Patents

Literature

45results about How to "Improve arc striking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

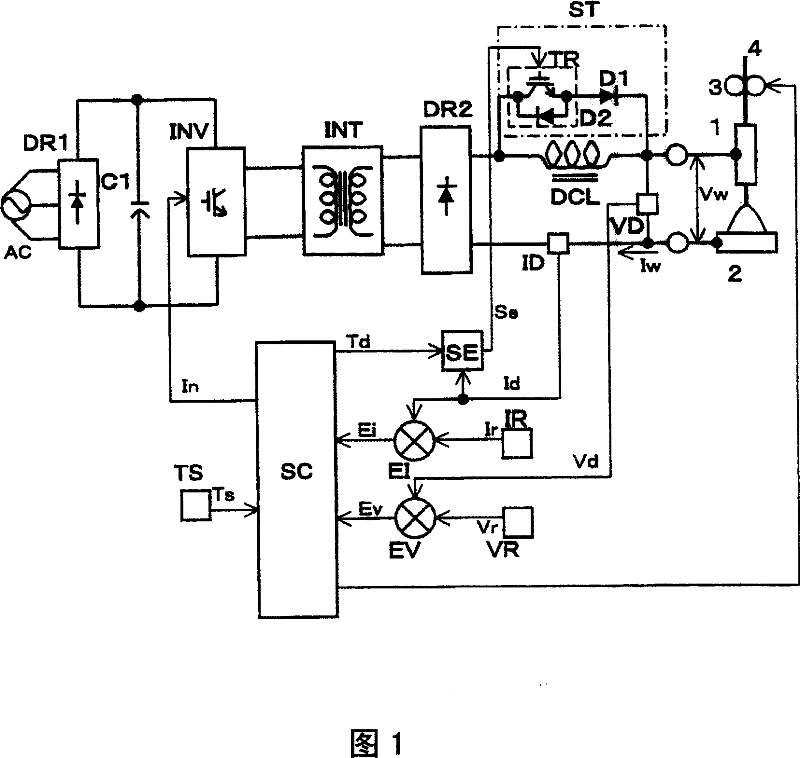

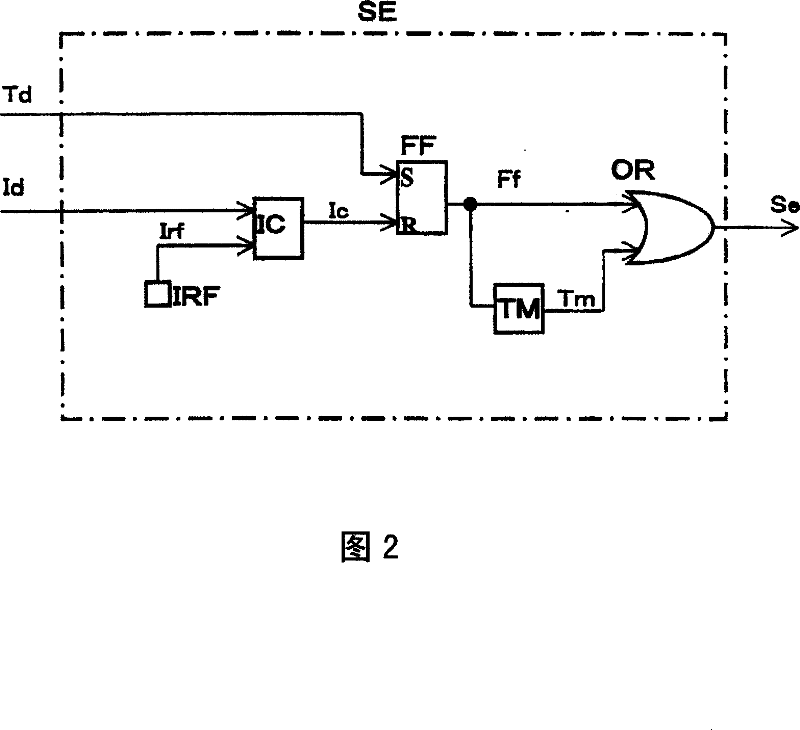

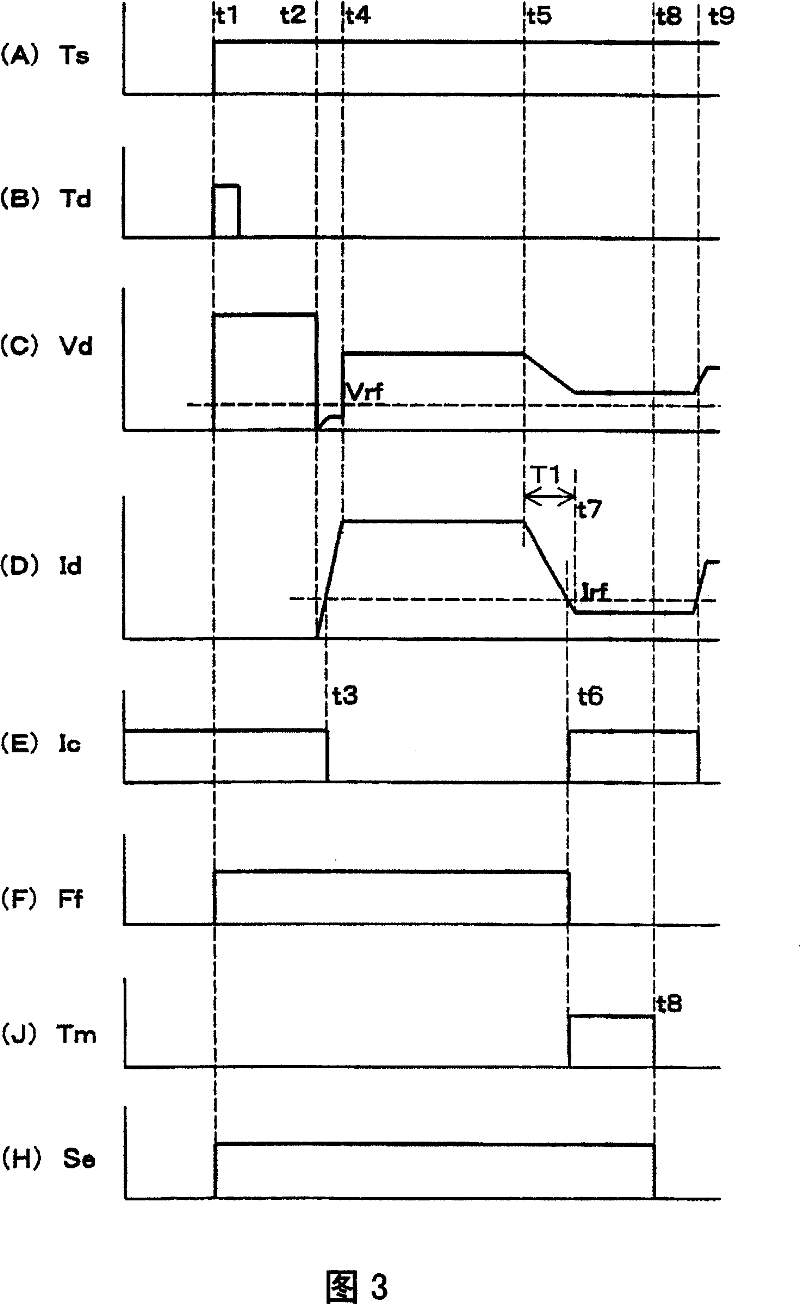

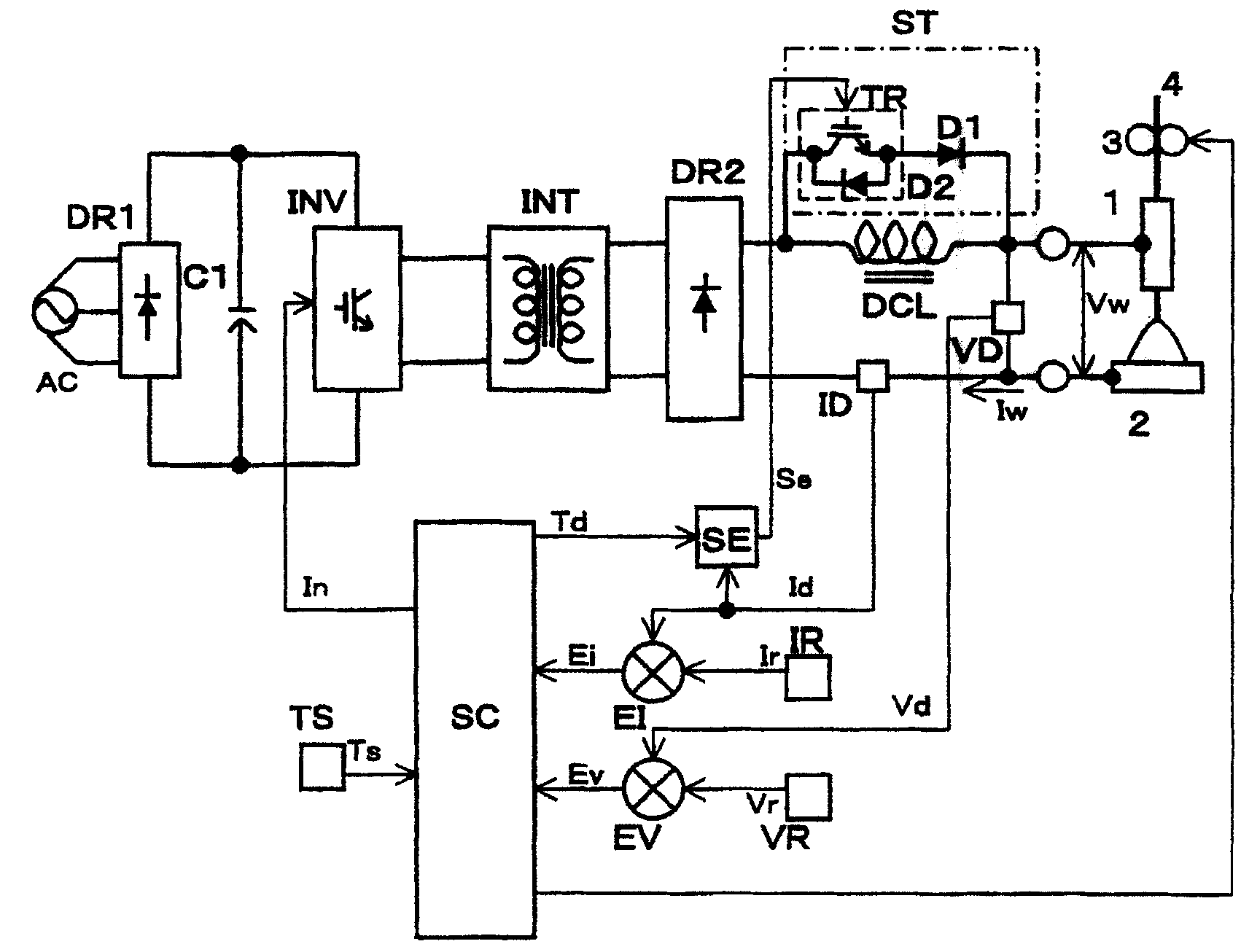

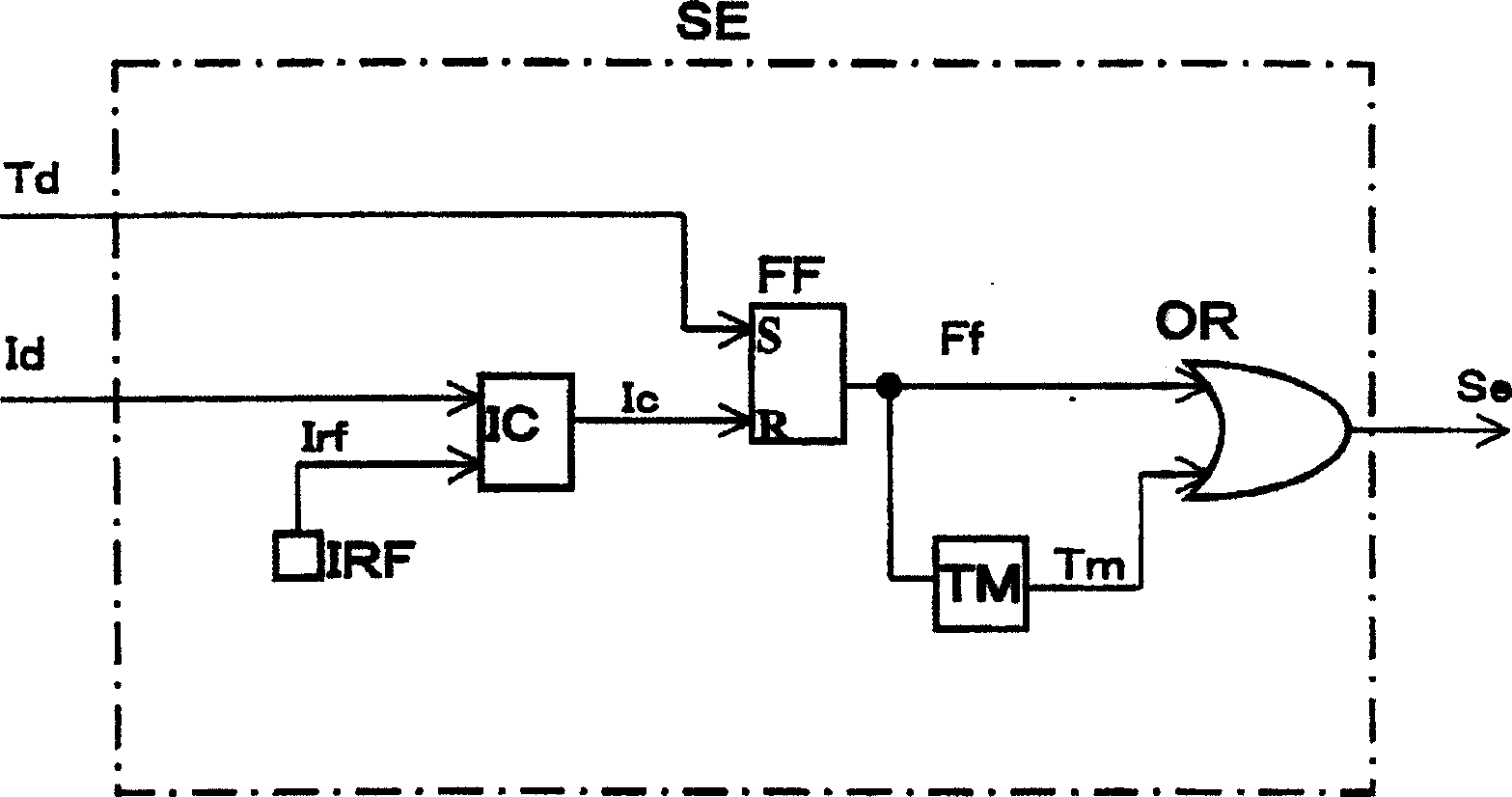

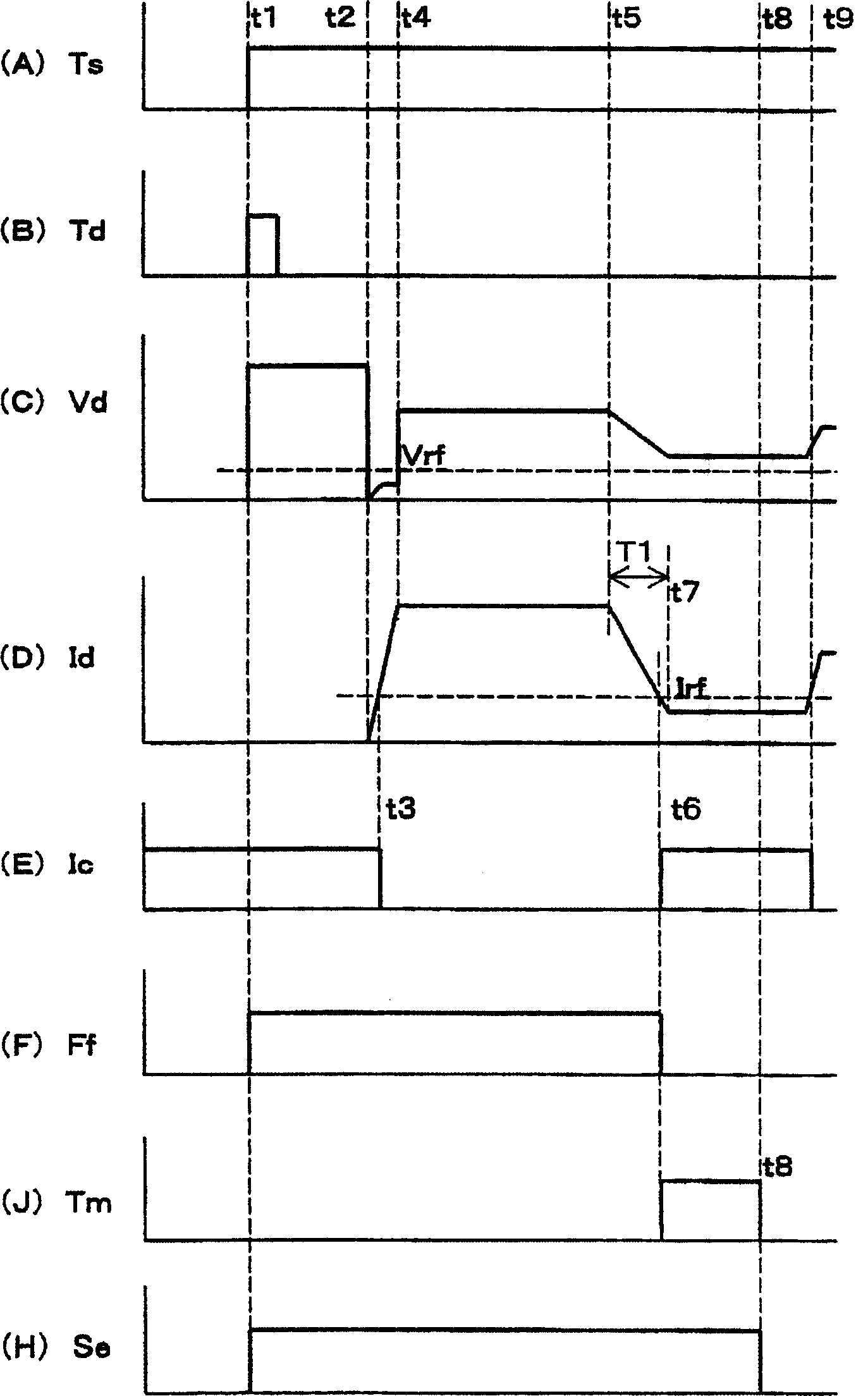

Arc start control method in consumable electrode arc welding

ActiveCN101204753AReduce contact resistance valueSuppresses instantaneous arcArc welding apparatusPower flowElectrical current

