Method for waste water precipitation treatment in construction

A precipitation treatment and construction technology, applied in the fields of neutralization water/sewage treatment, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc. problems, to achieve the effect of reducing the amount of addition and load, improving efficiency and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

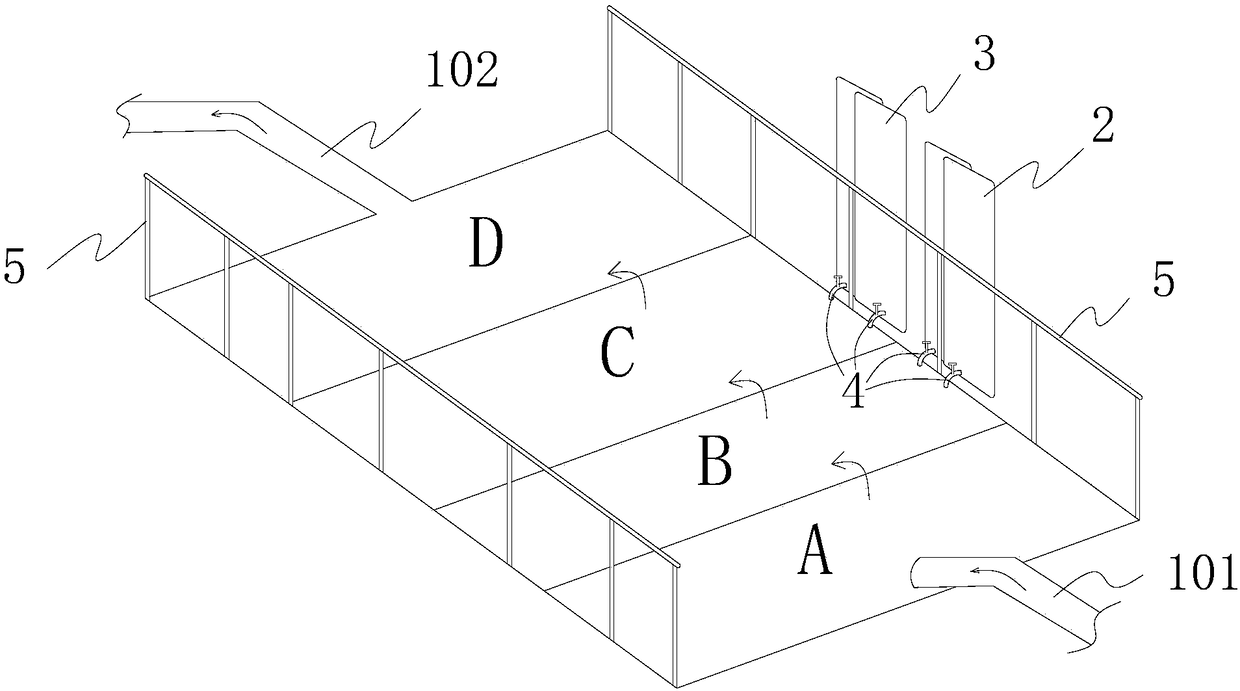

[0054] 1. Build a sedimentation tank

[0055] Calculate the daily average discharge X m according to the actual sewage discharge on site 3 / d, the volume of the sedimentation tank is designed according to 3 times the average daily discharge, and the total volume is not less than 3X m 3 . According to the design principles of advection sedimentation tanks, the effective water depth is 3 to 3.5 meters. The effective water depth refers to the actual water depth when the wastewater in each area of the sedimentation tank overflows to the next area. At this time, the water depth is the actual effective water depth where sedimentation occurs, which is lower than the construction depth of the sedimentation tank. The ratio of length to width is not less than 4 to calculate the size of the sedimentation tank, which can be changed as appropriate according to the actual situation.

[0056] The shape of the built sedimentation tank is as follows figure 1 As shown, according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com