate is high, and the secondary pollution is avoided.

Owner:CENT SOUTH UNIV

Method for producing cryolites by using aluminum electrolytic cell cathode carbon block alkaline leaching solution

The invention relates to a method for preparing cryolites by using an aluminum electrolytic cell cathode carbon block alkaline leaching solution, and belongs to preparation methods of the cryolites. The method comprises the following steps: grinding aluminum electrolytic cell cathode carbon blocks finely to a certain particle size, performing slurry mixing with alkali liquor, and performing agitation leaching at a heating temperature of 20-90 DEG C; then performing filtration to obtain a first filtrate and a first filter residue; adding sodium fluoride and a small amount of Na3AlF6 solids into the first filtrate; then controlling the speed of introducing NH3-rich gas or adding NH4F to generate a deposit under the action of heating agitation; and after reaction, performing filtration to obtain a second filtrate and a second filter residue, and drying the second filter residue at 100-150 DEG C to obtain a cryolite product. According to the method provided by the invention, by replacing acid leaching with alkali leaching, the requirement of a production process on equipment is reduced, treatment processes including floatation are reduced, an absorption process of hydrogen fluoride is reduced, and the treatment process is simplified; a high-temperature treatment process is not used, so that the energy consumption is reduced; and by adding a crystal seed, high-quality cryolites with uniform particle sizes are generated under the condition that the airflow rate is controlled. The method provided by the invention is simple in process, achieves closed cycle, is high in resource utilization rate and avoids secondary pollution.

Owner:CENT SOUTH UNIV

System and method for reducing trapped energetic proton flux at low earth orbits

ActiveUS20120223253A1Increase the precipitation rateReduce current shielding weightRadiation/particle handlingRadiation therapyUltra low frequencyPrecipitation

A system and method for reducing energetic proton flux trapped in the inner radiation belt by injecting Ultra Low Frequency (ULF) electromagnetic waves is disclosed. The ULF electromagnetic waves is generated by space or ground based transmitters and the frequency range is selected such that the injected waves are in gyrofrequency resonance with trapped 10 to 100 Mev protons. Pitch angle scattering of the trapped protons in gyro-resonance with the injected waves increases their precipitation rate by forcing their orbits into pitch angles inside the atmospheric loss-cone where they are lost by intaracting with the dense neutral atmosphere at altitudes below 100 km. The reduction of energetic proton flux trapped in the inner radiation belt allows use of commercial electronics with submicron feature size on Low Earth Orbit satellites and microsatellites without the operational constraints imposed by the presence of energetic proton fluxes trapped at the inner radiation belts.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

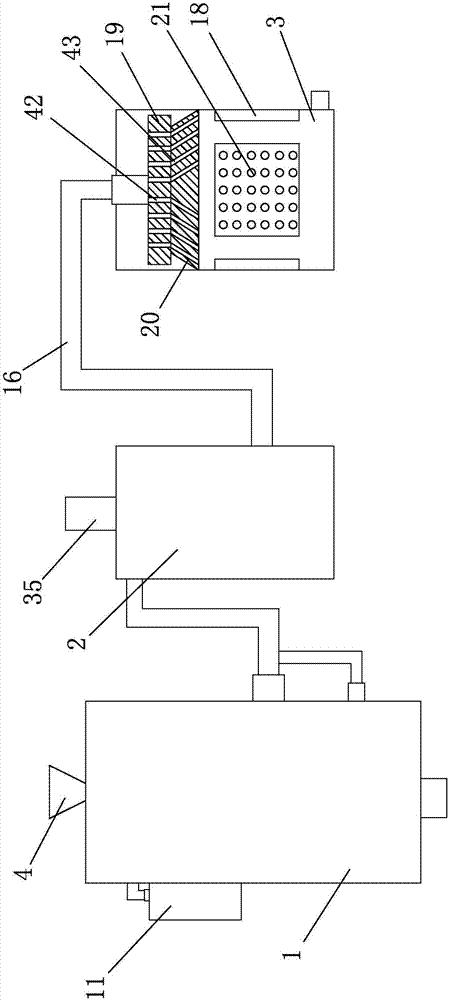

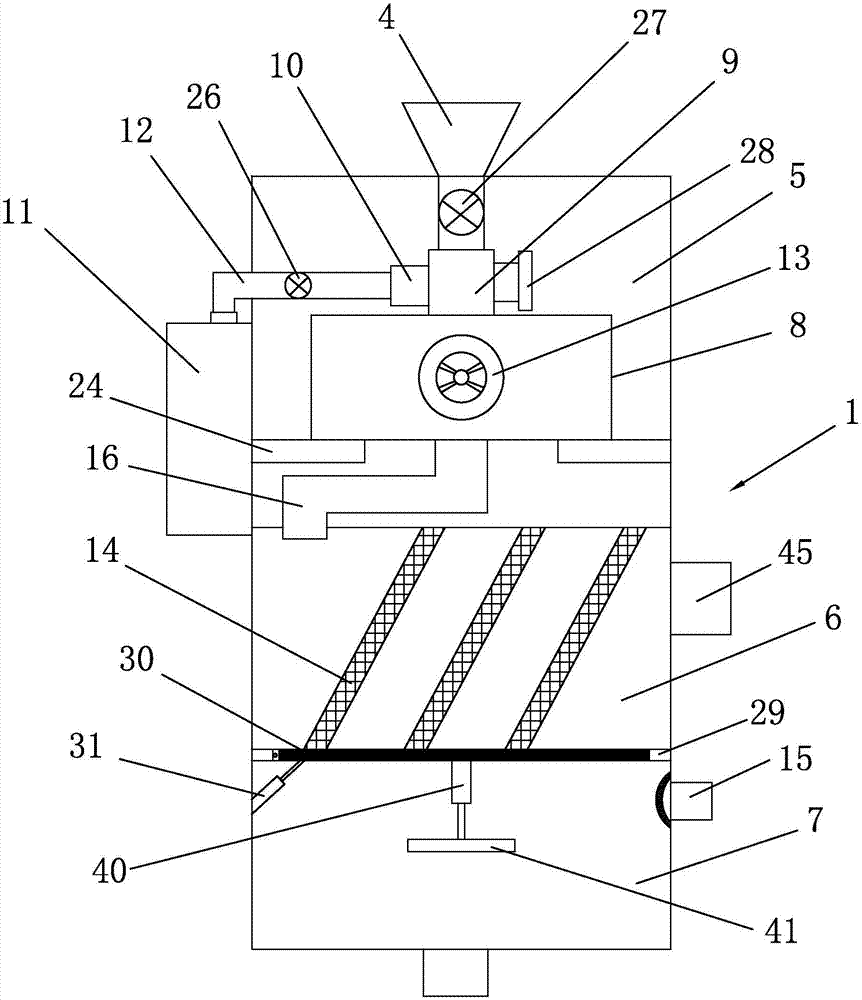

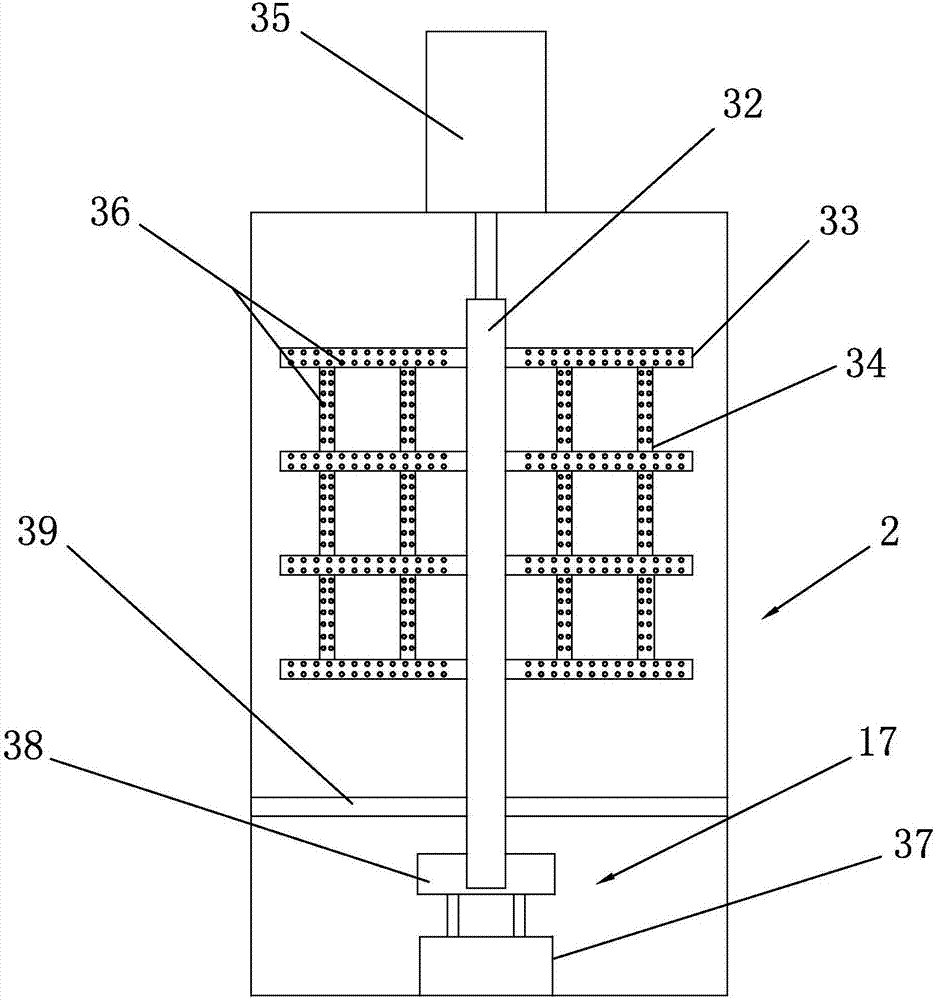

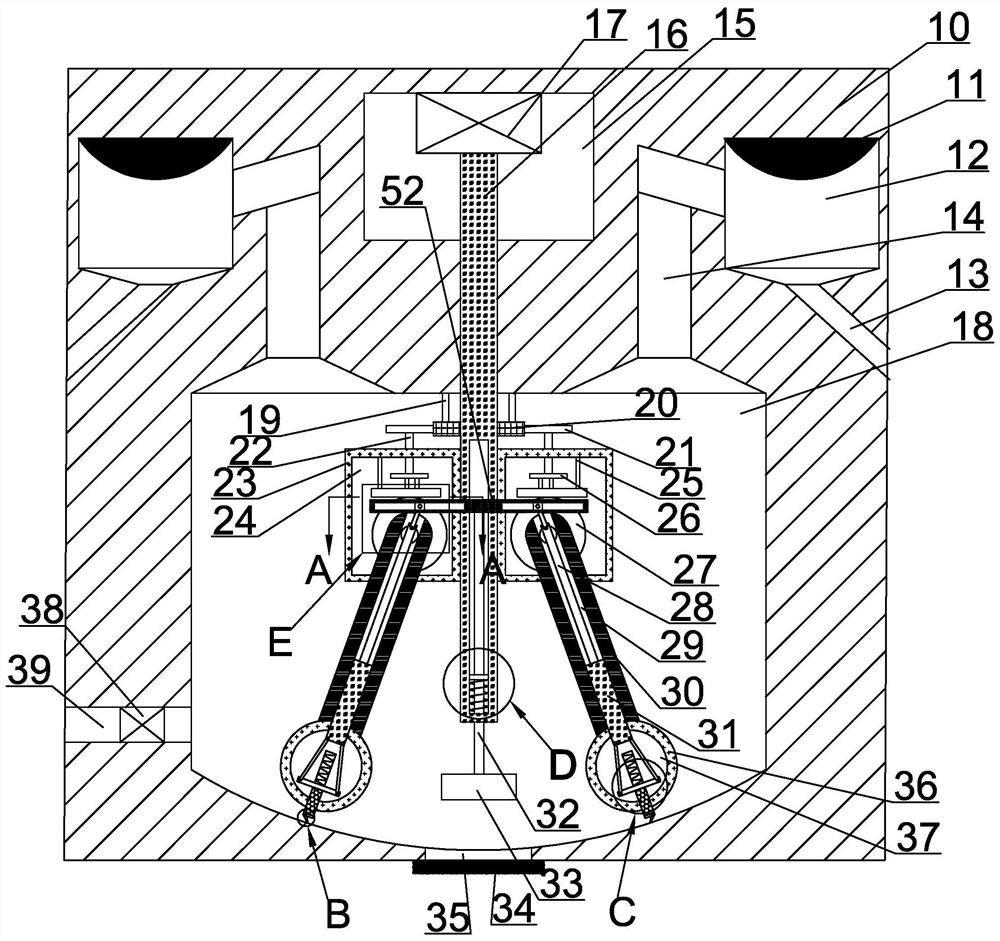

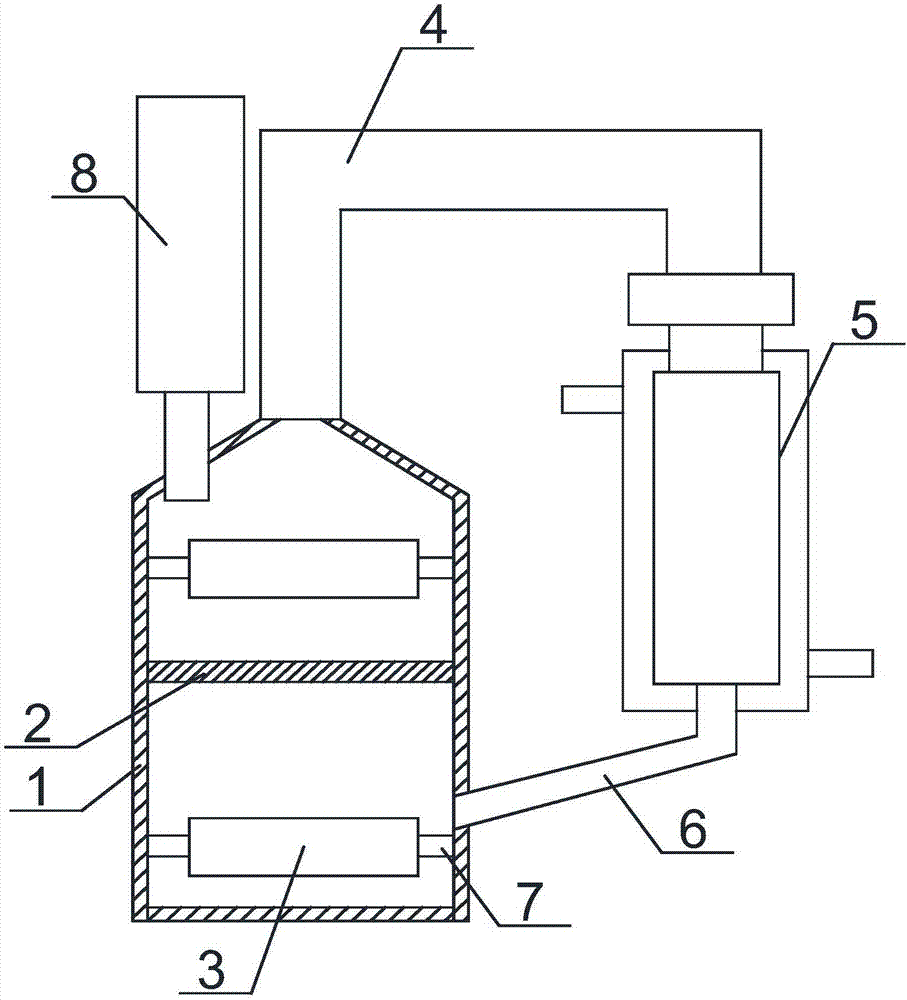

Sewage treatment device and method for landscape river way

InactiveCN107043186AImprove processing efficiencyIncreased precipitation rateSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeWater quality

The invention discloses a sewage treatment device for a landscape river way. The sewage treatment device comprises a sludge separation tank, an oxygenation tank and a disinfection tank, wherein a mixing cavity, a settling cavity and a sludge collecting cavity are sequentially arranged in the sludge separation tank from top to bottom, an oxygenation pipe and a rotating device are arranged in the oxygenation tank, and a flow dividing device and a heating plate are arranged in the disinfection tank. A sewage treatment method comprises the following steps: (1) filtering suspended matters; (2) separating sludge; (3) carrying out oxygenation treatment on sewage; (4) disinfecting the sewage; (5) inspecting the water quality; and (6) carrying out cleaning, inspection and repair. The sewage treatment device is simple in structure and strong in practicability; the sewage is gradually treated by virtue of the sludge separation tank, the oxygenation tank and the disinfection tank, so that the sewage treatment quality is effectively improved; meanwhile, by utilizing an oxygenation generator and an oxygenation pipe, the dissolved oxygen content in the sewage is increased, and the self-cleaning capacity of the river way is improved; and the device is high in working efficiency and low in energy consumption, the sewage treatment effect is obvious, and the comprehensive utilization rate is effectively increased.

Owner:ZHEJIANG BUSINESS TECH INST

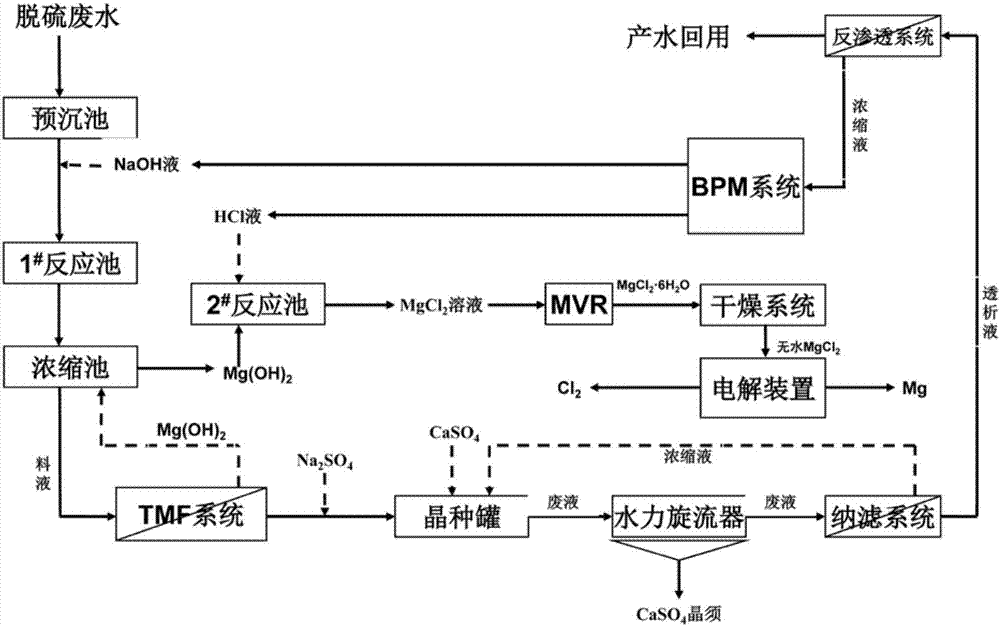

Recycling treatment process for thermal power plant desulfurization wastewater

InactiveCN107311350AReduce productionImprove stabilityCellsCalcium/strontium/barium sulfatesElectrolysisPower station

The invention discloses a recycling treatment process for thermal power plant desulfurization wastewater. The process includes: 1) subjecting desulfurization wastewater to triple box treatment, and then letting the treated wastewater enter a pre-sedimentation tank; 2) adding NaOH and letting it overflow into a 1# reaction tank to undergo reaction; 3) letting the effluent water of the 1# reaction tank enter a concentration tank, transporting the feed liquid in the concentration tank into a TMF system for filtering, returning the formed Mg(OH)2 to the concentration tank, and discharging Mg(OH)2 into a 2# reaction tank; 4) letting the TMF system produced water enter a seed crystal tank, outputting the waste liquid to a hydrocyclone, and making the clear liquid obtained by the hydrocyclone enter a nanofiltration system; 5) returning the concentrated liquid obtained by the nanofiltration system to the seed crystal tank, making the dialysate enter a reverse osmosis system, and conducting electric treatment on the obtained concentrated liquid; and 6) subjecting the MgCl2 feed liquid formed in the 2# reaction tank to evaporative crystallization to form MgCl2 crystals, and then conducting re-drying to obtain anhydrous MgCl2, and carrying out electrolytic treatment on the anhydrous MgCl2 to obtain elemental Mg and Cl2. The "chemical reaction+TMF system+seed crystal tank+hydrocyclone+nanofiltration system+reverse osmosis system+bipolar membrane" process involved in the invention can reuse 90% or more of water, and can utilize Mg, CaSO4 and NaCl in wastewater.