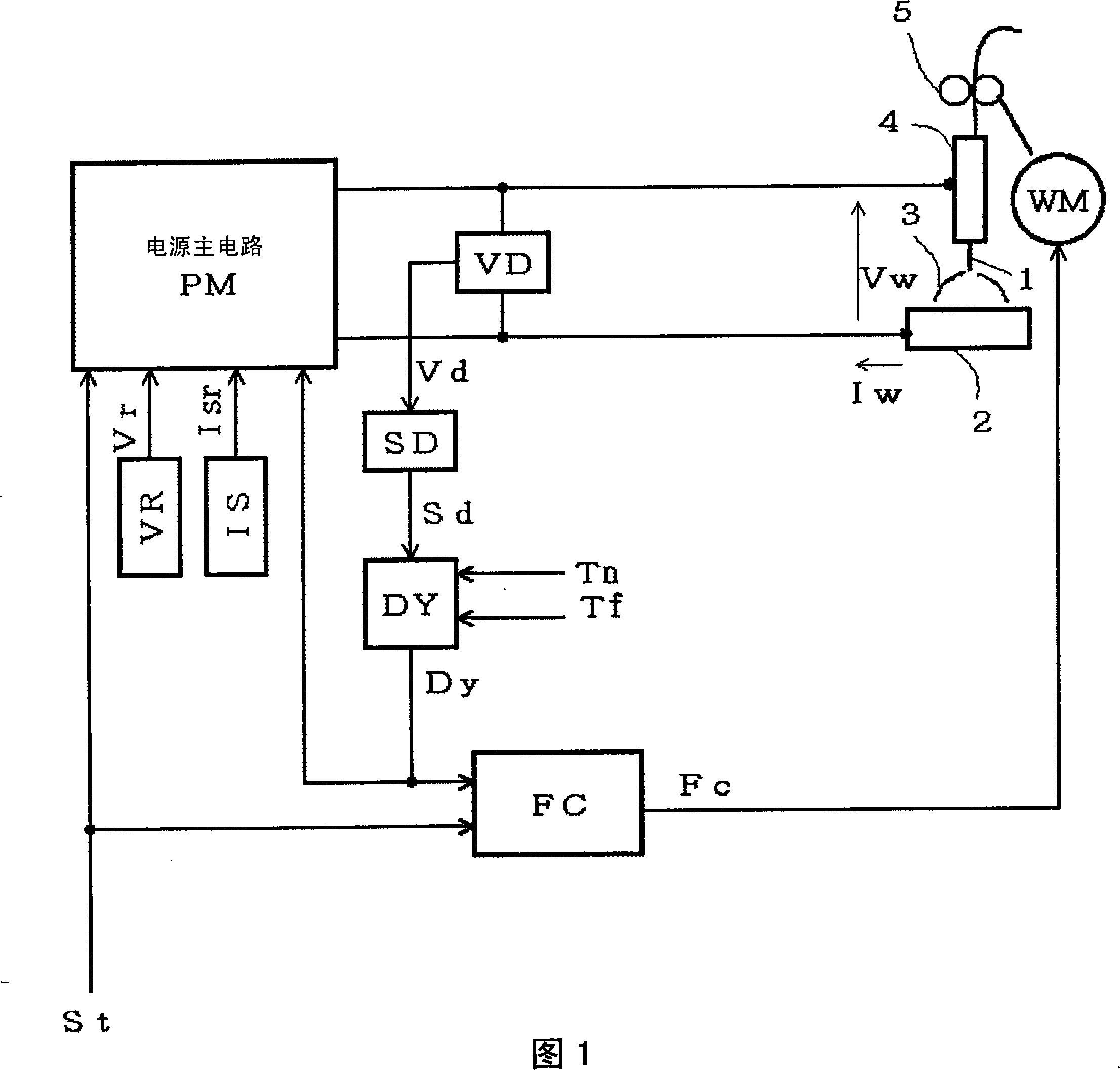

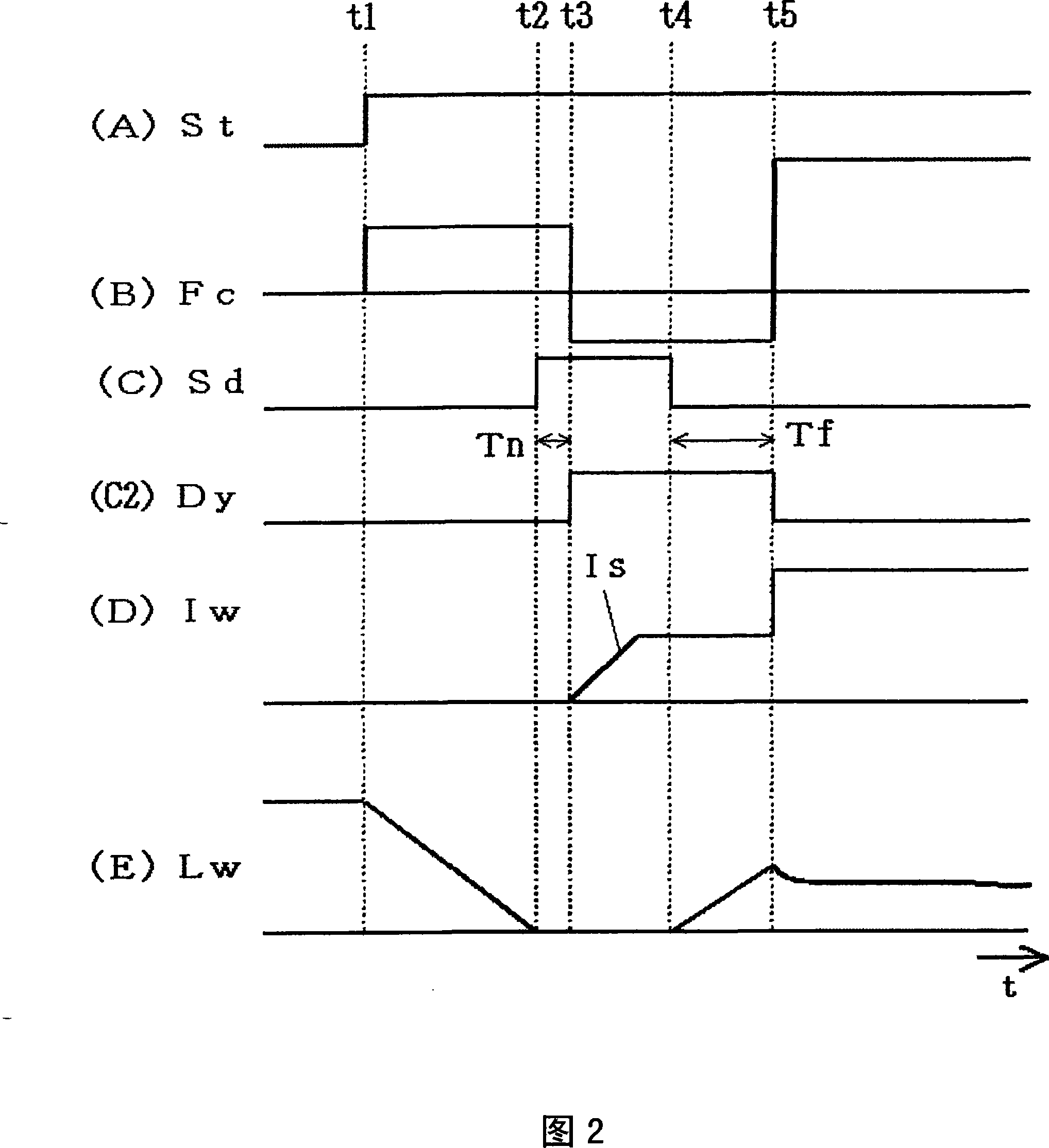

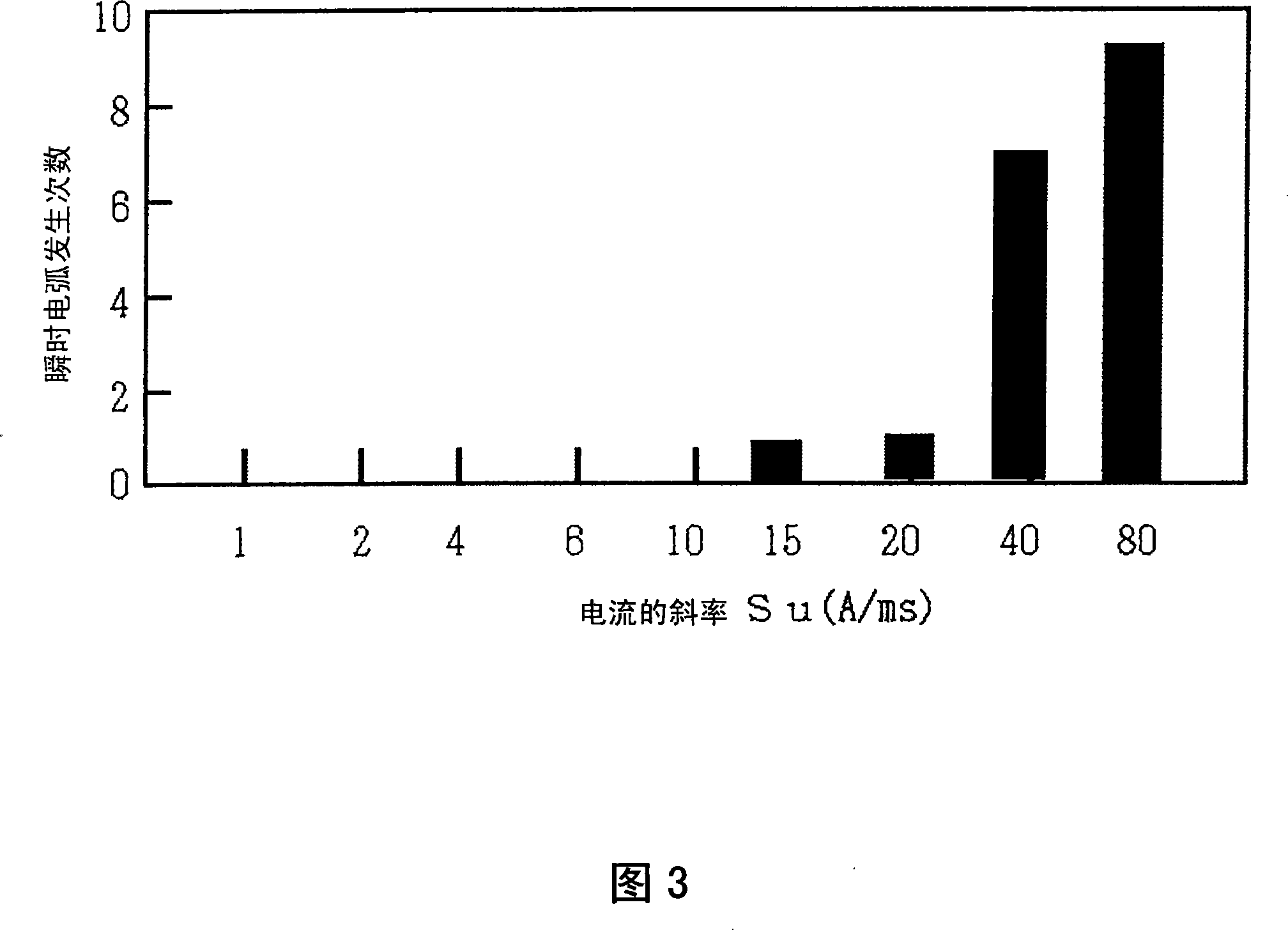

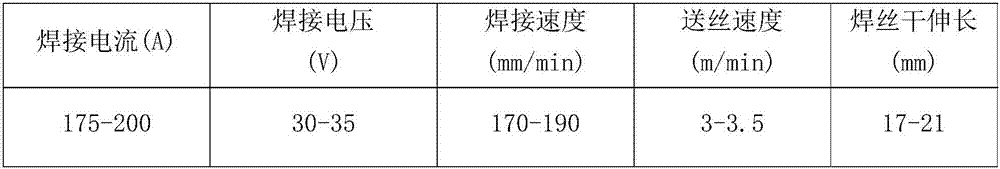

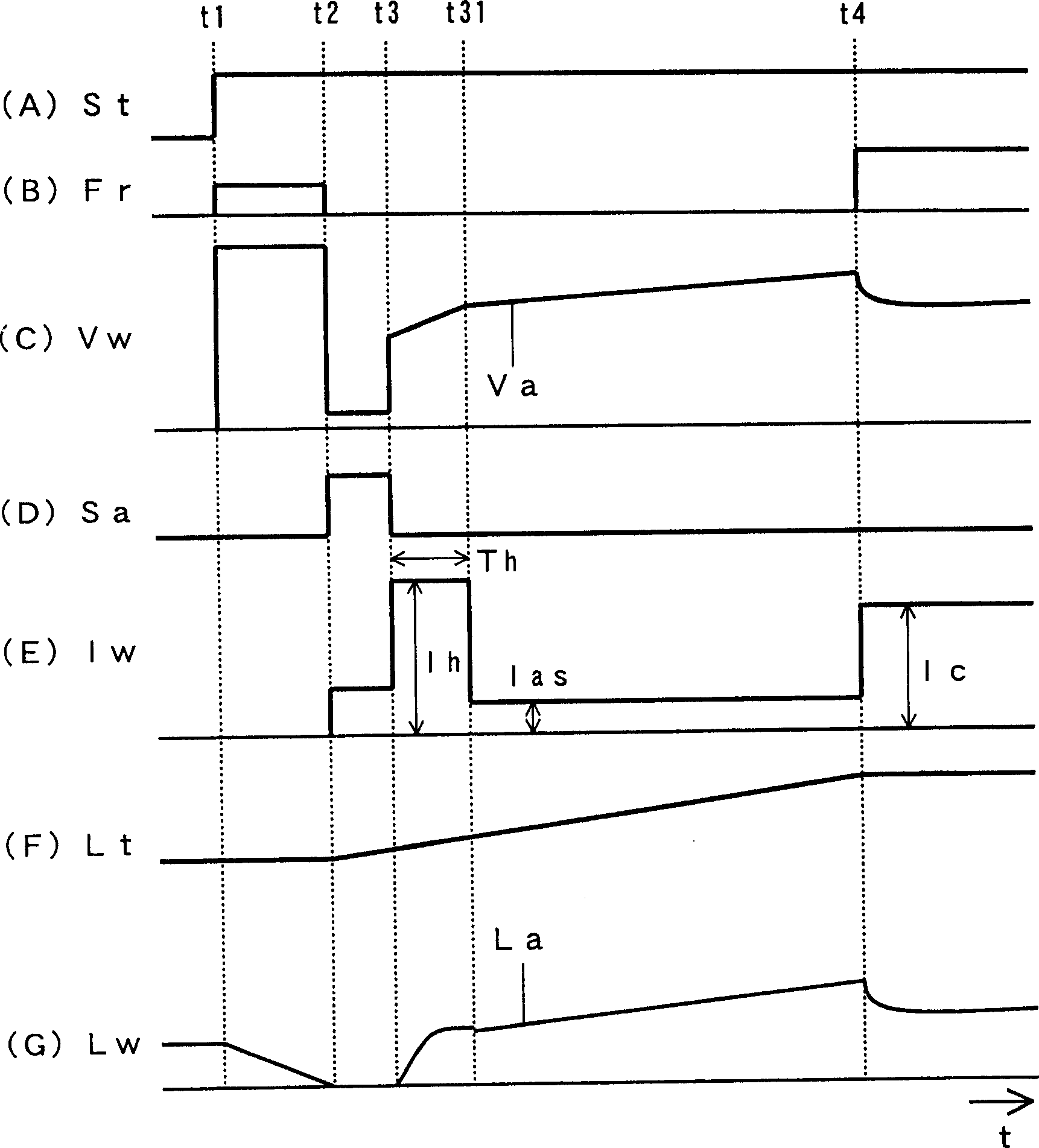

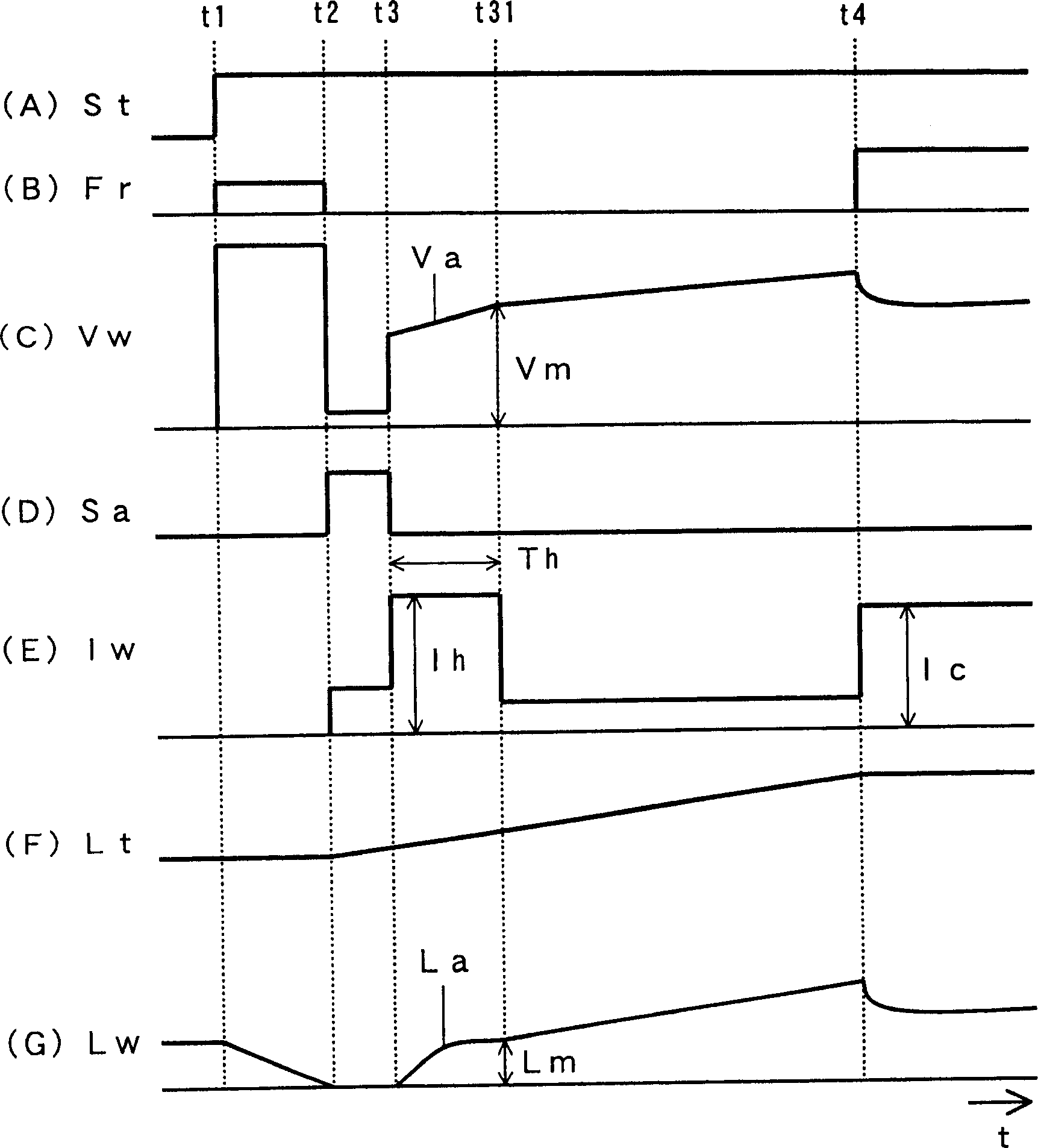

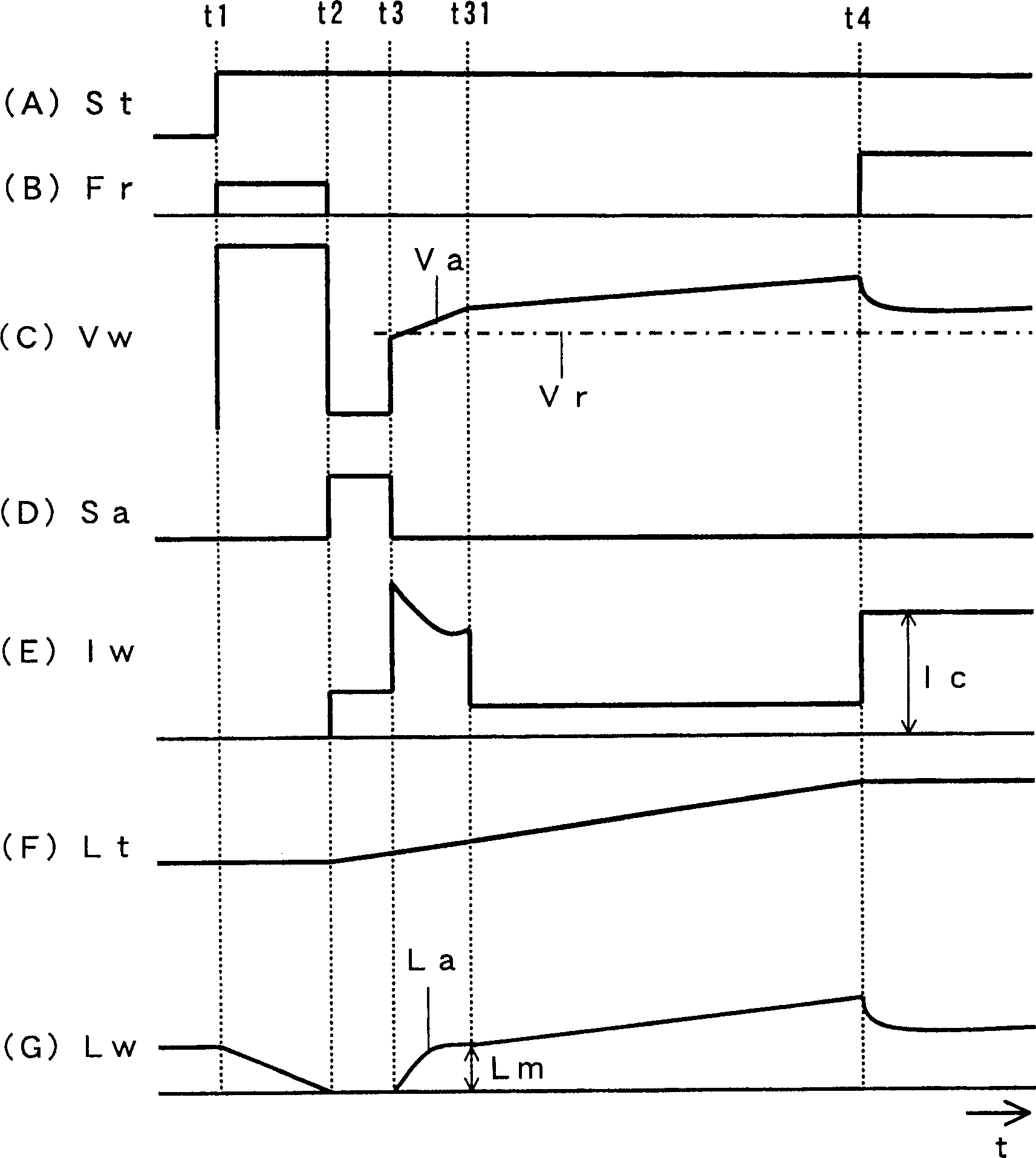

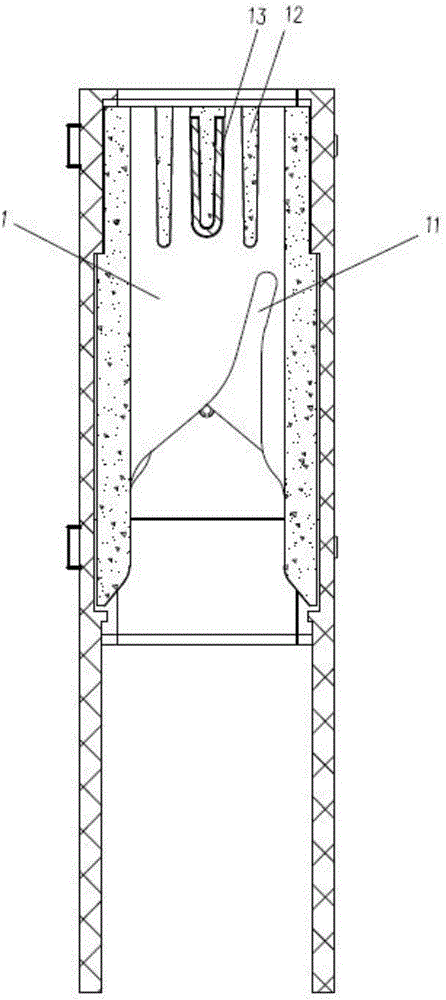

An arc start control method is provided for consumable electrode arc welding. According to this method, a welding wire (1), supplied through a welding torch (4), is brought into contact with a work (2) and an initial current is applied to the welding wire (1) (at time t2) and the work (2) that are held in contact with each other (at time t3). Then, an initial arc is generated by moving the welding wire (1) away from the work (2) with the application of the initial current maintained, and thereafter the initial arc is changed to a steady arc, wherein the initial current is increased gradually with a predetermined increase rate (at time t4). Thus when the welding starts, the welding wire (1) is temporarily contacted to the work (2) then separated from the same, in the contraction arc guide method generating arc to guide arc, arc guide badness on the work (20) to be welded coated by the welding wire (1) can be restrained.

