High frequency arc ignition circuit with direct current voltage output

A high-frequency arc striking, DC voltage technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problem of weak arc striking ability, and achieve the effect of quick action, easy arc striking, and improved arc striking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

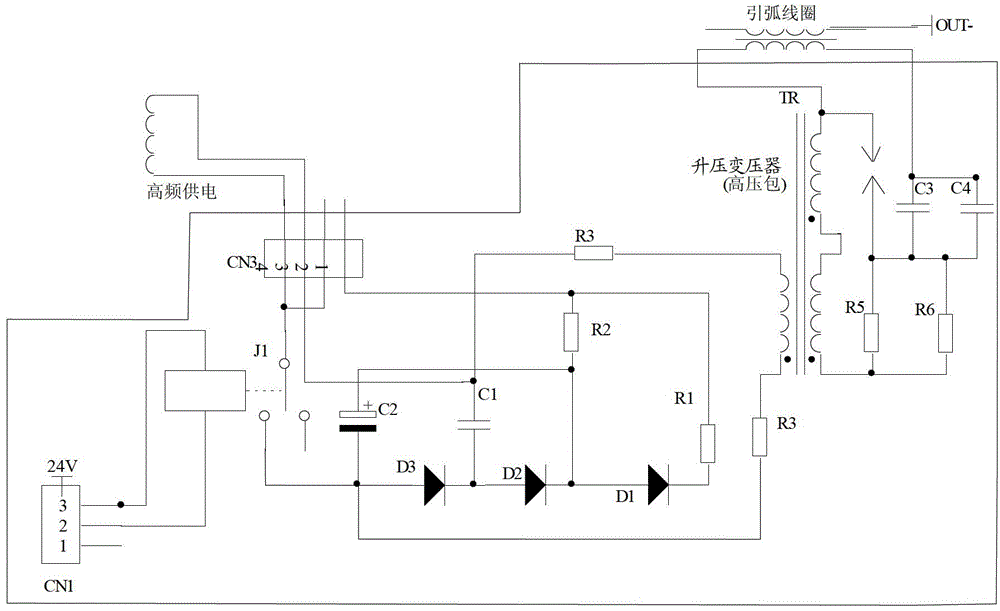

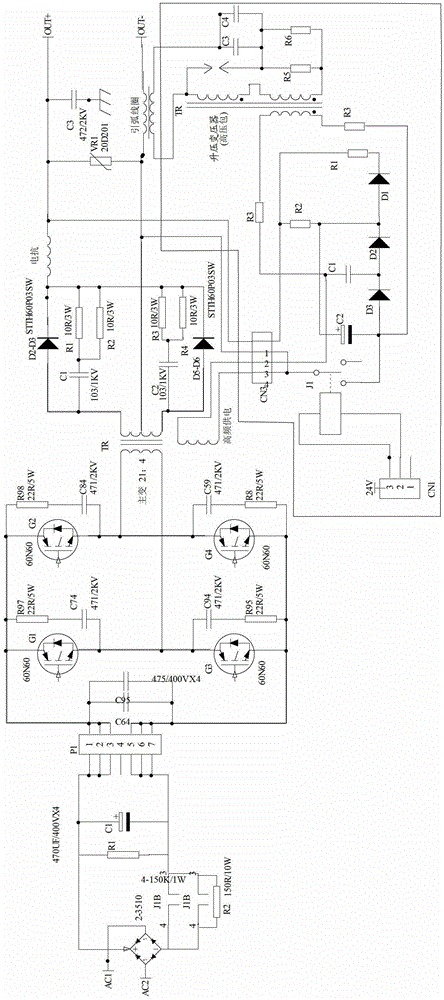

[0016] Such as figure 1 Shown, the present invention comprises high-frequency signal source, relay J1, voltage doubler circuit and high-frequency boost circuit; The main circuit of the welding machine is connected, and the generated high-voltage direct current is connected in parallel with the main circuit; the high-frequency boost circuit generates a high-frequency high-voltage signal, and the high-frequency high-voltage signal is coupled to the secondary negative output of the main circuit of the welding machine through a high-frequency coupler. Such as figure 2 As shown, the main circuit of the welding machine is a full-bridge hard switch, the secondary rectification is a full-wave rectification, the positive pole is added with a reactance output, and the negative pole is connected in series with a high-frequency coupling arc coil output.

[0017] The high-frequency signal source is used as the working power supply of the whole circuit, and is generally taken from the vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com