Owner:上拓环境科技(长兴)有限公司

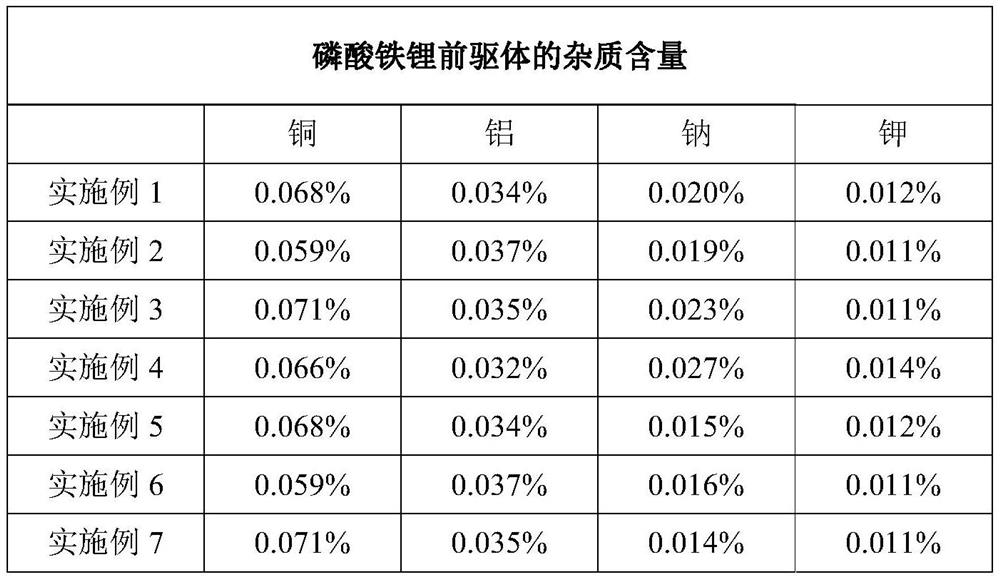

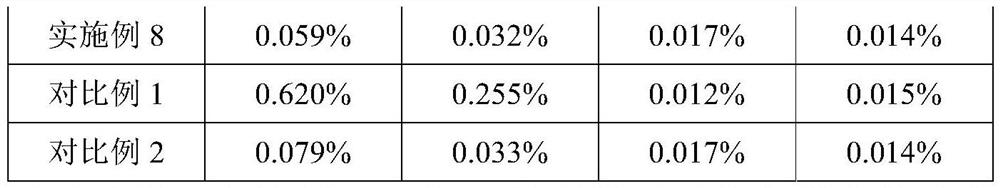

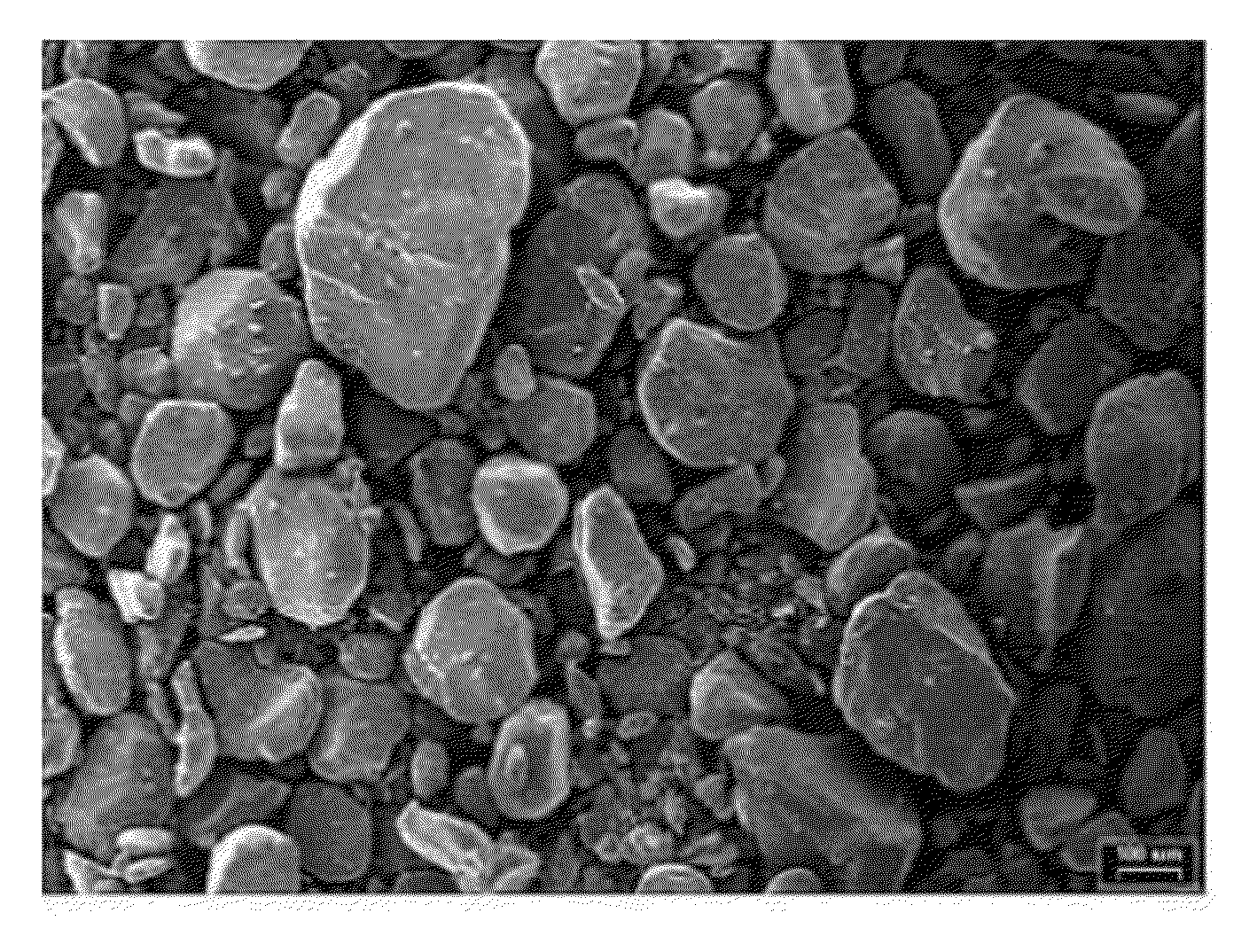

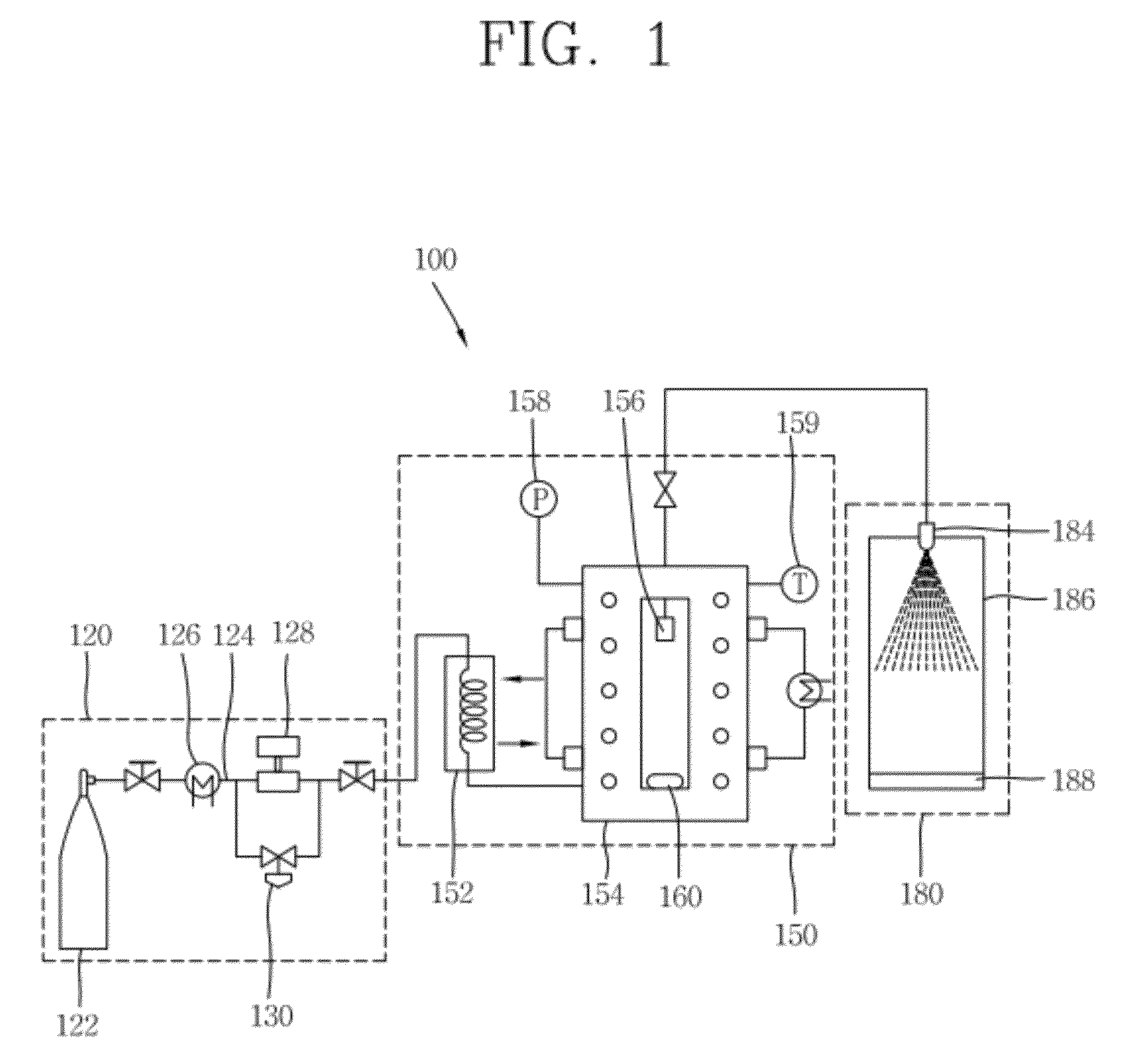

Method for producing lithium iron phosphate precursor by using retired lithium iron phosphate battery as raw material

ActiveCN112955404ALow impurity contentIncrease gram capacityCell electrodesWaste accumulators reclaimingLithium iron phosphateElectrolysis

A method for producing a lithium iron phosphate precursor by using a retired lithium iron phosphate battery as a raw material, comprising the following steps: immersing a battery cell in an acid solution; performing electrolyzation to recover copper; oxidizing ferrous ions; precipitating iron phosphate; precipitating lithium carbonate; and after precipitation is completed, performing one-step recovery to obtain the lithium iron phosphate precursor.

Owner:CONTEMPORARY AMPEREX TECH CO

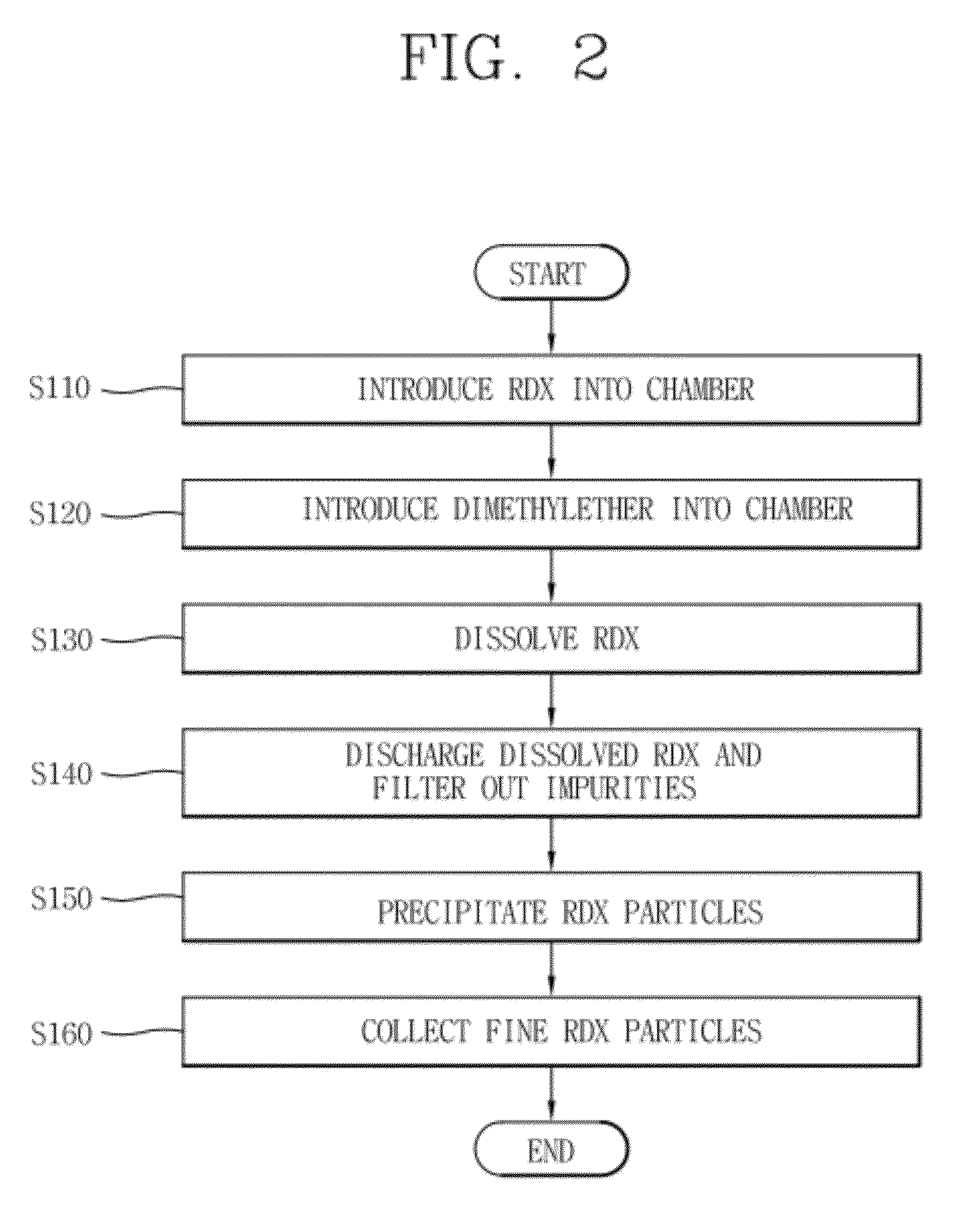

Recrystallization method of fine spherical rdx particle

ActiveUS20120276385A1Reducing recrystallization costProcess environmental protectionOrganic chemistrySynthetic resin layered productsMicroparticleAtmospheric pressure

The present invention relates to a method for recrystallizing fine spherical cyclotrimethylenetrinitramine (Research Department Explosive, hereinafter, referred to as “RDX”) particles, and the method for recrystallizing fine spherical RDX particles according to the present invention may include (a) introducing a powder material containing RDX into a container, (b) introducing a dimethylether compressed gas into the container and dissolving the RDX to form a RDX solution, (c) releasing and decompressing the RDX solution into atmospheric pressure to form crystallized RDX particles, and (d) separating and collecting the RDX particles.

Owner:AGENCY FOR DEFENSE DEV

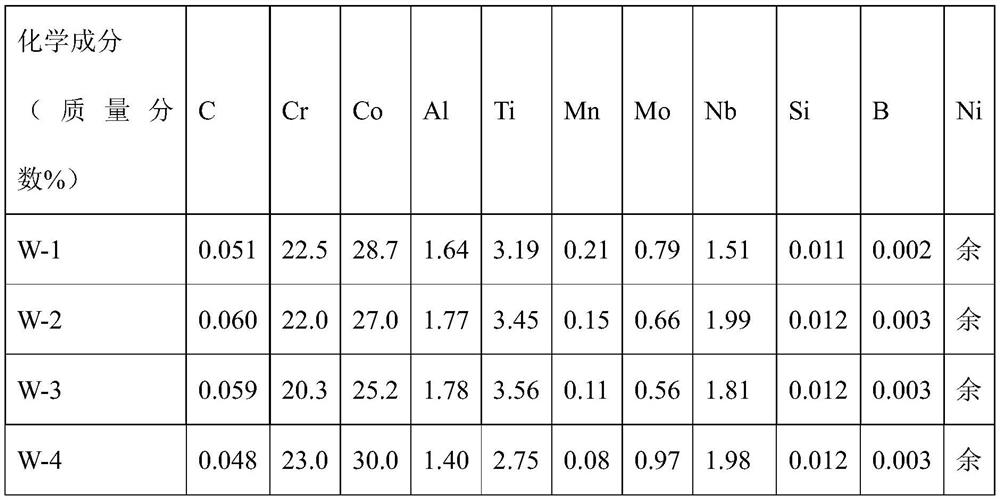

Nickel-cobalt-based high-temperature alloy welding wire

PendingCN112518172AImprove performanceIncrease contentWelding/cutting media/materialsSoldering mediaRare-earth elementSuperalloy

The invention belongs to the field of welding materials, and particularly relates to a precipitation strengthening type nickel-cobalt-based high-temperature alloy welding wire for welding a high-temperature part of an 800-DEG C ultra-supercritical power station. The welding wire is mainly characterized in that Ti / Al is more than or equal to 1.5 and less than or equal to 2, and C / Nb is more than orequal to 0.03. The yield strength of the welding wire at 800 DEG C is not less than 600 MPa. An alloy comprises, by mass percent, 25-30% of Co, 20-23% of Cr, 1.4-1.8% of Al, 2.1-3.6% of Ti, 1.5-2.0%of Nb, 0.5-1.0% of Mo, less than or equal to 0.1% of Si, less than or equal to 0.3% of Mn, less than or equal to 0.01% of Cu, less than or equal to 0.04% of C, less than or equal to 0.003% of B, and the balance of Ni, and no rare earth element is contained. A deposited metal matrix of the welding wire is an austenite (gamma) phase of a disordered face-centered structure, precipitation strengthening phases are a Ni3 (Al, Ti) gamma'phase and a primary carbide NbC, and carbide phases are distributed between crystals. The welding wire fills up the blank in the prior art, has excellent high-temperature performance, can be widely applied to homogeneous and heterogeneous welding of high-temperature alloy parts under the condition of ultra-supercritical water vapor at the temperature of 750-800 DEG C, and can also replace an existing nickel-based / nickel-cobalt-based high-temperature alloy welding wire.