Owner:DAIHEN CORP

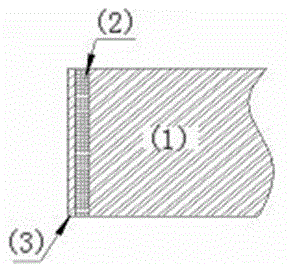

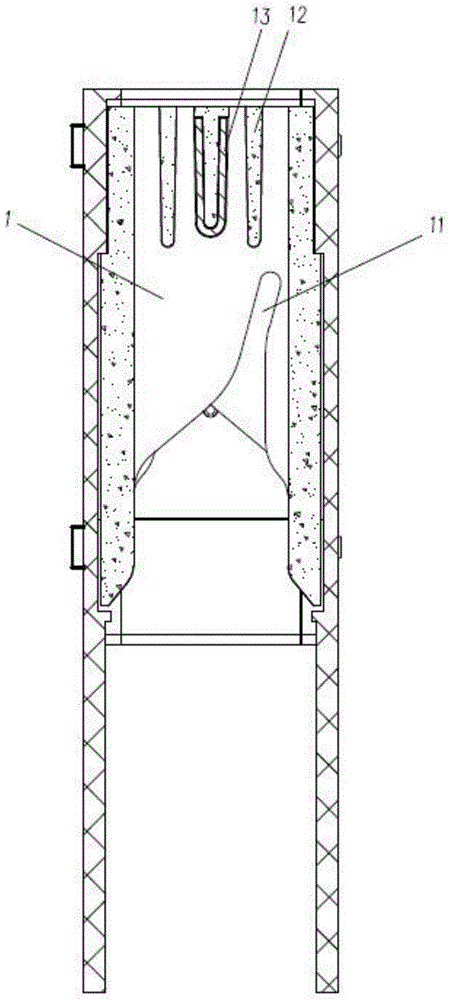

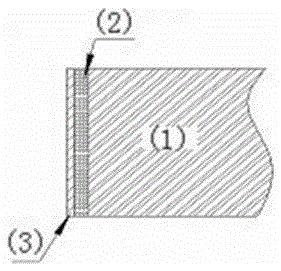

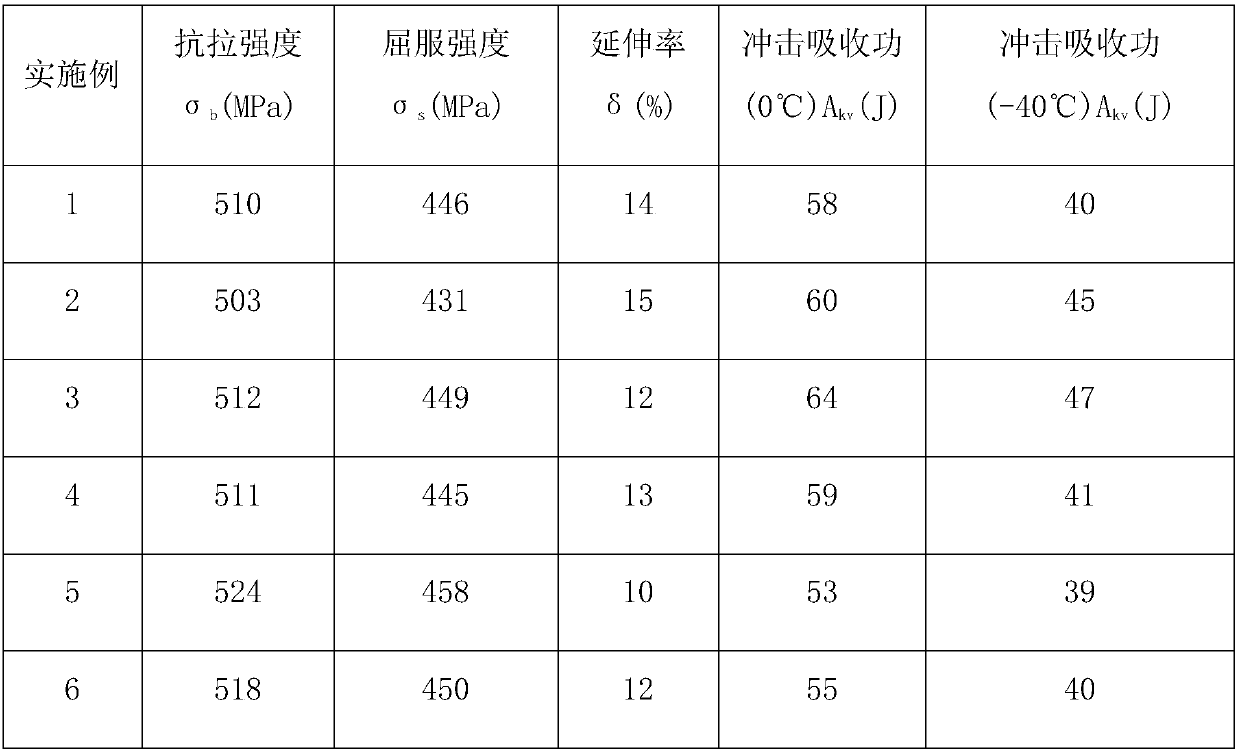

Self-protective flux-cored wire for all-position underwater wet welding in deep water environment

ActiveCN106964918AMeet weldingEasy arc startWelding/cutting media/materialsSoldering mediaSlagFilling rate

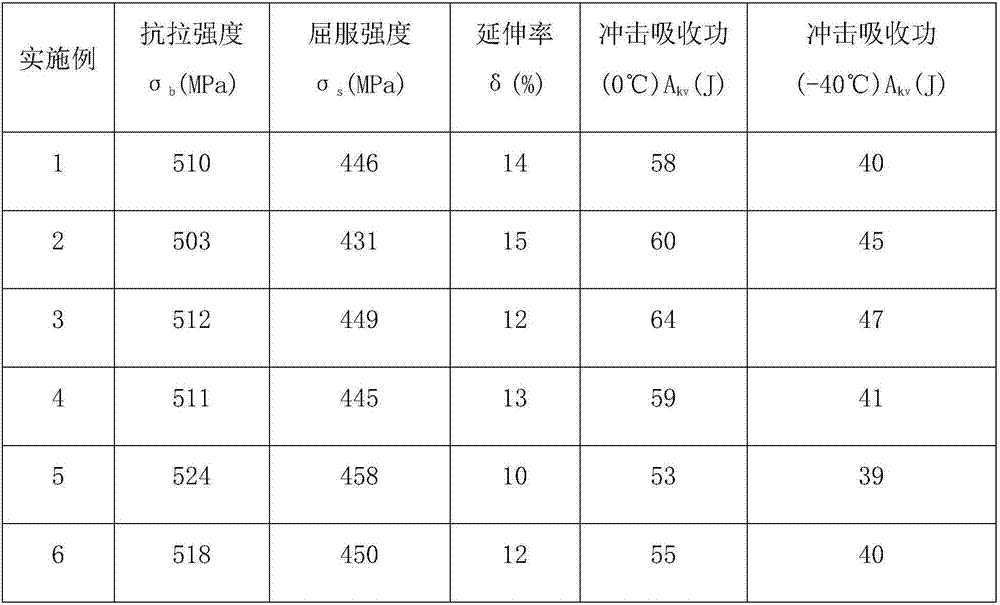

The invention belongs to the technical field of welding materials and discloses a self-protective flux-cored wire for all-position underwater wet welding in a deep water environment. The self-protective flux-cored wire comprises a metal skin and a flux core. The metal skin is formed by rolling an N6 nickel strip. The basic slag system of the flux core is an alkaline calcium fluoride-aluminum-magnesium slag system. The N6 nickel strip comprises, by weight, no smaller than 99.5% of Ni and Co in total, no larger than 0.06% of Cu, no larger than 0.10% of Fe, no larger than 0.05% of Mn, no larger than 0.10% of C, no larger than 0.10% of Si and no larger than 0.005% of S. The flux core comprises, by mass, 52-67% of fluoride, 14-20% of aluminum-magnesium alloy powder, 5-10% of calcium carbonate, 5-15% of ferromanganese, 3-10% of chromium, 4-10% of titanium and 1.5-5% of rare earth. The filling rate of the flux core in the flux-core wire is 24-32%. According to the scheme provided by the invention, the self-protective flux-cored wire can be used for welding under water by 100-200 meters, arcing is easy during welding, arc burning is stable, no arc blowout or breaking phenomenon occurs, an obtained welding seam is attractive in forming, the tensible strength of deposited metal after welding is larger than 500 MPa, and the self-protective flux-cored wire has good impact toughness and meets the all-position welding requirements of medium and low carbon steel and low alloy high strength steel in the deepwater environment.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

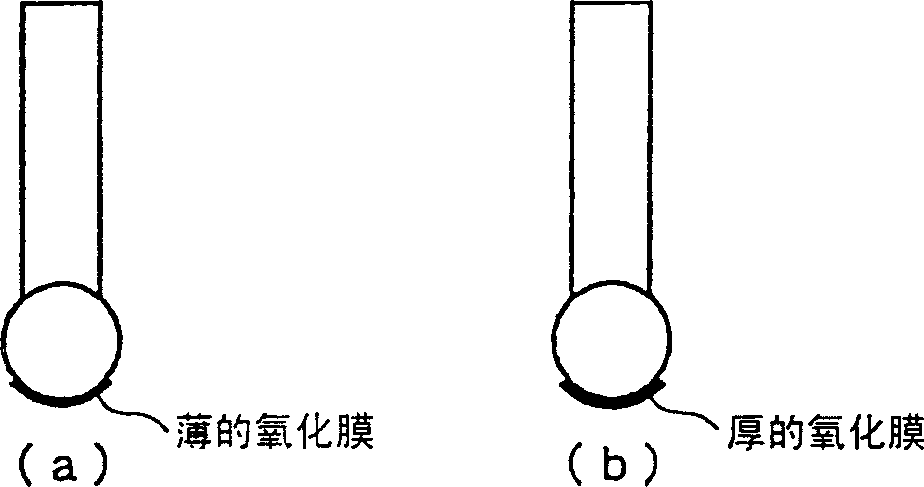

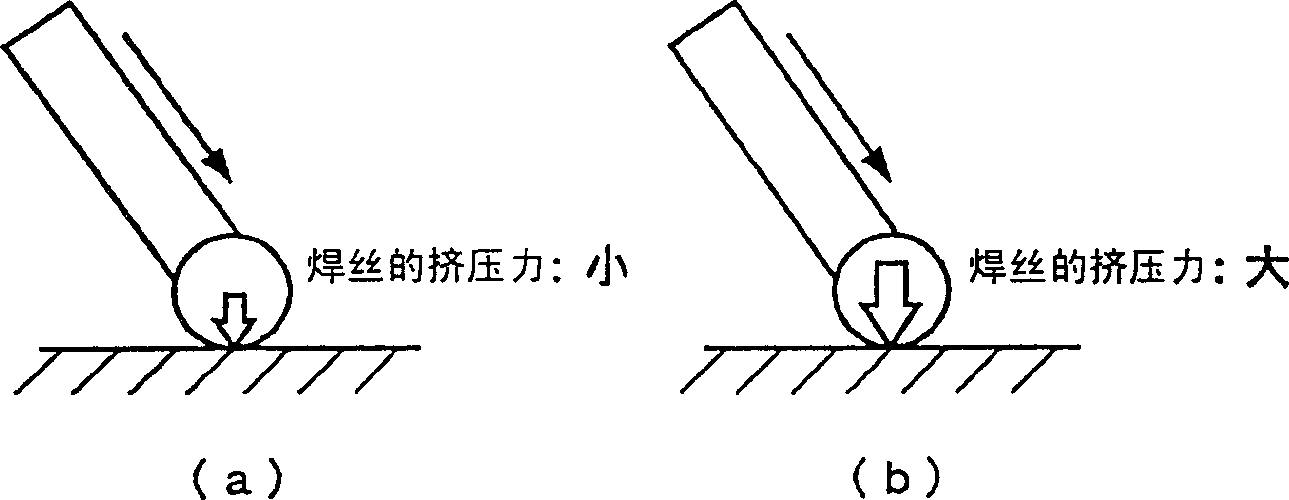

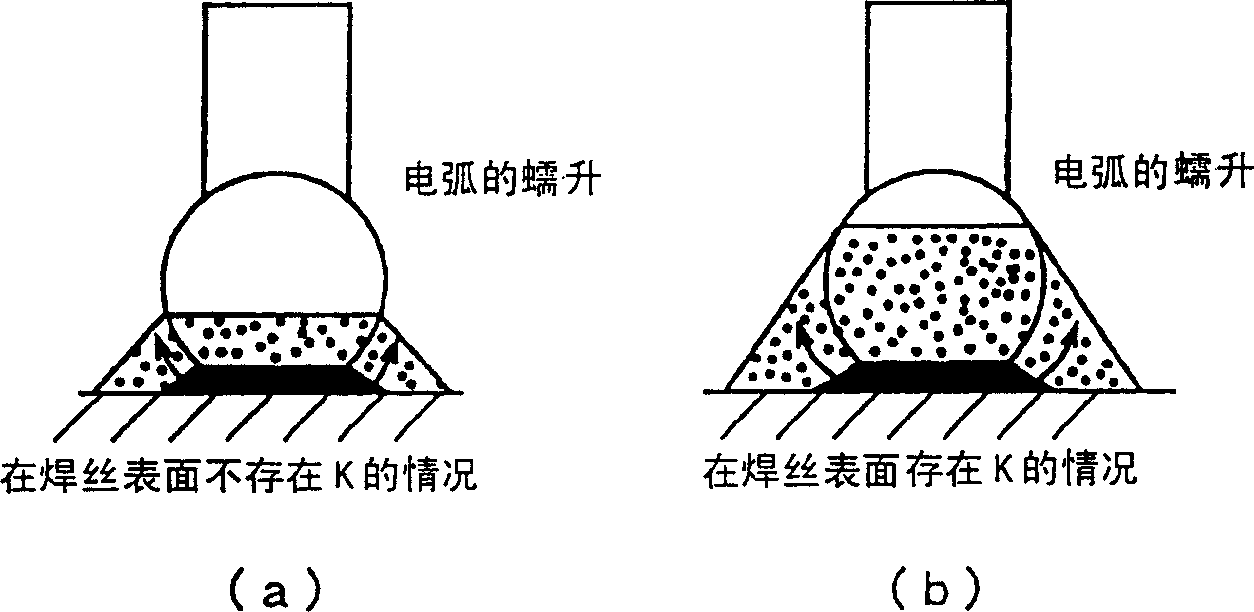

Solid welding wire for unplating welding use

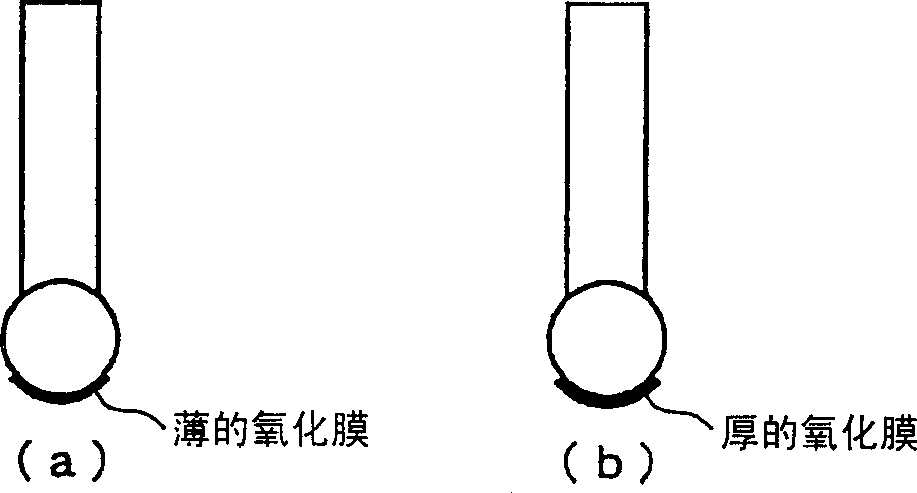

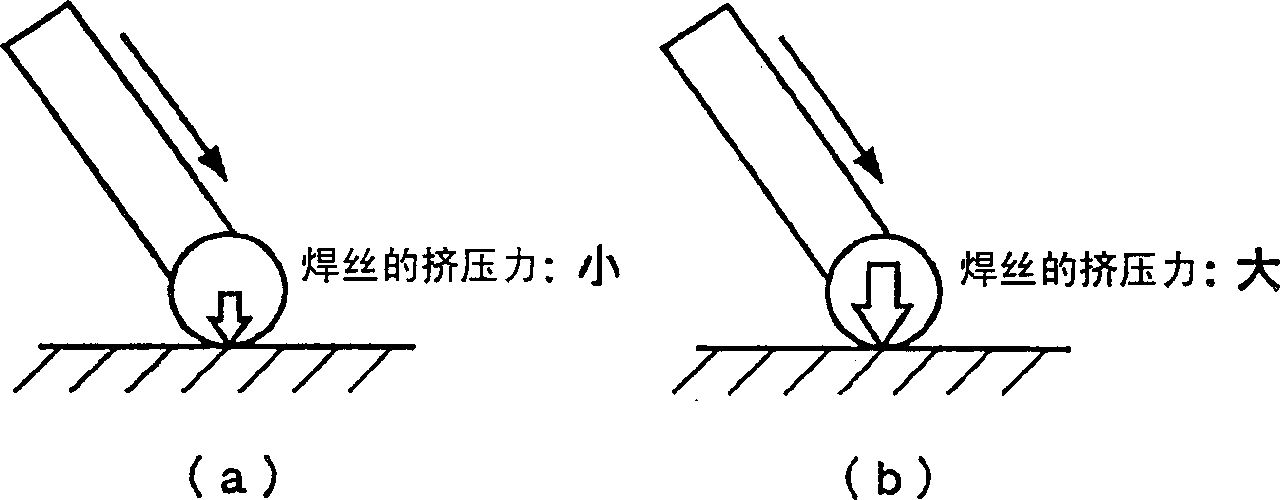

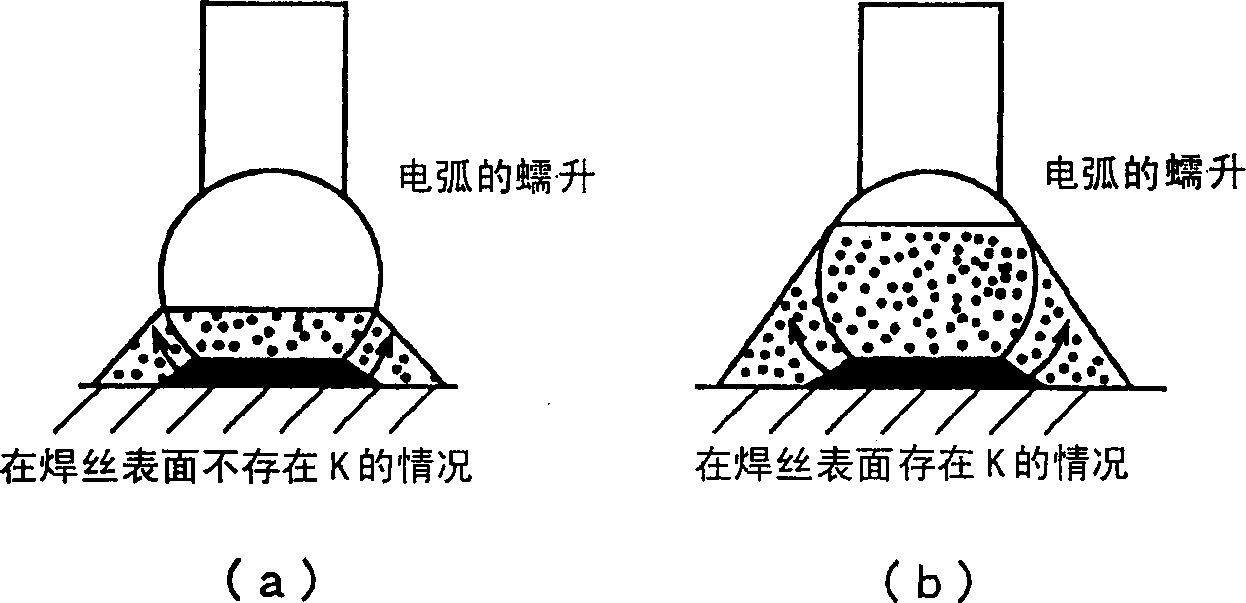

InactiveCN1453096AImprove arc striking effectWelding/cutting media/materialsSoldering mediaPotassiumCopper

A plating-free solid wire for welding of the present invention contains C: 0.04 to 0.12 mass%. Si: 0.5 to 1.1 mass%, Mn: 1.0 to 1.7 mass%, Ti: not more than 0.03 mass%, and remainder Fe. In addition, the expression: Si + Mn + ( 10 x Ti) ≤ 2.5 is satisfied, where Si, Mn, and Ti denote the contents of respective elements in the wire. The tensile strength of the wire is 900 to 1300 (N / mm2). A potassium compound is present in an amount of 2 to 10 ppm in terms of potassium; MoS2, 0.01 to 0.5 g per 10 kg of the wire; and an oil containing polyisobutene, 0.3 to 1.5 g per 10 kg of the wire, on the surface and / or immediately under the surface of the non-plated wire. With such a constitution, it is possible to improve both the wire feedability and the arc start characteristics.

