Recycling treatment process for thermal power plant desulfurization wastewater

A technology for thermal power plants and desulfurization wastewater, which is applied in gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problem of difficulty in ensuring the purity of crystalline salt, high dosing cost, steam consumption and electricity consumption. higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

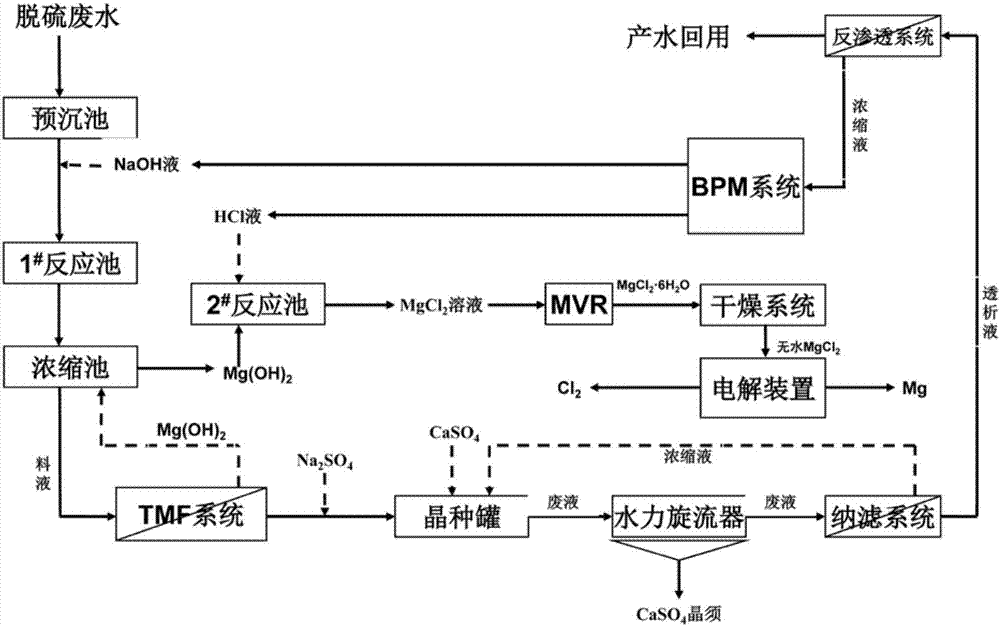

[0054] A resource treatment process for desulfurization wastewater from a thermal power plant comprises the following steps:

[0055] 1) The desulfurization wastewater is treated by the triple box process, and then enters the pre-sedimentation tank for treatment to obtain the sediment at the bottom and the supernatant at the upper part. The bottom of the pre-settling tank is conical for sludge discharge, and the upper part is equipped with an overflow mouth, the pre-sedimentation tank is used to remove the suspended CaSO in the desulfurization wastewater 4 Removal by gravity sedimentation;

[0056] 2), the supernatant obtained in the pre-sedimentation tank in step 1) overflows to the 1# reaction tank after adding NaOH, and the supernatant fully reacts with NaOH in the 1# reaction tank;

[0057] 3), in step 2), the effluent from the 1# reaction tank enters the concentration tank, and the feed liquid in the concentration tank is transported into the TMF system through a large-f...

Embodiment 2

[0062] like figure 1 As shown, a resource treatment system for desulfurization wastewater from a thermal power plant is characterized in that it includes:

[0063] The pre-sedimentation tank is used to treat the desulfurization wastewater after the three-box process. The bottom of the pre-settling tank is conical for sludge discharge, and the upper part is provided with an overflow port. Suspended CaSO 4Remove by gravity sedimentation to obtain the bottom sediment and the upper supernatant;

[0064] 1# reaction tank, the supernatant overflowed from the pre-sedimentation tank enters the 1# reaction tank through the pipeline, and fully reacts with NaOH in the 1# reaction tank;

[0065] Concentration tank, the effluent of 1# reaction tank enters the concentration tank for concentration to obtain Mg(OH) 2 And feed liquid, Mg(OH) 2 Concentration increases continuously, and after reaching a certain concentration, it is discharged to 2# reaction pool;

[0066] In the TMF system,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com