Method for using coal-based solid waste for overlying strata isolation grouting filling

A technology for isolated grouting and overlying rock, which is applied in the direction of filling, earthwork drilling, safety devices, etc., can solve the problems of grouting filling materials in short supply, poor combustion performance, land occupation, etc., and achieve the improvement of overlying rock isolation and grouting filling The dilemma of insufficient technical materials, the effect of improving fluidity and solving application problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

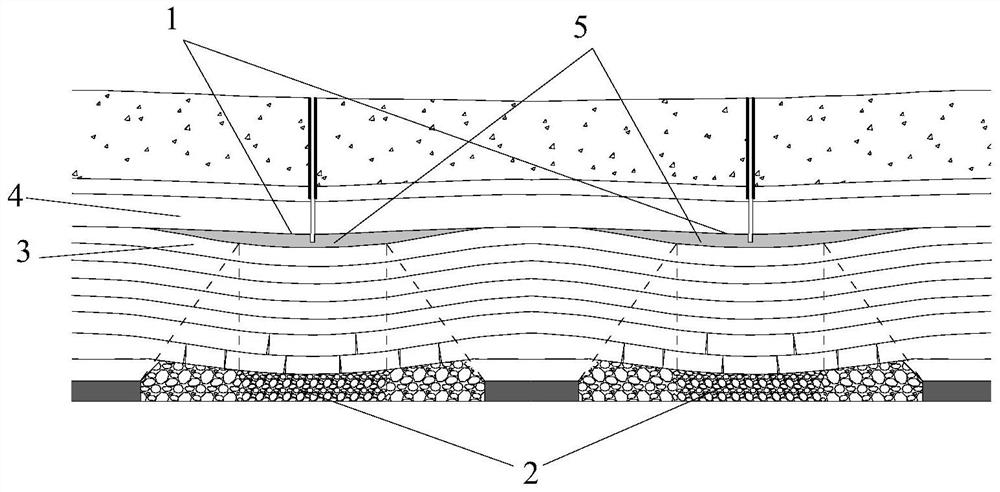

[0012] The technical solutions of the present invention will be described in more detail below in combination with the accompanying drawings in the embodiments of the present invention.

[0013] like figure 1 As shown, a method of using coal-based solid waste for overlying rock isolation grouting filling, crushing coal gangue into coal gangue powder with a particle size of 0.5-1.5mm, mixing it with fly ash and coal slime, adding it to water to prepare grouting grouting The slurry used for grouting shall be filled with different mixing ratios at different stages of grouting filling for overlying rock isolation; the fly ash and coal slime shall pass through a sieve with a square hole less than or equal to 2mm, and the amount of water in the injected slurry shall be The mass ratio should be less than 40%;

[0014] In the initial stage of overlying rock isolation grouting filling, there is an unfilled or underfilled overlying rock space 1 in the overlying rock, and a large amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com