Owner:KOBE STEEL LTD

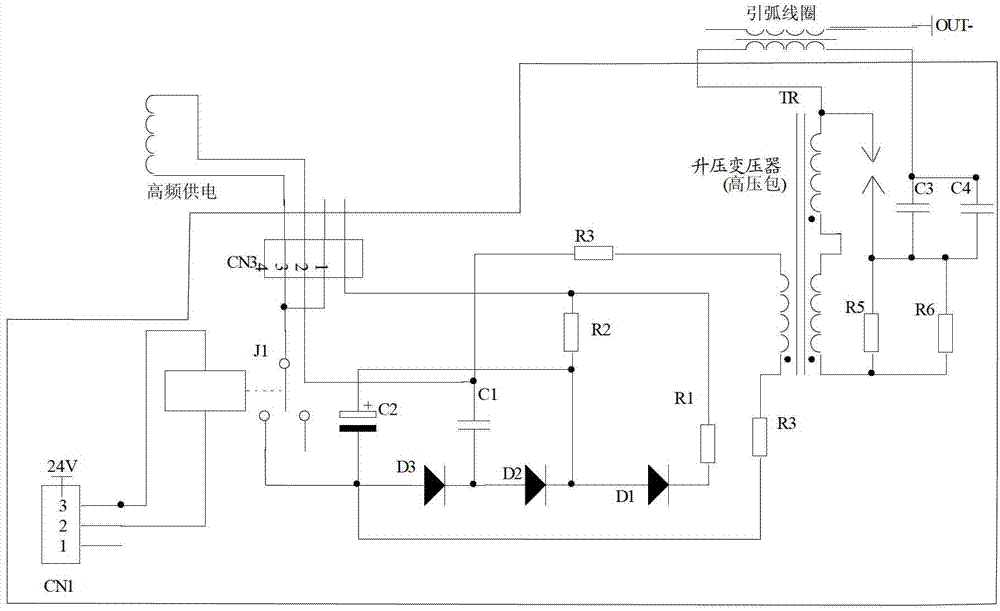

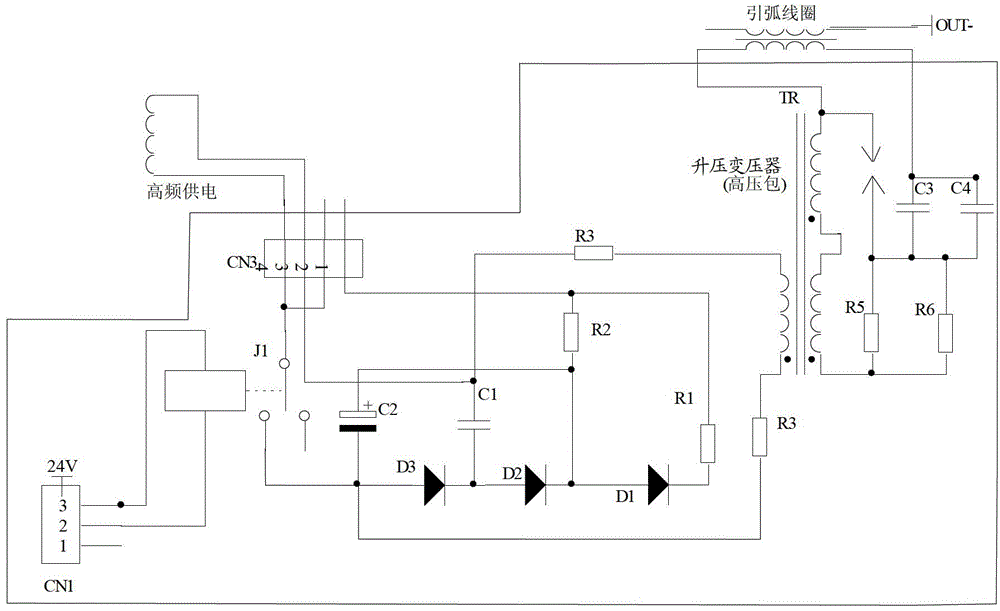

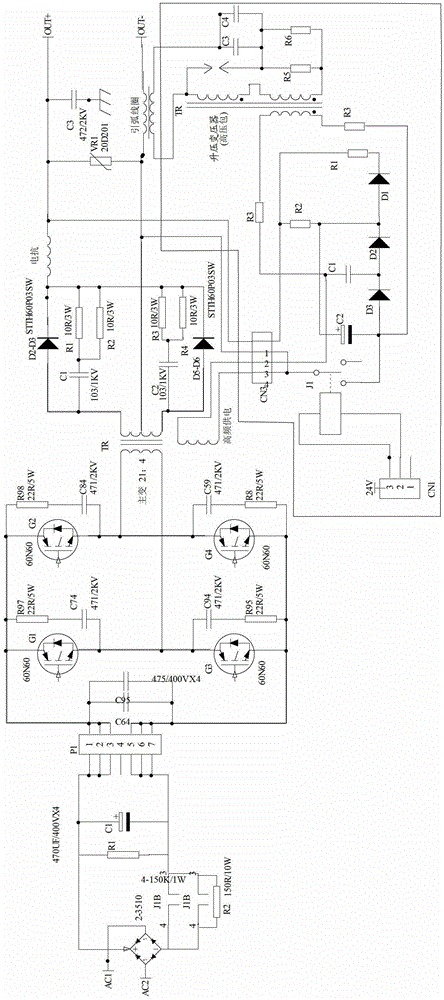

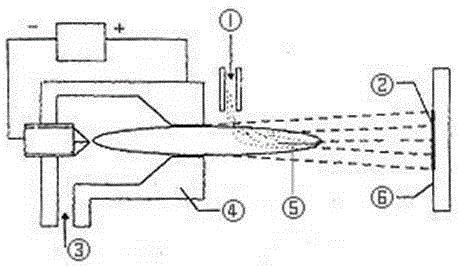

High frequency arc ignition circuit with direct current voltage output

InactiveCN103111719AEasy breakdownIncrease success rateArc welding apparatusEngineeringHigh pressure

The invention relates to a high frequency arc ignition circuit with direct current voltage output. The high frequency arc ignition circuit with direct current voltage output comprises a high frequency signal source, a relay, a high frequency voltage booster circuit and a voltage doubling circuit. The high frequency signal source is respectively connected with the input end of the voltage doubling circuit and the input end of the high frequency voltage booster circuit through the relay. The output end of the voltage doubling circuit outputs direct current voltage to secondary positive and negative electrodes of a welding machine main circuit. The high frequency voltage booster circuit produces high frequency high voltage signals and the high frequency high voltage signals are coupled to the secondary negative electrode of the welding machine main circuit and outputted. With the aid of the voltage doubling circuit, the direct current voltage is added to the high frequency arc ignition circuit with direct current voltage output on the condition of high frequency arc starter, air can be punctured more easily at the time of high frequency arc starter, arcing is easier, and success rate of arcing and arcing performance of the welding machine can be improved.

Owner:广东世博科焊接工程技术有限公司

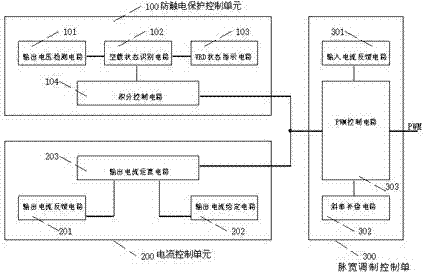

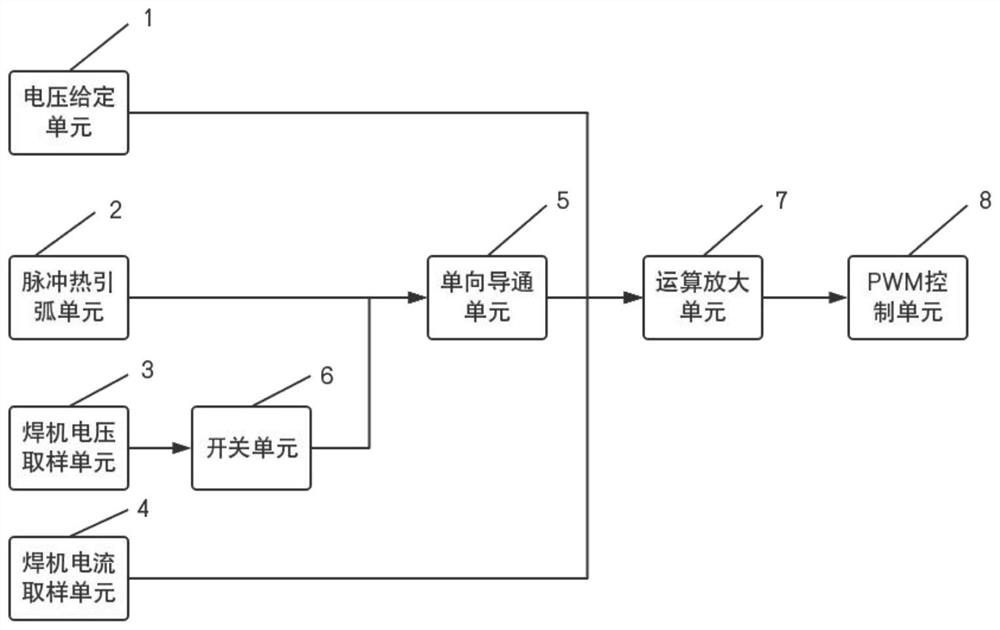

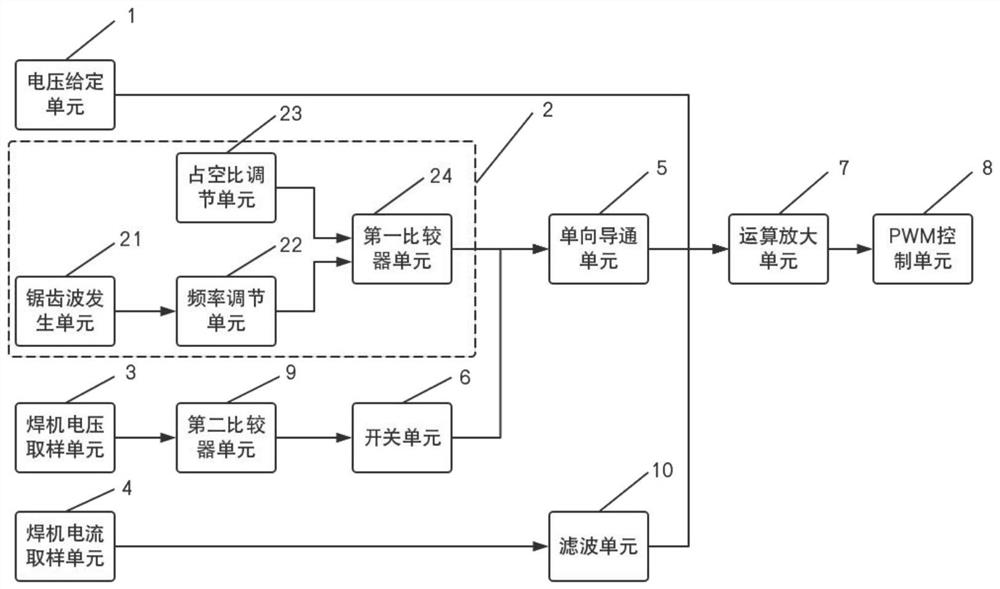

Electric shock protection device for electric welding machine

ActiveCN102416519AEliminate the risk of electric shock accidentsGood arc striking effectArc welding apparatusControl signalControl circuit

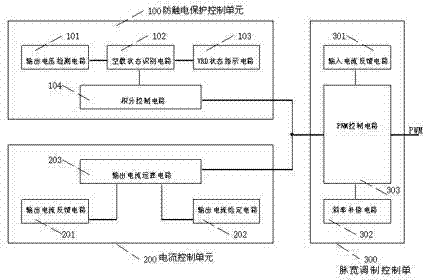

The invention discloses an electric shock protection device for an electric welding machine. The device comprises a pulse width modulation control unit, and an electric shock protection control unit and a current control unit which are in circuit connection with the input end of the pulse width modulation control unit, wherein the electric shock protection control unit comprises an integral control circuit in circuit connection with the input end of the pulse width modulation control unit, an unloaded state identification circuit in circuit connection with the input end of the integral control circuit, an output voltage detection circuit in circuit connection with the input end of the unloaded state identification circuit, and an electric shock protection state indication circuit in circuit connection with the output end of the unloaded state identification circuit. The electric shock protection control unit detects output voltage, the current control unit detects output current, a voltage control signal and a current control signal are output to the pulse width modulation control unit, and the pulse width modulation control unit outputs direct-current pulse with a linearly adjustable duty cycle to drive an inversion switch main circuit, so that the hidden danger of human body electric shock accidents can be reliably eliminated, and a good arc striking effect is ensured.

