CoPxOy nano-array composite material grown on surface of conductive substrate as well as preparation and application of CoPxOy nano-array composite material

A conductive base material and composite material technology, applied in the field of nano-array composite materials, can solve the problems of unsuitable large-scale production and application, environmental pollution, etc., and achieve the effects of good hydrogen production performance, improved precipitation rate, and accelerated transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

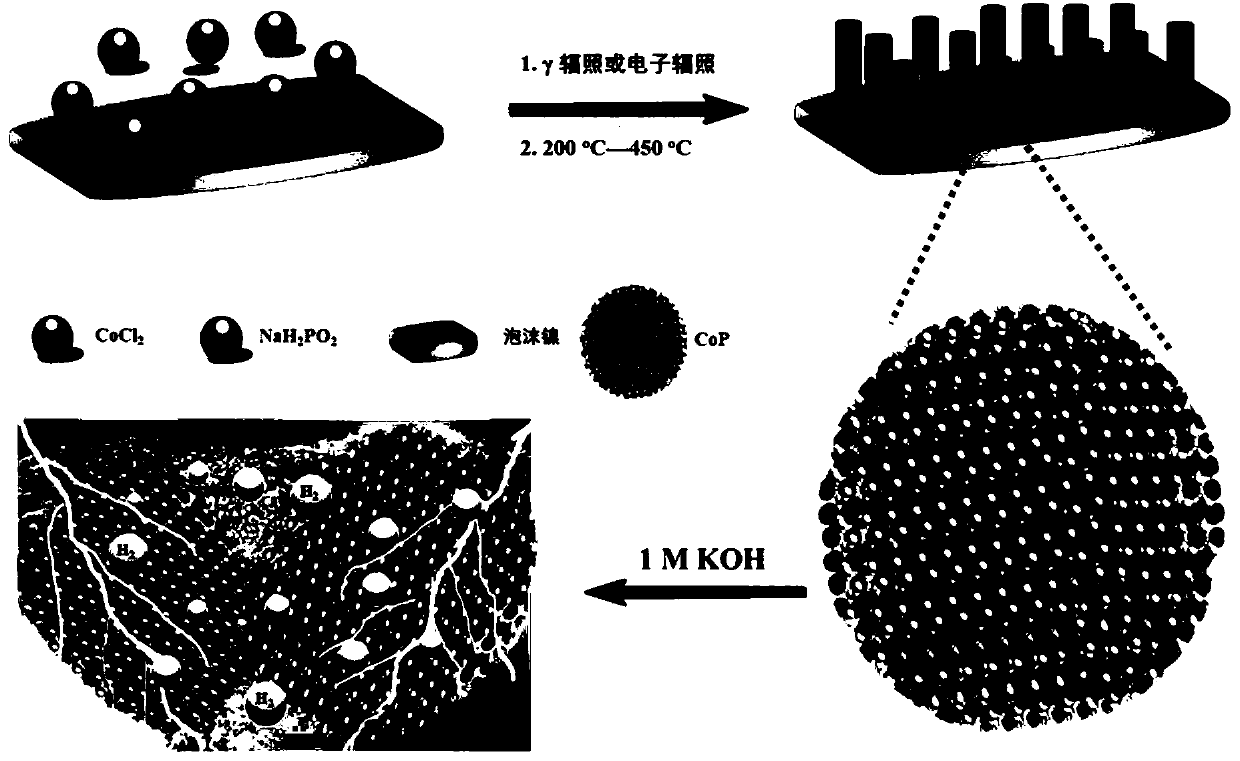

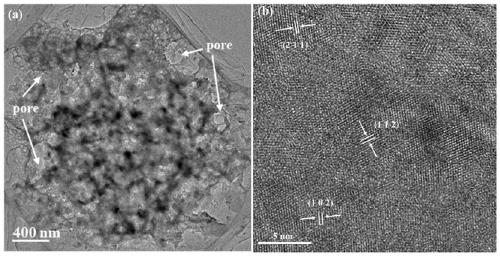

[0036] A NF self-supporting superhydrophilic and superaerophobic CoP for hydrogen production from water electrolysis in alkaline solution x o y Nano array material, its preparation method is as follows:

[0037] 1) Cut the commercialized NF into 20×50mm rectangular slices, first wash them ultrasonically with hydrochloric acid (HCl), then ultrasonically wash them with distilled water, and finally wash them ultrasonically with ethanol. After washing, dry overnight in a vacuum oven at 60 °C. Hang the dried NF on a rubber stopper and store it in a vacuum oven at 60°C for later use.

[0038] 2) 2.2g CoCl 2 ·6H 2 O and 4.5 g NaH 2 PO 2 ·H 2 O was added to a test tube containing 50mL of isopropanol and ultrapure water with a volume ratio of 1:1, stirred and dissolved, and placed in N 2 Drain the air under the atmosphere, and after 15 minutes, seal it with the rubber stopper containing suspended NF in step 1), NF is completely immersed in the solution, and after sealing, send ...

Embodiment 2

[0046] With embodiment 1 step 2) in 60 Co gamma rays were changed to electron beams produced by an electron accelerator, the absorbed dose rate was 10kGy / pass, and the absorbed dose was 200kGy. Other conditions were the same as in Example 1, and NF@CoP for hydrogen production by electrolysis of water was obtained. x o y Catalytic material, where x=0.9, y=0.3.

Embodiment 3

[0048] Change the absorbed dose rate in step 2) of Example 1 to 10Gy / min, and other conditions are the same as in Example 1 to obtain NF@CoP for hydrogen production by electrolysis of water x o y Catalytic material where x=0.5, y=0.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com