Owner:CHINA HUANENG GRP CO LTD +1

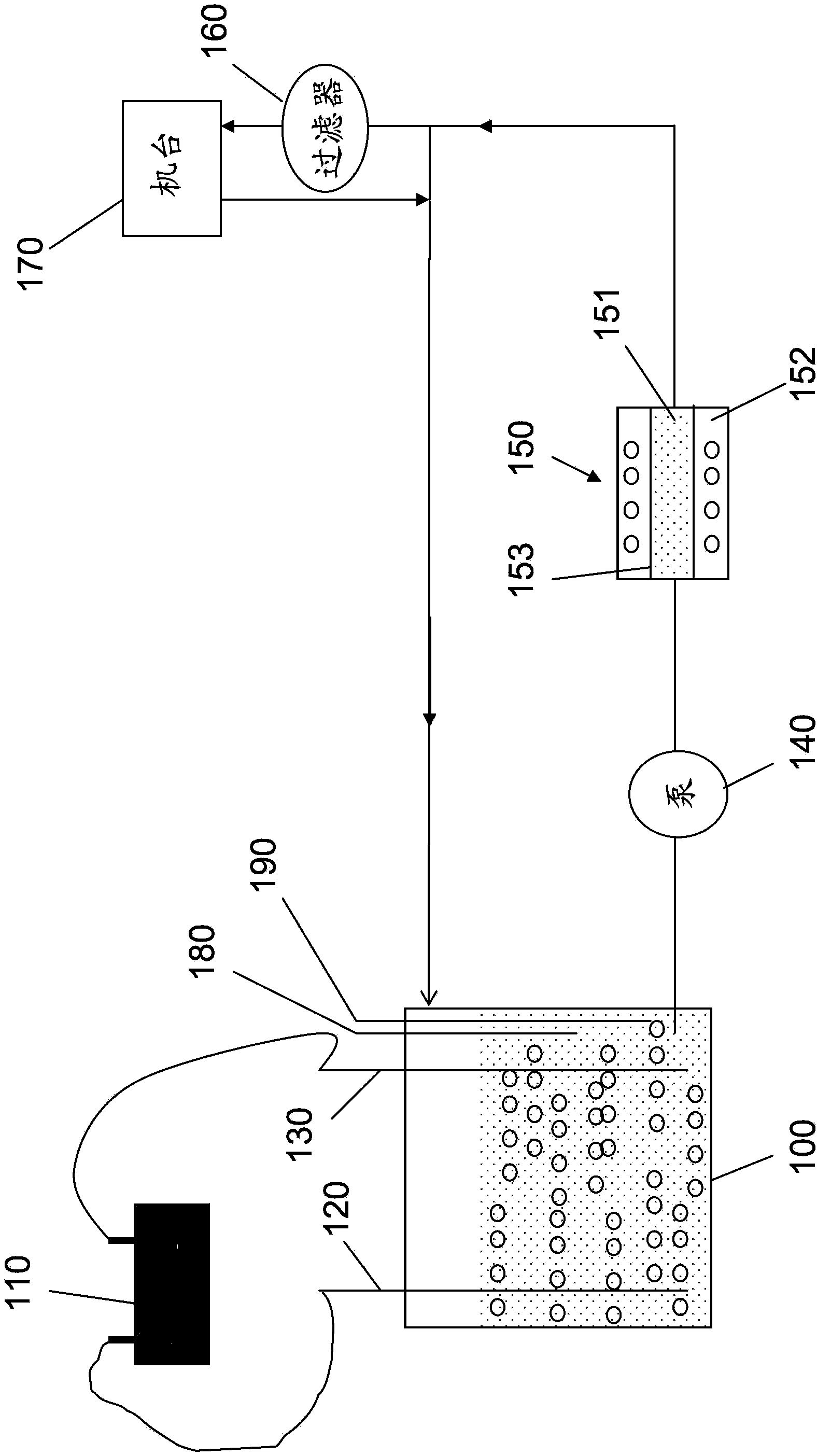

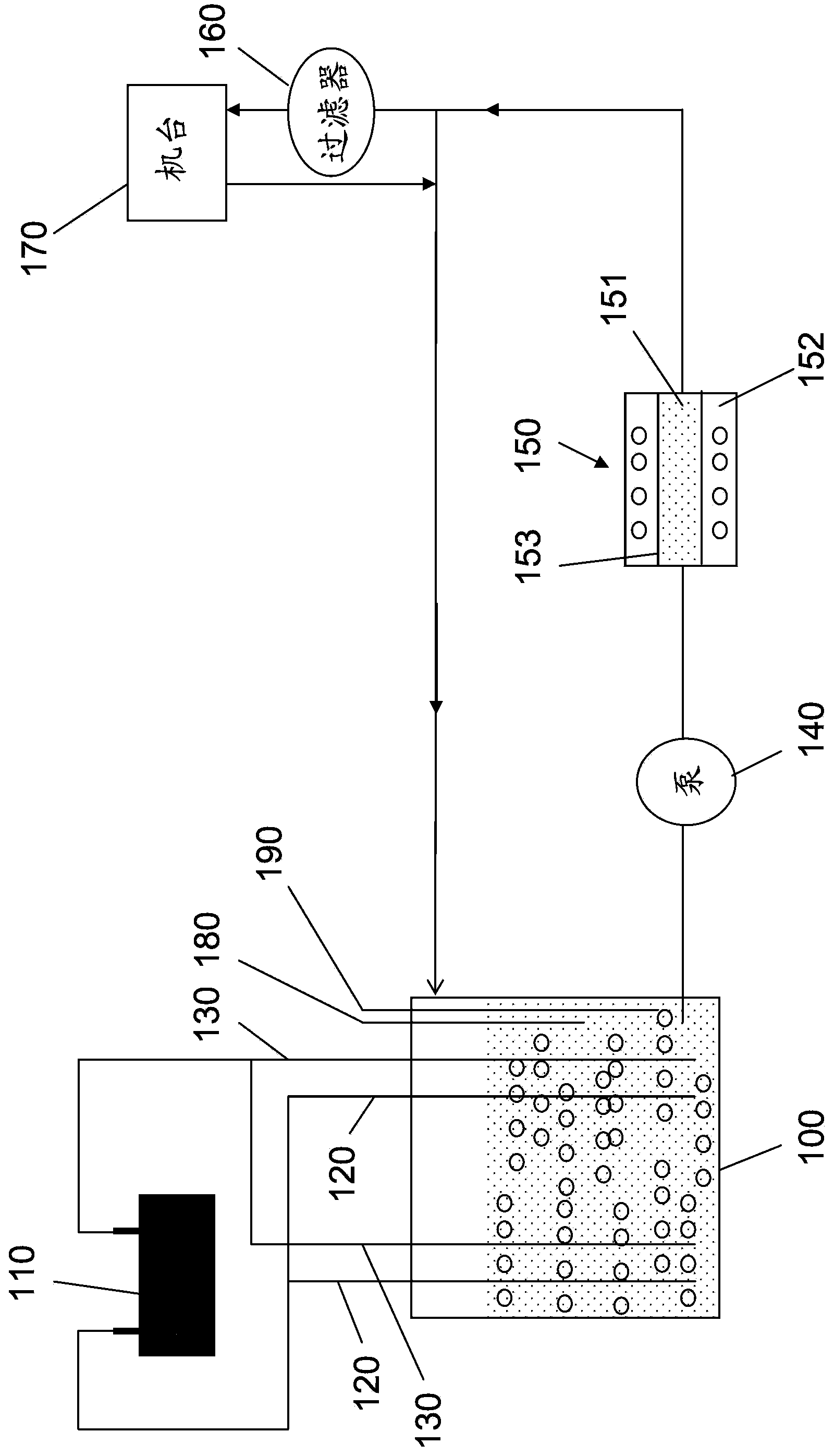

Polishing solution recycling apparatus

InactiveCN104141165AWill not affect the use againIncreased precipitation rateElectrolysis componentsElectricityElectrolysis

The invention discloses a polishing solution recycling apparatus. The apparatus comprises a storage tank, a power supply, a first circulating pump and a degasser. The storage tank is used for storing a polishing solution, and an anode plate and a cathode plate are arranged in the storage tank. The anode of the power supply is electrically connected with the anode plate, and the cathode of the power supply is electrically connected with the cathode plate. The inlet of the first circulating pump is connected with the bottom of the storage tank, the outlet of the first circulating pump is connected with the liquid inlet of the degasser, the liquid outlet of the degasser is connected with the top of the storage tank, and the degasser can remove bubbles in the polishing solution. The arrangement of the degasser realizes the removal of the bubbles in the polishing solution. The improvement of the copper ion separation rate due to the increase of the current and voltage output of the power supply during electrolysis has no influences on the reuse of the polishing solution; and the apparatus runs in a cycle manner, and avoids outward waste liquid emission, so the apparatus does not pollute the environment, saves raw materials and reduces the process cost.

Owner:ACM RES SHANGHAI

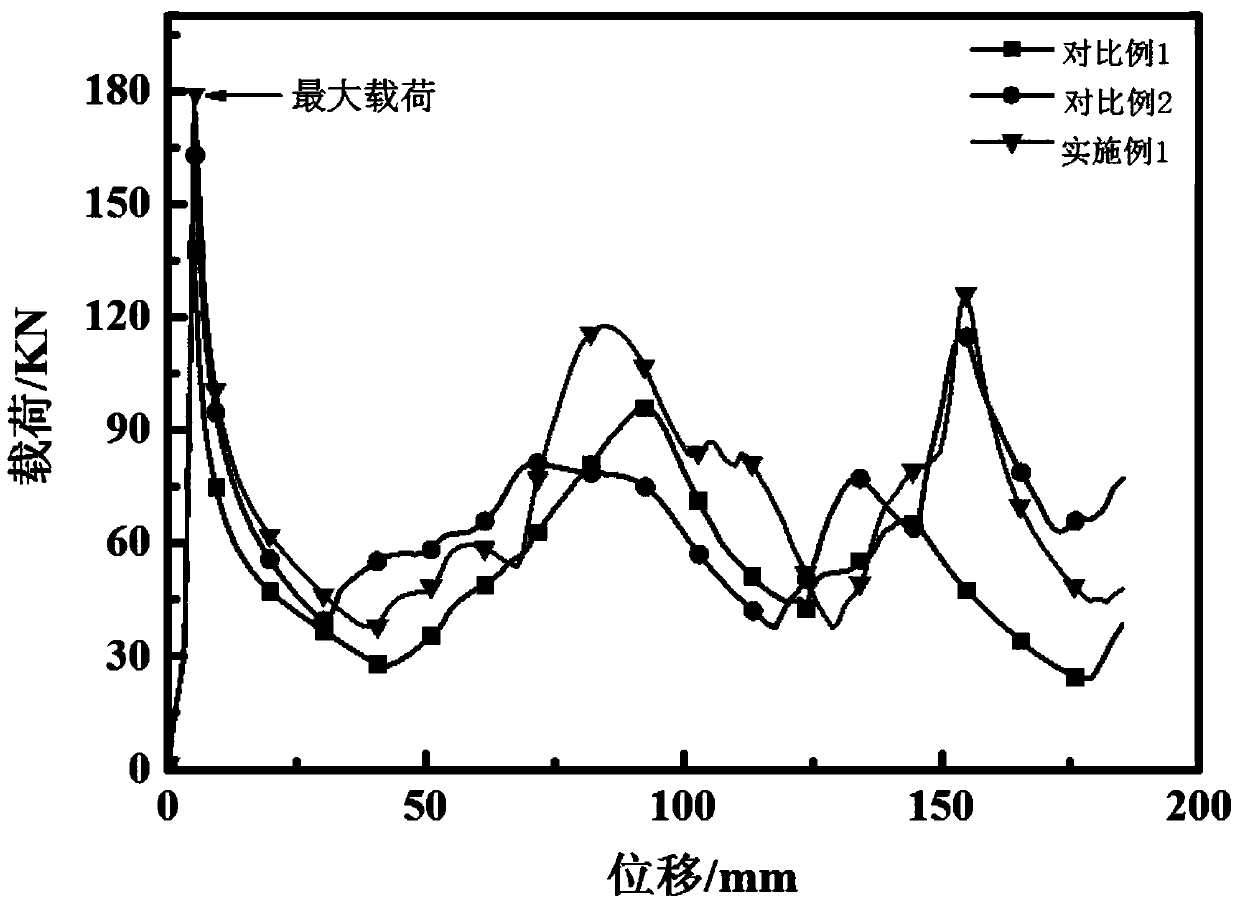

Al-Mg-Si-Cu alloy with high energy absorption property and preparation method thereof

The invention belongs to the field of aluminum alloy material manufacturing and relates to an Al-Mg-Si-Cu alloy with a high energy absorption property, the alloy is prepared by the following elementsin percentage by weight: 0.6-1.0% of Si, less than or equal to 0.35% of Fe, 0.4-0.7% of Cu, less than or equal to 0.3% of Mn, 0.6-1.0% of Mg, 0.1-0.3% of Cr, 0.1-0.3% of V, less than or equal to 0.1%of Ti, less than or equal to 0.05% of the rest single impurity content, less than or equal to 0.15% of total impurity and the balance of Al. in the preparation method, the stretched and straightened aluminum alloy profile is subjected to two-stage artificial aging within 24 hours, the first-stage artificial aging process is 150+ / -5 DEG C * (1-2)h, and the second-stage artificial aging process is 220+ / -5 DEG C * (4-5)h; aluminum alloy materials with better mechanical properties and energy absorption properties can be produced by adjusting alloy compositions and subsequent production processes,the safety of the aluminum alloy as an energy absorption element is improved, and the application range of the aluminum alloy in traffic products is enlarged.

Owner:CHINA ZHONGWANG

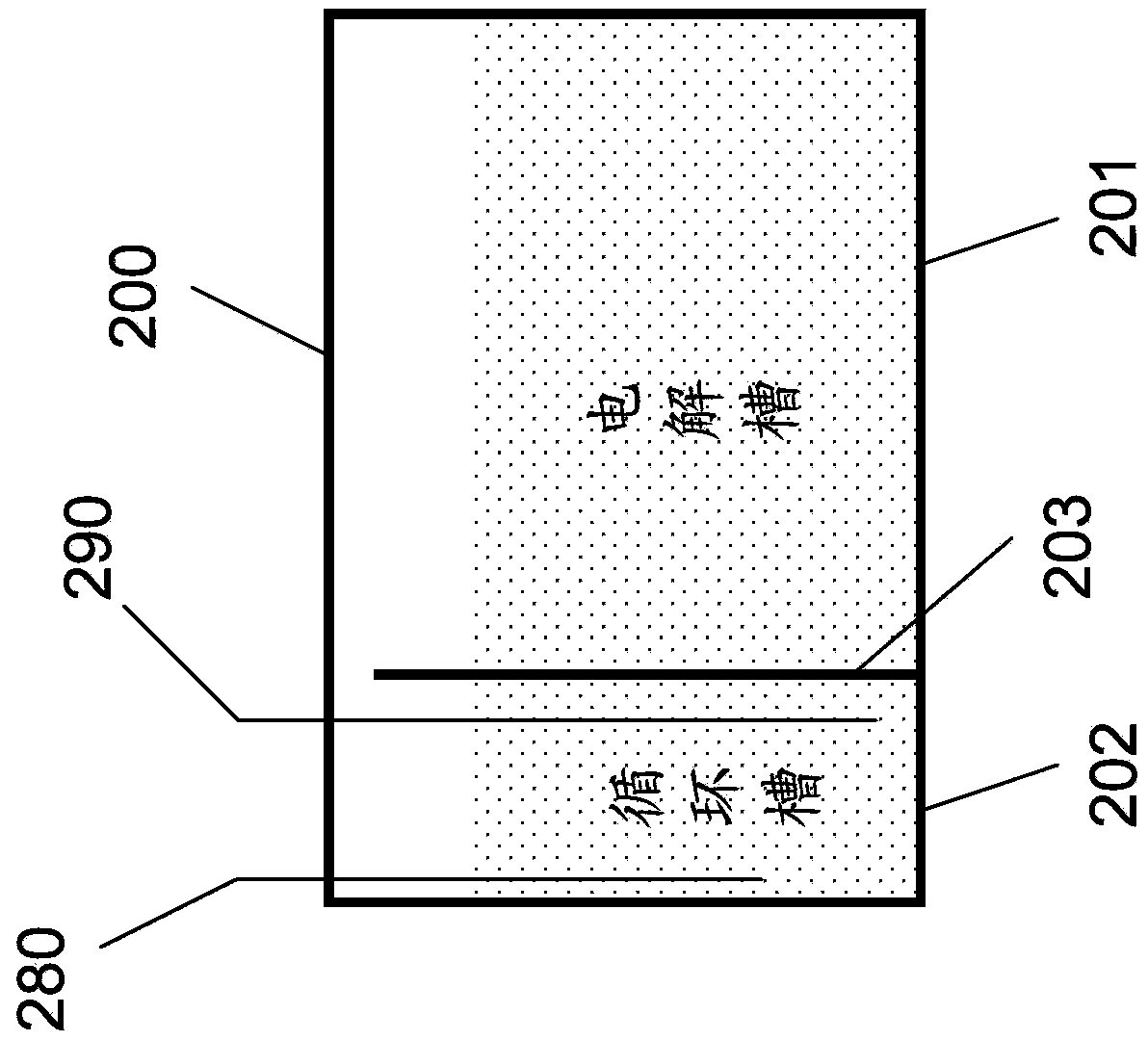

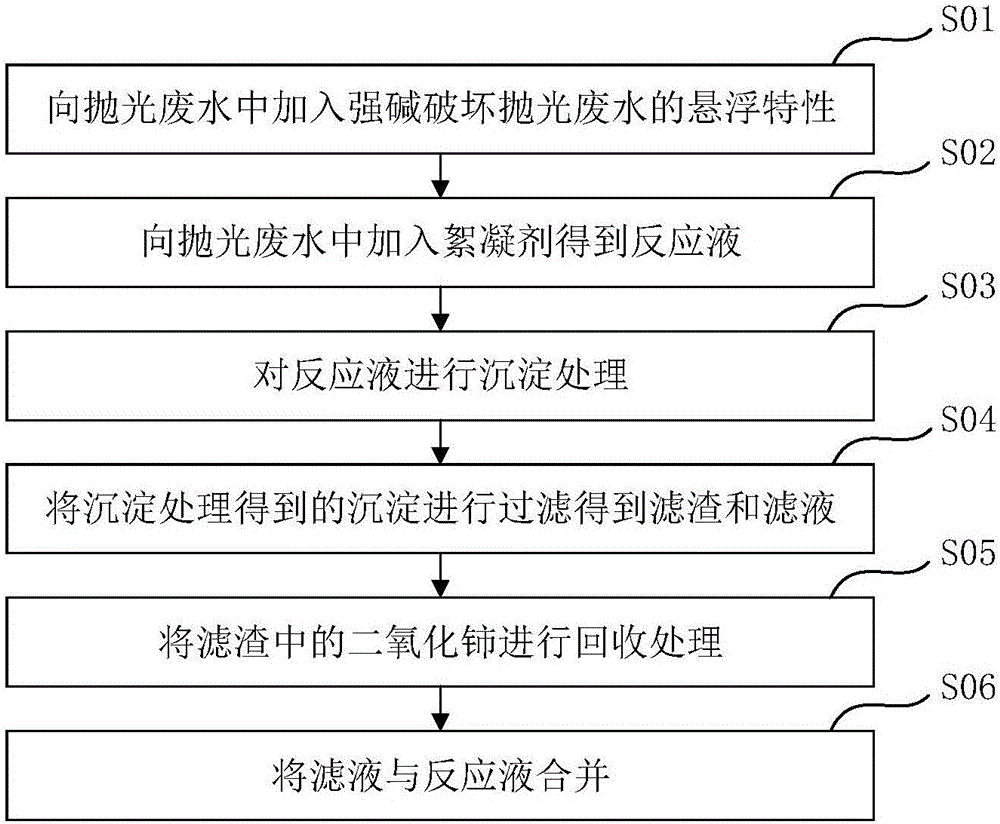

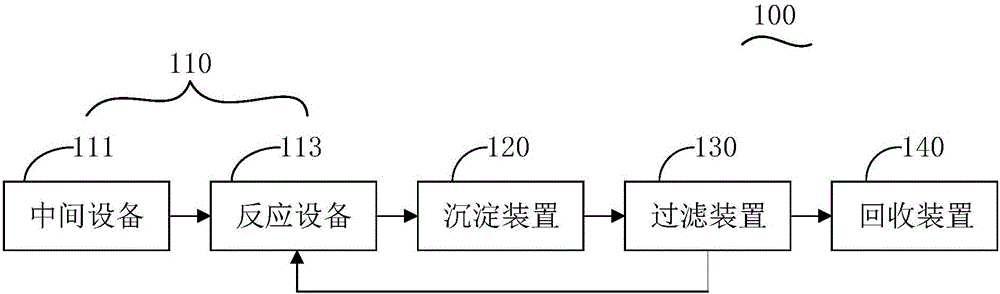

Polishing wastewater treatment method and polishing wastewater treatment system

ActiveCN106396175AAccelerated settlementImprove processing efficiencyWaste water treatment from ceramic industriesTreatment involving filtrationWater treatment systemAluminium chlorohydrate

The invention relates to a polishing wastewater treatment method. Polishing wastewater contains cerium dioxide and a sodium salt suspending agent. The polishing wastewater treatment method comprises following steps: strong base is added to the polishing wastewater to damage a suspension characteristic of the polishing wastewater, and an intermediate liquid is obtained; a flocculating agent is added to the intermediate liquid for flocculation treatment, a reaction liquid is obtained, and the flocculating agent contains polyaluminum chloride and polyacrylamide; the reaction liquid is subjected to sedimentation treatment. The strong base is added to the polishing wastewater and can react with the suspending agent in the polishing wastewater to damage the suspension characteristic of the suspending agent, or the suspending agent is dissolved in an alkaline environment to result in failure of the suspending agent in the polishing wastewater, meanwhile, the viscous state of the polishing wastewater is damaged, the polishing wastewater becomes prone to sedimentation, then the commonly used flocculating agent is added, and by means of the scheme, the sedimentation rate is greatly increased.

