Polishing wastewater treatment method and polishing wastewater treatment system

A treatment method and wastewater technology, applied in the field of polishing wastewater treatment and polishing wastewater treatment system, can solve the problems of low efficiency of polishing wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

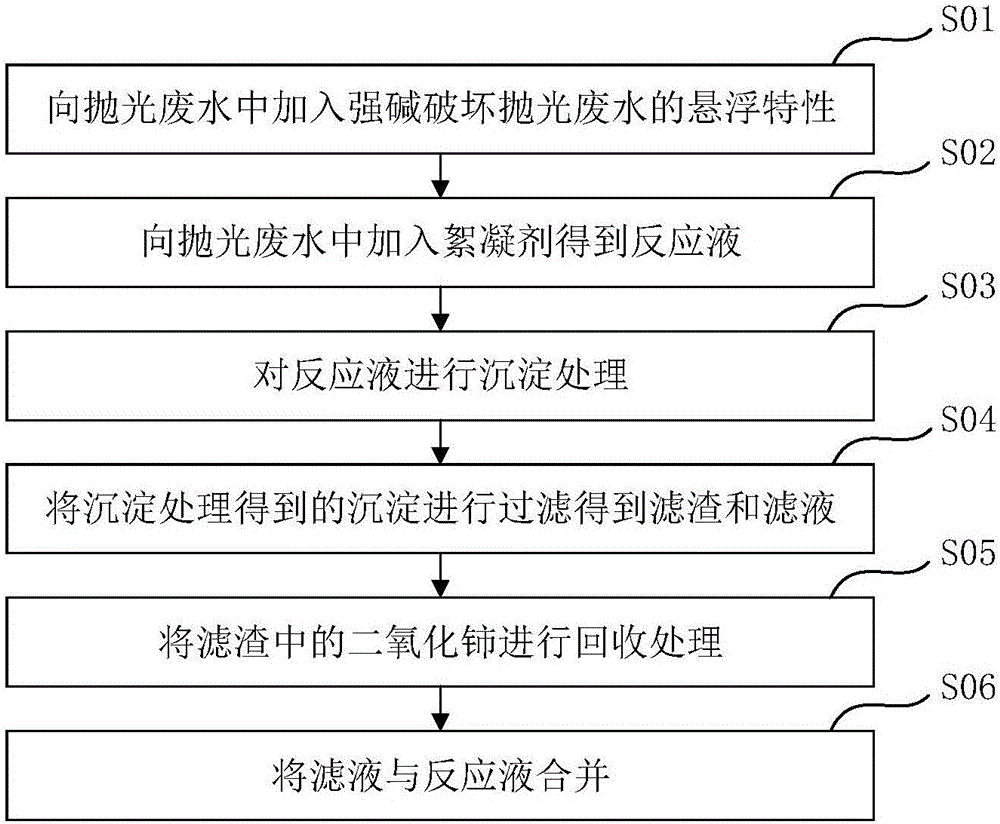

[0067] 1 ton of polishing waste water is processed, containing cerium dioxide and sodium salt suspending agent sodium hexametaphosphate and sodium polyacrylate in the polishing waste water, adding 10g of sodium hydroxide in the polishing waste water to adjust the pH value of the polishing waste water to be 8.0, After the water quality is uniform, add 250g of polyaluminum chloride and 5g of polyacrylamide to the polishing waste water; then carry out precipitation treatment on the polishing waste water after adding sodium hydroxide and flocculant for 2h.

[0068] The gravimetric method was used to detect the content of ceria in the supernatant of the polishing waste liquid and the precipitation treatment. After testing, the removal rate of ceria in the supernatant reaches 85%.

Embodiment 2

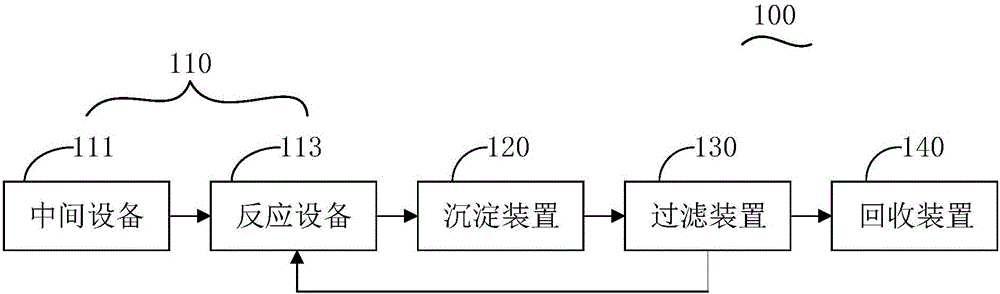

[0070] 1 ton of polishing waste water is processed, containing cerium dioxide and sodium salt suspending agent sodium hexametaphosphate and sodium polyacrylate in the polishing waste water, adding 11g of sodium hydroxide to the polishing waste water to adjust the pH value of the polishing waste water to be 8.5, It is recorded as the intermediate liquid. After the water quality is uniform, 240g of polyaluminum chloride and 6g of polyacrylamide are added to the polishing wastewater; then the polishing wastewater added with sodium hydroxide and flocculant is subjected to precipitation treatment for 0.5h. The precipitated sludge is introduced into a filter press for pressure filtration treatment, the filter residue intercepted by the filter press is collected, and the cerium oxide in the filter residue is recovered. The filtrate obtained by filtration is mixed with the intermediate liquid and processed again.

[0071] The gravimetric method was used to detect the content of ceria ...

Embodiment 3

[0073] 1 ton of polishing waste water is treated. The polishing waste water contains cerium dioxide and sodium salt suspending agent sodium hexametaphosphate and sodium polyacrylate. Adding 12g of sodium hydroxide to the polishing waste water to adjust the pH of the polishing waste water is 9.0 to obtain intermediate liquid. After the water quality is uniform, add 260g of polyaluminum chloride and 4g of polyacrylamide to the polishing wastewater; then pass the polishing wastewater with sodium hydroxide and flocculant into it for precipitation treatment for 2h. The precipitated sludge is introduced into a vacuum filter for filtration treatment, the filter residue is collected, and the cerium oxide in the filter residue is recovered. The filtrate passing through the vacuum filter is mixed with the intermediate liquid for further processing.

[0074] The gravimetric method was used to detect the content of ceria in the supernatant of the polishing waste liquid and the precipitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com