Method for electroplating a cylindrical inside surface of a work-piece-extending substantially over a semi-circle

An inner surface, cylindrical technology, applied in the field of electroplating the cylindrical inner surface that actually extends beyond the semicircular workpiece, can solve the problems of structural complexity, sealing and guiding difficulties, etc., and achieve the effect of simple structural conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

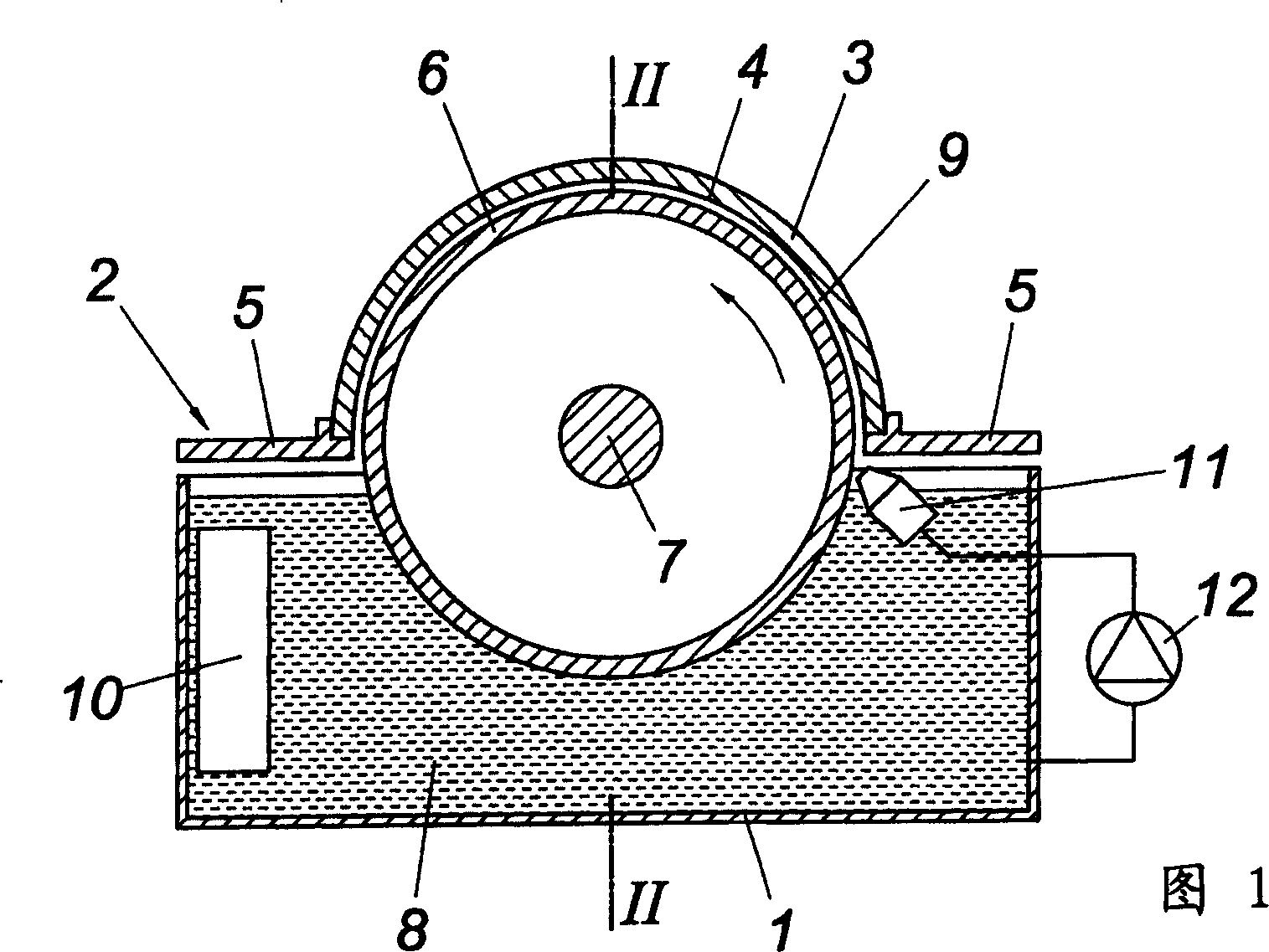

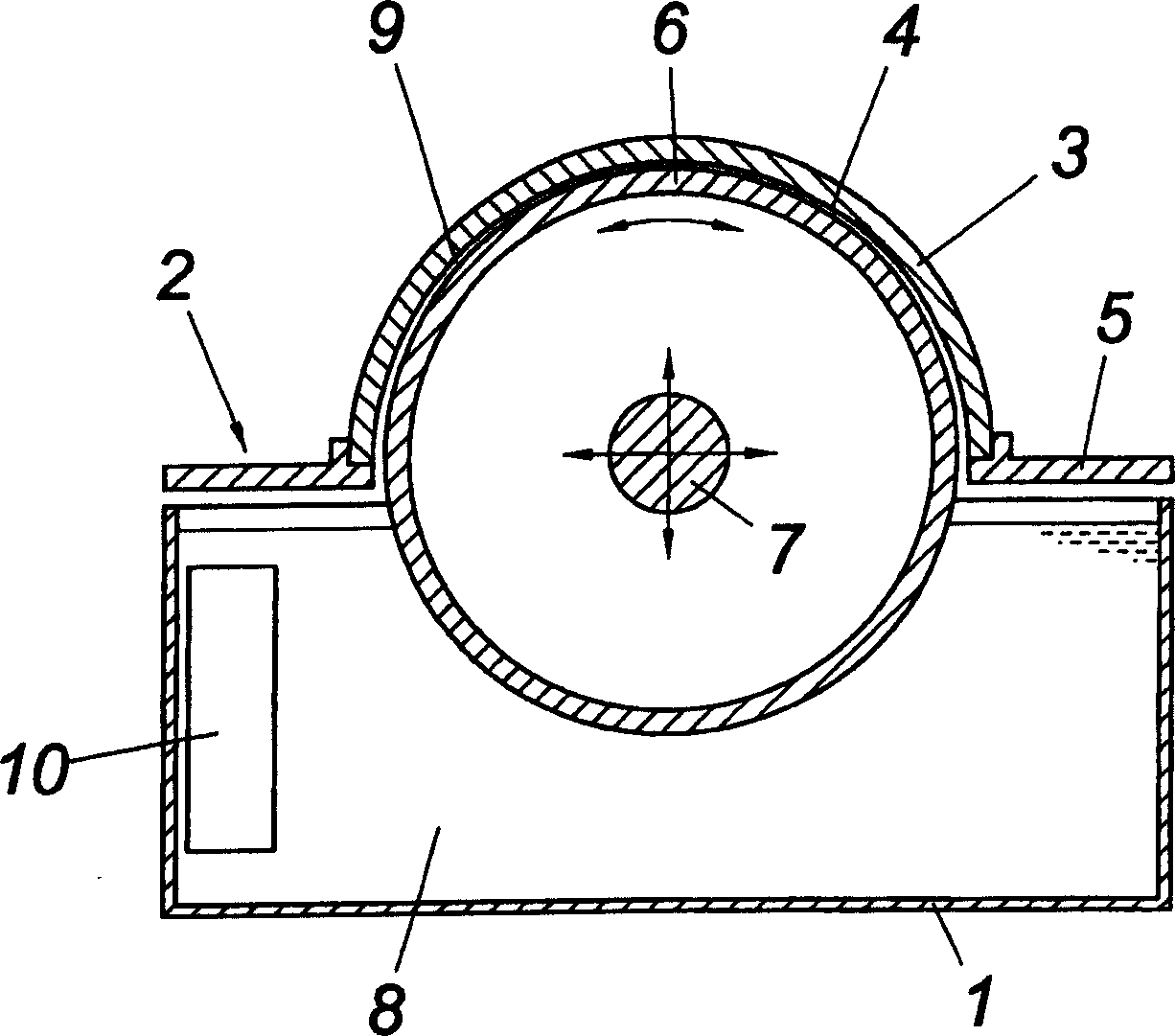

[0026]According to FIG. 1 , the exemplary apparatus comprises a tank 1 above which is a fixture 2 for a workpiece 3 comprising a cylindrical inner surface 4 to be electroplated, exhibiting a semicircular cross-section, for example in the form of a semicylindrical The component representation. The fixture 2 consists of a slide guide 5 with two slides on which the axial surface of the workpiece 3 is supported. A guide 6 in the form of a rotor is coaxial with the inner surface 4 of the workpiece 3 and the rotor is driven by a shaft 7 in a speed-controlled manner. Said guide 6 is partly submerged in the electrolytic tank 8 to circulate electrolyte from the tank 8 through the gap 9 between the guide 6 and the inner surface 4 of the workpiece 3 . By choosing the dimensions of the gap 9 and the circulation speed of the guide means 6 it is possible in an advantageous manner to maintain a laminar flow of the electrolyte through the gap 9 and the metal layer to be electroplated on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com