Owner:WGTECH JIANGXI

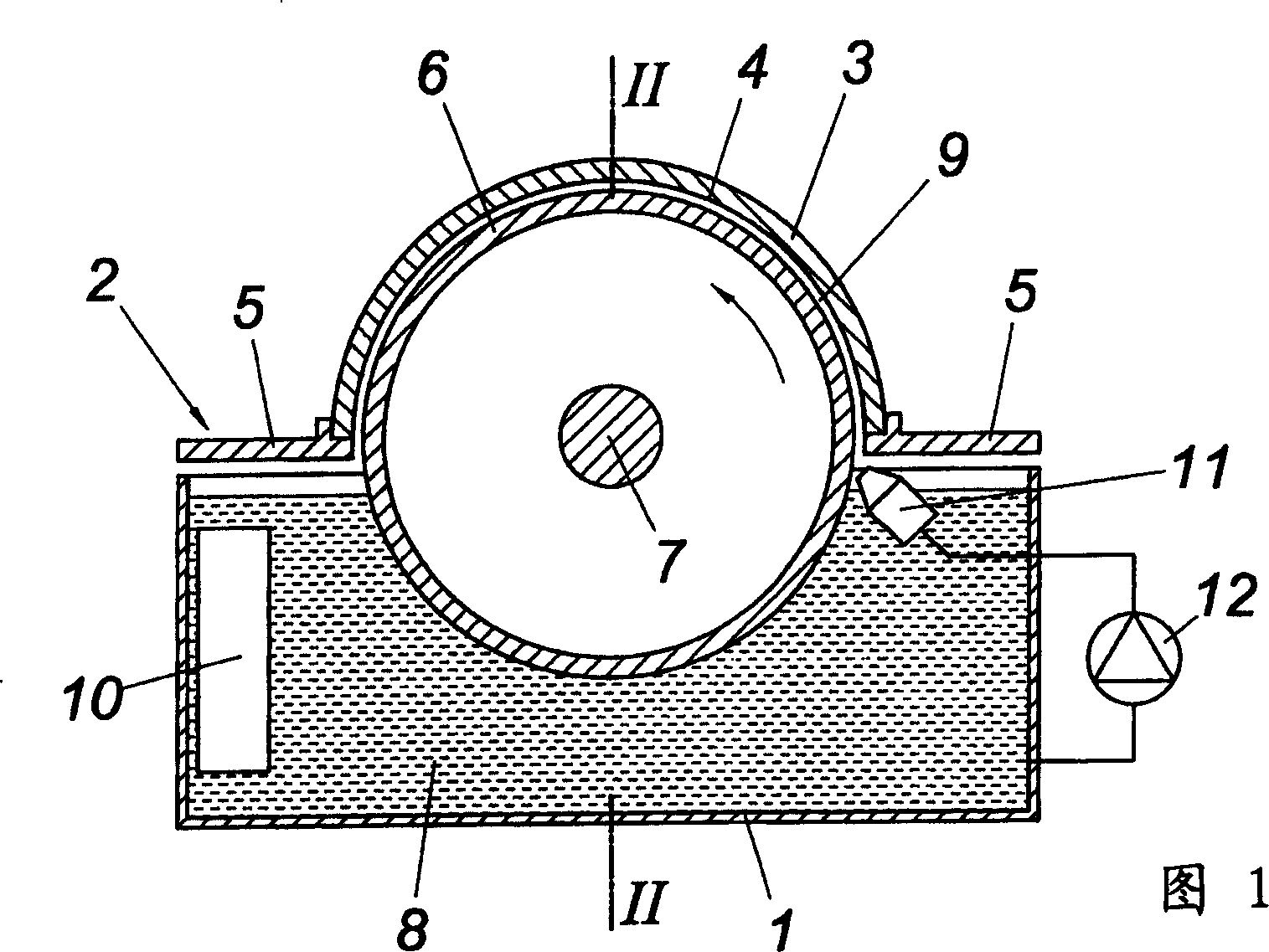

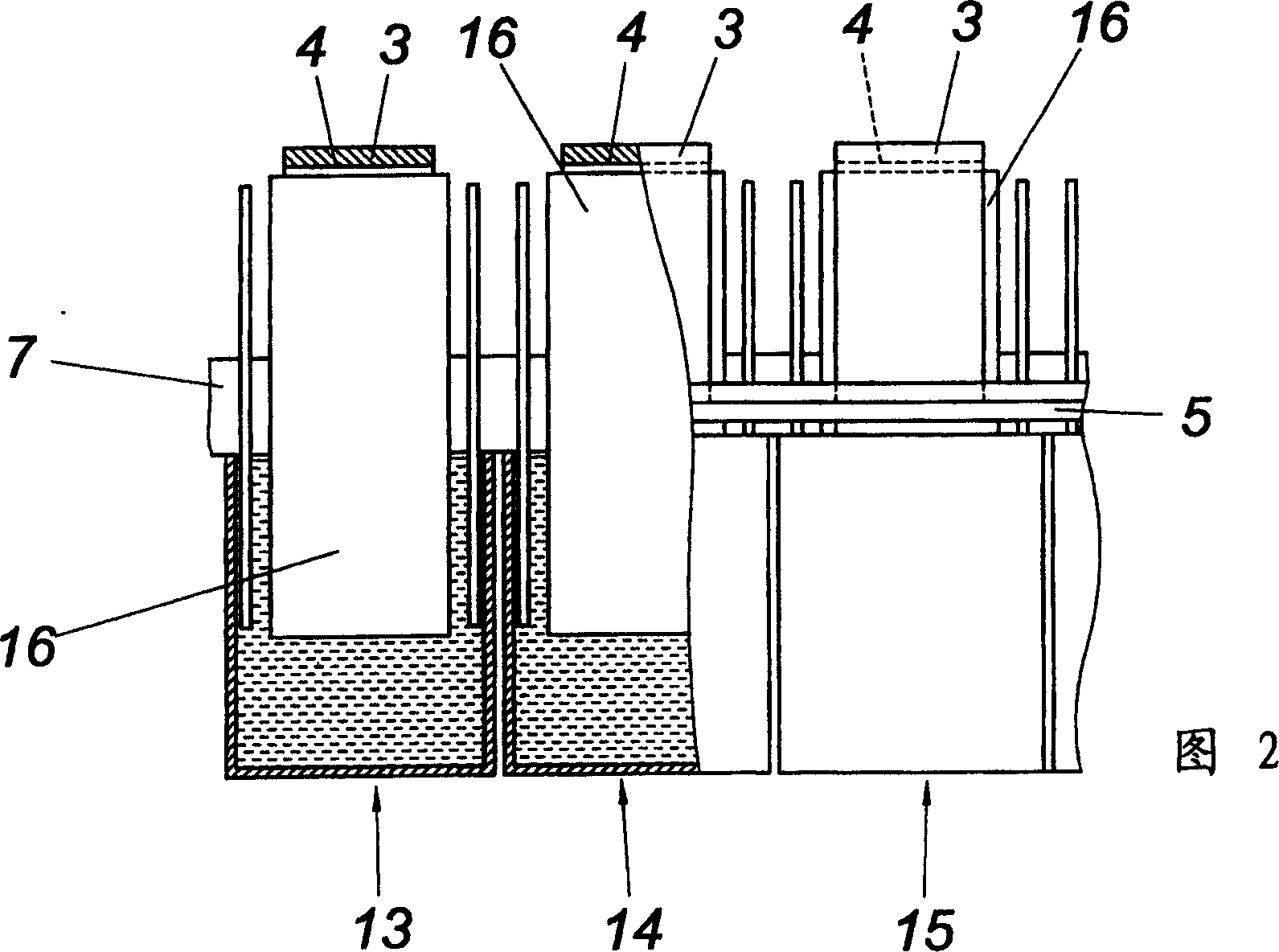

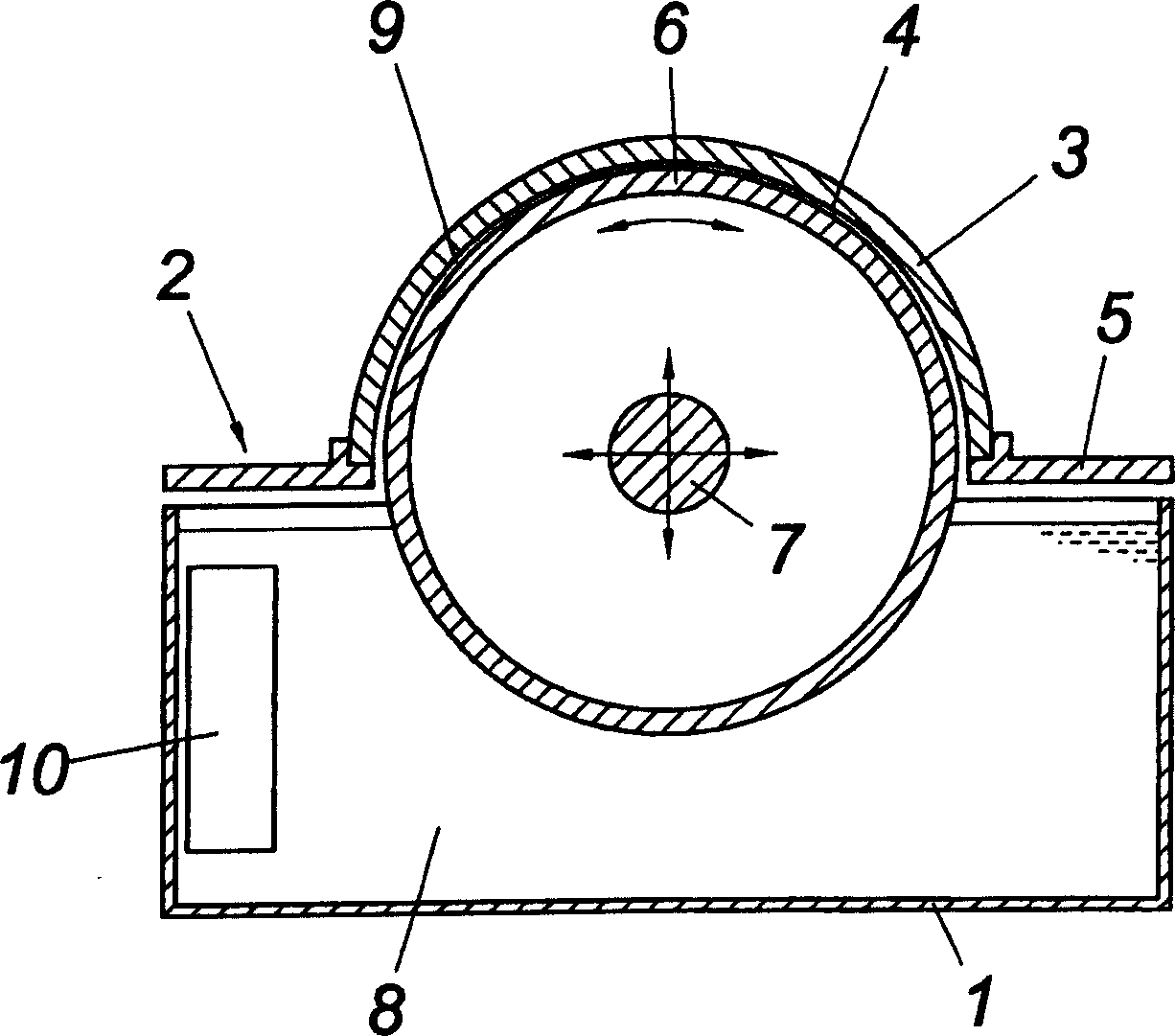

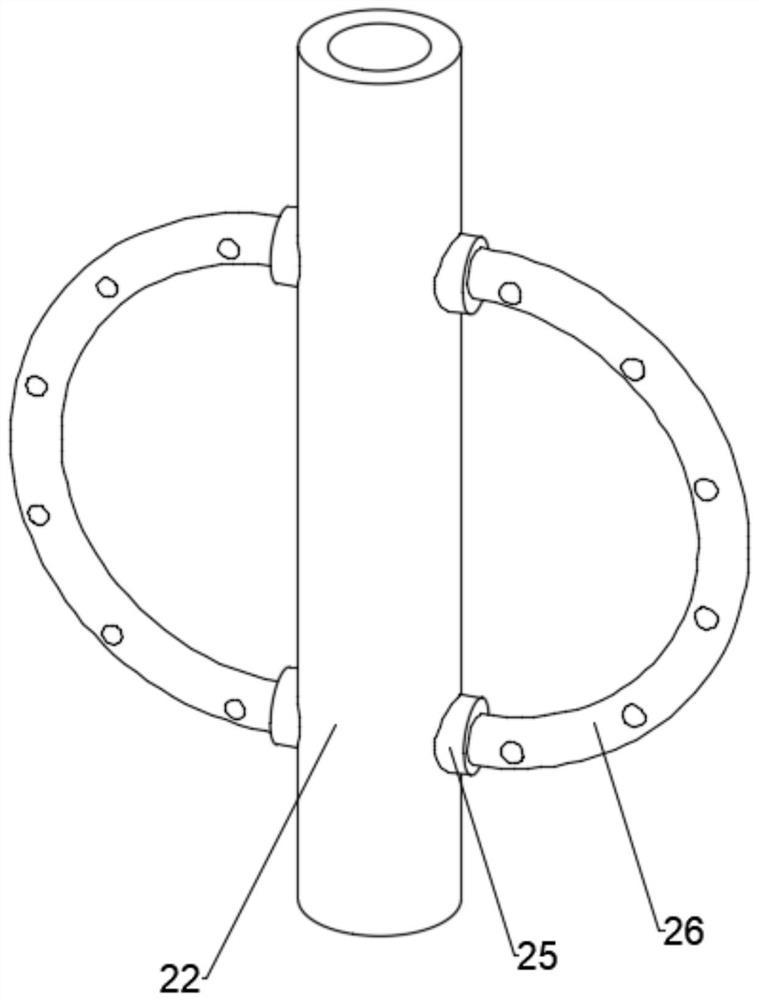

Method for electroplating a cylindrical inside surface of a work-piece-extending substantially over a semi-circle

InactiveCN1542168AMaintain cycle movementIncreased precipitation rateJewellerySEMI-CIRCLEEngineering

Owner:MIBA GLEITLAGER GMBH

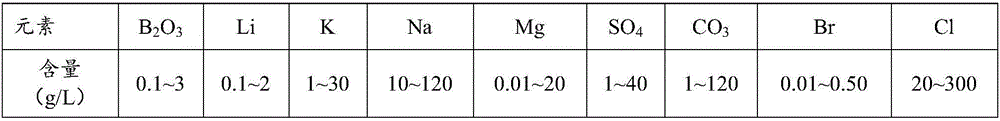

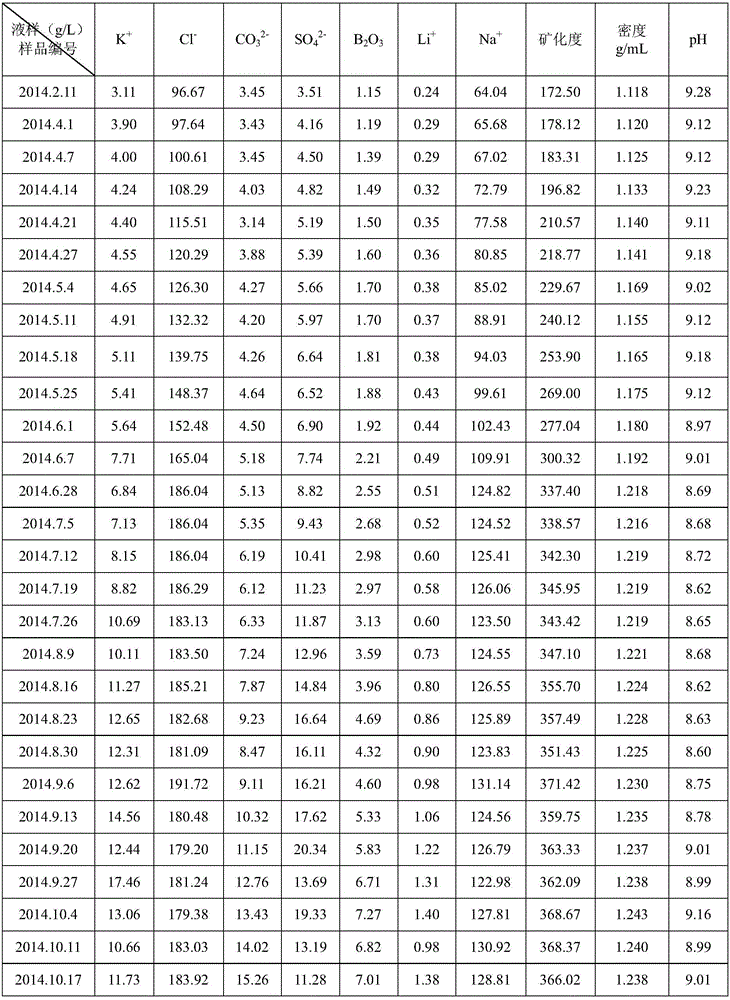

Method for preparing lithium carbonate from plateau carbonate bittern

ActiveCN105905929ARapid enrichmentGet rid of dependenceGeneral water supply conservationMultistage water/sewage treatmentLithium carbonateEvaporation

The invention provides a method for preparing lithium carbonate from plateau carbonate bittern. The method comprises the following steps: subjecting original carbonate bittern A to evaporation before autumn and winter, adjusting the concentration of lithium ions so as to allow the lithium ions not to be precipitated in the form of minerals and introducing the carbonate bittern A to a deep-pool salt field for evaporation when the concentration of lithium ions reaches 1.2 to 1.8 g / L; as considerable mirabilite decahydrate is precipitated at first when temperature is -15 to -5 DEG C and the concentration of lithium ions rapidly increases, carrying out solid-liquid separation so as to obtain bittern B when the concentration of sulfate ions decreases to 4 to 7 g / L and the concentration of lithium ions increases to 2.6 to 3.5 g / L; introducing the bittern B into a heating system for heating to 20 to 60 DEG C, allowing a first batch of lithium carbonate concentrate and bittern C to be precipitated; subjecting the bittern C to refrigeration at a temperature of -20 DEG C or below so as to realize precipitation of mixed salt I and carrying out solid-liquid separation when the concentration of sulfate ions decreases to 15 g / L or below and the concentration of lithium ions increases to 2 g / L or above so as to obtain bittern D; and continuing evaporating the bittern D, adding bittern with a carbonate ion concentration of 60 g / L or above when the concentration of lithium ions reaches 2.6 to 3.5 g / L again and carrying out heating to 20 to 60 DEG C so as to allow a second batch of lithium carbonate concentrate to be precipitated.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

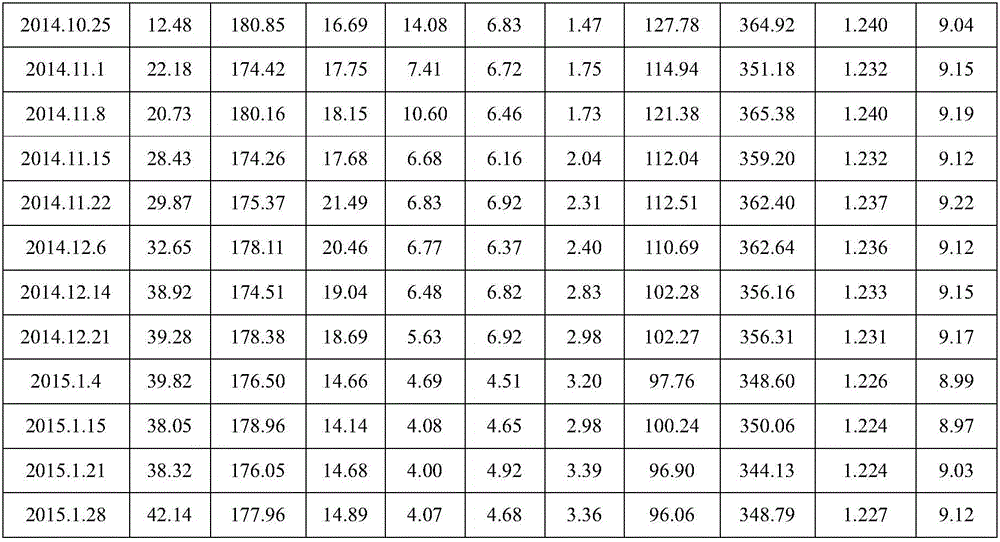

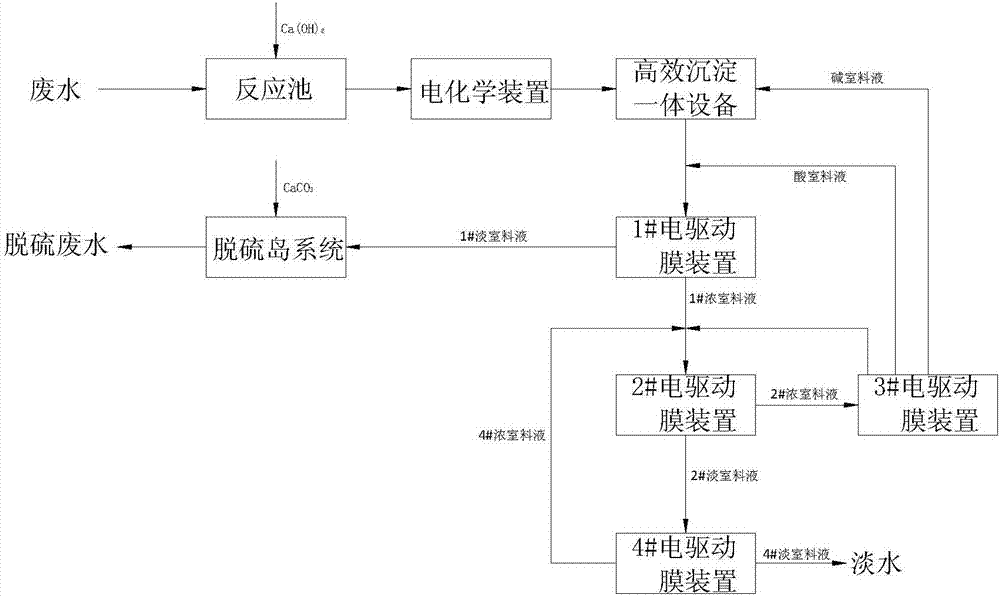

All-electric driven desulfurization waste water zero-emission treatment method and all-electric driven desulfurization waste water zero-emission treatment system

InactiveCN107473465AIncreased precipitation rateHigh removal rateWaste water treatment from gaseous effluentsMultistage water/sewage treatmentElectric driveZero emission

The invention belongs to the field of desulfurization wastewater treatment, and in particular relates to an all-electrically driven zero-discharge treatment method and system for desulfurization wastewater. The all-electrically driven zero-discharge treatment method and system for desulfurization wastewater provided by the present invention can be combined through the combined process of chemical reaction + electrochemical device + high-efficiency precipitation integrated equipment + a multivalent separation electric drive membrane + concentration electric drive membrane + bipolar membrane More than 90% of the water in the desulfurization wastewater can be reused, and at the same time, the Na2SO4 and NaCl in the wastewater can be used as resources, and the production of gypsum does not require the purchase of acid and alkali in the treatment process; the desulfurization wastewater driven by all electricity provided by the present invention The zero-emission treatment method and system treatment of flue gas desulfurization wastewater in thermal power plants have both economic and social benefits, and are of research and promotion value.

