All-electric driven desulfurization waste water zero-emission treatment method and all-electric driven desulfurization waste water zero-emission treatment system

A desulfurization wastewater and treatment method technology, applied in the direction of gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the high cost of evaporation and crystallization treatment, increase the cost of ton water treatment, steam consumption and power consumption High-level problems, to achieve the effect of improving resource utilization, reducing zero-emission treatment costs, and reducing CODCr content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An all-electric drive zero-discharge treatment method for desulfurization wastewater, comprising:

[0038] (1) Adding Ca(OH) to desulfurization wastewater 2 , to remove F contained in desulfurization wastewater - , SO 4 2- and some Mg 2+ ;

[0039] (2) Electrolytic treatment of the effluent from step (1) for further removal of Mg 2+ , reduce NaCl concentration and COD in wastewater Cr content;

[0040] (3) Add NaOH to the effluent water of step (2), and blow in CO in the air 2 , to remove Mg from wastewater 2+ and Ca 2+ , so that the total hardness of wastewater is below 20 mg / L;

[0041] (4) Add HCl to the effluent water of step (3) and adjust the pH to 7.0~9.0, and then pass it into the first electric-driven membrane device, and the first electric-driven membrane device will - and SO 4 2- Separation to obtain SO rich in the light room feed liquid 4 2- , the concentrated chamber feed solution is rich in Cl - ;

[0042] (5) The feed liquid in the dilute...

Embodiment 2

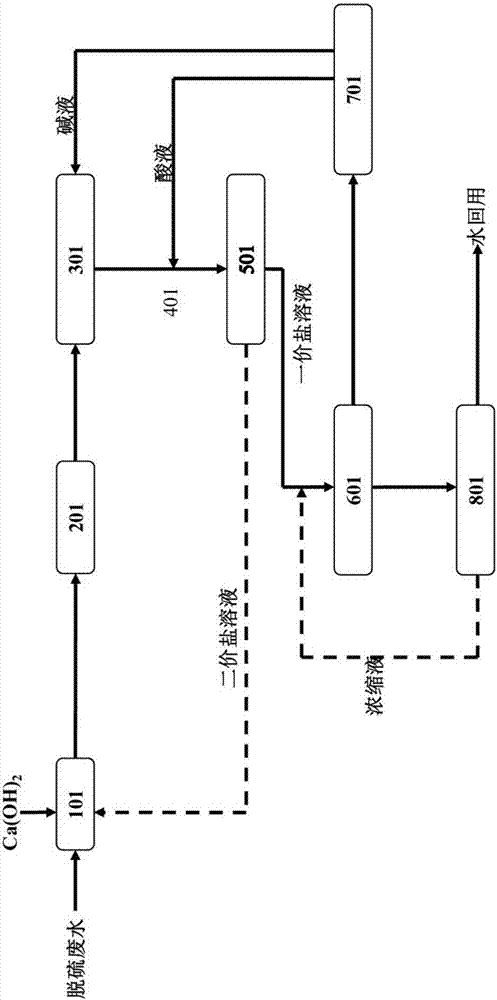

[0049] An all-electrically driven zero-discharge treatment system for desulfurization wastewater, comprising: a reaction pool 101, in which Ca(OH) is added to the desulfurization wastewater 2 , to remove F contained in desulfurization wastewater - , SO 4 2- and some Mg 2+ ; Electrochemical device 201, the inlet of electrochemical device 201 is connected with the outlet of reaction tank 101; High-efficiency precipitation integrated equipment 301, the entrance of efficient precipitation integrated equipment 301 is connected with the outlet of electrochemical device 201; The first electrically driven membrane device 501, the inlet of the first electric-driven membrane device 501 is connected to the outlet of the high-efficiency precipitation integrated equipment 301, and the acid solution addition inlet 401 is set on the connecting pipeline, and the feed liquid outlet of the first electric-driven membrane device 501 is connected to the reaction pool 101 connected; the second e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com