Polishing solution recycling apparatus

A recycling and polishing solution technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of waste of raw materials, deterioration of the surface finish of silicon wafers, and rising production costs, so as to improve the precipitation rate, save raw materials, and reduce process costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

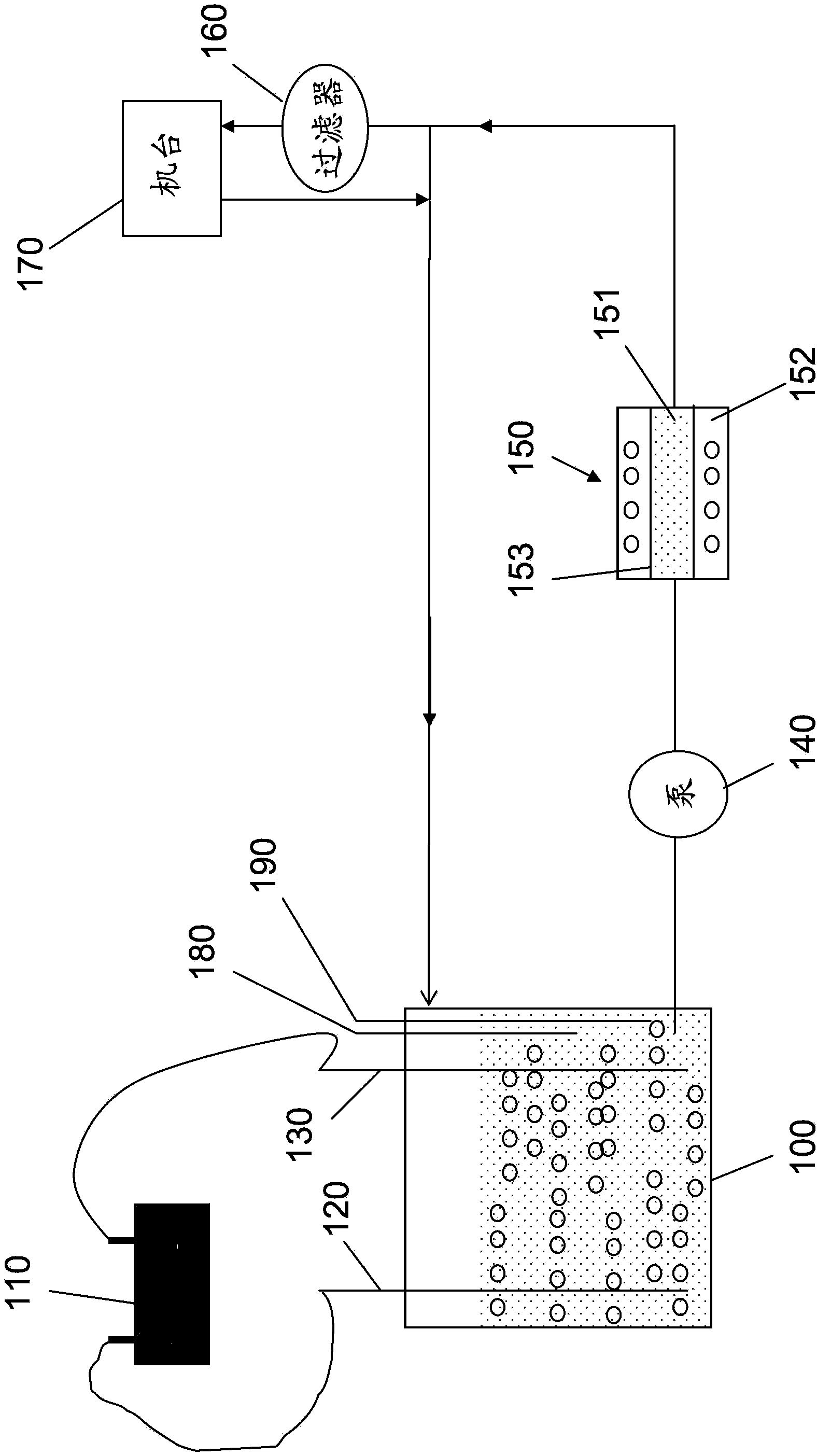

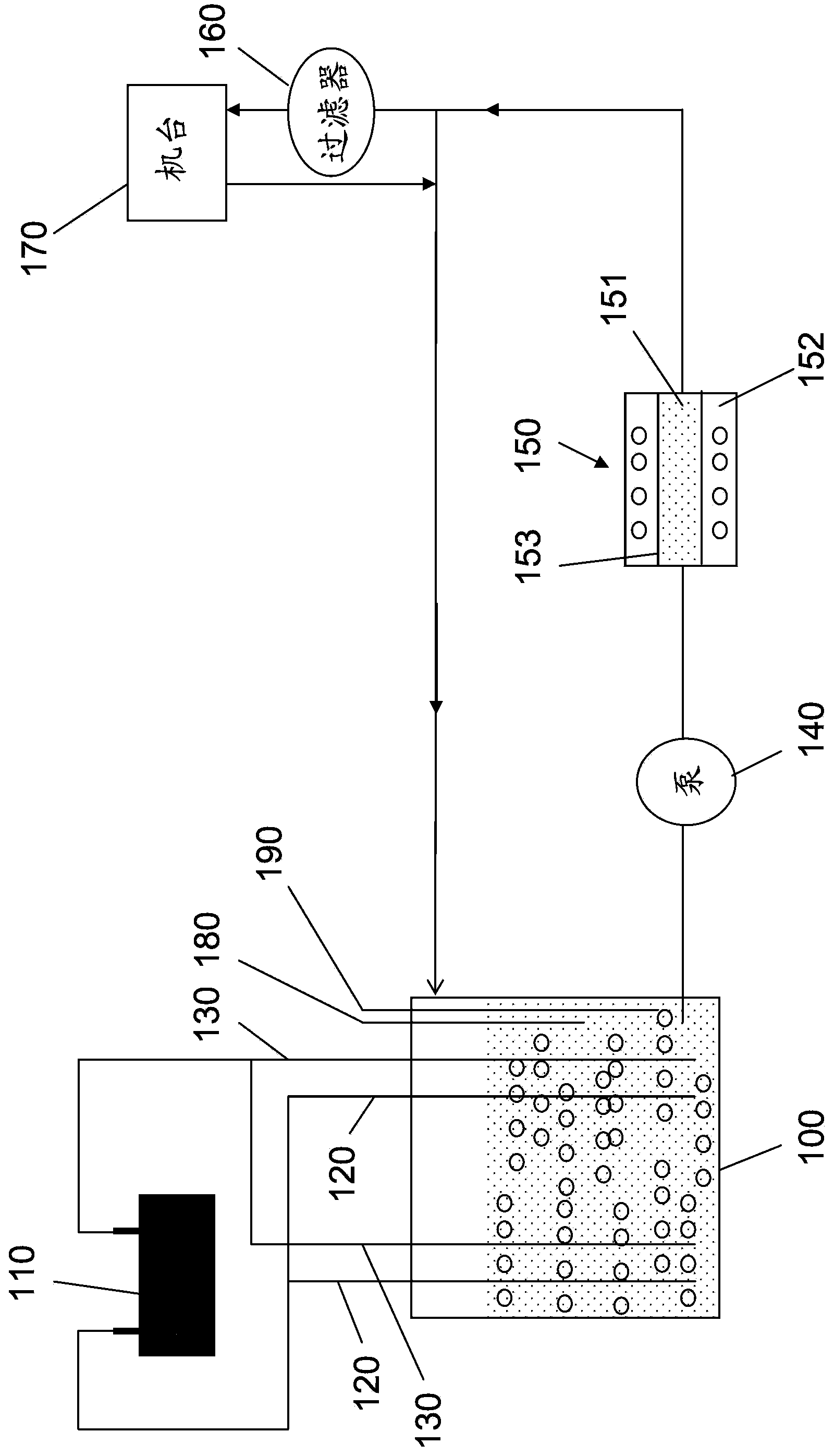

[0020] refer to figure 1 , discloses an embodiment of the polishing liquid recycling device according to the present invention, the polishing liquid recycling device includes a storage tank 100 , a power source 110 , a first circulating pump 140 and a degassing device 150 .