Owner:SUNUP ENVIRONMENTAL TECH CO LTD

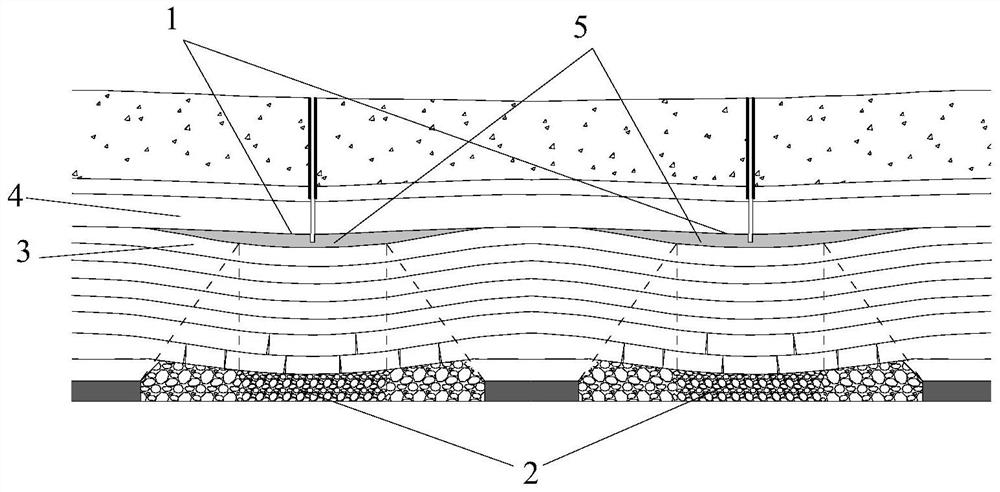

Phase-change microbial capsule grouting method for seepage prevention of fractured rock mass

PendingCN112324465ATo achieve anti-seepageOvercoming prejudices that cannot be usedUnderground chambersTunnel liningMicroorganismParaffin wax

The invention discloses a phase-change microbial capsule grouting method for seepage prevention of fractured rock mass. The method comprises the following steps of, S1, determining a grouting hole site on a rock mass fracture, and drilling to form a grouting hole; S2, mixing a paraffin capsule with boosting oil to obtain a first mixture; S3, mixing a microbial capsule with water to obtain a secondmixture; S4, heating the first mixture, and keeping the temperature of the first mixture at 35 - 40 DEG C; and S5, continuously injecting the second mixture into the rock mass fractures through a grouting device, and meanwhile, the intermittently injecting the first mixture into the rock mass fractures through the grouting device. The paraffin capsule and the boosting oil are used for storing heat in advance, then the first mixture and the second mixture are simultaneously and continuously injected into the rock mass fracture through the grouting device, liquid-solid phase change can be generated through precooling of the paraffin capsule, and heat is released, so that the effect of increasing the fracture temperature is achieved, a good environment is provided for microorganism growth, and rock mass seepage prevention in the alpine region is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

Method for preparing cryolite from aluminum reduction cell cathode carbon block alkali leachate

InactiveCN107840357AEliminate hazardsLow costAluminium fluoridesHydrogen fluorideResource utilization

The invention relates to a method for preparing cryolite from aluminum reduction cell cathode carbon block alkali leachate and belongs to a cryolite preparation method. The method disclosed by the invention comprises the steps: levigating an aluminum reduction cell cathode carbon block to a certain particle size, mixing with alkali liquor to perform pulp mixing, mixing and leaching under a heatingtemperature of 20 to 90 DEG C and then filtering to obtain first filtrate and first filter residue; adding sodium fluoride and a little Na3AlF6 solid into the first filtrate, then controlling a speedfor inflating NH3-enriched gas or adding NH4F, generating precipitate under the heating and stirring action and filtering to obtain second filtrate and second filter residue after reaction finishes;drying the second filter residue under 100 to 150 DEG C to obtain a cryolite product. According to the method disclosed by the invention, acid leaching is replaced by alkali leaching, so that a requirement of a production process for equipment is reduced; furthermore, treating processes of flotation and the like are reduced, a hydrogen fluoride absorption process is reduced, and the treating technology is simplified; a high-temperature treating technology is prevented from being used, and energy consumption is reduced; high-quality cryolite with an even particle size is generated by adding seed crystal under the condition of controlling an air flow rate. The method disclosed by the invention has the advantages of simple technology, closed loop, high resource utilization rate and no secondary pollution.

Owner:达州励志环保科技有限公司

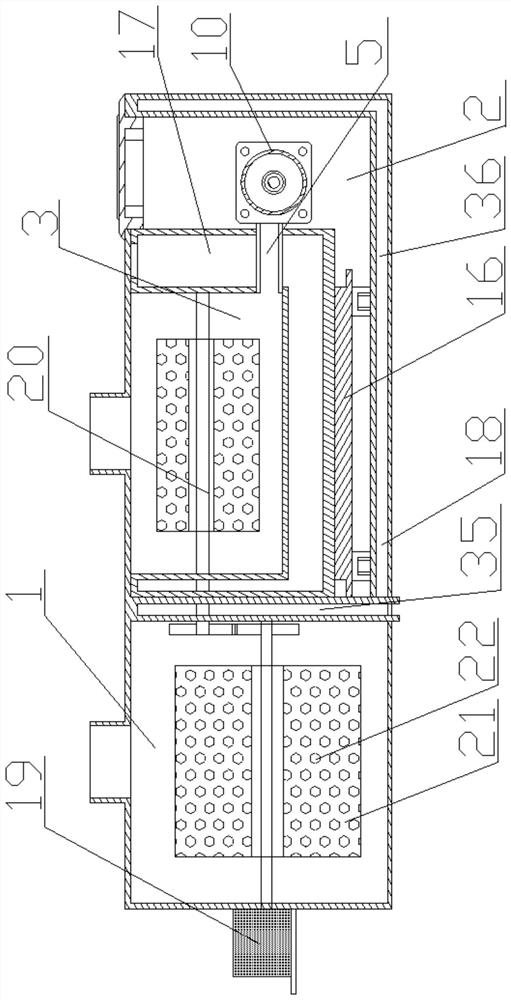

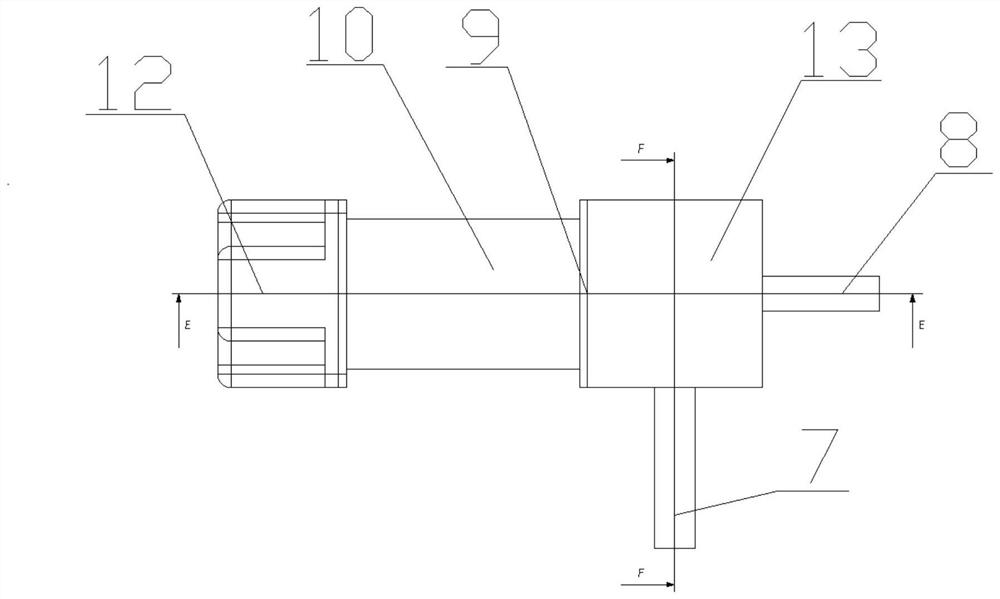

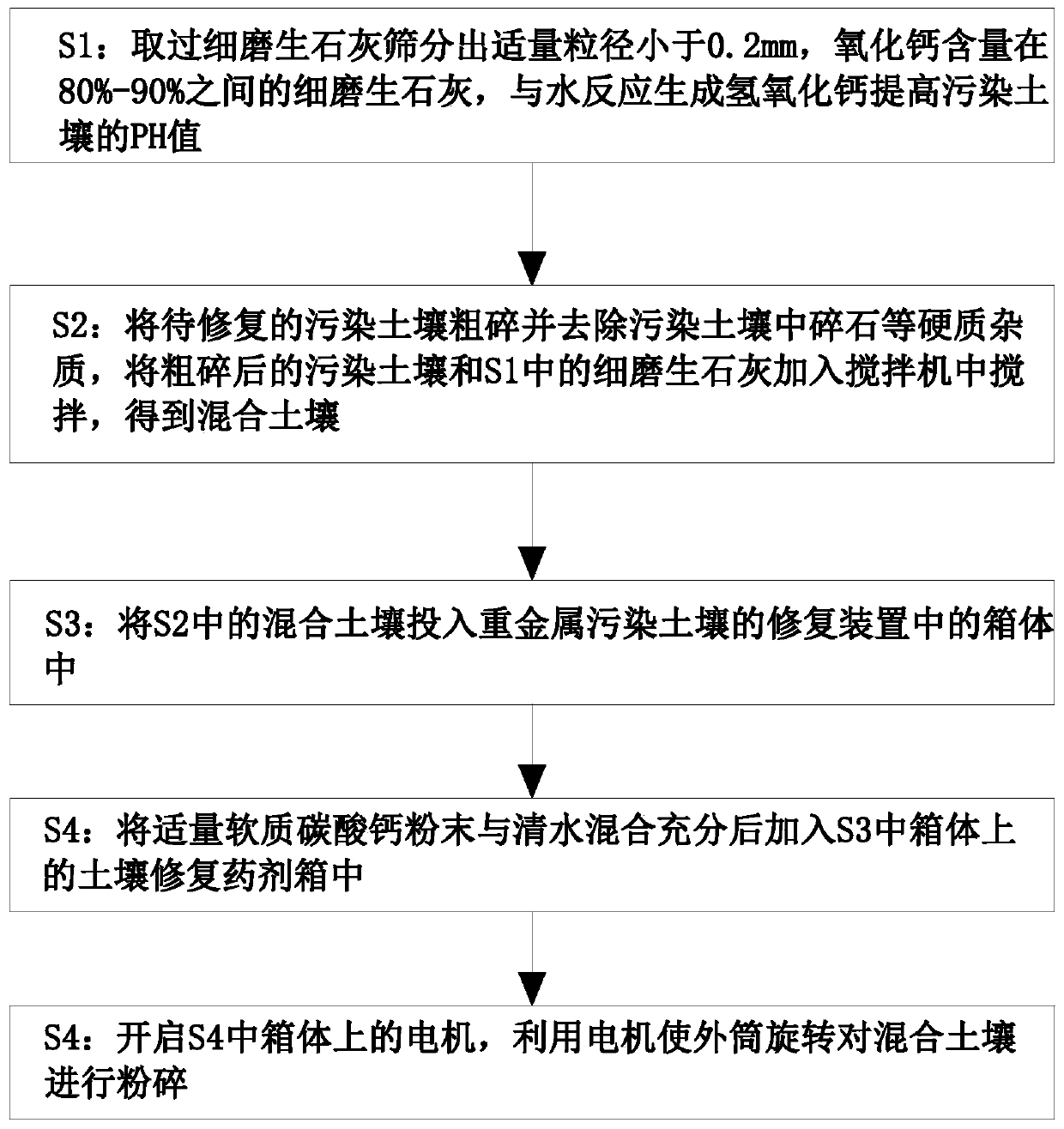

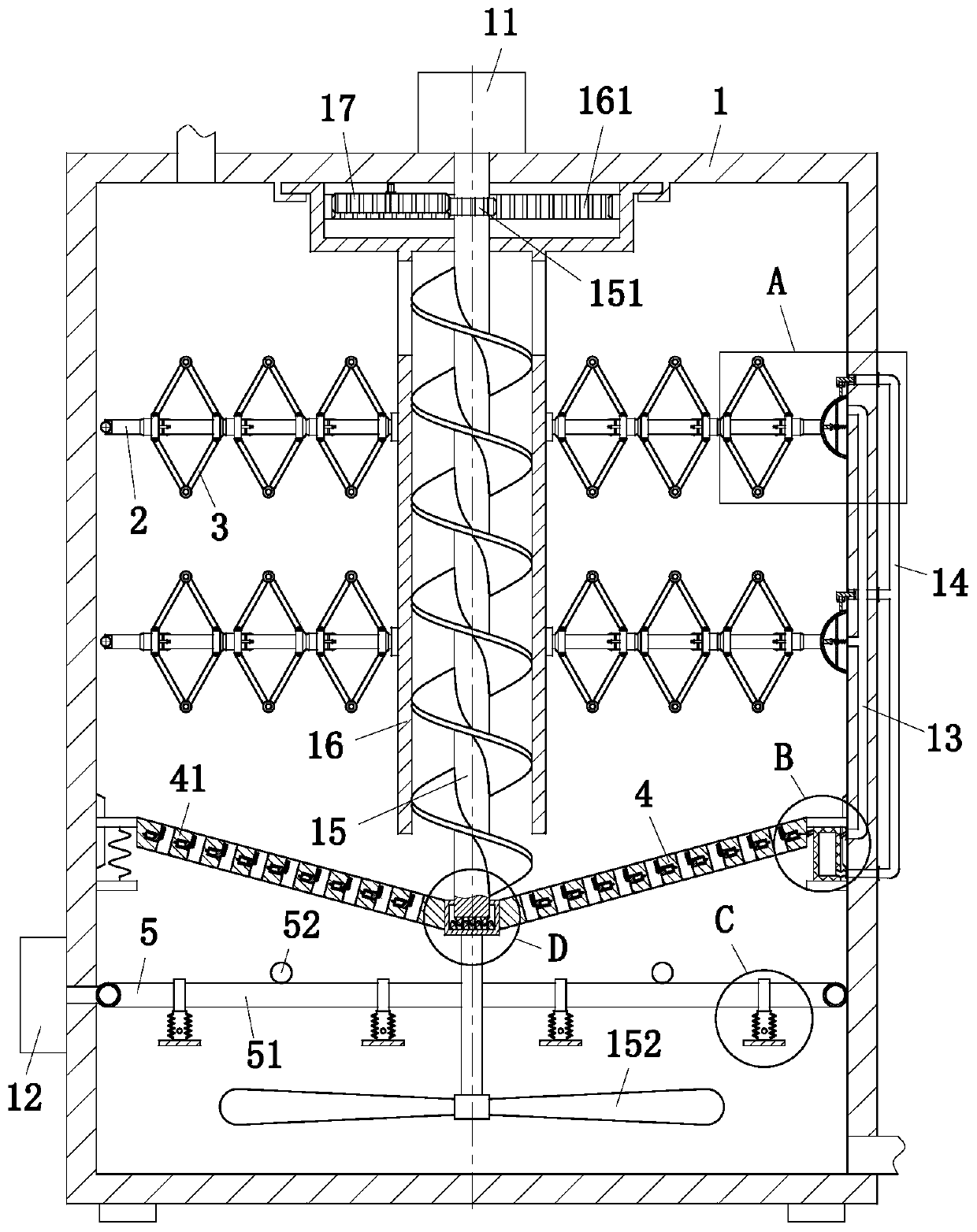

Heavy metal contaminated soil remediation method

InactiveCN109731896AAvoid damageImprove work efficiencyContaminated soil reclamationCalcium hydroxideHydrogen

The invention belongs to the technical field of soil remediation, and particularly discloses a heavy metal contaminated soil remediation method. The heavy metal contaminated soil remediation method includes steps of screening over-fine ground quicklime to obtain an appropriate quantity of fine ground quicklime with the particle sizes smaller than 0.2 mm and the calcium oxide content ranging from 80% to 90%, and carrying out reaction on the fine ground quicklime and water to generate calcium hydroxide so as to increase the PH (potential of hydrogen) value of contaminated soil; coarsely crushingthe to-be-remedied contaminated soil, removing hard impurities such as crushed stone in the contaminated soil, adding the coarsely crushed contaminated soil and the fine ground quicklime into stirring machines and stirring the coarsely crushed contaminated soil and the fine ground quicklime to obtain mixed soil; inputting the mixed soil into a tank of a heavy metal contaminated soil remediation device, sufficiently mixing appropriate quantities of soft calcium carbonate powder and clear water with each other, and then adding the soft calcium carbonate powder and the clear water into a soil remediation chemical tank on the tank; switching on a motor on the tank, allowing an outer barrel to rotate by the aid of the motor and smashing the mixed soil. The heavy metal contaminated soil remediation method has the advantages that hydroxide or carbonate combined-state salt precipitate forming by heavy metal elements in the soil can be promoted, and accordingly the soil remediation efficiencycan be improved.