Owner:SHANGHAI GREATWAY WELDING EQUIP

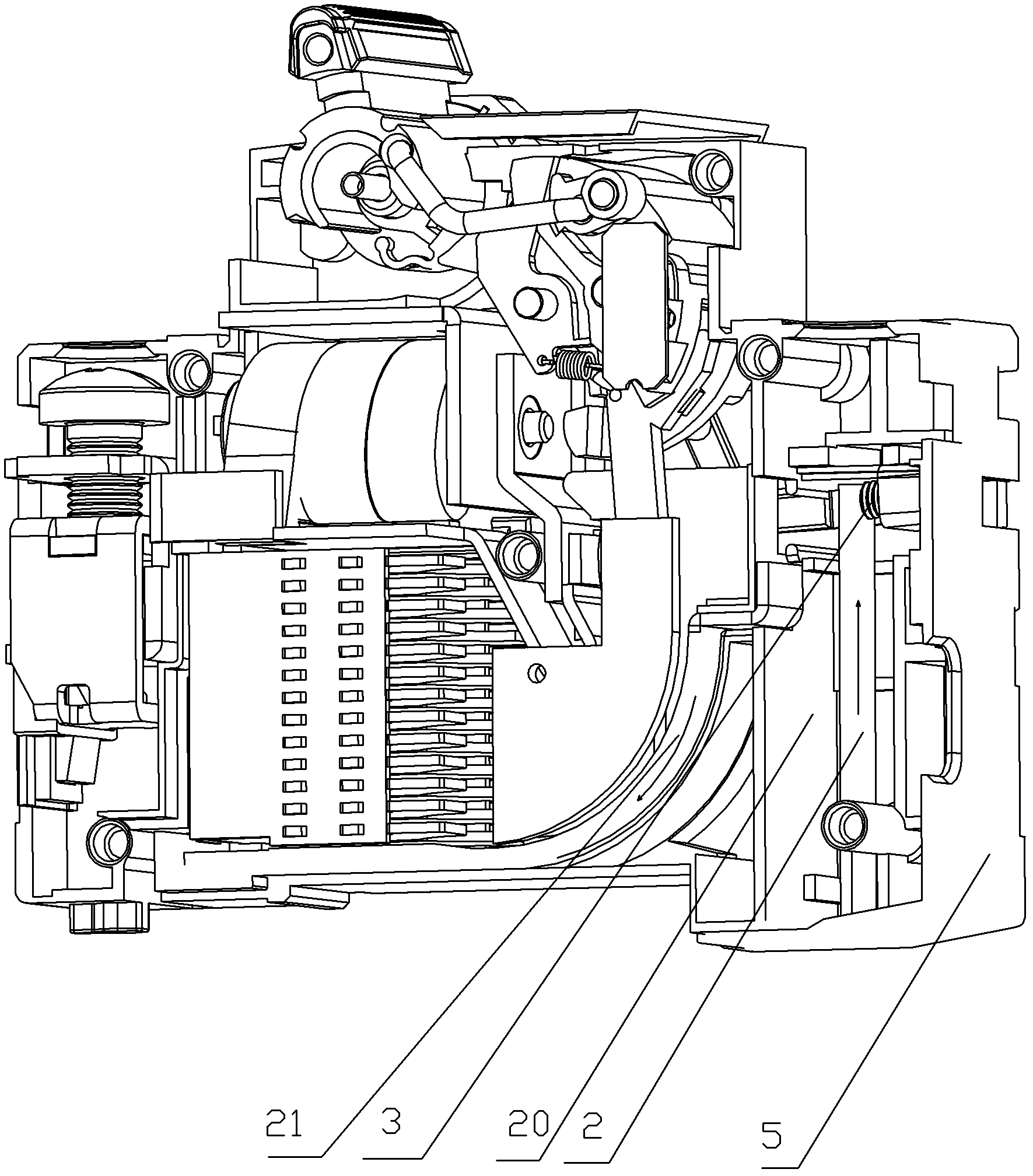

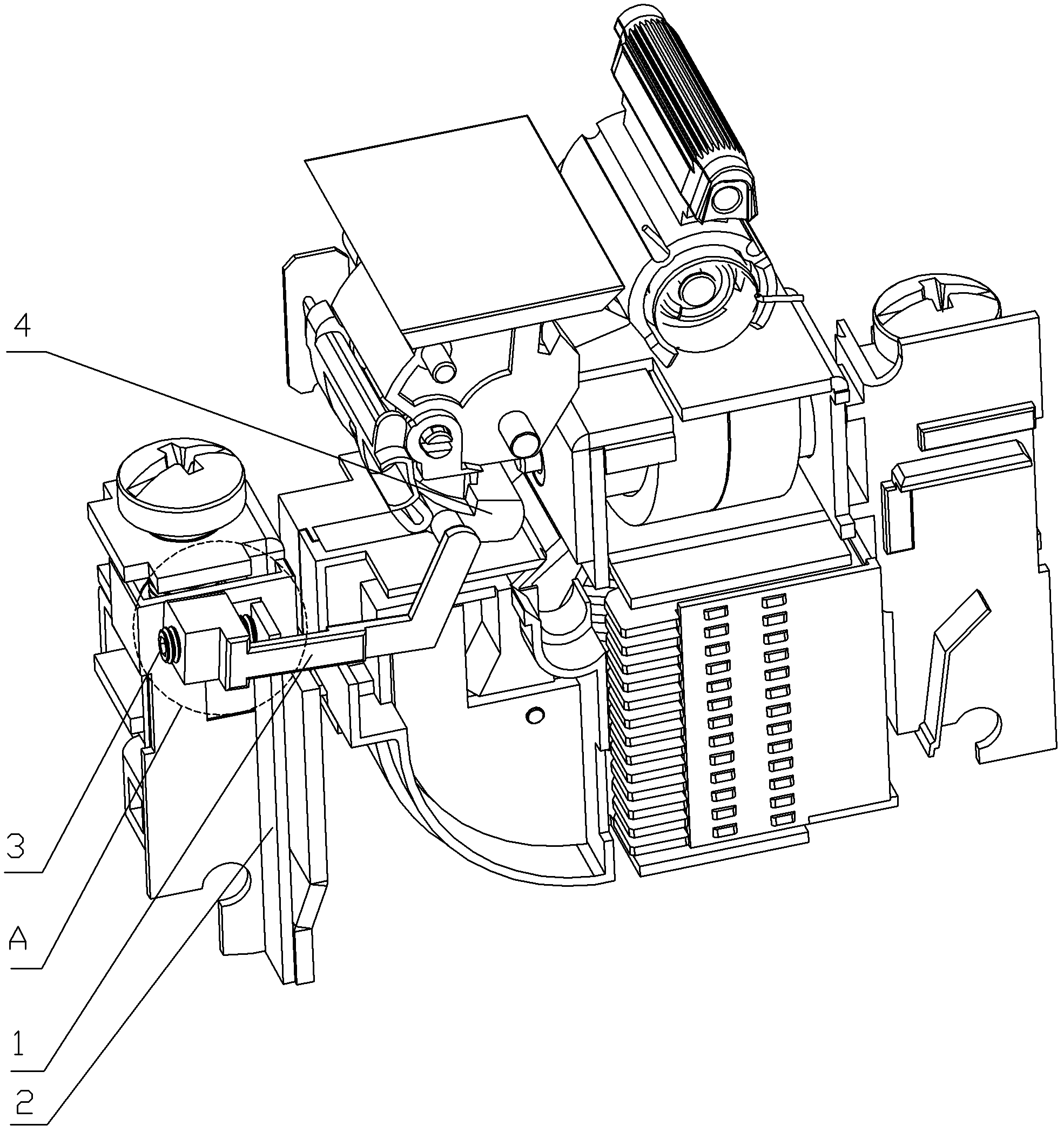

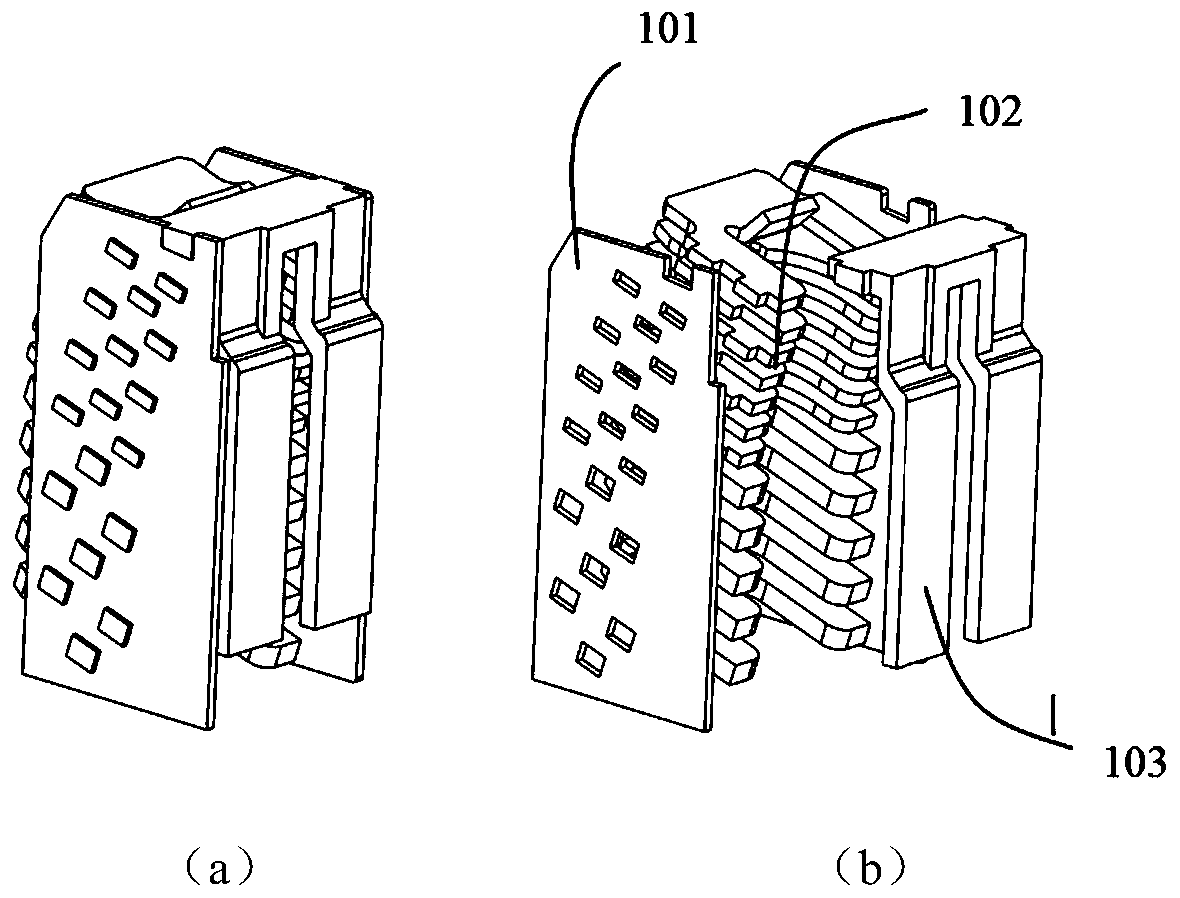

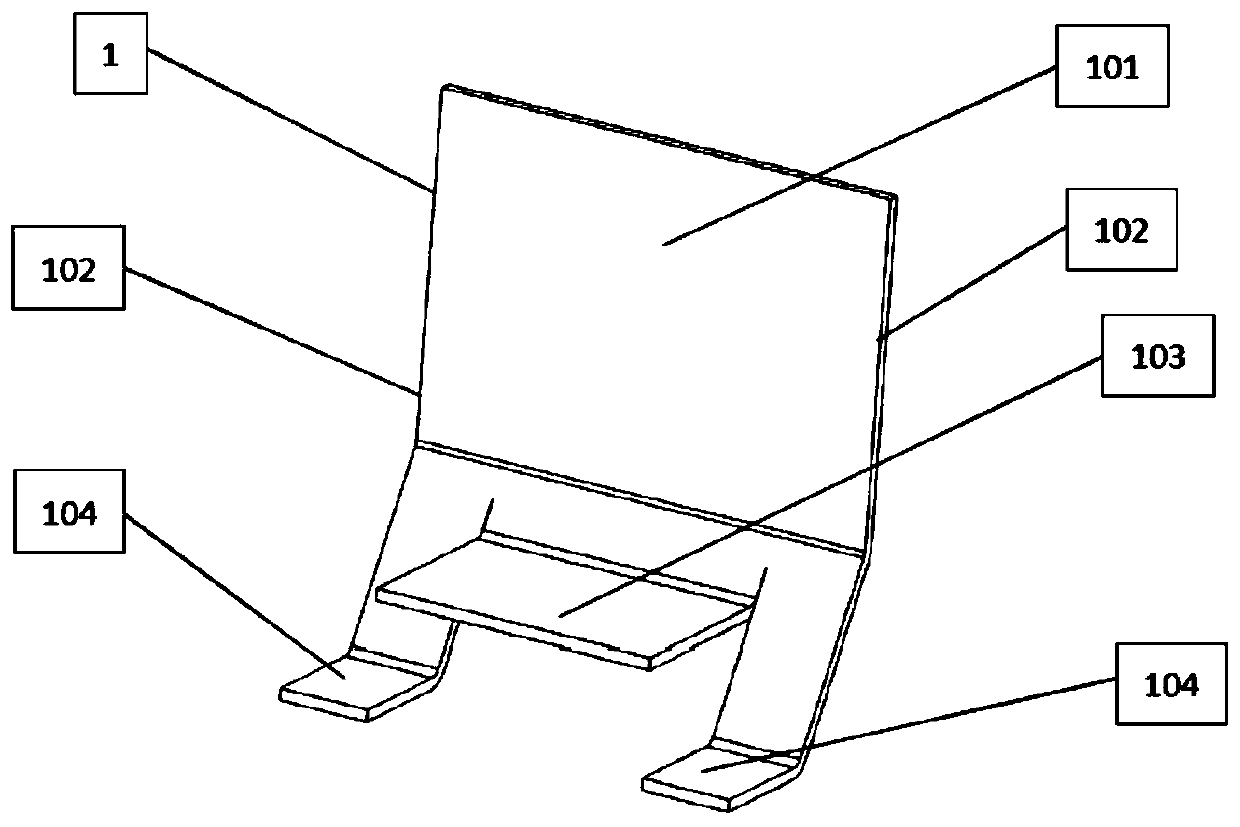

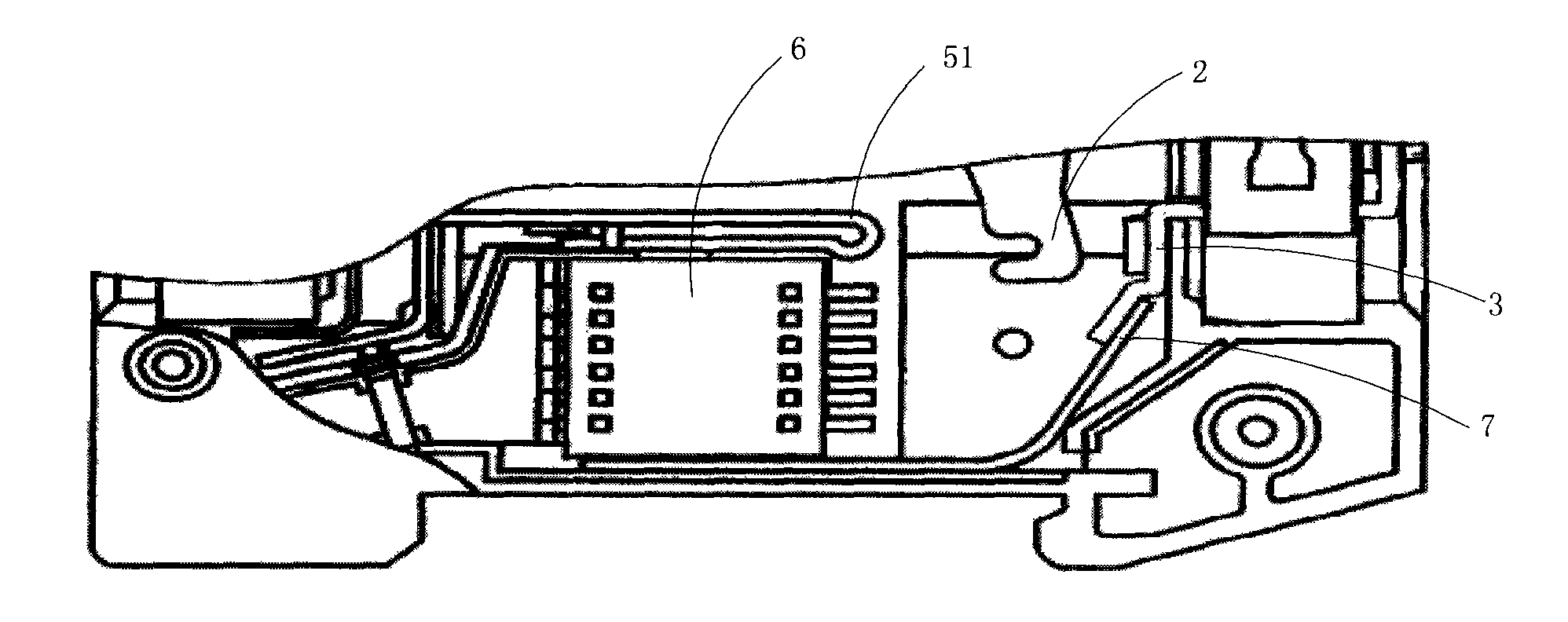

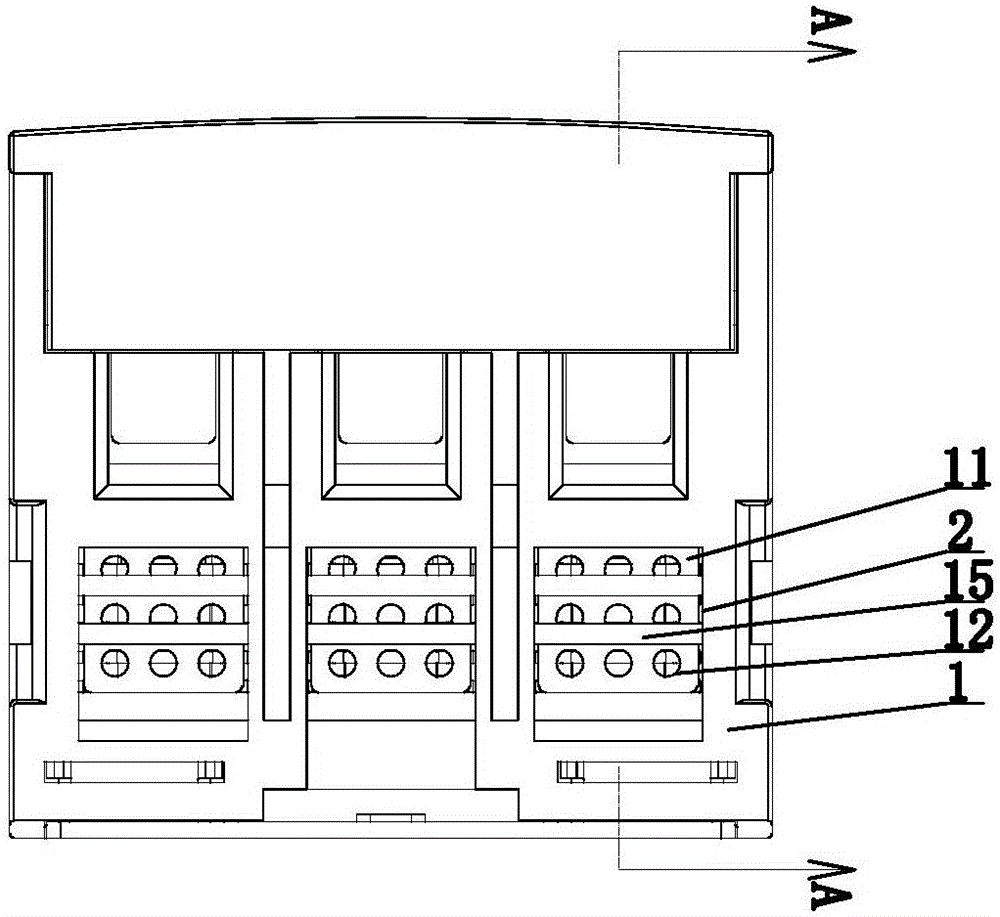

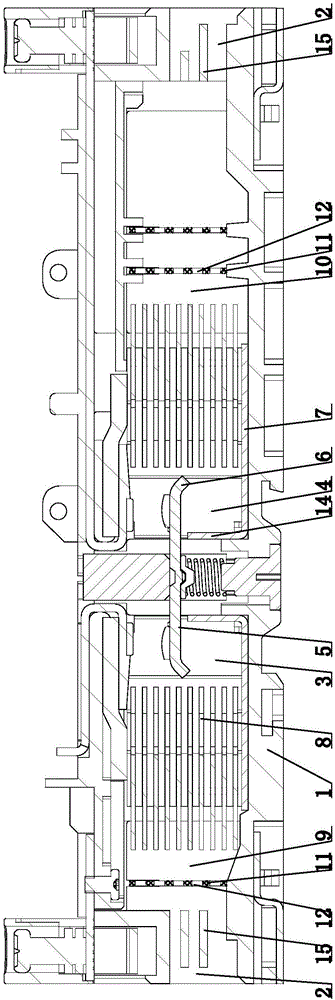

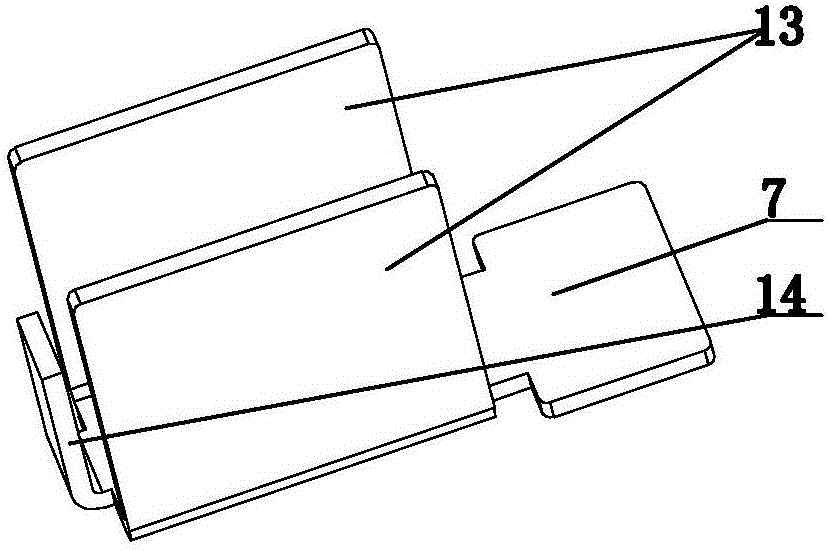

Electromagnetic device of breaker

InactiveCN103681143AEasy to disassembleEasy to replaceProtective switch operating/release mechanismsCircuit breakerMagnet

The invention relates to an electromagnetic device of a breaker, belonging to the technical field of breakers. The electromagnetic device is mounted in a breaker housing, and comprises a magnet yoke, wherein three sides of the magnet yoke are surrounded, an extension portion through which a coil skeleton is fixed is arranged at one end of the magnet yoke, a gap which is clamped with a static contact rod is arranged at the other end of the magnet yoke, and the static contact rod is equipped with a contact; the static contact rod is U-shaped and comprises a rhombic tail portion; and the integrated static contact rod is also equipped with a clamping portion whose shape corresponds to the shape of the gap of the magnet yoke, and the magnet yoke is equipped with positioning clamp pins. According to the invention, the magnet yoke whose three sides are surrounded can position and fix the coil skeleton, so that the coil skeleton can be conveniently dismounted, a spring of an iron core can be conveniently replaced, and an push rod in the iron core does not fall off; the rhombic tail portion of the static contact rod greatly improves the arc ignition effect, shortens the arc stagnation time, and enables arcs to enter an explosion chamber; and the magnetic yoke is clamped with the static iron core to improve the working efficiency.

Owner:CNC ELECTRIC GRP

Arc start control method in robot welding

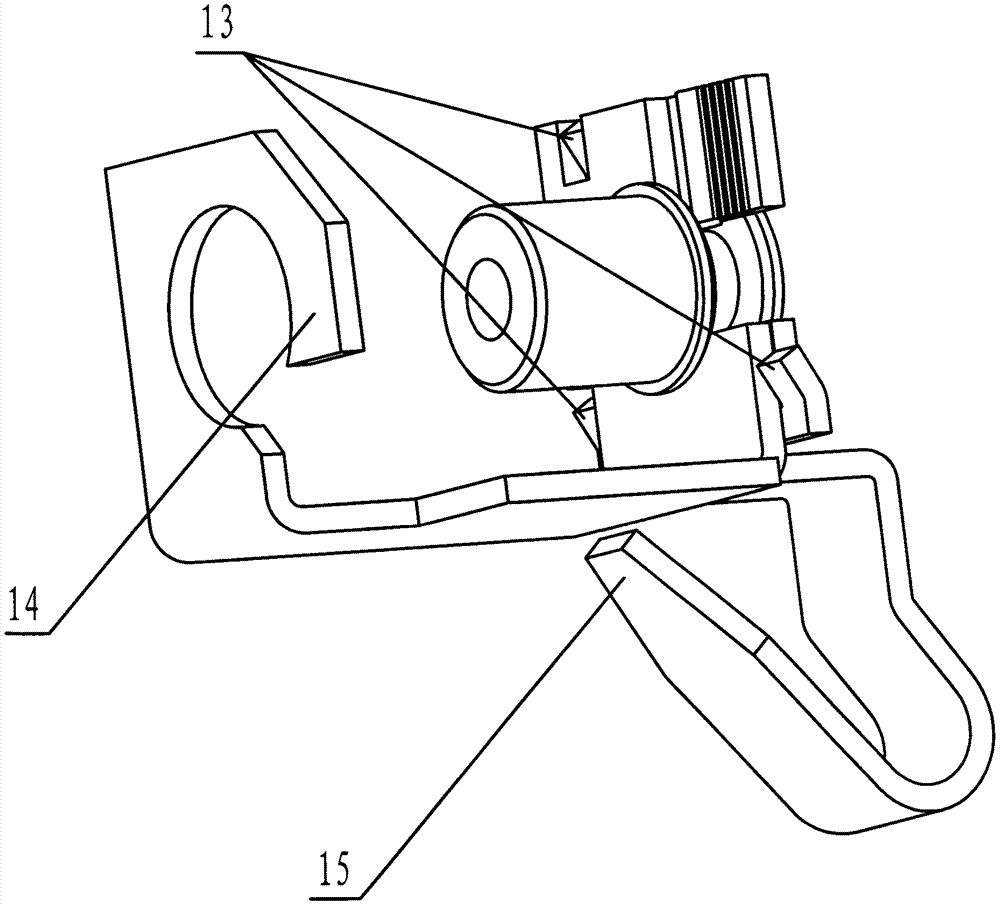

An arc start control method in robot welding includes the steps of shorting a welding wire with a base metal, retracting a welding torch by a welding robot (RM) for taking the welding wire off the base metal to generate an initial arc, retracting the welding torch to a predetermined position with maintaining the initial arc maintained while applying an initial arc current smaller than a steady welding current during an initial arc period, and starting to feed the welding wire steadily and to supply the steady welding current so as to make a transition from the initial arc to a steady arc as well as starting to move the welding torch along a welding line. During a re-shorting prevention period which starts from a beginning of the initial arc period, a re-shorting prevention current which is larger than the initial arc current is applied in order to prevent re-shortening between the tip of the wire and the base metal right after the initial arc is generated. Thereafter, the initial arc current is applied.

