An Auxiliary Device for Maxwell Vacuum Gauge to Safely Measure the Vacuum Degree of Fuel Tank

An auxiliary device and vacuum gauge technology, which is applied in the field of transformer manufacturing, can solve the problems of polluting the body, product scrapping, mercury backflow, etc., and achieve the effects of increasing accuracy, reducing time spent, and preventing misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

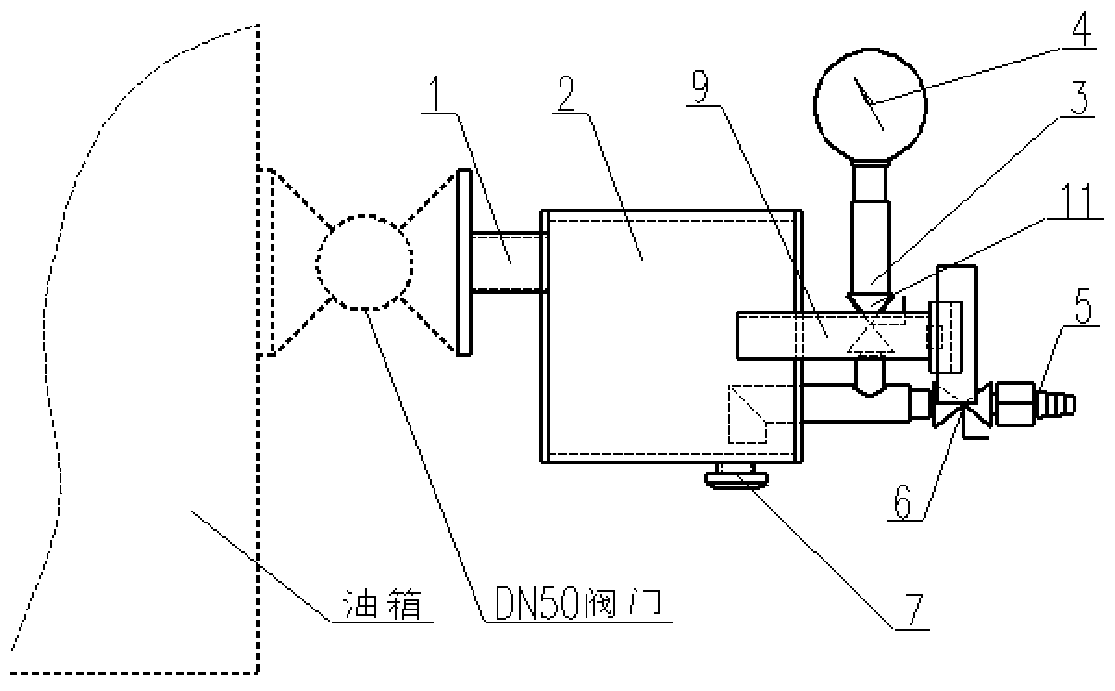

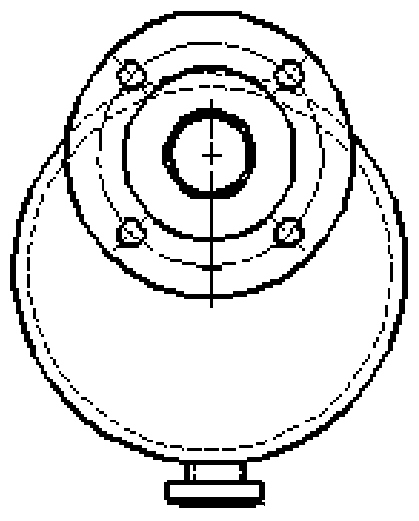

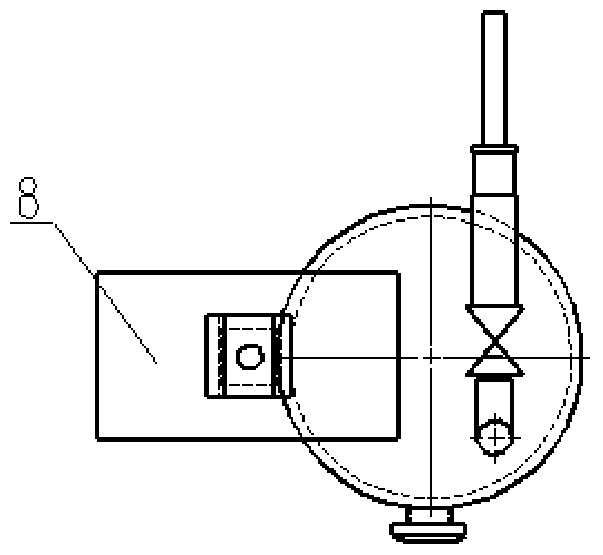

[0024] Such as Figure 1 to Figure 4 As shown, the present invention is an auxiliary device for a Maxwell vacuum gauge for safely measuring the vacuum degree of an oil tank, comprising a pipe joint 1 with a live flange, a box body 2, a Maxwell vacuum gauge bracket 9, a vacuum pressure gauge 4, and a Maxwell vacuum gauge Meter 8 and conversion joint 10; Wherein,

[0025] A pipe joint 1 with a live flange is installed on one side of the box body 2, and is used to connect with the oil tank that needs to measure the vacuum degree;

[0026] The McFarland vacuum gauge bracket 9 and the transition pipe 10 are installed on the other side of the box body 2 relative to the pipe joint 1 with a live flange, and the McFarland vacuum gauge 8 is installed on the Maxwell vacuum gauge bracket 9, through the McFarland vacuum gauge The vacuum gauge su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com