Owner:叶淑源

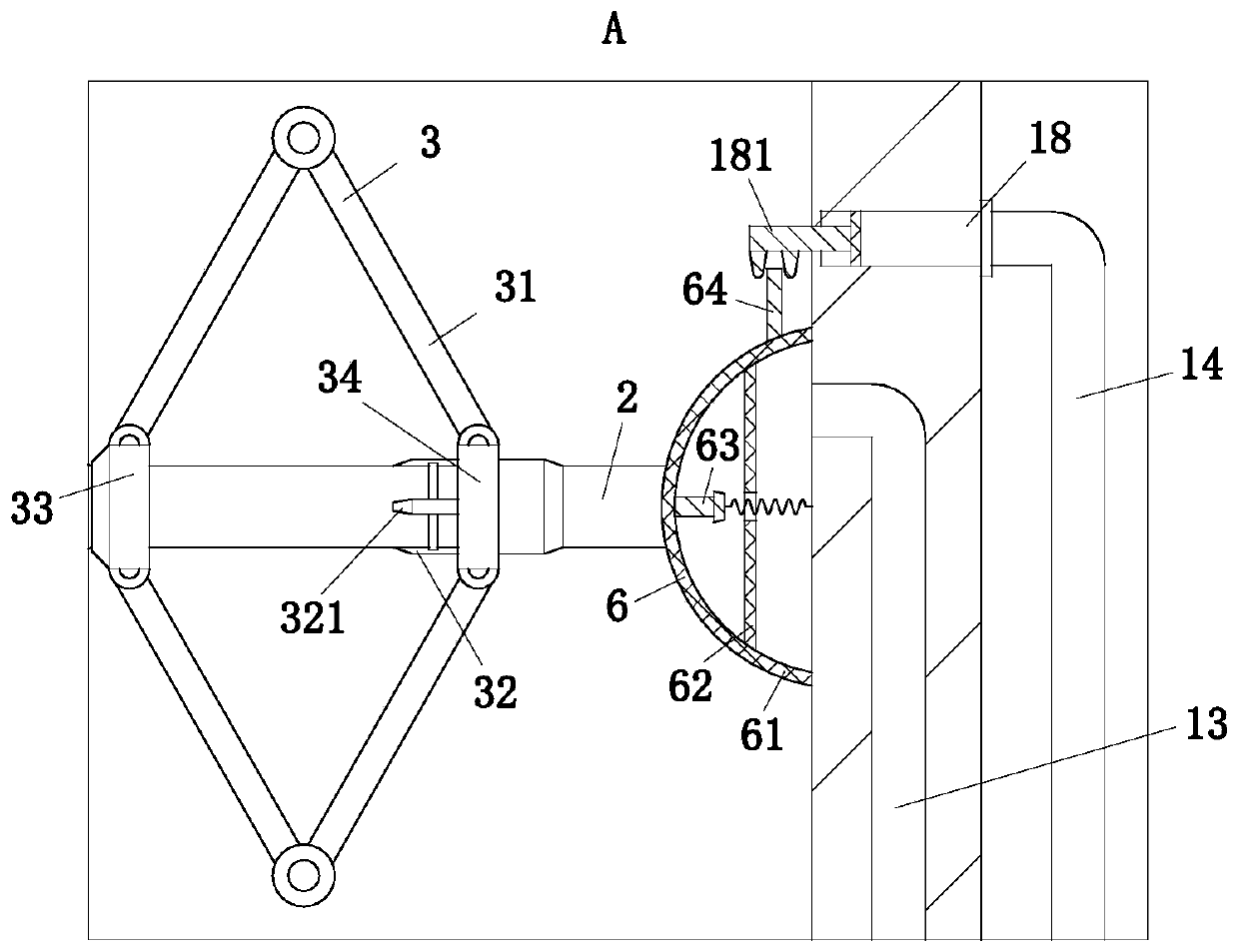

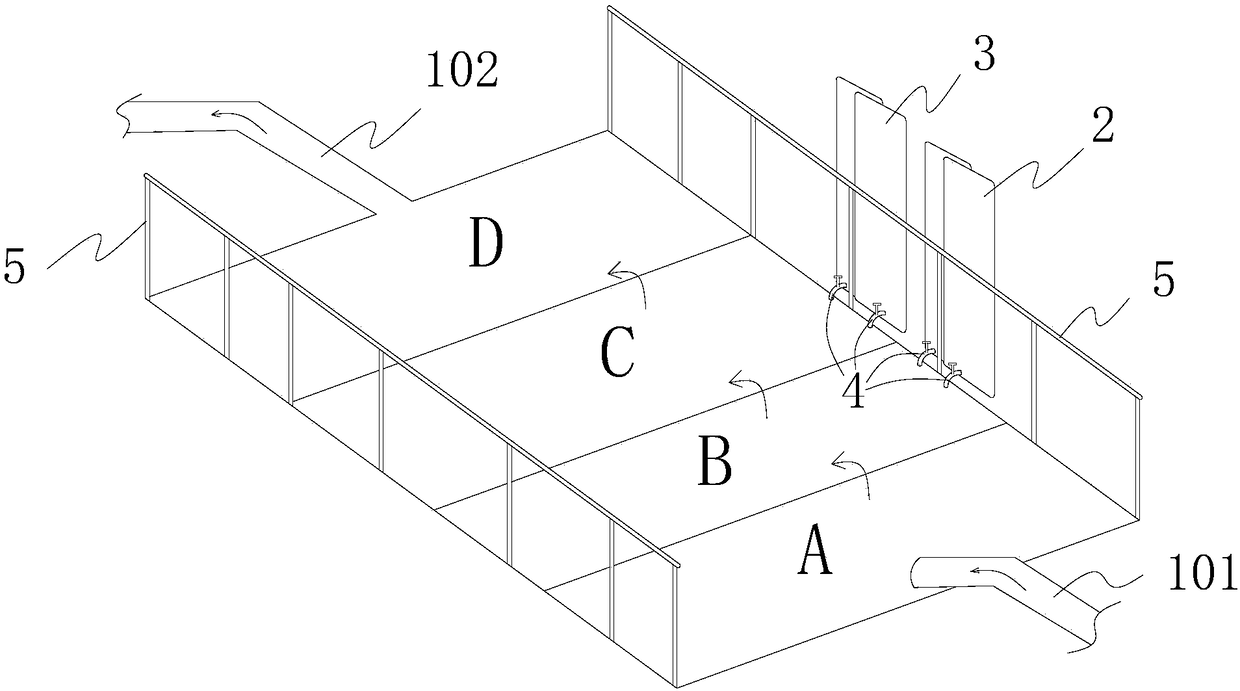

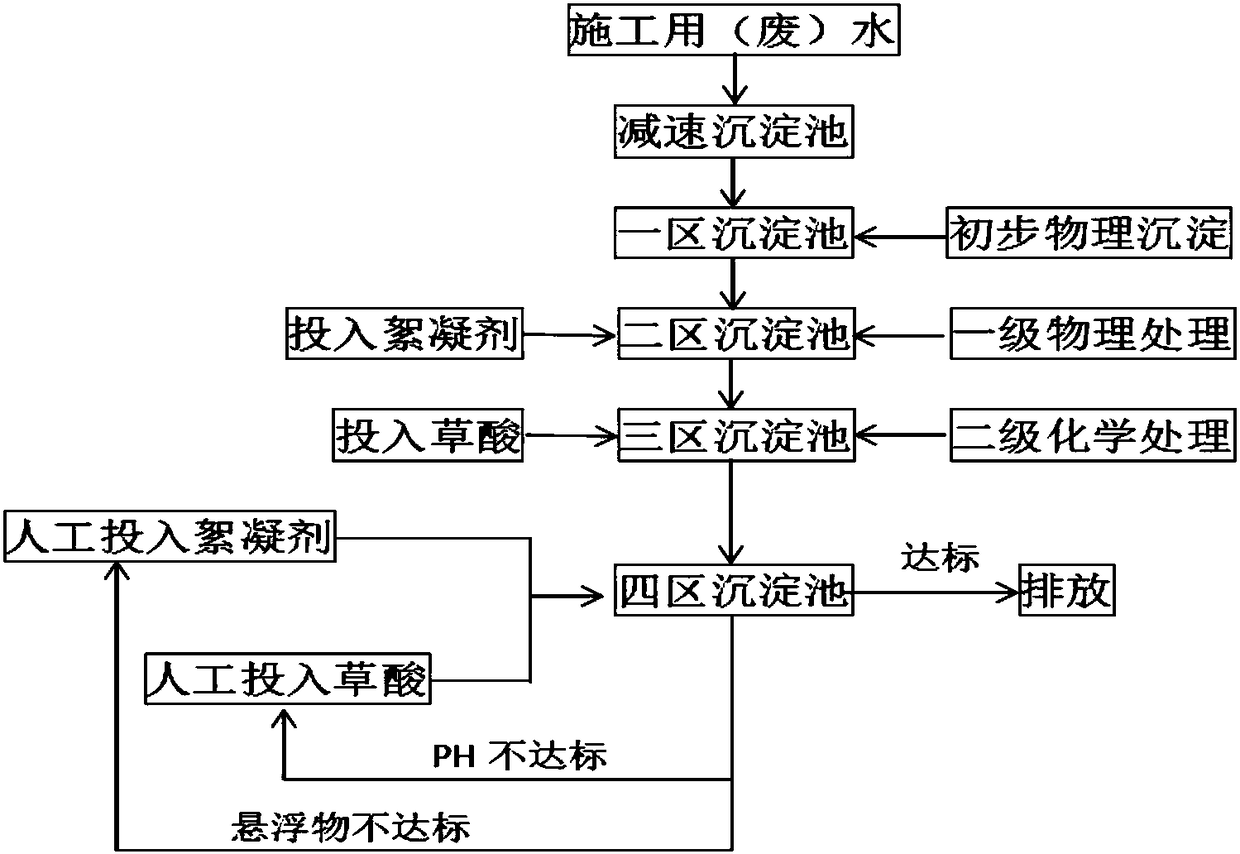

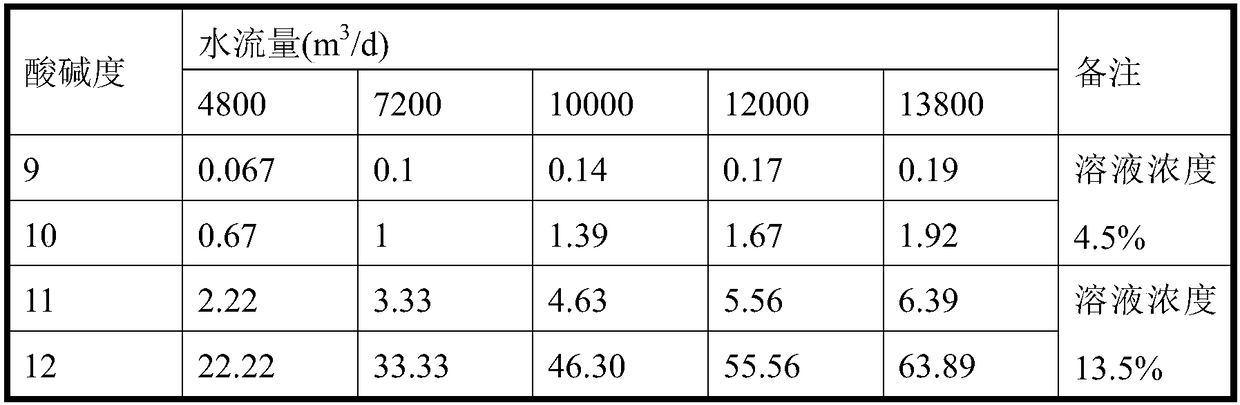

Method for waste water precipitation treatment in construction

InactiveCN108191021AImprove processing efficiencyImprove qualityWater treatment parameter controlWater contaminantsChemical treatmentOxalic acid

The invention discloses a method for waste water precipitation treatment in construction. The method comprises the following steps of (1) precipitation pool building: a precipitation pool is separatedinto four regions including a first region, a second region, a third region and a fourth region in sequential adjacent arrangement; the adjacent regions are separated by separation walls, and waste water can go over the separation walls through overflowing to enter the next region; (2) primary physical treatment: building construction waste water decelerates in the first region and generates natural precipitation; (3) first-stage physical treatment: a flocculating agent adding device is arranged in the second region and is used for automatically adding flocculating agents; (4) second-stage chemical treatment: the third region is provided with an oxalic acid adding device for automatically adding oxalic acid; (5) discharging: under the condition that the waste water in the fourth region conforms to the discharge standard, the natural overflow discharge is performed. The method for waste water precipitate treatment in building construction has the advantages that the precipitation efficiency is high; the environment protection standard requirement is met; the adaptation capability on the waste water treatment is high; the waste water contaminant fluctuation change treatment requirement is met; the cost is low; the implementation is easy.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Composite type reinforcing microelectrolysis simulation processing method

ActiveCN106477786AImprove processing efficiencyRaise the possibilityWater treatment compoundsWater contaminantsElectricityWastewater

The invention relates to a composite type reinforcing microelectrolysis simulation processing method. Firstly an acid, hydrogen peroxide and copper ions are respectively added into pharmaceutical wastewater containing phenyl rings and simulated wastewater containing phenyl rings in turn, and all the substances are mixed uniformly. Then a direct current is connected to the wastewater, and iron carbon balls are added. The pH value is adjusted by adding an alkali after full reaction. PAM and PAC are added to accelerate wastewater deposition, and a supernatant is obtained after the deposition is finished. The composite type reinforcing microelectrolysis simulation processing method has the advantages that the hydrogen peroxide is added to the wastewater and the electricity is connected to the wastewater based on the prior art in the composite type reinforcing microelectrolysis simulation processing method; more hydroxyl radicals are generated by using the hydrogen peroxide role during an energization process while the iron carbon microelectrolysis processing efficiency is ingeniously increased; in addition, an Electro-Fenton principle is correspondingly formed because the ferroelectric microelectrolysis will generate a large amount of ferrous ions; in the action of a plurality of complex mechanisms, the phenyl ring opening and bond broken possibility is increased greatly, so that a removal rate of benzene series is improved.

Owner:NANTONG DAHENG ENVIRONMENTAL ENG CO LTD

Zero-emission treatment technology of desulfurization waste water in thermal power station

InactiveCN107253785AReduce productionImprove stabilityWater contaminantsWater softeningElectrolysisPower station

The invention discloses a zero-emission treatment technology of desulfurization waste water in thermal power station. The zero-emission treatment technology comprises the following steps: 1) reacting in a reaction tank; 2) conducting electrolysis treatment; 3) treating through high-efficiency precipitation integrated equipment; 4) treating through NO.1 electric driving membrane device to obtain SO4<2->-containing NO.1 diluted chamber liquor and Cl<->-containing NO.1 concentrated chamber liquor; 5) treating NO.1 diluted chamber liquor through a desulfurization island system; 6) treating NO.1 concentrated chamber liquor through a No.2 electric driving membrane device to obtain NO.2 concentrated chamber liquor and NO.2 diluted chamber liquor; 7) treating NO.2 concentrated chamber liquor through a No.4 electric driving membrane device to obtain NO.4 diluted chamber liquor and NO.4 concentrated chamber liquor; and 8) treating NO.2 diluted chamber liquor through a No.3 electric driving membrane device. By utilizing chemical reaction, electrochemical devices, high-efficiency precipitation integrated equipment, multivalence separation electric driving membrane, concentration electric driving membrane and a bipolar membrane combination technology, more than 90% of water in desulfurization waste water can be recycled, and gypsum can be produced by utilizing Na2SO4 and NaCl in the waste water, without the need of purchasing acid and alkali in treatment process.

Owner:上拓环境科技(长兴)有限公司

Method for using coal-based solid waste for overlying strata isolation grouting filling

PendingCN114233380AExcellent sedimentation rateIncreased precipitation rateMaterial fill-upSolid waste managementMining engineeringSlurry

The invention relates to a method for applying coal-based solid waste to overlying strata isolation grouting filling, according to different properties of coal gangue, coal ash and coal slime in the coal-based solid waste during overlying strata isolation grouting filling, the overlying strata isolation grouting filling performance of coal gangue powder can be improved by adding the coal ash and the coal slime, and when the coal ash and the coal slime reach a certain proportion, the coal ash and the coal slime are added into the coal-based solid waste to improve the overlying strata isolation grouting filling performance. The fluidity of the coal gangue powder can be improved, and the precipitation rate of the coal gangue powder is reduced. Furthermore, according to the state of the overlying strata space, the overlying strata isolation grouting filling is divided into the four stages of starting, developing, stabilizing and ending, and according to the development characteristics of fractures under the overlying strata during grouting in the four stages and the flow characteristics of slurry, the different stages of overlying strata isolation grouting filling are provided; different mixing proportions are adopted for overlying strata isolation grouting filling; the application problem of the coal gangue in grouting filling is solved, and the dilemma that materials of the overlying strata isolation grouting filling technology are insufficient and the dilemma that the coal gangue occupies land and pollutes the environment can be effectively improved.

Owner:徐州格润矿山技术开发有限公司

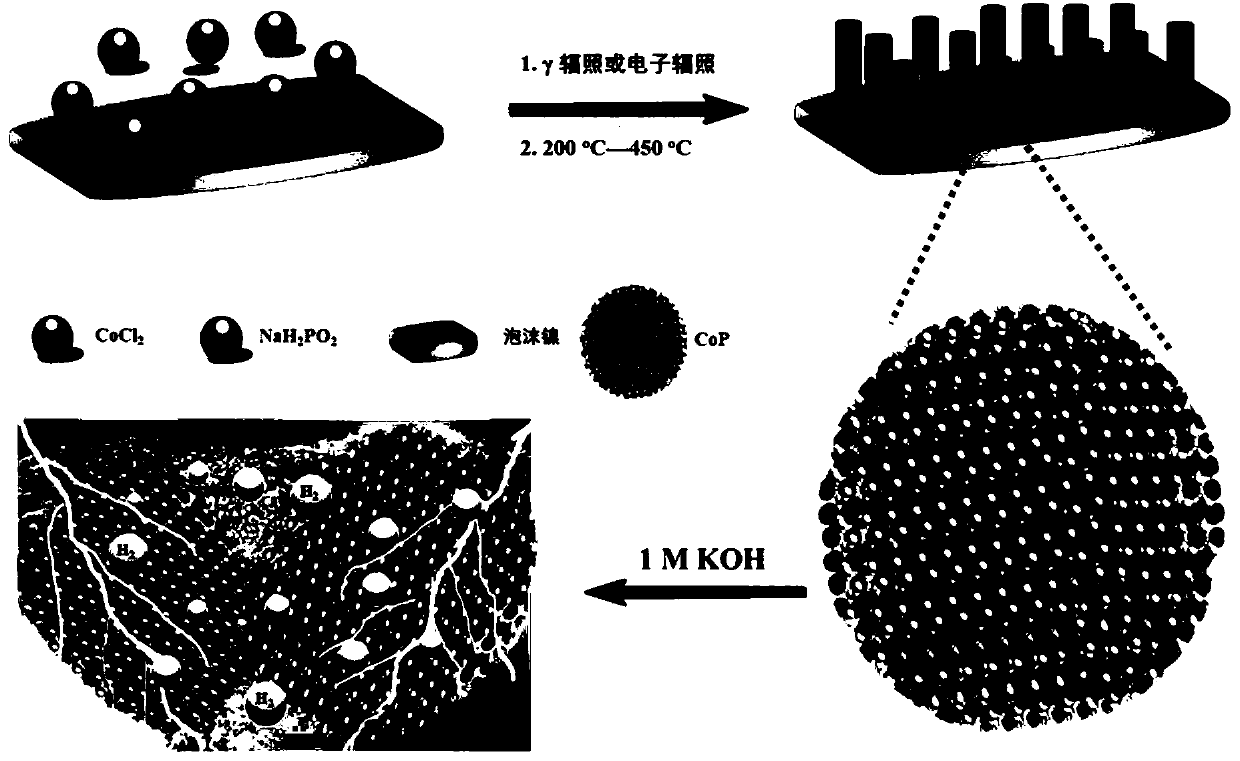

CoPxOy nano-array composite material grown on surface of conductive substrate as well as preparation and application of CoPxOy nano-array composite material

ActiveCN111250119AUnique application advantagesElectrolyzed water has good hydrogen production performanceCatalyst activation/preparationElectrodesElectrolysisElectron density

The invention discloses a CoPxOy nano-array composite material grown on surface of a conductive substrate as well as preparation and an application of the CoPxOy nano-array composite material. A gammaray or electron beam radiation reduction and heat treatment method is adopted; an oxygen-doped cobalt phosphide (CoPxOy) nano array (x is greater than 0.5 and less than 1, and y is greater than 0.1 and less than 0.5) is grown on a conductive substrate in a regulated manner; the CoPxOy nano array structure has super-hydrophilic and super-oleophobic properties and is good in water electrolysis hydrogen production performance in an alkaline solution, the super-hydrophilic property accelerates the transmission rate of electrolyte to the surface of an electrode, and the super-oleophobic property improves the precipitation rate of hydrogen, so that the overpotential of HER is further reduced; the oxygen-doped cobalt phosphide enriches the electron density, so that the conductivity is improved,the transmission rate of the electrolyte is increased, and the catalytic hydrogen evolution performance is improved. Moreover, a radiation method can be initiated at room temperature, does not need toadd an initiator, is efficient and easy in condition control, does not generate highly toxic PH3 gas in the preparation process, is environment-friendly, and has a wide application prospect.

Owner:PEKING UNIV

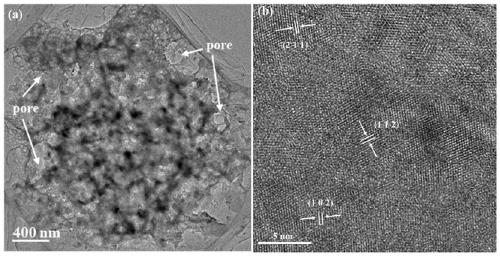

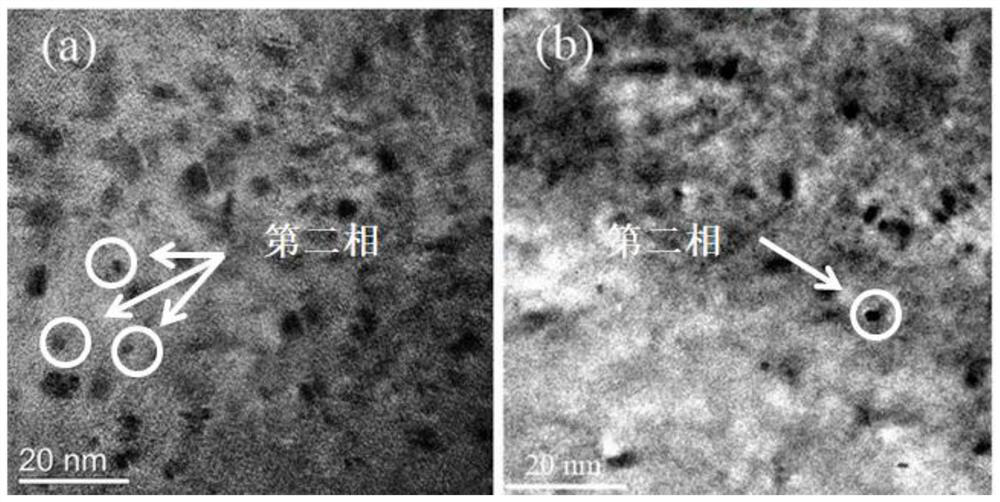

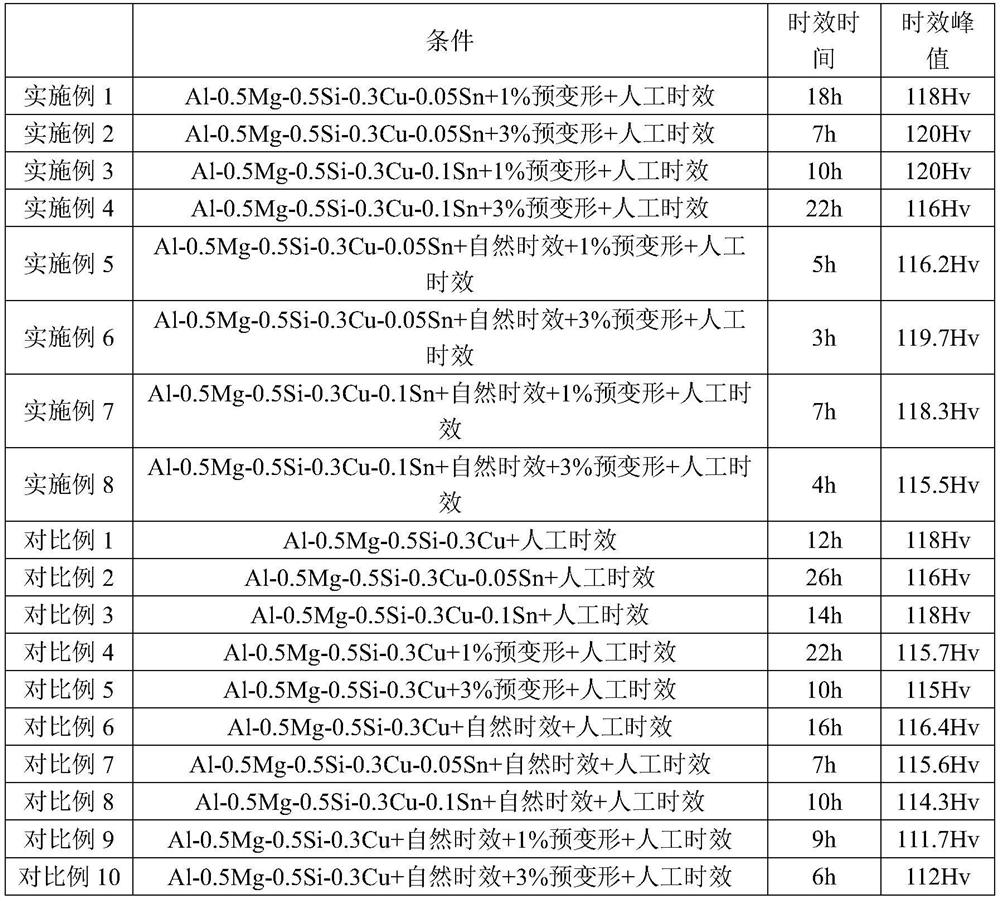

High-performance Al-Mg-Si-Cu-Sn aluminum alloy and preparation method thereof

ActiveCN114703407AImprove mechanical propertiesIncrease peak hardening timePre deformationNatural aging

The invention discloses a high-performance Al-Mg-Si-Cu-Sn aluminum alloy and a preparation method thereof, and the high-performance Al-Mg-Si-Cu-Sn aluminum alloy comprises the following alloy components in percentage by mass: 0.1 to 1.0 percent of Mg, 0.3 to 1.2 percent of Si, 0.1 to 0.6 percent of Cu, 0.01 to 0.2 percent of Sn, less than or equal to 0.02 percent of inevitable impurities and the balance of Al. According to the alloy component proportion, the preparation method of the Al-Mg-Si-Cu-Sn alloy comprises the steps of smelting, pouring, homogenizing, extruding or rolling, solid solution, pre-deformation (natural aging can be carried out before pre-deformation) and artificial aging treatment. By optimizing the alloy component design and the synergistic effect of related processes, the number of second phases of the alloy is increased, and the precipitation rate of the second phases can be remarkably increased. Compared with the prior art, the effects of synchronously improving the mechanical property of the aluminum alloy and shortening the peak hardening time are achieved.