Owner:DAIHEN CORP

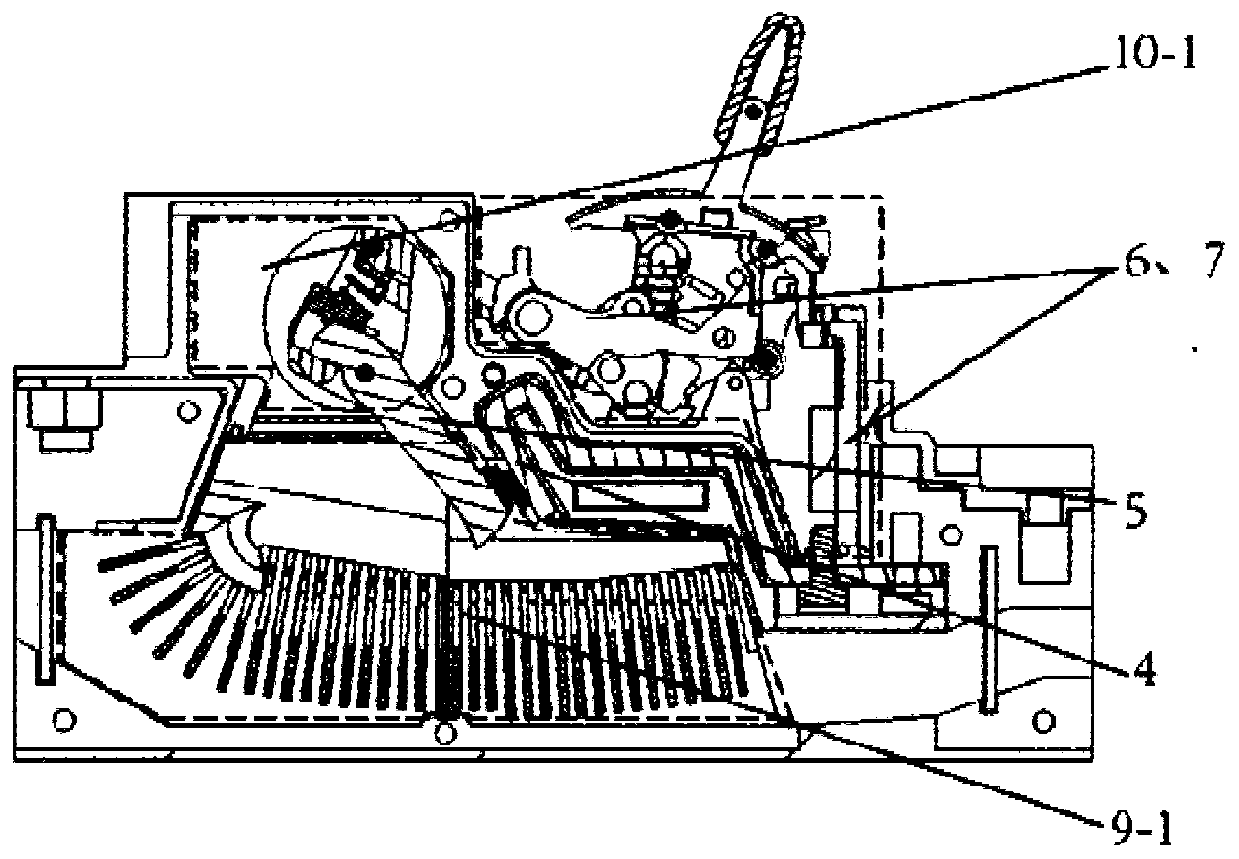

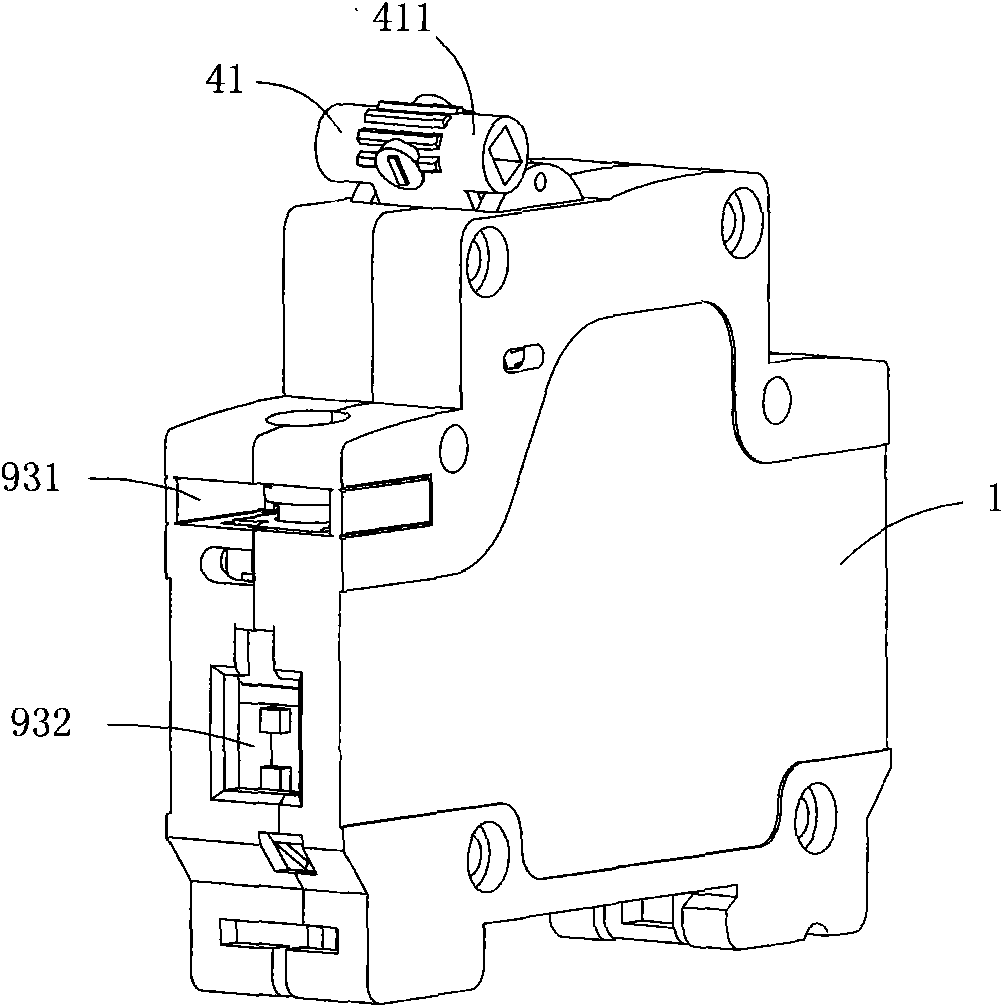

Small-sized circuit breaker

InactiveCN102568944AStrong breaking abilityImprove arc striking effectProtective switch detailsCircuit-breaking switch detailsEngineeringCircuit breaker

The invention provides a small-sized circuit breaker, comprising a shell, a double-gold sheet, a lock buckle, an arc extinguish chamber, a wiring column, a movable contact, a movable contact bracket and a shaft passing through the movable contact bracket, wherein the double-gold sheet comprises a double-gold sheet fixed end and a double-gold sheet movable end; the small-sized circuit breaker is further provided with a separation plate which is located between the double-gold sheet and an arc striking sheet; the separation plate corresponds to the shell to form a cavity ,and the double-gold sheet is arranged in the cavity. According to the small-sized circuit breaker, the double-gold sheet is not affected by the heating of other elements; in addition, an magnetic field generated by electric arcs on the double-gold sheet is separated from the magnetic field generated by the electric arcs of the arc striking sheet and the magnetic fields do not interfere with each other, so that the arc-striking effect of the arc striking sheet is good, and the breaking performance of the circuit breaker is good.

Owner:上海巢安电气有限公司

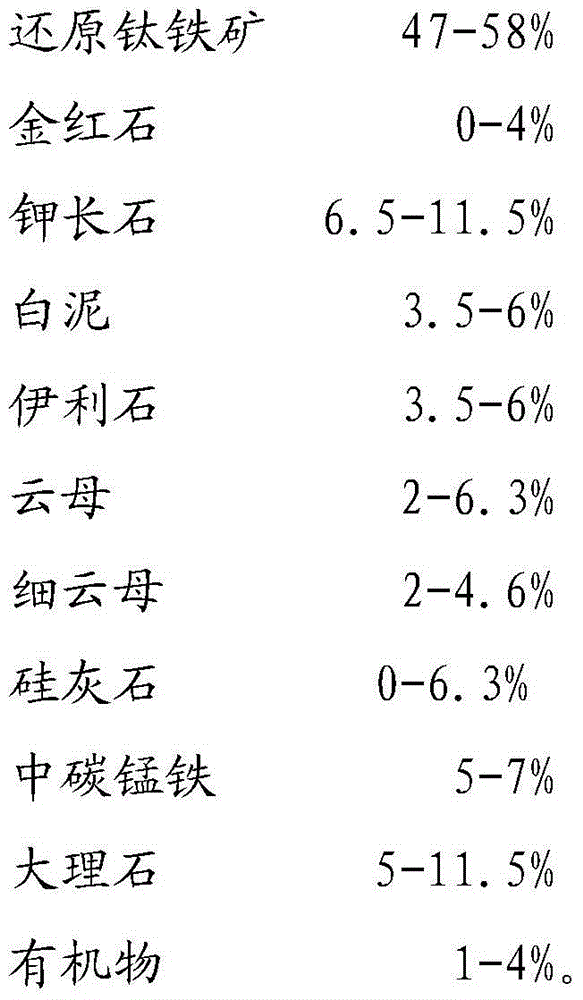

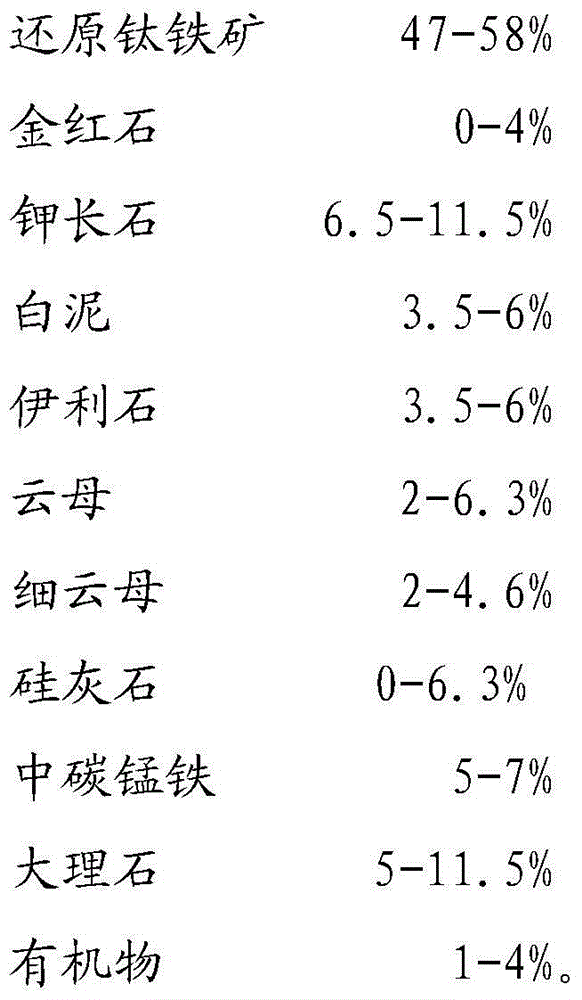

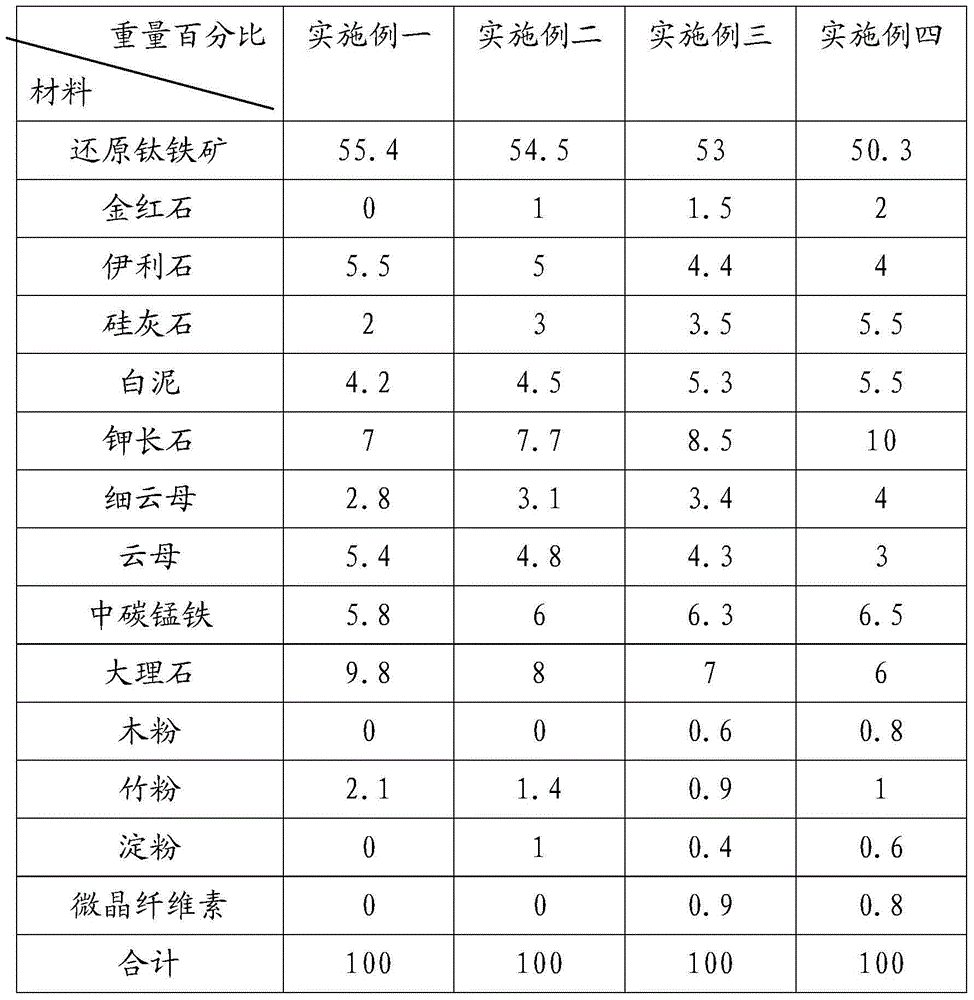

42 kg-level titania type carbon steel covered electrode and preparation method thereof

ActiveCN103551754AReduce pollutionReduce energy consumptionWelding/cutting media/materialsSoldering mediaPotassium feldsparWollastonite

The invention discloses a 42 kg-level titania type carbon steel covered electrode and a preparation method thereof. The 42 kg-level titania type carbon steel covered electrode comprises a core wire; the formula of a covered electrode coating comprises the following components in percentage by weight: 47-58% of reduced ilmenite, 0-4% of rutile, 6.5-11.5% of potassium feldspar, 3.5-6% of lime mud, 3.5-6% of illite, 2-6.3% of mica, 2-4.6% of fine mica, 0-6.3% of wollastonite, 5-7% of mid-carbon ferromanganese, 5-11.5% of marble and 1-4% of organic matters. The covered electrode can be prepared through a universal manufacturing technology of screw-type or hydraulic-type production equipment in the industry without special requirements, has excellent welding technological properties, mechanical properties and production press coating performance, and can be in AC / DC use.

Owner:天津大桥龙兴焊接材料有限公司

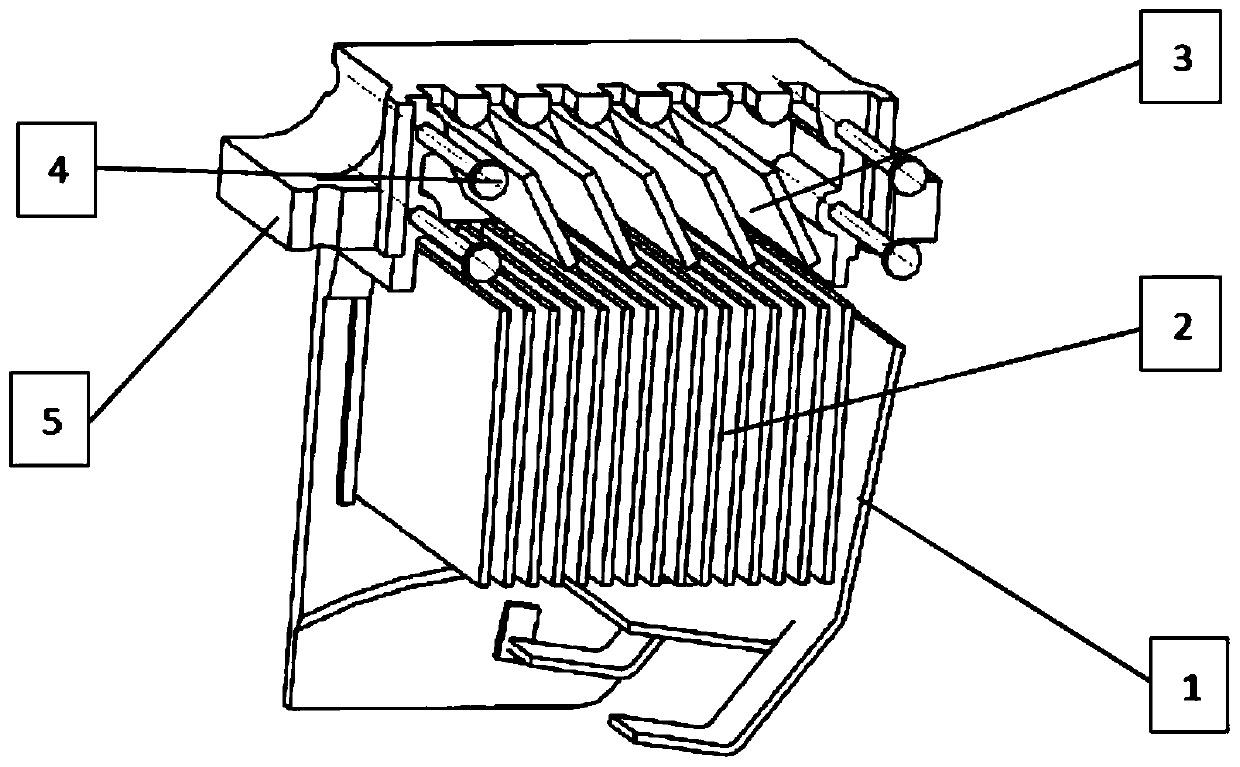

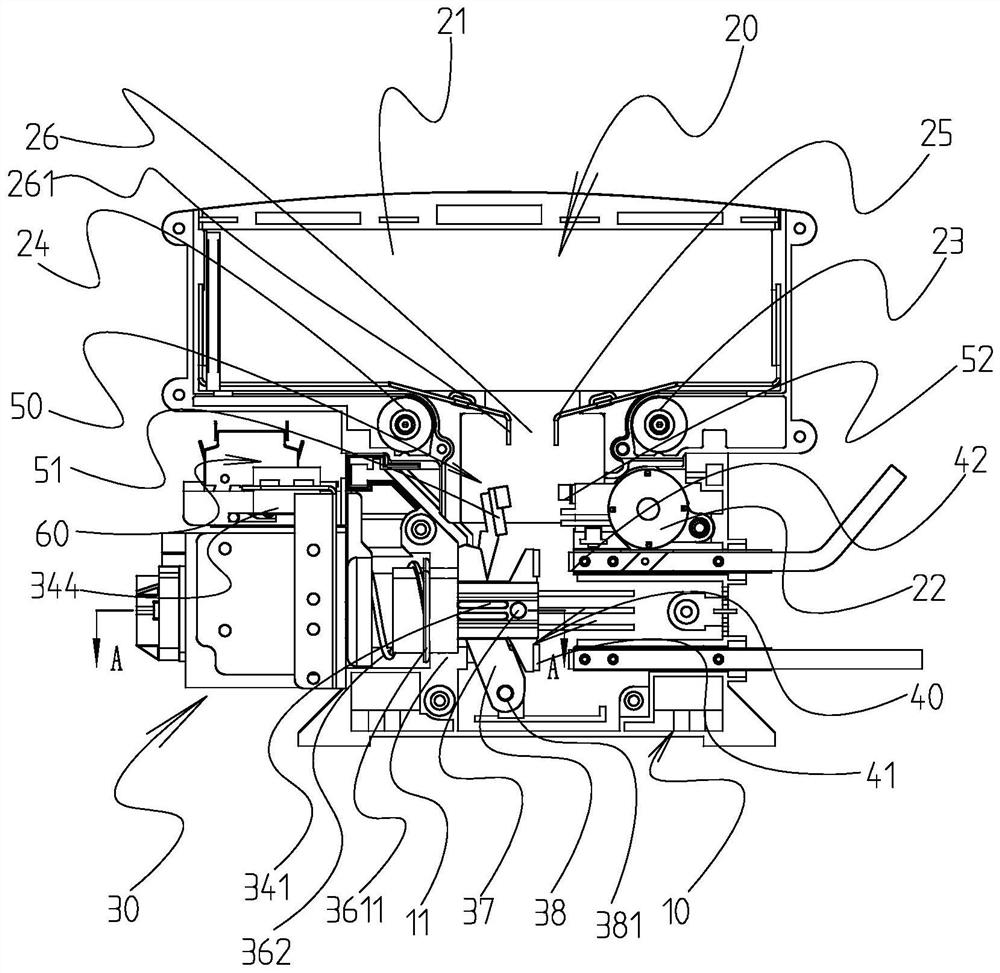

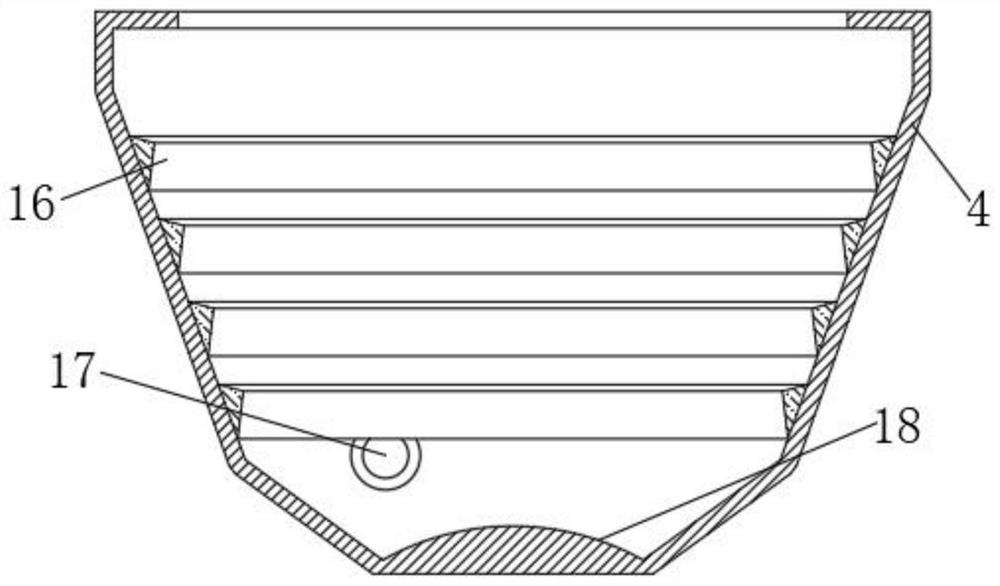

Contact arc extinguishing system of circuit breaker

PendingCN109904045AGood arc striking effectGood ventilation and exhaustElectric switchesCircuit-breaking switch contactsElectric arcHigh pressure

