Heavy metal contaminated soil remediation method

A technology of polluted soil and remediation method, which is applied in the restoration of polluted soil, etc. It can solve problems such as pollution, damage to remediation devices, and hindrance to plant growth and development, and achieve the effects of improving screening efficiency, facilitating dredging, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

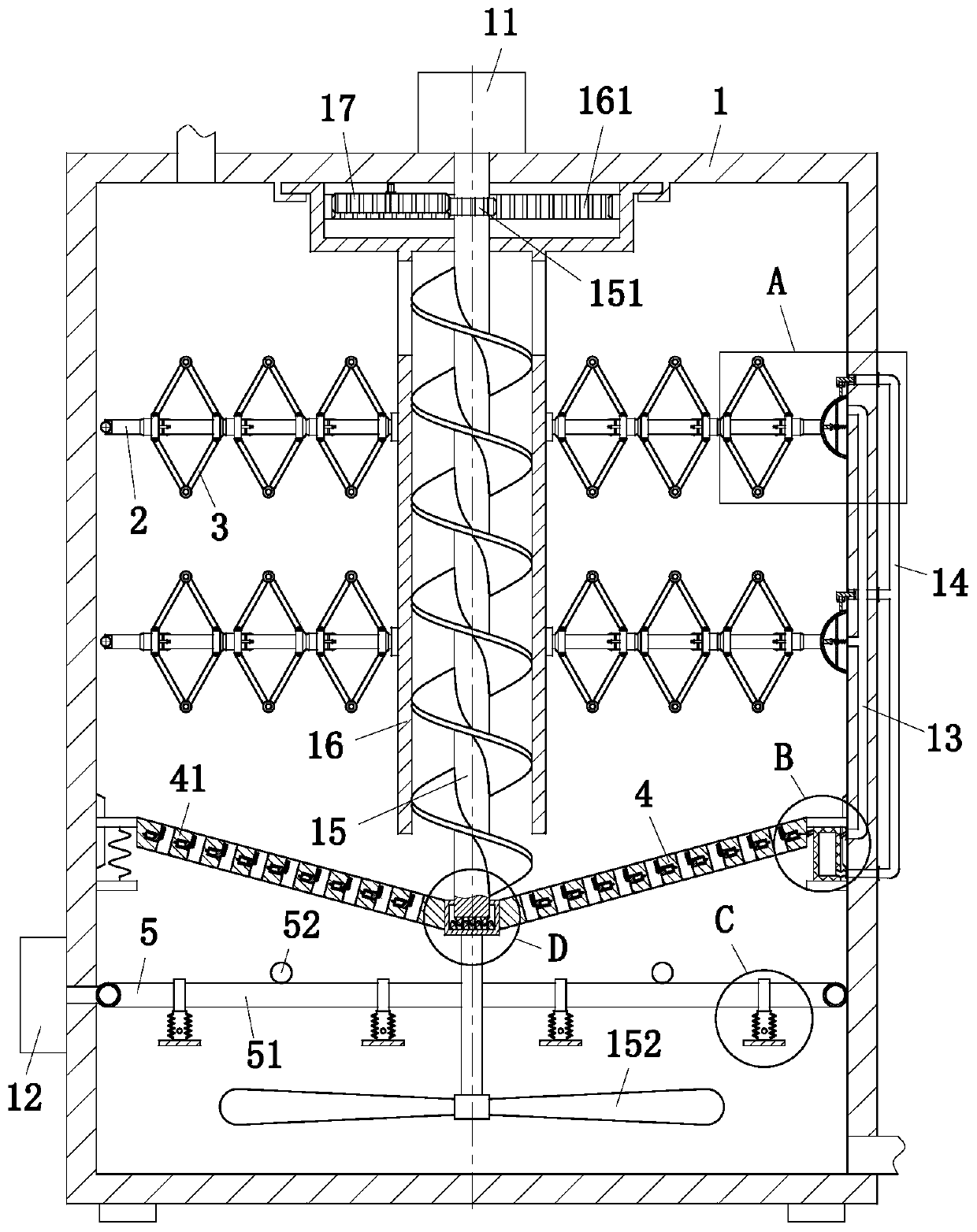

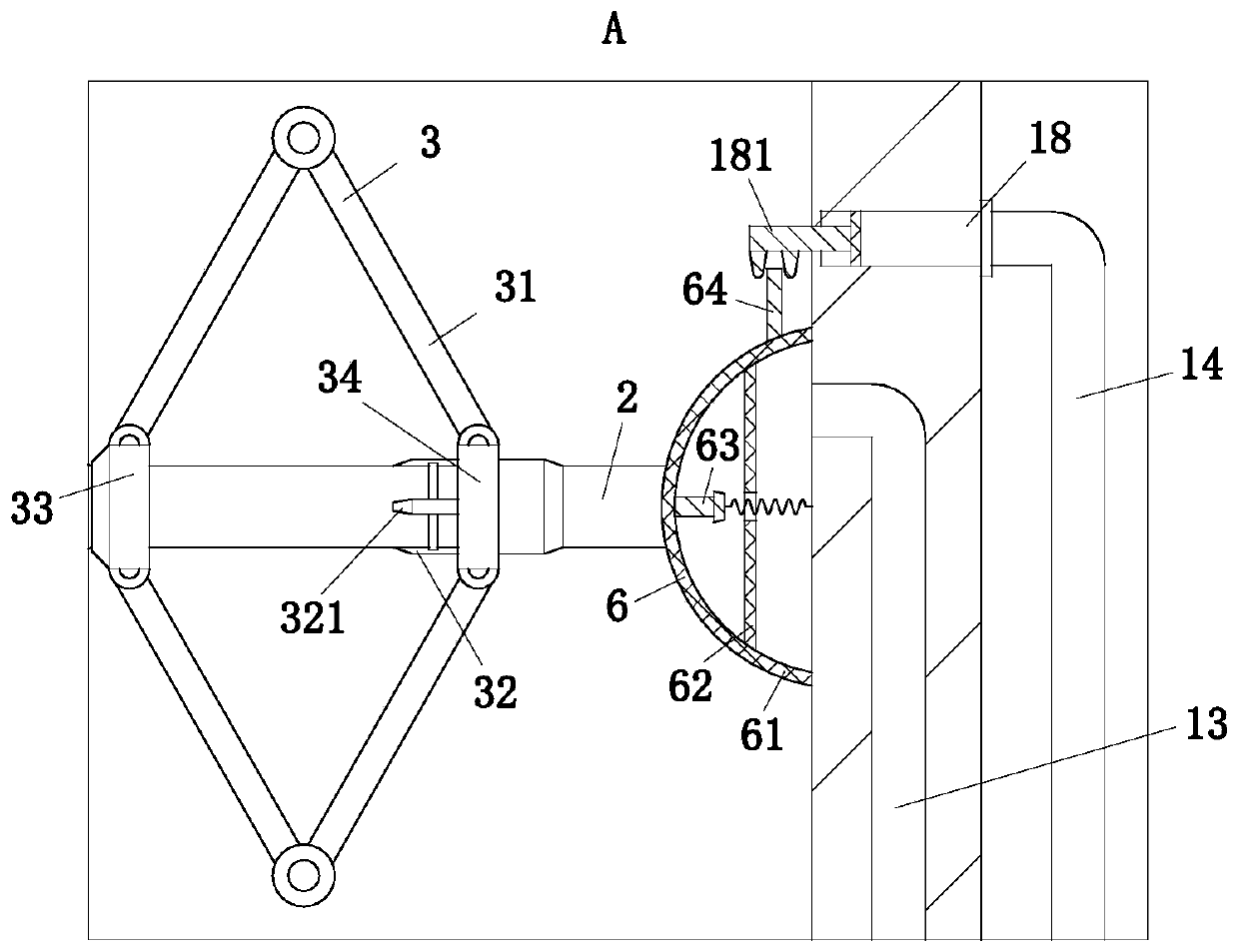

[0038] use Figure 1 to Figure 6 A method for repairing heavy metal-contaminated soil of the present invention is described as follows.