Owner:JILIN UNIV

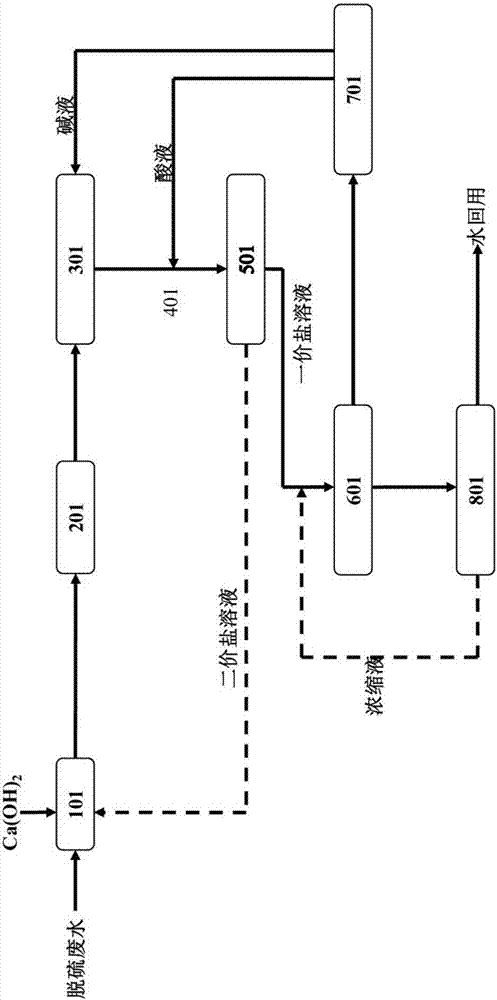

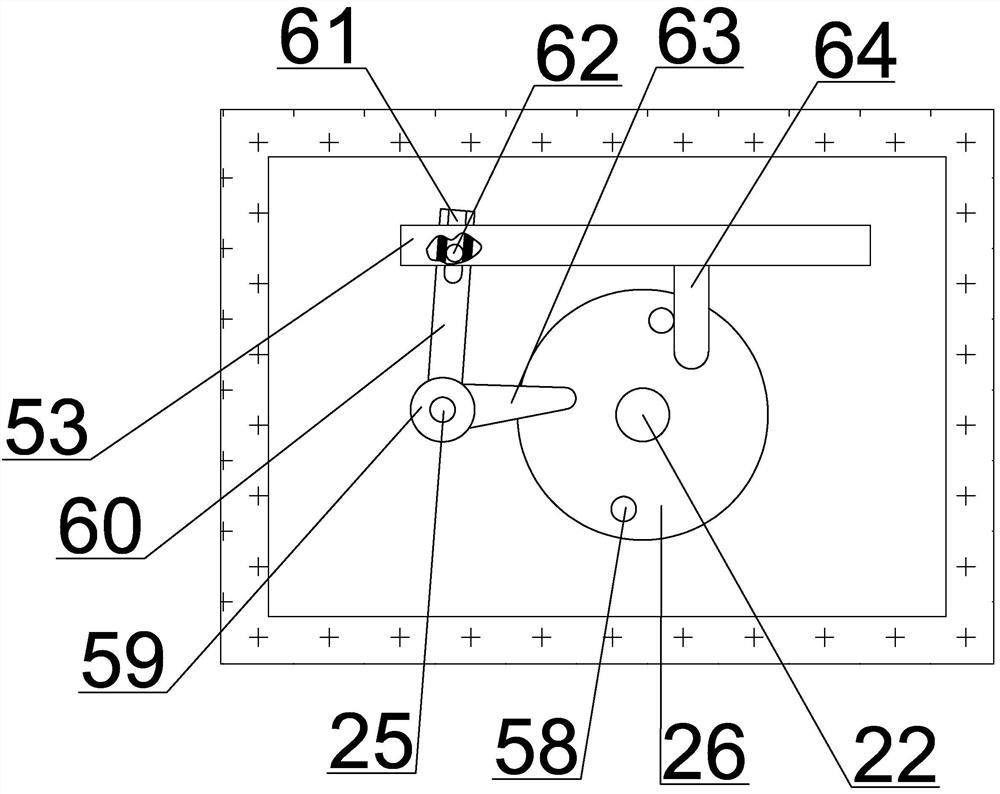

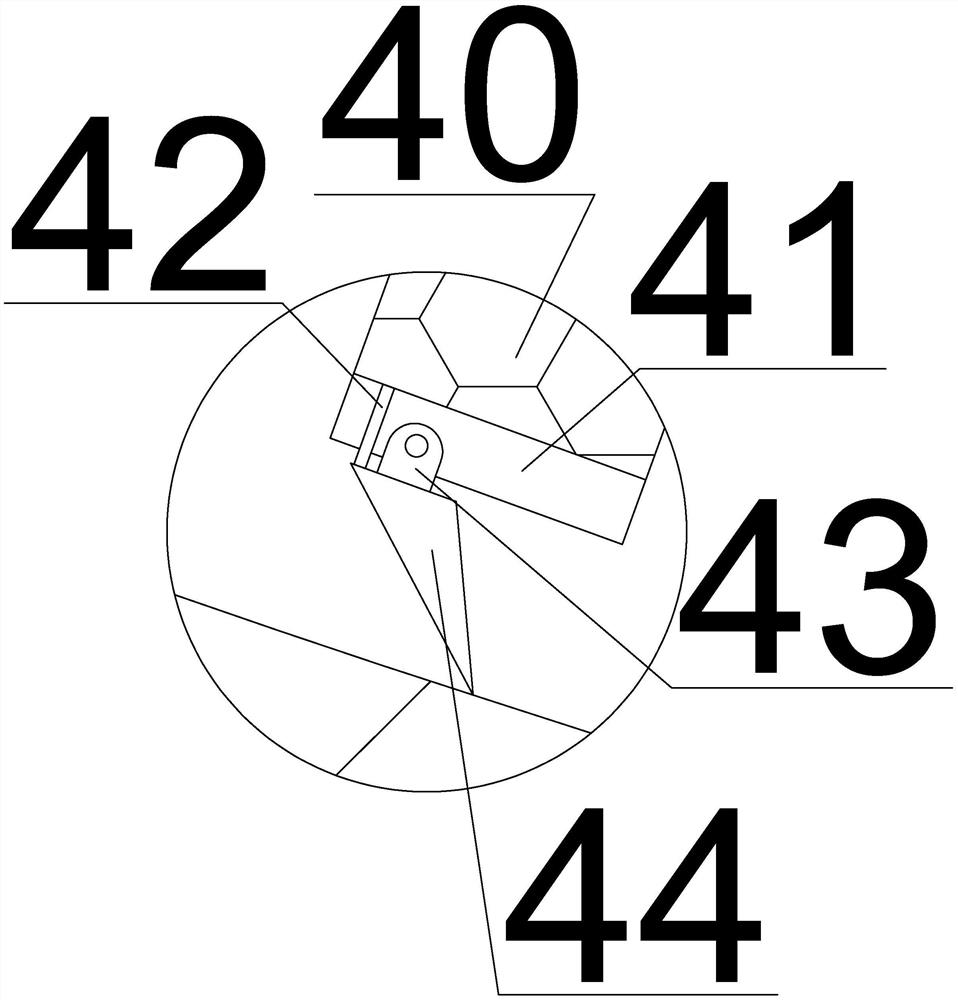

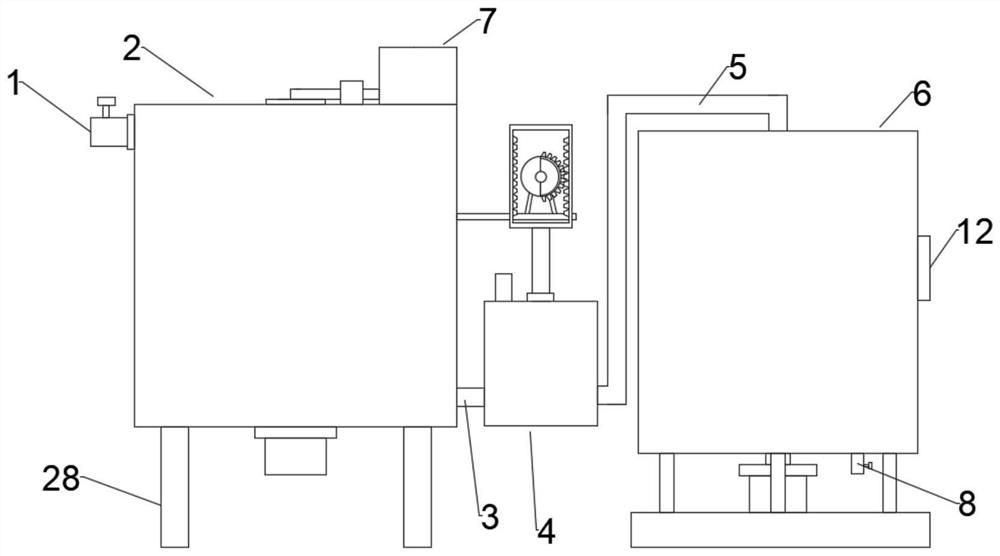

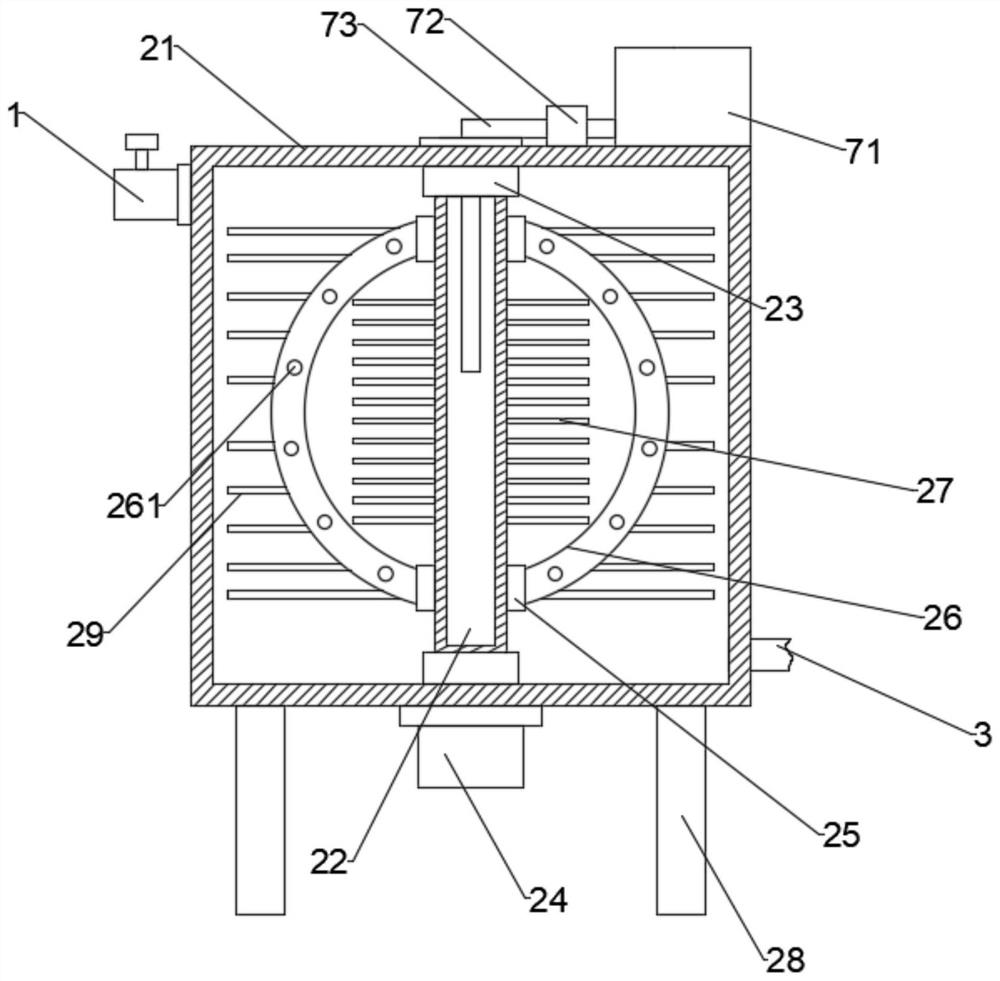

Extraction device for ammonium chloride in methyl tin mercaptide production wastewater

InactiveCN112516617AEfficient extractionAvoid wastingShaking/oscillating/vibrating mixersRotary stirring mixersMethyl palmoxirateAmmonium chloride mixture

The invention discloses an extraction device for ammonium chloride in methyl tin mercaptide production wastewater. The extraction device comprises a machine body and is characterized in that a power space is arranged in the machine body, a power mechanism is arranged in the power space and used for providing power for the device, and condensation spaces are respectively arranged on the left side and the right side of the power space. The two condensation spaces are distributed in a bilateral symmetry manner relative to the power space. According to the extraction device, ammonium chloride in wastewater can be effectively extracted, the solution can be fully stirred to accelerate precipitation of ammonium chloride crystals when the amount of solution is high at the beginning, and when the solution is gradually volatilized, it shows that the ammonium chloride crystals are precipitated; at the moment, the ammonium chloride crystals attached to the inner side wall are scraped and collected, waste of the ammonium chloride attached to the inner wall is greatly avoided, meanwhile, the crystals are scraped in time, precipitation of the ammonium chloride crystals is facilitated, the precipitation rate of the crystals is greatly increased, and thus the working efficiency is improved.

Owner:王晓钰

A nucleic acid extraction and purification device

ActiveCN112226338BIncreased precipitation rateFirst-level purification achievedBioreactor/fermenter combinationsBiological substance pretreatmentsTransfer mechanismCheck valve

The invention discloses a nucleic acid extraction and purification device, which comprises a feeding pipe, a primary purification mechanism, a reagent feeding mechanism, a transfer mechanism, a secondary purification mechanism and a sample outlet tube, and the feeding pipe is connected to the primary purification mechanism. On the left side, the right side of the primary purification mechanism is connected to the left side of the transfer mechanism through the first connecting pipe, the upper end of the primary purification mechanism is connected to a reagent feeding mechanism, and the right side of the transfer mechanism is connected to the second The upper end of the first-stage purification mechanism is connected, the lower end of the second-stage purification mechanism is connected with a sample outlet pipe, a first one-way valve is installed in the first connecting pipe, and a second one-way valve is installed in the second connecting pipe. The present invention realizes the multi-stage extraction and purification of materials through the mutual cooperation of the primary purification mechanism, the reagent feeding mechanism, the transfer mechanism and the secondary purification mechanism, and improves the extraction and purification efficiency and purity.

Owner:上海钧济医学检验所有限公司

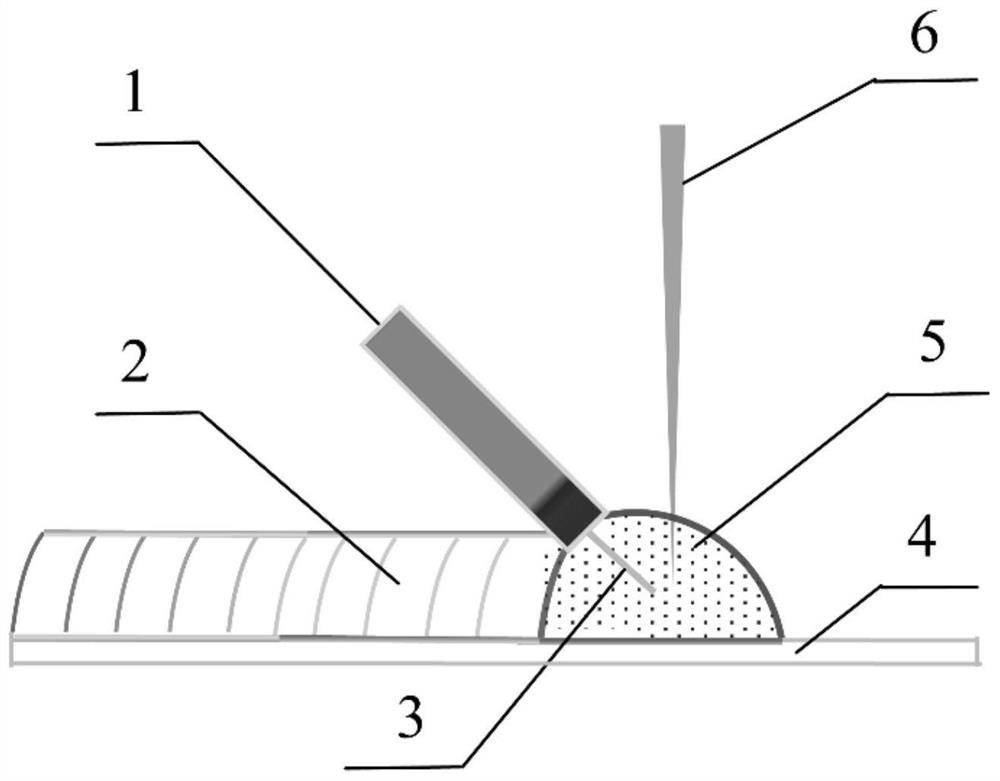

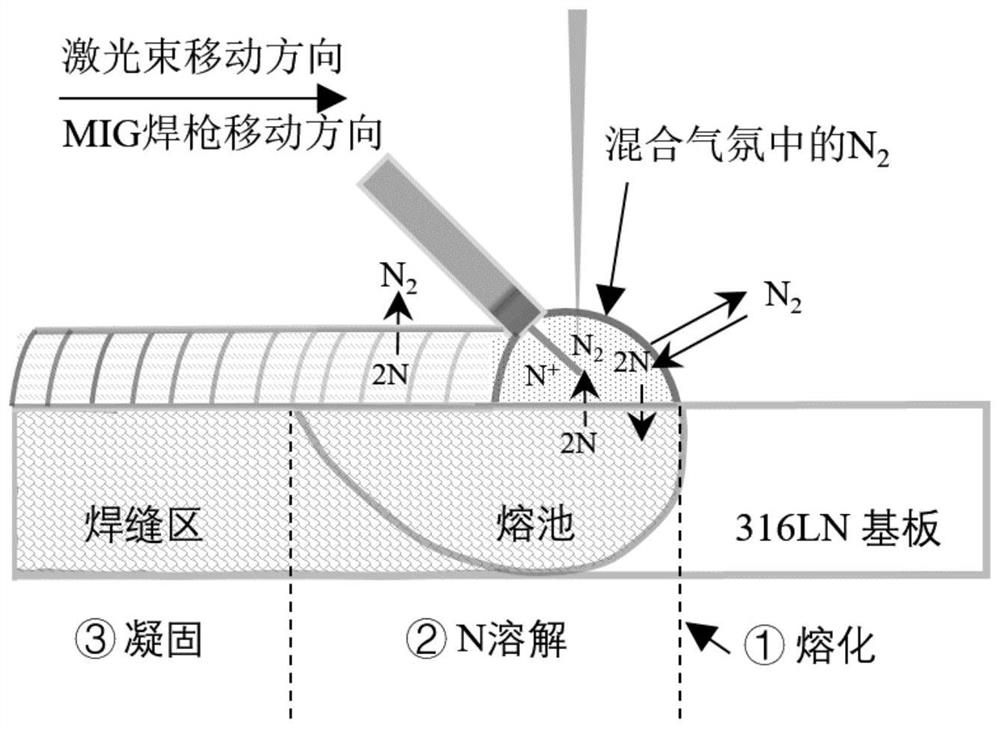

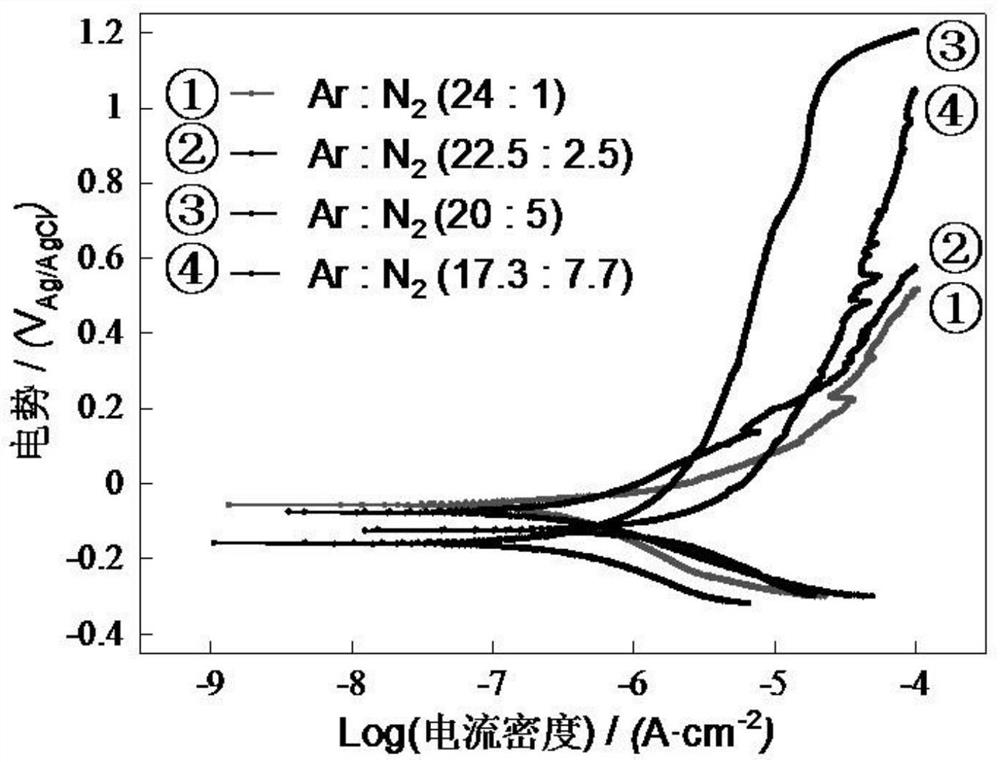

Method and device for improving corrosion resistance of MIG welding Cr-Ni series stainless steel