The invention provides a contact arc extinguishing system of a circuit breaker. The contact arc extinguishing system comprises a left side arc extinguishing chamber and a right side arc extinguishingchamber which are oppositely arranged, by taking a vertical line vertical to the bottom surface of a shell of the circuit breaker as a benchmark, the left side arc extinguishing chamber deflects towards the left, the right side arc extinguishing chamber deflects towards the right, and exhaust ports are formed in the left end part of the left side arc extinguishing chamber and the right end part ofthe right side arc extinguishing chamber respectively; an arc extinguishing grid sheet is arranged in the left side arc extinguishing chamber and the right side arc extinguishing chamber respectively, the arc extinguishing grid sheet in the left side arc extinguishing chamber deflects towards the left, and the arc extinguishing grid sheet in the right side arc extinguishing chamber deflects towards the right; and a separation arc extinguishing sheet is arranged between the left side arc extinguishing chamber and the right side arc extinguishing chamber. The contact arc extinguishing system provided by the invention realizes a double air outlet design on a single breakpoint moulded case circuit breaker, the separation grid sheet is arranged between the grid sheets, track of an electric arcis separated, and the electric arc is respectively guided to the two air outlets by combining arc striking sheets at the two sides, so that high temperature and high pressure gas is discharged to theoutside of the shell as soon as possible. The contact arc extinguishing system provided by the invention greatly increases available cavity volume of each arc extinguishing chamber, quantity, depthsand sectional areas of the grid sheets of the arc extinguishing chambers can be increased respectively, and capacity of the arc extinguishing system is greatly improved.

Owner:SHANGHAI ELECTRICAL APP RES INST +1

Method of performing glass surface metallization by utilization of plasma technology

A method of performing glass surface metallization by utilization of a plasma technology is disclosed. Direct-current arc laminar plasma beams adopting Ar and N2 as working gases are adopted as a heat source. Two intermediate coatings are successively sprayed onto the surfaces of a glass substrate and firmly combined to the glass. By adoption of the method of performing glass surface metallization, large-scale mass production in the atmospheric environment can be achieved, the production efficiency is high, and the powder material utilization rate is high. The produced metallization coatings largely adjust the coefficient of linear expansion of sealing joints so that the sealing joints and metals with a unmatched coefficient of linear expansion can be subjected to metal solder braze welding, the joints are firm and reliable and good in gas tightness.

Owner:CHENGDU PLASMAJET SCI & TECH

Electrode fused arc welding machine

ActiveCN101036956AReduce the inductance valueInhibit deteriorationArc welding apparatusPower flowWelding power supply

A melting electrode type arc welding machine, which supplies an output between a consumable electrode and an object to be welded through a reactor provided in an output path in a welding power source, the above melting electrode type arc welding machine is equipped with: an arc ignition circuit, which is connected in series The source side of the switching element and the anode side of the diode are connected, the input terminal of the reactor is connected to the drain side of the switching element, and the output terminal of the reactor is connected to the cathode side of the diode; and an arc ignition control circuit, which is inputted When the welding start signal is turned on, the switching element is turned on, and the starting current of a large current is passed between the molten electrode and the object to be welded for a predetermined time. Then, when the energization of the starting current is completed, it transitions to the initial current of a small current. When the initial current flows, the switching element is turned off. Therefore, even if the inductance of the reactor provided in the output path in the welding power source is a large value, the arc ignition performance can be improved.

Owner:DAIHEN CORP

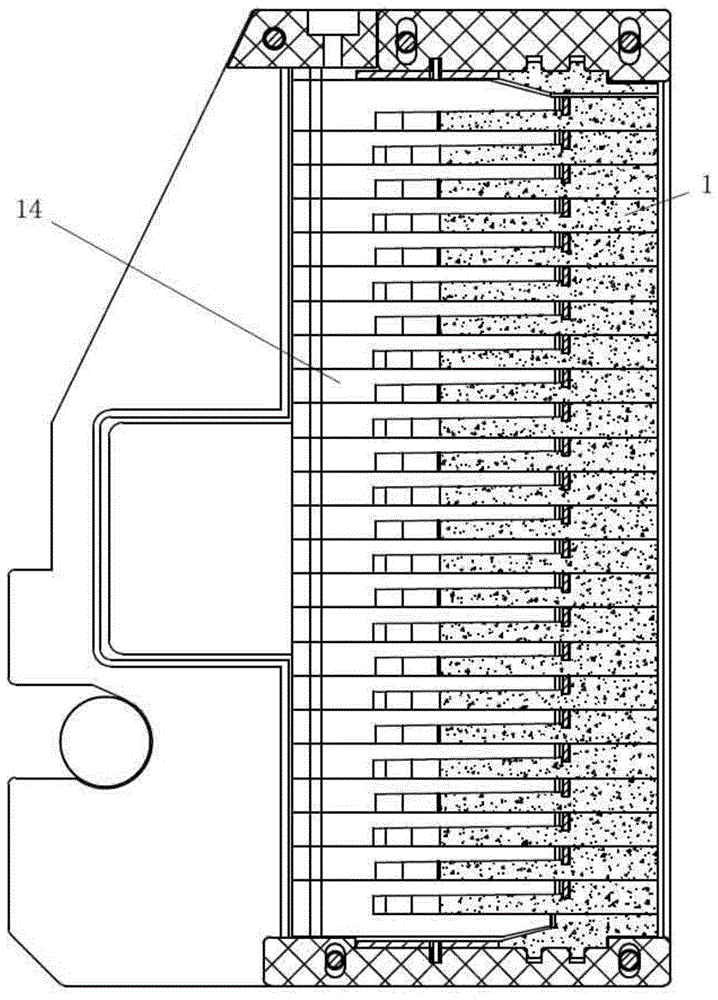

Arc extinguish chamber and direct current contactor adopting same

ActiveCN103560032ASolve the problem of large loss and short lifeExtend the trajectoryElectric switchesState of artHigh pressure

The invention relates to an arc extinguish chamber and a direct current contactor adopting the arc extinguish chamber. The direct current contactor comprises a moving contact assembly and a stationary contact assembly, wherein an upper arc guide angle assembly bent upwards is arranged beside a moving contact of the moving contact assembly, a lower arc guide angle assembly bent downwards is arranged beside a stationary contact of the stationary contact assembly, the arc extinguish chamber is arranged between the upper arc guide angle assembly and the lower arc guide angle assembly, arc guide pieces are alternatively arranged in the arc extinguish chamber in a layering mode, an arc guide port is formed in one end of each arc extinguish piece, a plurality of arc extinguish ribs facing the interior of the arc extinguish chamber are arranged at the other end of each arc extinguish piece at intervals, and a metal piece connected in a bending mode is arranged at least on one arc extinguish rib. The arc extinguish chamber and the direct current contactor adopting the arc extinguish chamber resolve the problems in the prior art that the motion time of the electric arc in the arc extinguish chamber is too long, and the arc extinguish chamber is large in loss and short in service life under the conditions that currents are too strong or too weak, can rapidly pull the electric arc to the maximum, timely and effectively extinguishes the electric arc and is safe and durable.

Owner:ANDELI GRP

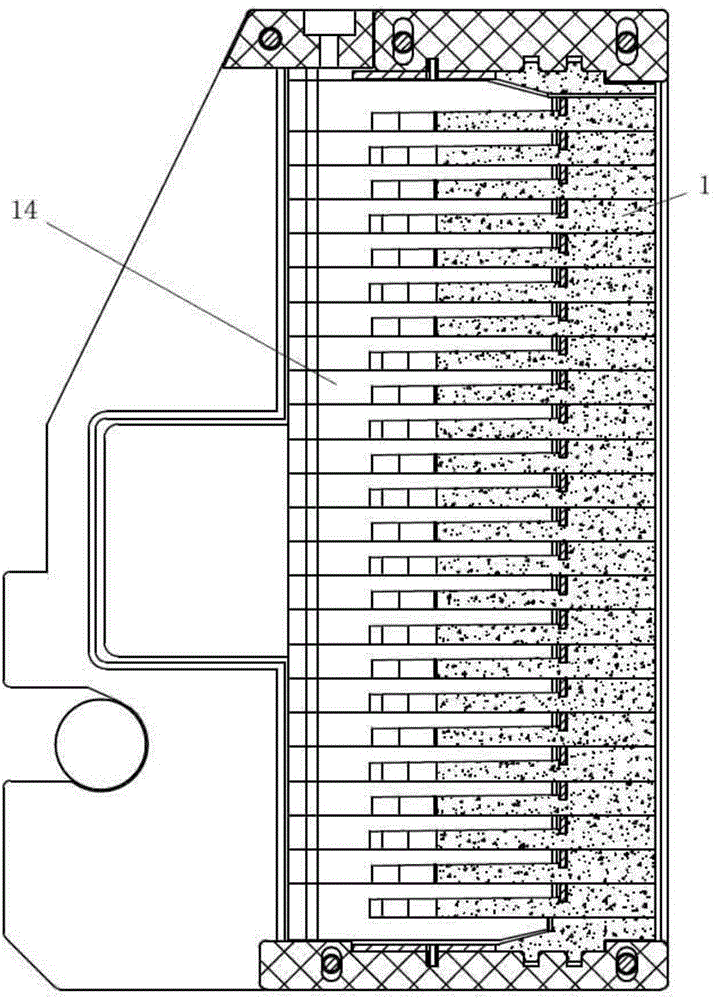

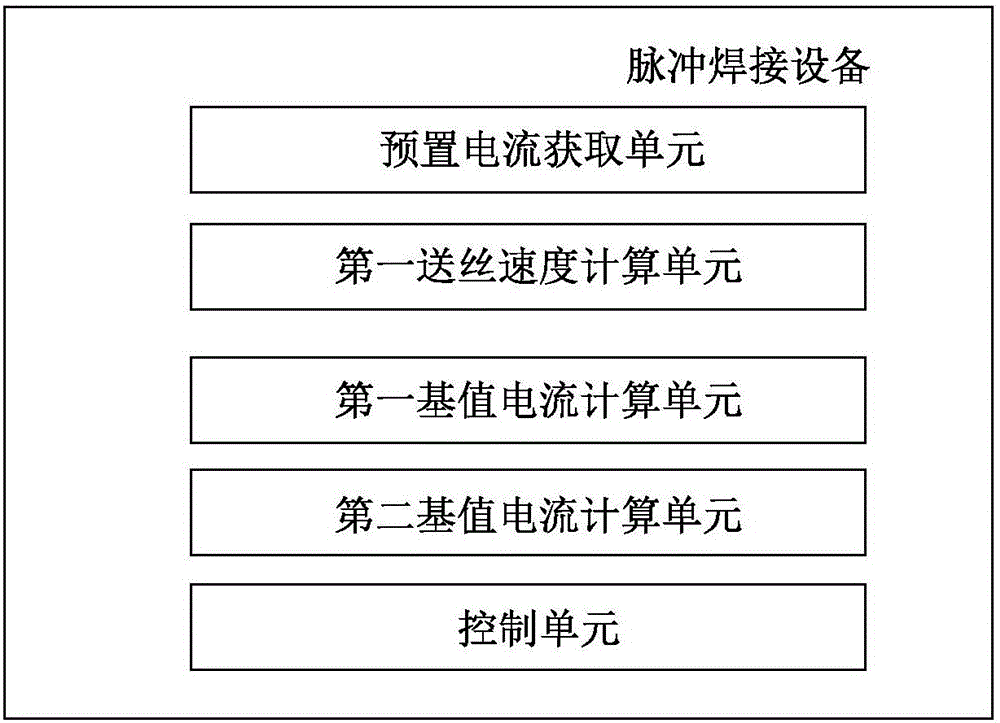

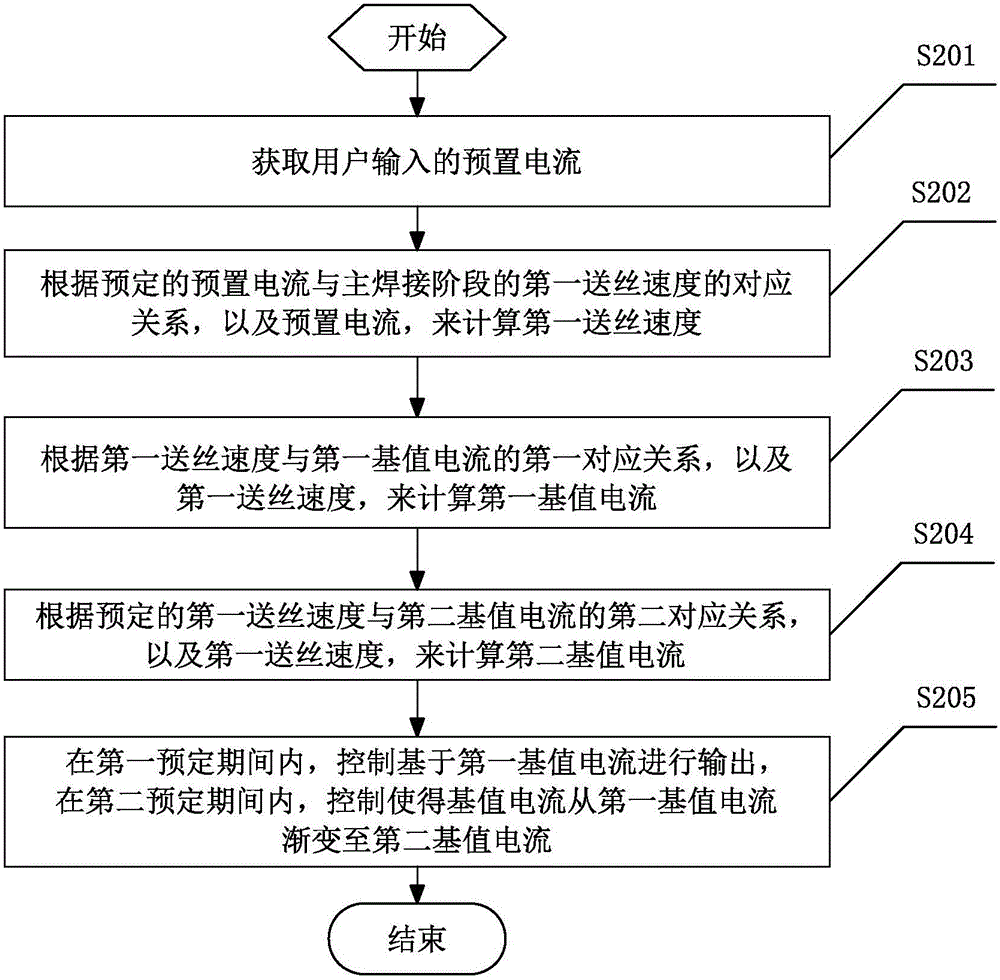

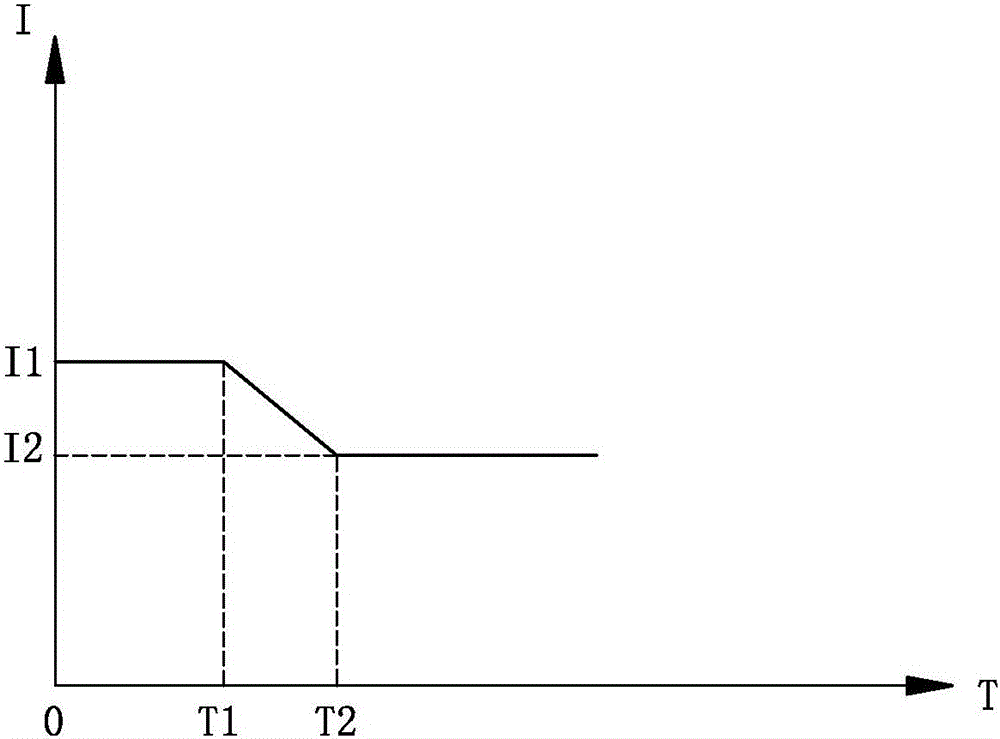

Pulsation welding equipment and control method thereof

ActiveCN105728898AOvercoming easy arc breakingOvercome harsh noiseArc welding apparatusEngineeringControl unit

The invention provides pulsation welding equipment. The pulsation welding equipment comprises a preset current obtaining unit, a first wire feed speed calculating unit, a first background current calculating unit, a second background current calculating unit and a control unit. The control unit controls output based on first background current within the first scheduled period starting from switching on of a welding gun switch, and controls to enable the background current to gradually change from the first background current to second background current within the second scheduled period from ending of the first scheduled period to starting of the main welding stage. The welding quality can be effectively improved.

