Zero-emission treatment technology of desulfurization waste water in thermal power station

A thermal power plant, desulfurization wastewater technology, applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the high cost of dosing, high treatment cost, increase the cost of ton water treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A zero-discharge treatment process for desulfurization wastewater from thermal power plants, comprising the following steps:

[0051] 1), send the wastewater into the reaction tank, and add Ca(OH) 2 To react, Ca(OH) 2 with F in wastewater - , SO 4 2- , Mg 2+ Reaction to form insoluble substances, remove F contained in wastewater - , some SO 4 2- and Mg 2+ , the reaction tank is equipped with mechanical stirring equipment and high-efficiency aeration equipment to improve the reaction efficiency of wastewater in the reaction tank;

[0052] 2), the wastewater treated in step 1) is sent to an electrochemical device for electrolysis to further remove Mg 2+ , reduce the NaCl and CODCr concentration in waste water, described electrochemical device comprises electrode, rectifier, cell body equipment and cable, and described electrode is to be the steel material containing iron, and electrochemical device outputs current along with rectifier during operation The rise o...

Embodiment 2

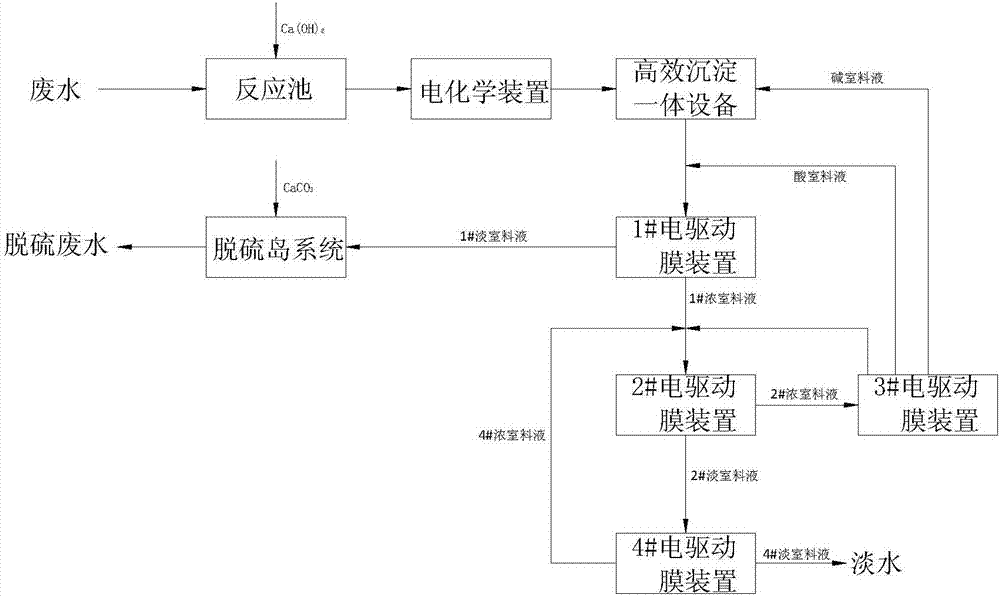

[0060] Such as figure 1 As shown, a zero-discharge treatment system for desulfurization wastewater from a thermal power plant includes:

[0061] Reaction tank, by adding Ca(OH) to the reaction tank 2 , and F in wastewater - , SO 4 2- , Mg 2+ The reaction forms insoluble substances, thereby removing the F contained in the wastewater - , some SO 4 2- and Mg 2+ , the reaction tank is equipped with mechanical stirring equipment and high-efficiency aeration equipment to improve the reaction efficiency of wastewater in the reaction tank;

[0062] Electrochemical device, the electrochemical device includes electrodes, rectifiers, cell equipment and cables, the electrodes are made of iron-containing steel, and the electrolytic treatment of the effluent of the reaction cell is further removed by the electrochemical device. 2+ , reduce NaCl and COD in wastewater Cr Concentration, the tiny bubbles produced can play an air flotation effect and improve the removal effect of suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com