ActiveCN113814563AGuaranteed arc stabilityHigh nitrogen contentLaser beam welding apparatusSS - Stainless steelNitrogen gas

The invention belongs to the related technical field of Cr-Ni series stainless steel welding, and discloses a method and device for improving corrosion resistance of MIG welding Cr-Ni series stainless steel. The method comprises the steps that in the protective gas atmosphere, a to-be-welded piece is welded through laser beam assisted MIG electric arcs during MIG welding, wherein the protective gas is mixed gas of inert gas and nitrogen, the gas flow ratio of the inert gas to the nitrogen is 22.5:2.5-17.5:7.5, and the energy of the laser beam is 0.6-1.5 KW, so that the laser irradiates the surface of the to-be-welded piece to generate metal steam to provide stable cathode spots for MIG electric arcs to promote MIG electric arc ionization; and meanwhile, the nitrogen is subjected to ionization reaction, so that the nitrogen content of a molten pool is increased, then the solidification temperature interval of an austenite phase is expanded, transformation from ferrite to austenite is accelerated, and the corrosion resistance is improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

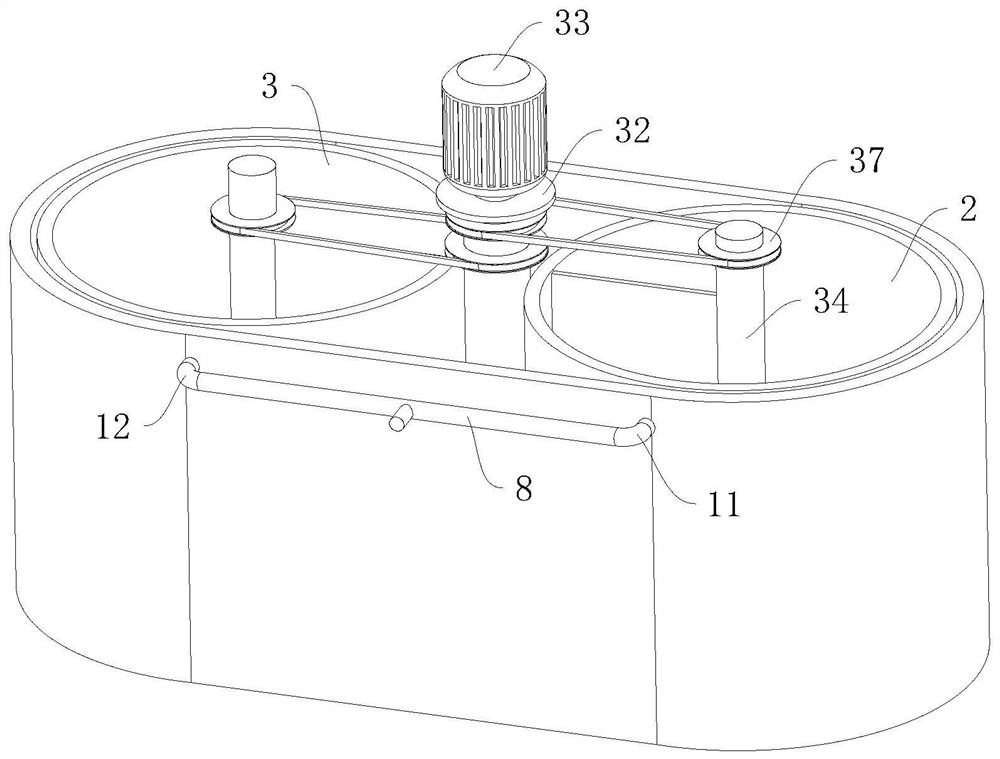

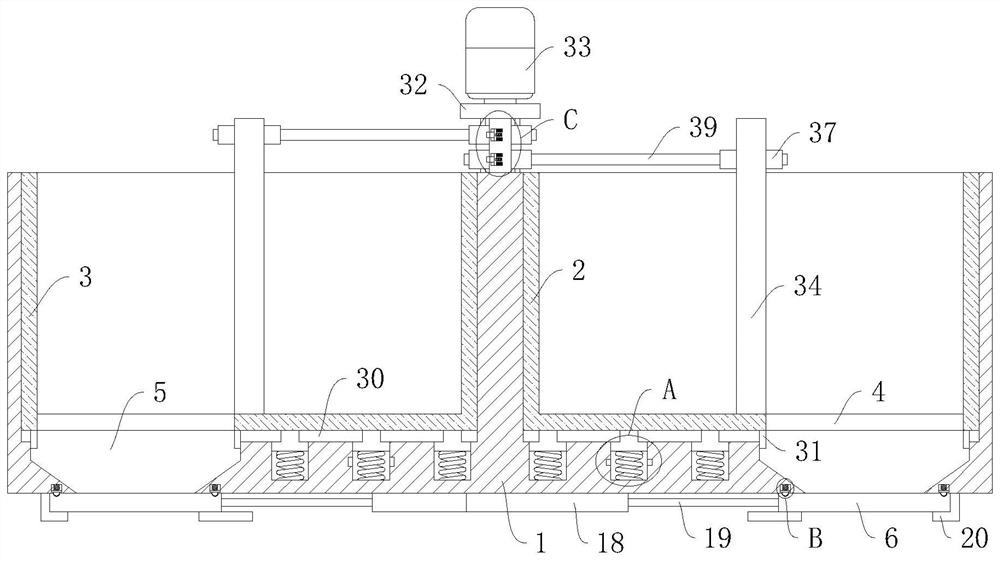

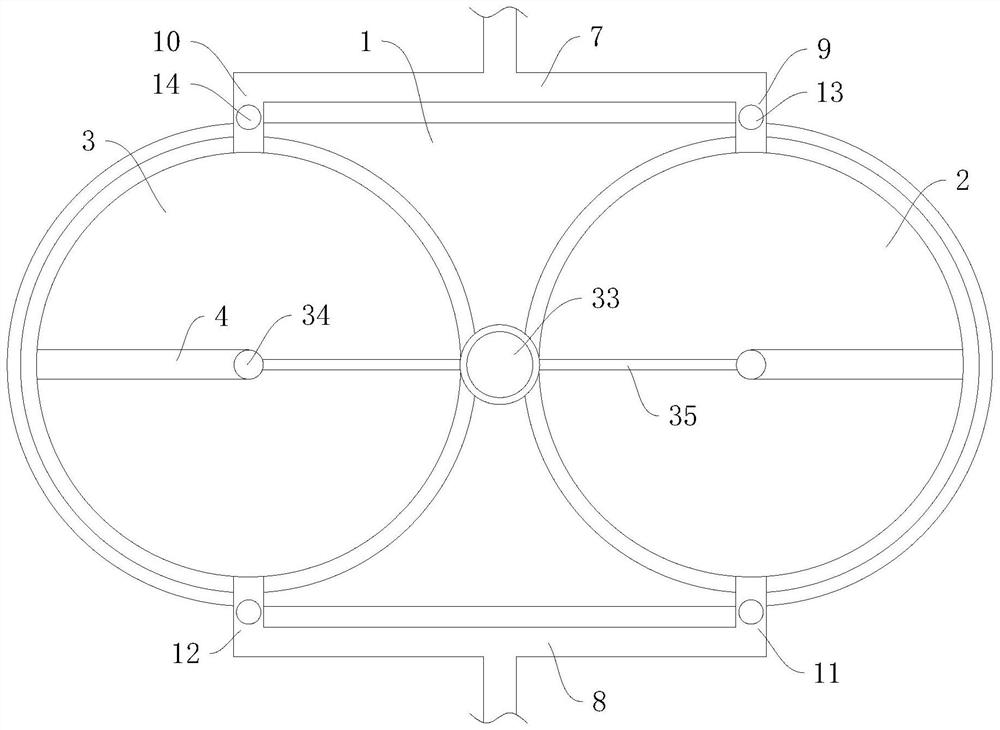

Multi-stage sedimentation tank for chalcopyrite beneficiation

InactiveCN114307269AClean up in timeIncreased precipitation rateSedimentation settling tanksSoil scienceChalcopyrite

The invention relates to the technical field of sedimentation tanks, in particular to a multistage sedimentation tank for chalcopyrite beneficiation, which comprises a plurality of sedimentation tanks connected with each other, each sedimentation tank comprises a mounting seat, a first water tank and a second water tank, the first water tank and the second water tank are symmetrically mounted in the mounting seat, and drain outlets are formed in the bottom walls of the first water tank and the second water tank. Two sewage discharge grooves corresponding to the sewage discharge ports are symmetrically formed in the bottom wall of the mounting seat, the bottom ends of the sewage discharge grooves extend to the lower side of the mounting seat, two sealing bottom plates used for sealing the sewage discharge grooves are symmetrically mounted on the bottom wall of the mounting seat, and the bottom ends of the first water tank and the second water tank are connected with gravity sensing assemblies. According to the multistage sedimentation tank for chalcopyrite beneficiation, impurities settled in the sedimentation tank can be cleaned in time, and the situation that sedimentation processing is stopped when the impurities are cleaned and collected can be avoided, so that the sedimentation rate of the multistage sedimentation tank for chalcopyrite beneficiation is increased, and the use effect is good.

Owner:芦佳骏

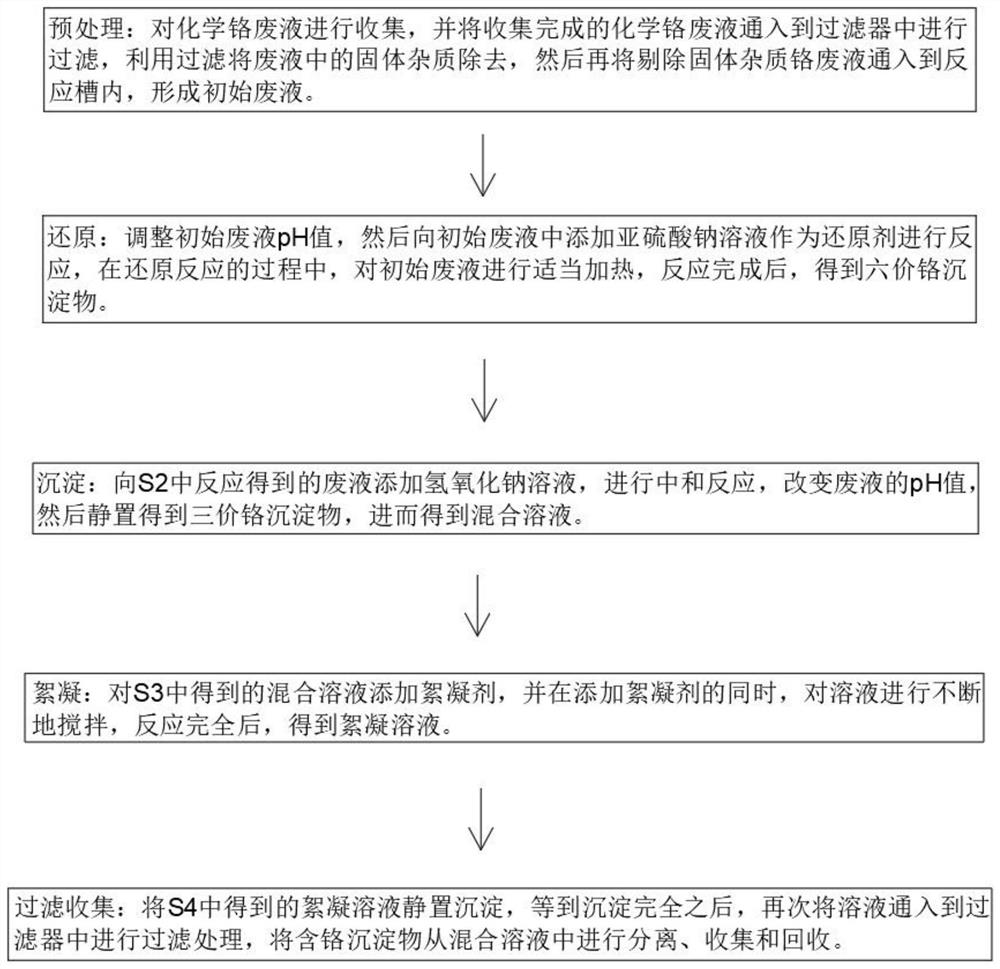

Chemical chromium waste liquid efficient resourceful treatment process

PendingCN113651464AEasy to handleAvoid affecting the reduction reaction processWater treatment parameter controlWater contaminantsFlocculationChemical waste

The invention relates to the technical field of chromium waste liquid treatment, in particular to a chemical chromium waste liquid efficient resourceful treatment process which comprises the following steps: S1, pretreatment: collecting and filtering chemical chromium waste liquid to form initial waste liquid; S2, performing reduction; S3, precipitating; S4, performing flocculation; and S5, filtering and collecting: standing and precipitating the flocculation solution obtained in S4, and filtering to realize separation, collection and recovery. According to the method, on the basis of an original chromium waste liquid reduction precipitation method, a filtering step is added before reduction and after precipitation, small solid impurities mixed in chemical waste liquid can be removed through filtering before reduction, the follow-up reduction reaction process is prevented from being influenced, filtering is adopted after precipitation, so that chromium-containing chemicals mixed in the solution can be removed, the treatment effect of the whole chromium-containing waste liquid is improved, the precipitation rate is greatly improved, and the efficient and rapid treatment of the chromium-containing chemical waste liquid can be realized.

Owner:苏州翔展环保工程有限公司

Plant processing device for circularly extracting natural active components of plant

InactiveCN107469401AIncrease concentrationIncrease precipitationSolid solvent extractionSolventUtilization factor

The invention discloses a plant processing device for circularly extracting natural active components of plant. The plant processing device comprises a reaction tank, wherein a horizontally placed separating plate is arranged in the reaction tank; a reaction chamber of the reaction tank is divided into upper and lower sealing chambers by the separating plate; material drums are arranged in the two sealing chambers; drum walls of the material drums are hollow; filtering clothes are covered on the inner walls of the material drums; a connecting pipe is jointed above the reaction tank; one end of the connecting pipe is connected with the sealing chamber above the separating plate; a vertically placed condenser pipe is connected with the other end of the connecting pipe; the condenser pipe is located on one side of the reaction tank and is bias above the sealing chamber under the separating plate; a liquid outlet at the lower end of the condenser pipe is connected with the sealing chamber under the separating plate through an inclined pipe. According to the invention, a decocted solution for decocting the first batch of plants is used as a solvent for decocting the second batch of plants, the concentration of the detected solution is quickly increased, the decocted solution is circularly decocted and the use ratio of the plant is increased.

Owner:成都康辉生物科技有限公司

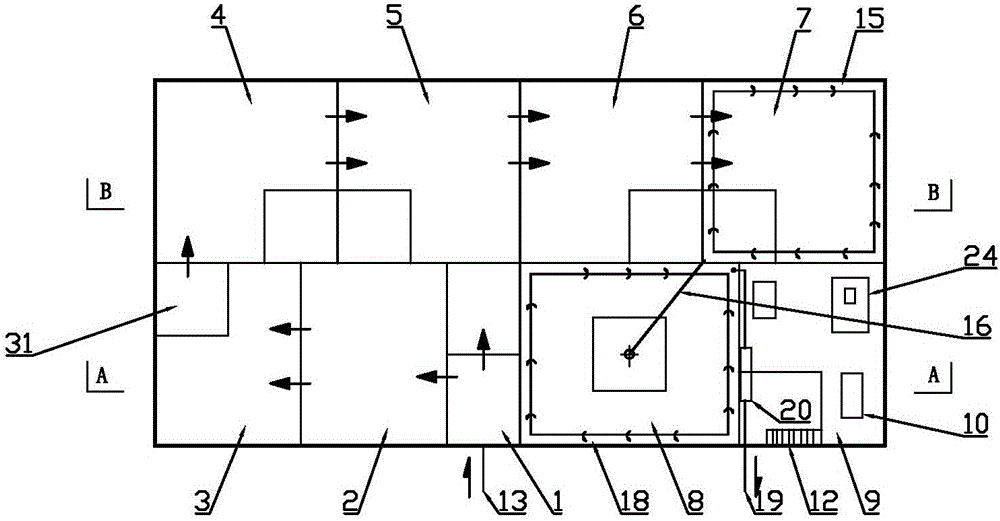

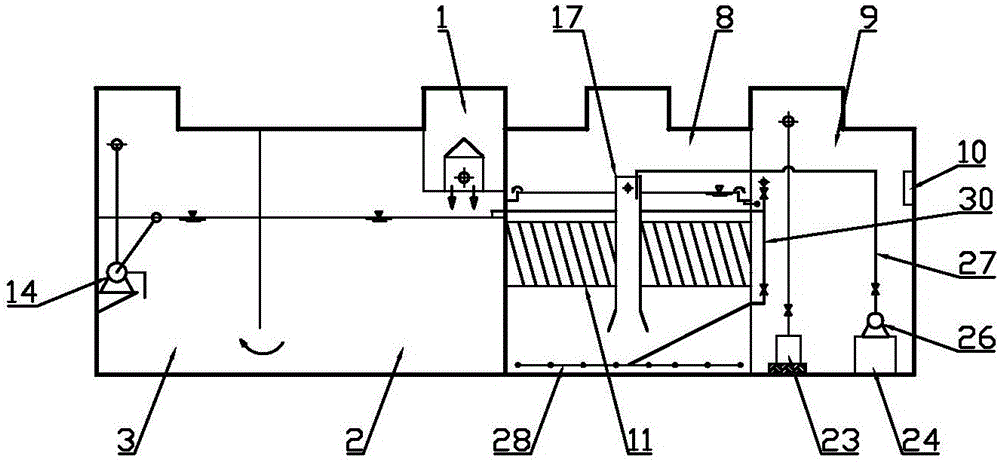

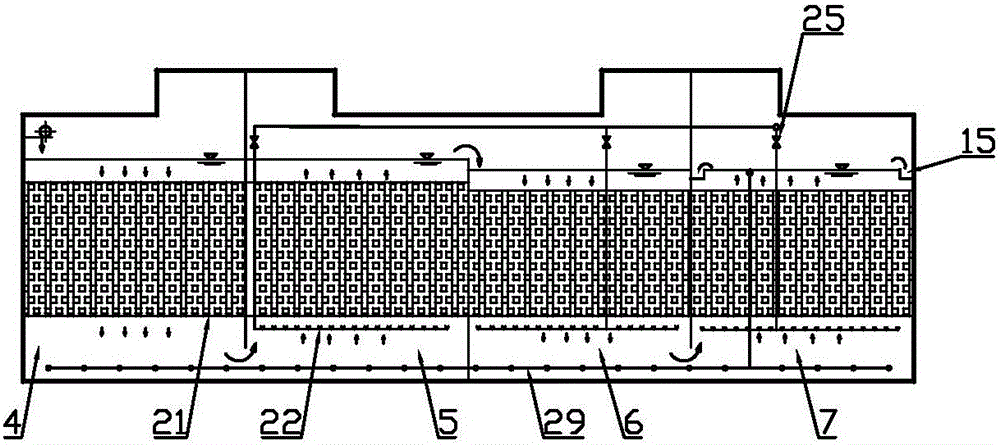

Buried integrated domestic sewage treatment device and method

ActiveCN104710078BShort engineering cycleDoes not occupy floor spaceMultistage water/sewage treatmentChemical treatmentFiltration

The invention discloses an underground integrated domestic sewage treatment device and a method thereof, and belongs to the field of purification of the domestic sewage. The underground integrated domestic sewage treatment device comprises a grilling tank, an adjusting tank, an anaerobic digestion tank, an anaerobic biological filtration tank, an aerobiotic biological filtration tank I, an aerobiotic biological filtration tank II, an aerobiotic biological filtration tank III, a vertical flow sedimentation tank and a control chamber, wherein the underground integrated domestic sewage treatment device is an underground stereoscopic integrated device; the control chamber comprises an upper layer part and a lower layer part; the upper layer part is arranged at the upper part of the control chamber; an electric control box and an ultraviolet device are arranged in the upper layer part; a fan and a chemical adding device are mounted at the lower layer part. The underground integrated domestic sewage treatment device is small in occupied area, convenient in drainage and low in energy consumption; the energy conservation and environment protection are facilitated; by virtue of the auxiliary adoption of the chemical treatment process on the main basis of biological degradation, the emission of the water with the up-to-standard water quality is ensured.

Owner:DALIAN JIAOTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com