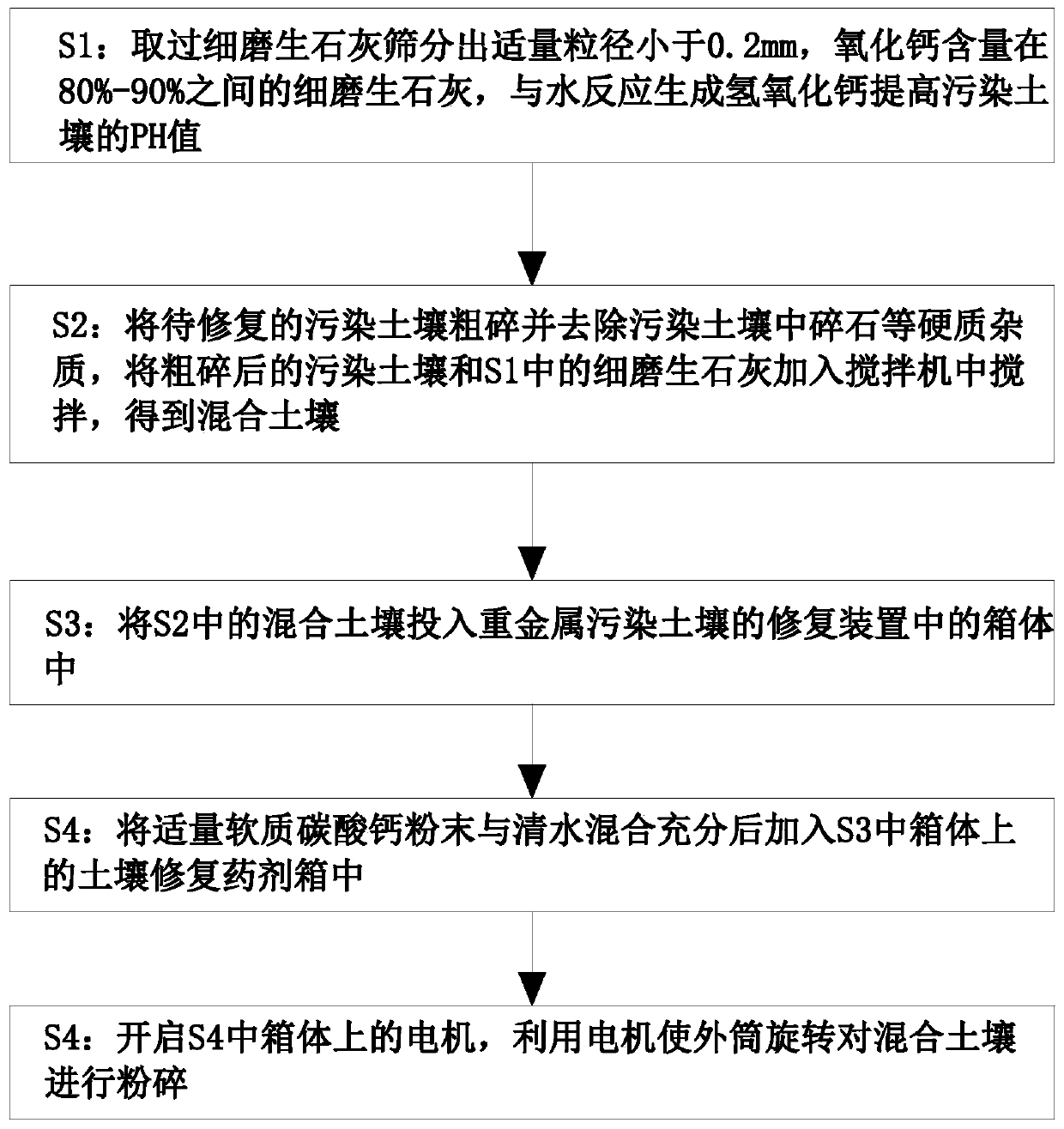

[0039] Such as Figure 1 to Figure 6 Shown, a kind of remediation method of heavy metal contaminated soil of the present invention, the method comprises the steps:

[0040] S1: Take the finely ground quicklime and sieve out an appropriate amount of finely ground quicklime with a particle size of less than 0.2mm and a calcium oxide content between 80% and 90%, and react with water to generate calcium hydroxide to increase the pH value of the polluted soil; through calcium oxide and Water reacts to generate calcium hydroxide, which increases the pH value of polluted soil, promotes the formation of hydroxide precipitation of heavy metal elements in polluted soil, and effectively reduces the content of heavy metal elements in polluted soil;

[0041] S2: Coarsely crush the polluted soil to be repaired and remove hard impurities such as gravel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com