Method for producing lithium iron phosphate precursor by using retired lithium iron phosphate battery as raw material

A lithium iron phosphate battery and lithium iron phosphate technology, applied in secondary batteries, battery electrodes, battery recycling, etc., can solve the problems of multiple aluminum foil separation processes, high impurity content, and large environmental pollution, and achieve good cycle performance and capacity Retention rate, the effect of less harm to the environment and operators, and low recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

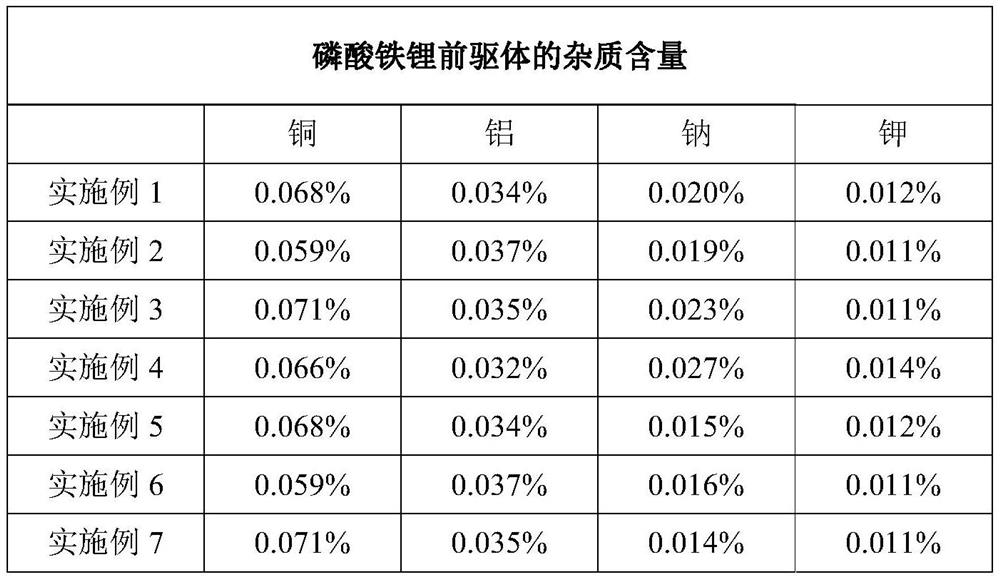

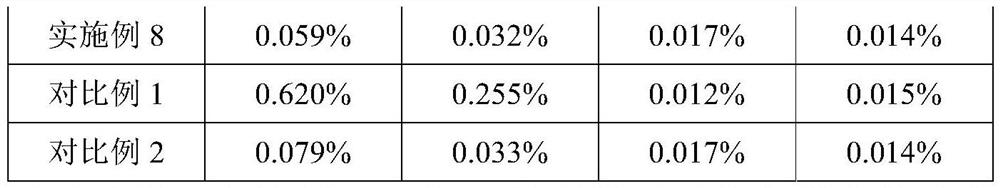

[0039] Examples 1 to 4 adopt the following method to produce lithium iron phosphate precursors using decommissioned lithium iron phosphate batteries as raw materials.

[0040] (1) Recycling and discharging of decommissioned batteries: Soak a 100Ah decommissioned lithium iron phosphate battery whose capacity has declined to 80% in water for discharge, and then disassemble to obtain the battery cell.

[0041] (2) Soaking the battery in acid: Break the battery and soak it in acid to dissolve it. During the process of soaking in acid, keep stirring or raise the temperature to increase the reaction rate. During the soaking process, lithium iron phosphate, aluminum foil and a small amount of copper foil will be dissolved, but the separator, most of the copper foil, graphite, positive electrode binder and conductive agent will not be dissolved. In the process of cell acid dissolution, the reaction between aluminum and hydrochloric acid will produce a large amount of hydrogen. It is n...

Embodiment 5~8

[0047] Steps (1)-(4) and (6) of Embodiments 5-8 are the same as Embodiments 1-4, the difference is only in step (5). In the step (5) of Examples 5-8, that is, in the step of precipitating iron phosphate, the pH is not adjusted by adding alkali to the solution after the oxidation reaction, but the pH is adjusted by electrolysis. Specifically: add a carbon plate cathode and a carbon plate anode to the solution after the oxidation reaction for electrolysis, and the reaction that occurs at the cathode is 2H + +2e - →H 2 ↑, thus, the concentration of hydrogen ions in the electrolyte gradually decreases, and the alkalinity gradually increases.

[0048] The specific reagents and parameters in Examples 1-8 are shown in Table 1 below.

[0049] Concrete reagent and parameter of table 1 embodiment 1~8

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com