Method for preparing doped nanometer titanium oxide photocatalyst

A nano-titanium dioxide and photocatalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems affecting photocatalytic activity, achieve good dispersion, uniform particle size distribution, and huge The effect of applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

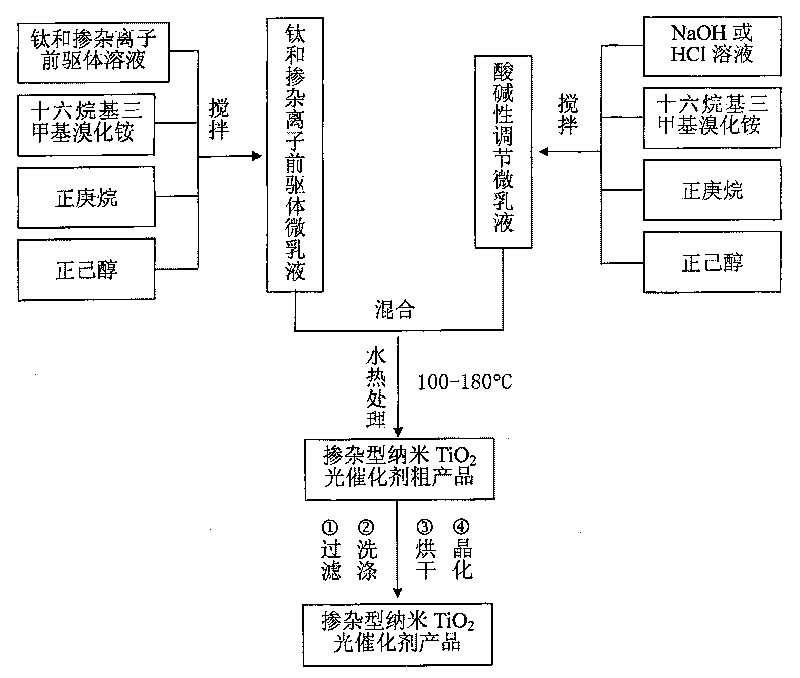

[0037] Such as figure 1 As shown, accurately weigh or measure 1.5g of cetyltrimethylammonium bromide, 2.7mL of n-hexanol, 16.8mL of n-heptane and 1M TiCl 4 Solution 1.64mL and 1M SnCl 4 Put 0.16 mL of the solution in an Erlenmeyer flask and stir until a uniform microemulsion is formed; accurately weigh or measure 1.5 g of cetyltrimethylammonium bromide, 2.7 mL of n-hexanol, and 2.7 mL of n-heptane in another Erlenmeyer flask 16.8mL and 1.8mL of 1M NaOH solution, stir until a uniform microemulsion is formed. Mix the above two groups of microemulsions, stir them, move them into a hydrothermal reaction kettle, put them into an oven, and react at 180°C for 8 hours. After the reaction is completed and naturally cooled, open the hydrothermal reaction kettle, and take out the white powder at the bottom by centrifugation. Wash it three times with ethanol and deionized water, and bake it in a high-temperature oven at 600°C for 2 hours to obtain doped nano-TiO 2 : Sn 4+ Photocatalys...

Embodiment 2

[0041] Such as figure 1 As shown, accurately weigh or measure 1.5g of cetyltrimethylammonium bromide, 2.7m of n-hexanol, 16.8mL of n-heptane and 1M TiCl 4 Solution 1.64mL and 1M La(NO 3 ) 3 Put 0.16 mL of the solution in an Erlenmeyer flask and stir until a uniform microemulsion is formed; accurately weigh or measure 1.5 g of cetyltrimethylammonium bromide, 2.7 mL of n-hexanol, and 2.7 mL of n-heptane in another Erlenmeyer flask 16.8mL and 1.8mL of 1M NaOH solution, stir until a uniform microemulsion is formed. Mix the above two groups of microemulsions, stir them, move them into a hydrothermal reaction kettle, put them into an oven, and react at 180°C for 8 hours. After the reaction is completed and naturally cooled, open the hydrothermal reaction kettle, and take out the white powder at the bottom by centrifugation. Wash it three times with ethanol and deionized water, and bake it in a high-temperature oven at 600°C for 2 hours to obtain doped nano-TiO 2 :La 3+ catalyst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com