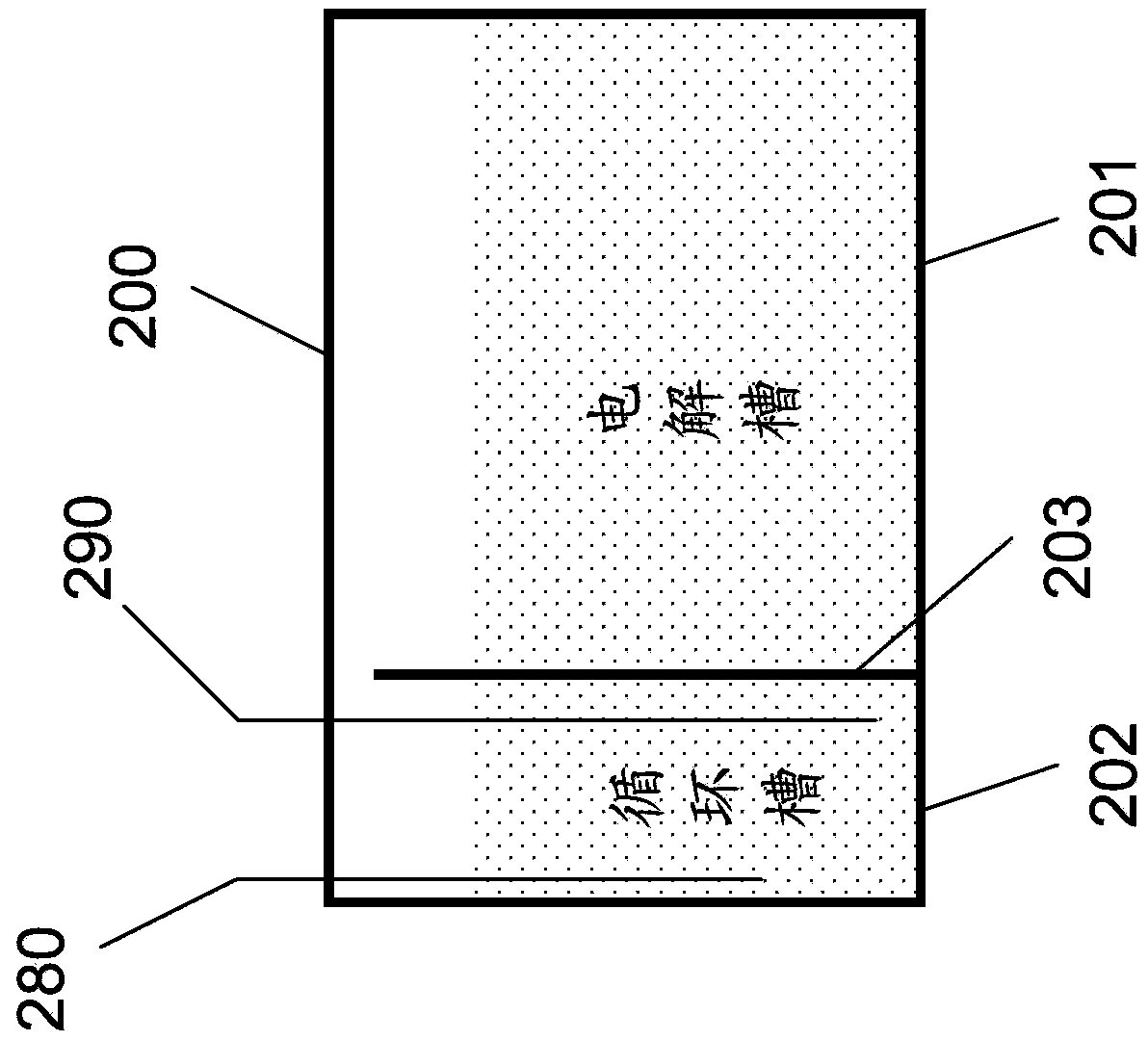

[0021] The storage tank 100 stores the polishing solution. The storage tank 100 is provided with an anode plate 120 and a cathode plate 130. The anode plate 120 is electrically connected to the anode of the power supply 110, and the cathode plate 130 is electrically connected to the cathode of the power supply 110. When the power supply 110 is turned on for electrolysis , the metal copper precipitated in the polishing solution is adsorbed on the cathode plate 130, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com