Chemical chromium waste liquid efficient resourceful treatment process

A treatment process and recycling technology, applied in the field of high-efficiency recycling of chemical chromium waste liquid, can solve the problems of poor treatment effect, doping, incomplete reduction reaction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

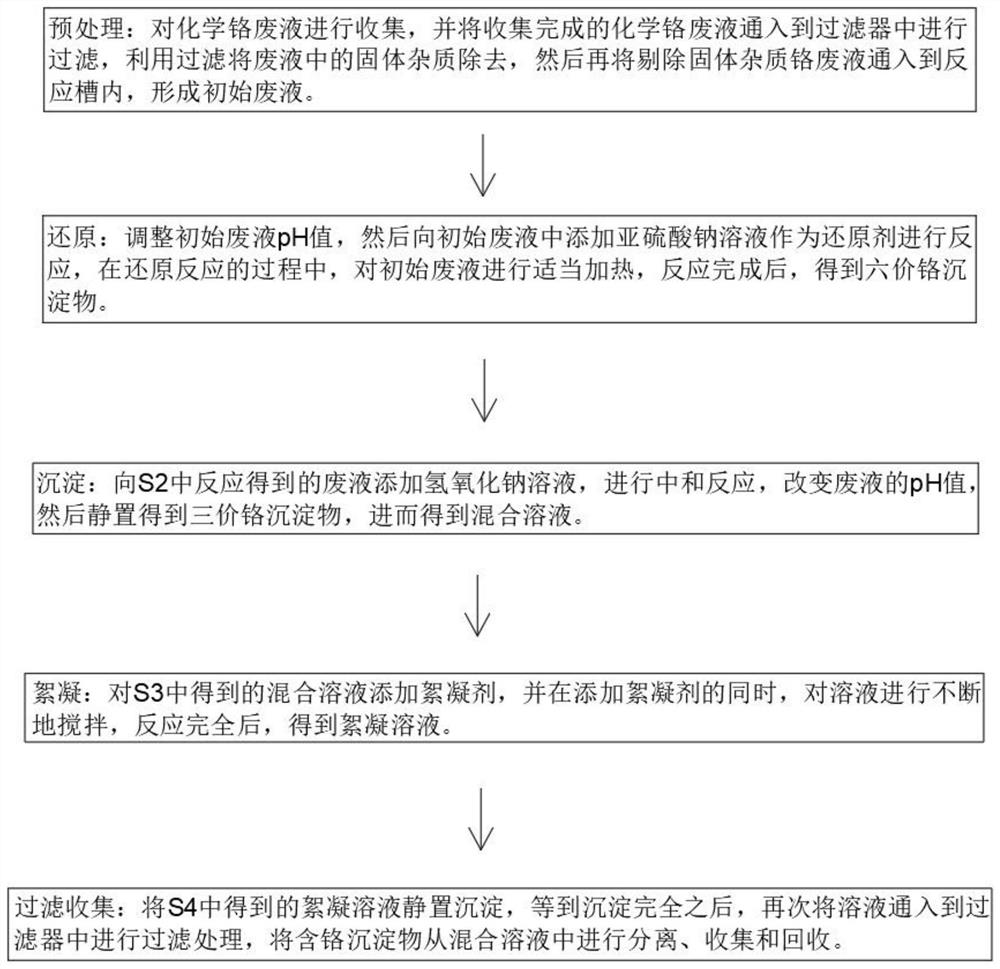

[0029] Embodiment 1, refer to figure 1 , a high-efficiency resource treatment process for chemical chromium waste liquid, comprising the following steps:

[0030] S1: Pretreatment, collect the chemical chromium waste liquid, pass the collected chemical chromium waste liquid into the filter for filtration, use the filtration to remove the solid impurities in the waste liquid, and then remove the solid impurities chromium waste The liquid is passed into the reaction tank to form the initial waste liquid. In the process of pretreatment and filtration, the fine solid particles doped in the chemical waste liquid can be removed, and the impact on the subsequent reduction and precipitation processes can be reduced to the greatest extent. , to ensure that the reaction is completely carried out;

[0031] S2: Reduction, adjust the pH value of the initial waste liquid, the pH value of the adjusted initial waste liquid is 2.5, then add sodium sulfite solution to the initial waste liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com