Owner:PANASONIC WELDING SYST TANGSHAN

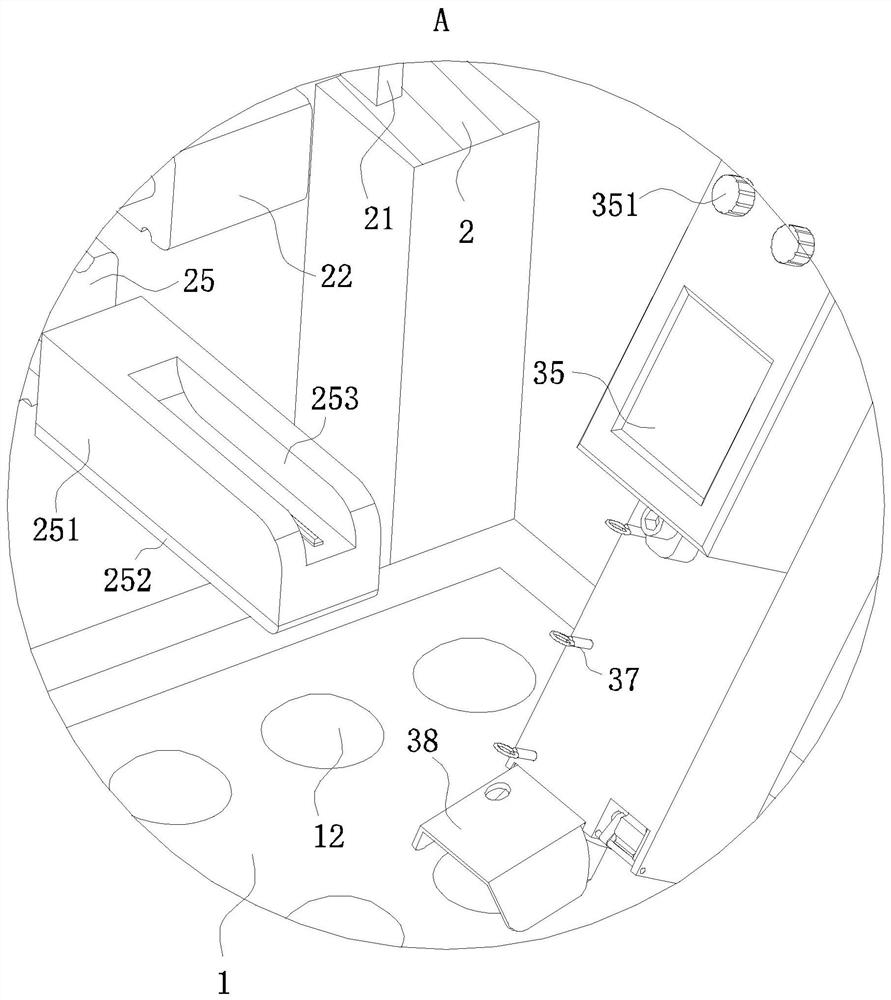

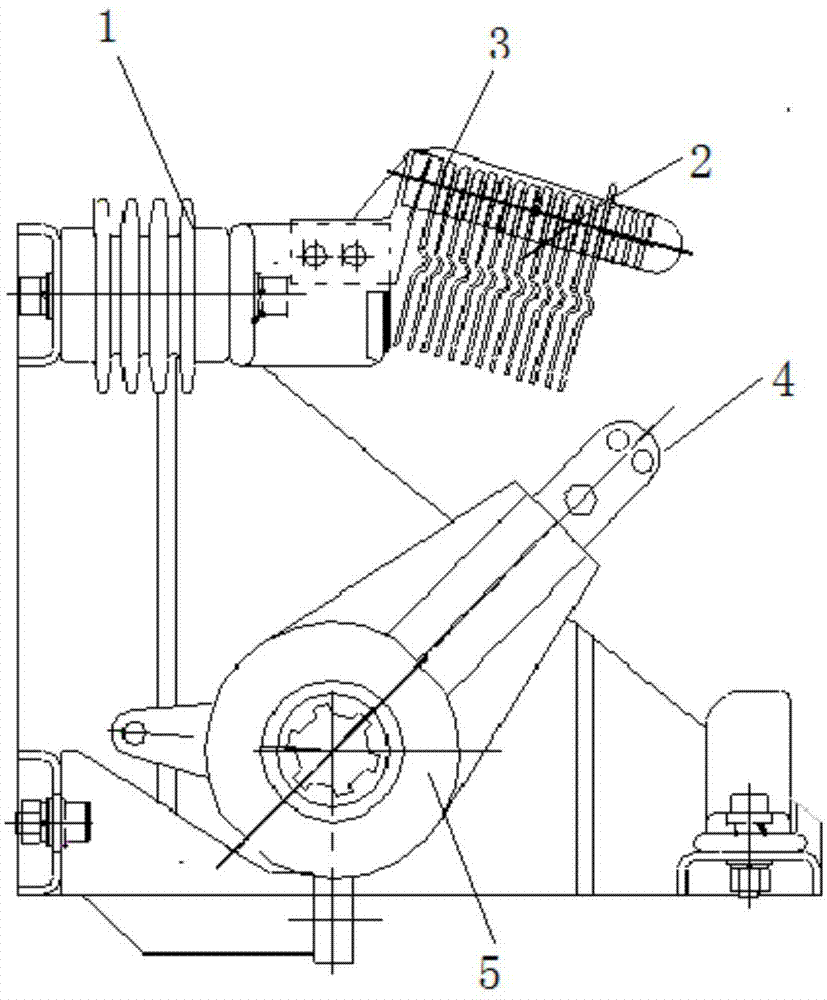

Arc striking device of electric welding machine and arc striking method thereof

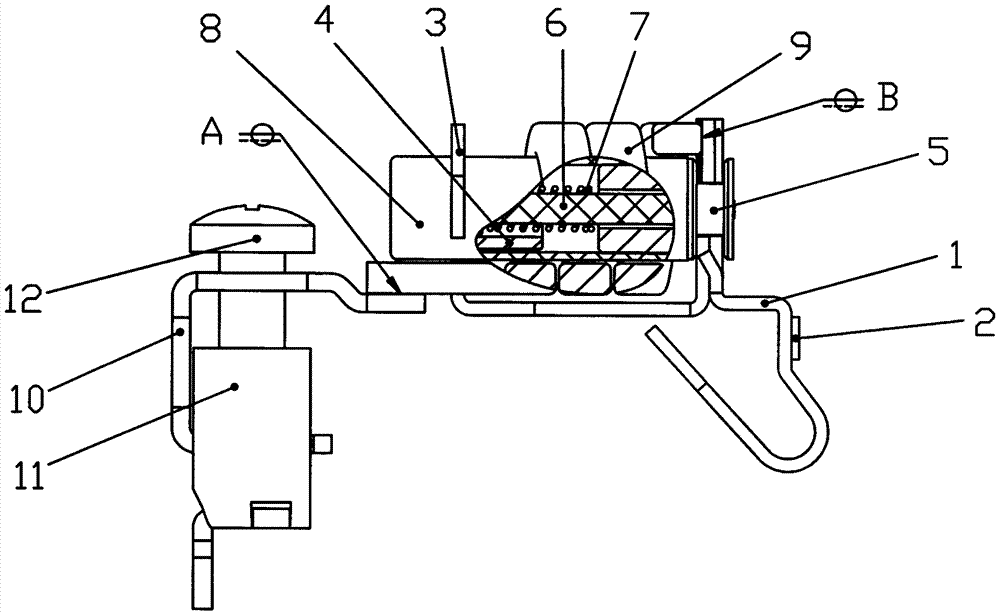

ActiveCN111906409APrevent oxidationImprove welding effectArc welding apparatusShielding gasElectric machinery

The invention belongs to the technical field of electric welding machines, and particularly relates to an arc striking device of an electric welding machine and an arc striking method thereof. The arcstriking method comprises the following steps that S1, workpieces to be welded are placed on a base I, and the workpieces are pressed through a fixing plate; the distance between the two workpieces is adjusted through an air cylinder III; and test blocks made of the same material are placed in a test clamping groove; S2, on the basis of S1, a power supply is switched on, an arc striking box is started, a tungsten electrode is controlled to be close to the test blocks, and the arc striking effect is tested; S3, after S2 is completed, the test blocks are taken down, and the distance between thetungsten electrode and the workpieces is adjusted; S4, on the basis of S3, the angle of the welding position of the tungsten electrode and the workpieces is adjusted; and S5, whether a welding wire is used or not is selected according to the material of the welding workpieces, and when the welding wire is used, the welding wire is sent to a welding position, a motor is controlled to operate, a protection plate is enabled to be close to the tungsten electrode, and protective gas is introduced and released. The arc striking device is good in arc striking effect, stable in work, reliable in performance and safe to use.

Owner:ZHEJIANG LAOSHIDUN WELDING EQUIP

Frame-type circuit breaker arc striking and extinguishing device and contact arc extinguishing system

ActiveCN111092007AIncrease breaking currentImprove arc extinguishing performanceCircuit-breaking switch detailsStructural engineeringArc extinction

The invention discloses a frame type circuit breaker arc striking and extinguishing device and a contact arc extinguishing system. The frame-type circuit breaker contact arc extinguishing system comprises a frame-type circuit breaker arc striking and extinguishing device, wherein a lower end of an arc striking sheet in the arc striking and extinguishing device of a frame-type circuit breaker is provided with a contact system corresponding to the arc striking sheet, the contact system is arranged in an arc isolating cover, a contact support is arranged below the contact system, fixed clamping plates are arranged on a left side and a right side of the contact support respectively, a left end and a right end of the arc isolating cover are connected with the two fixed clamping plates respectively, the arc isolating cover and a lower end of the contact support are arranged on the support, and a bus is arranged on the support. The system is advantaged in that electric arcs led out through the arc striking and extinguishing device are led into the contact arc extinguishing system, the breaking current and arc extinguishing performance of the circuit breaker contact system can be effectively improved, burning loss of a main contact of the contact system is effectively reduced, the actual service life of the contact system is prolonged, and the actual service life cycle of the contact system and a circuit breaker is prolonged.

Owner:SHANGHAI ELECTRICAL APPLIANCES RES INSTGROUP +1

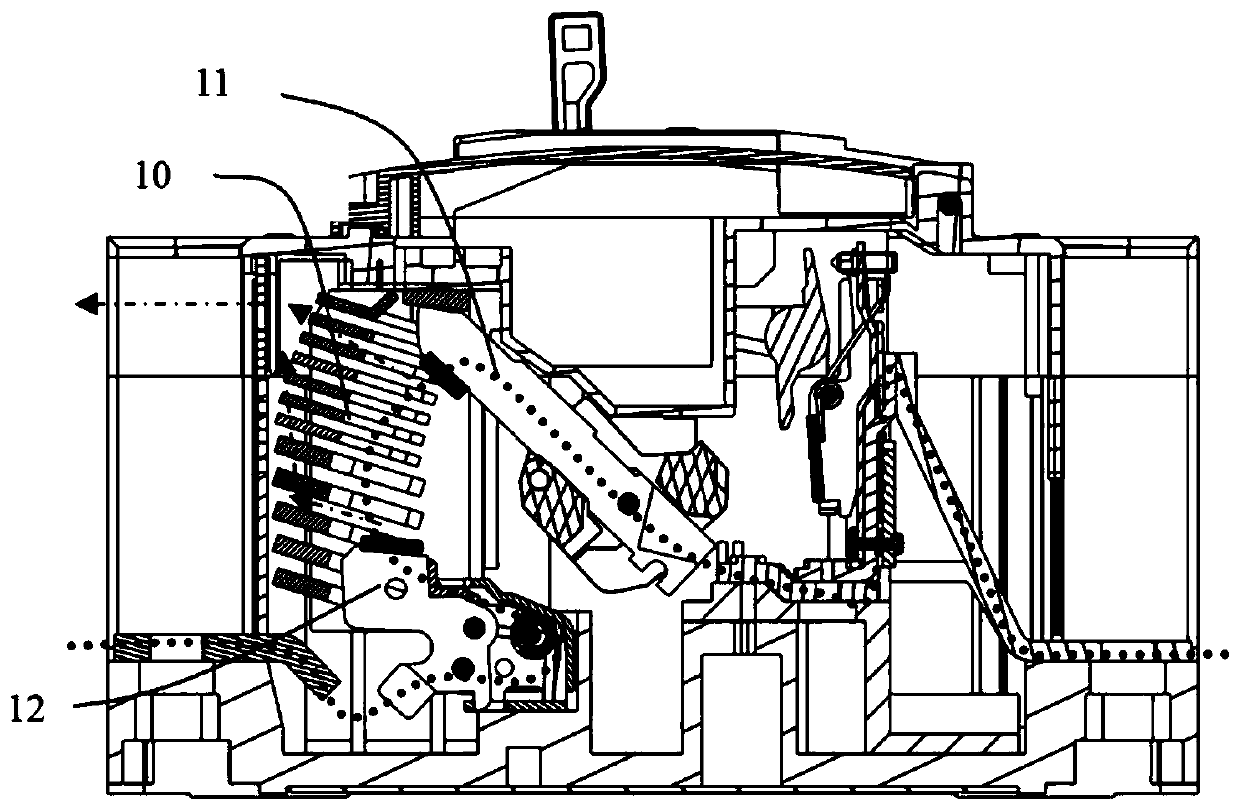

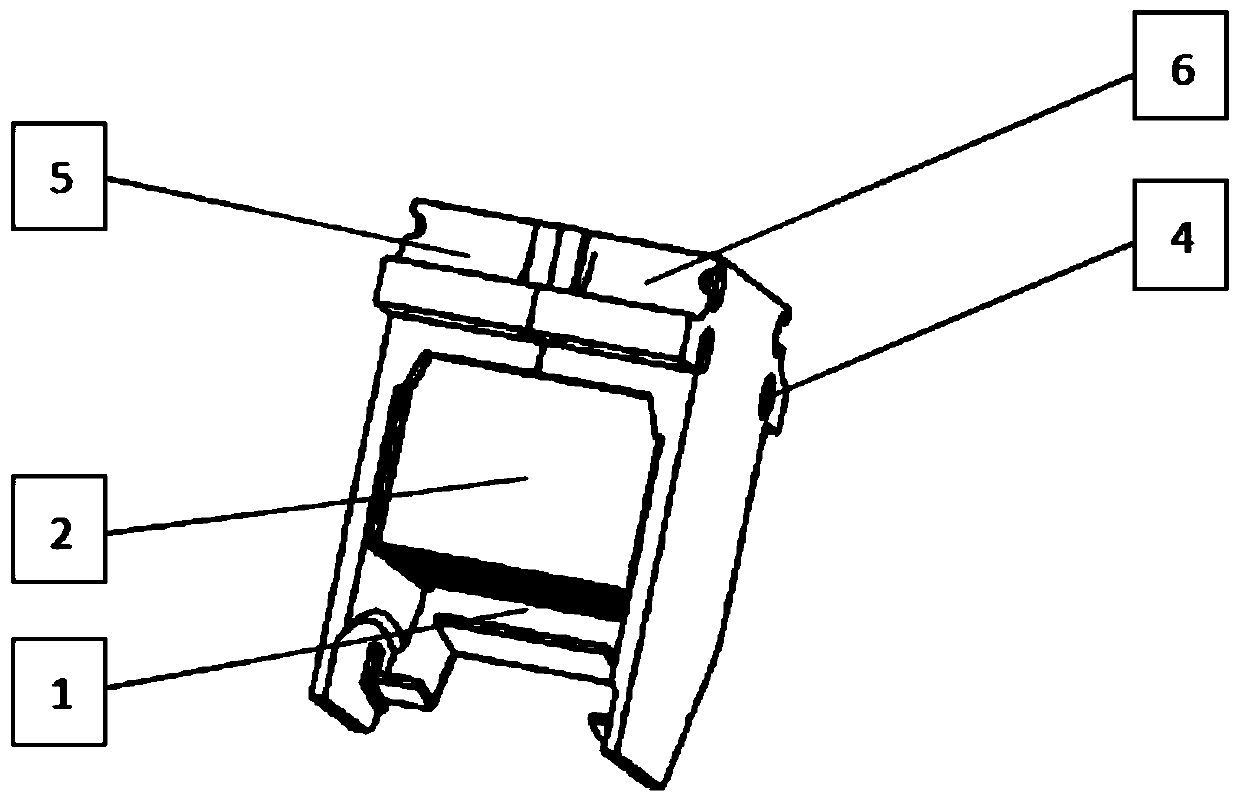

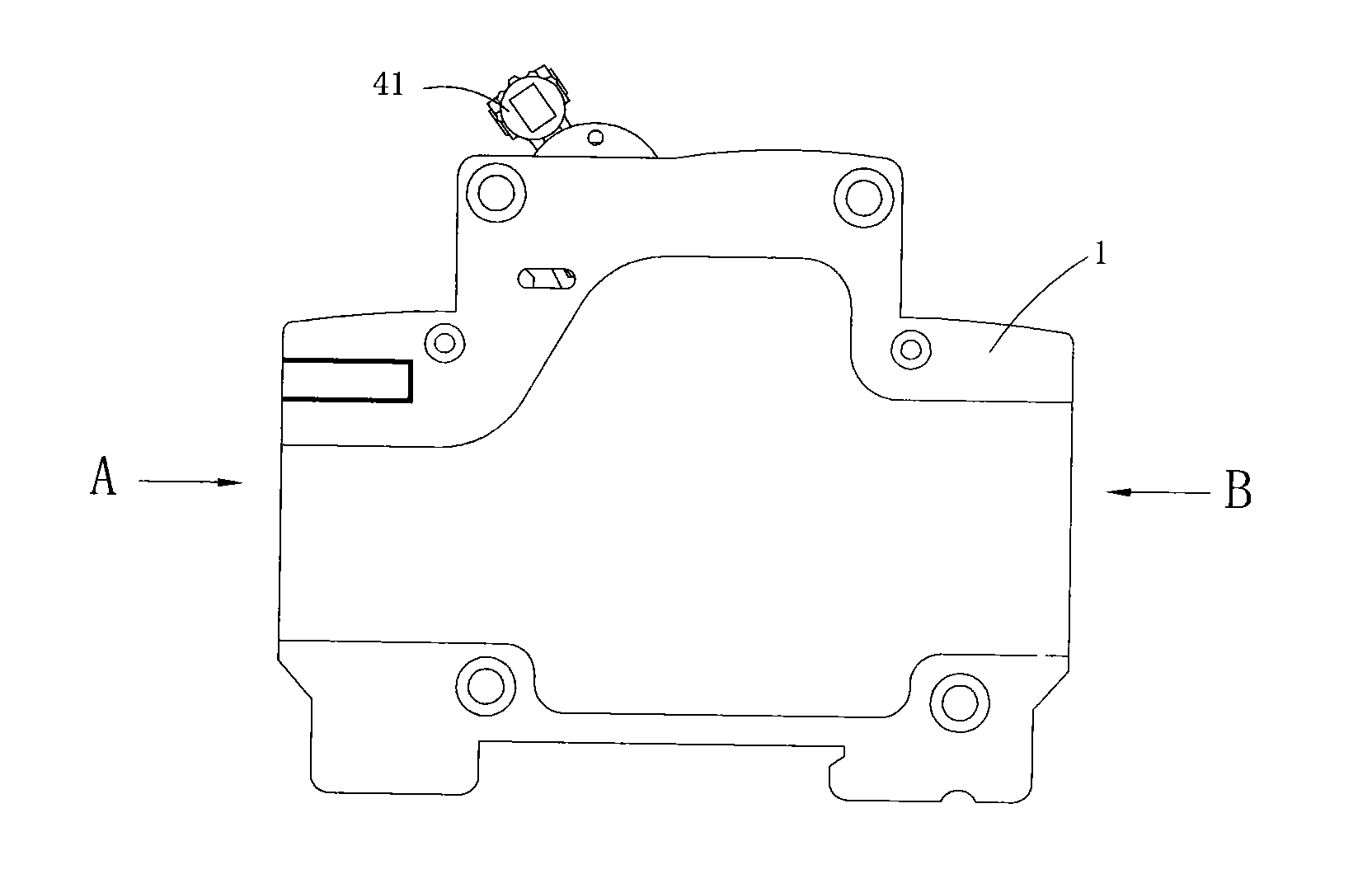

Small breaker

ActiveCN101593643AImprove arc striking effectImprove short circuit breaking capacityElectric switchesSwitch terminals/connectionsElectricityCircuit breaker

The invention discloses a small breaker. The breaker comprises a plastic shell, a movable contact, a static contact, an operation mechanism, an electromagnetic tripping mechanism, an arc extinguish chamber and a run-on tab, wherein the electromagnetic tripping mechanism comprises a magnetic yoke; one end of the run-on tab is electrically connected with the static contact, while the other end of the run-on tab extends into the arc extinguish chamber; and the arc extinguish chamber is positioned under the magnetic yoke. The small breaker is characterized by comprising an iron arc guide plate; one end of the arc guide plate, namely a fixed end, is fixed on the bottom of the magnetic yoke, while the other end of the arc guide plate, namely an arc guide end, is bent downwards and close to the movable contact. The small breaker has the advantages of effectively improving the capability of short circuit disjunction of the breaker, easily achieving the level of 6,000A energy level 3, and has short arcing time less than 6 milliseconds.

Owner:环宇集团(南京)有限公司

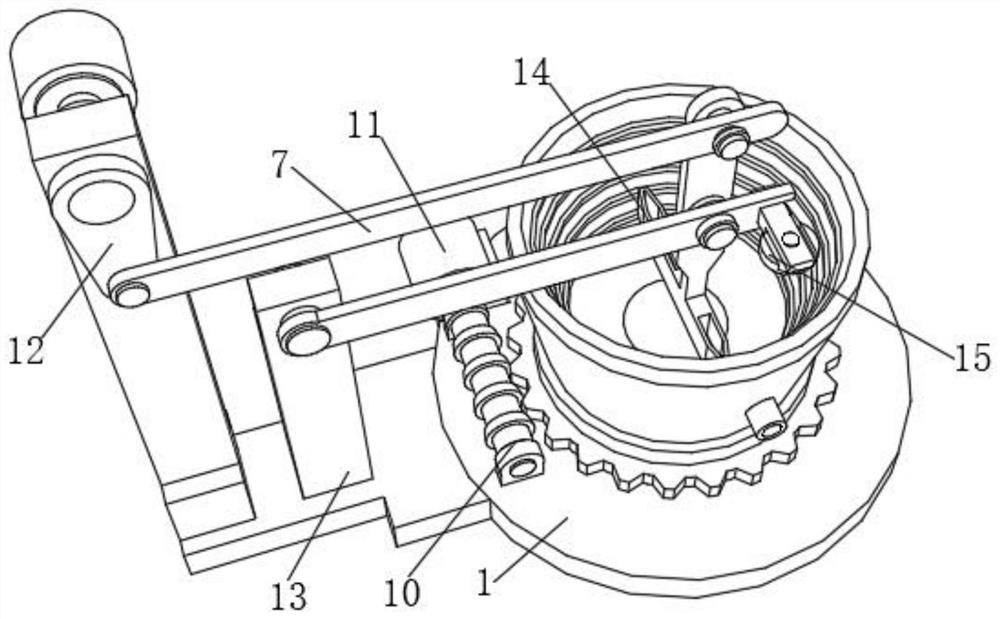

Electromagnetic contactor

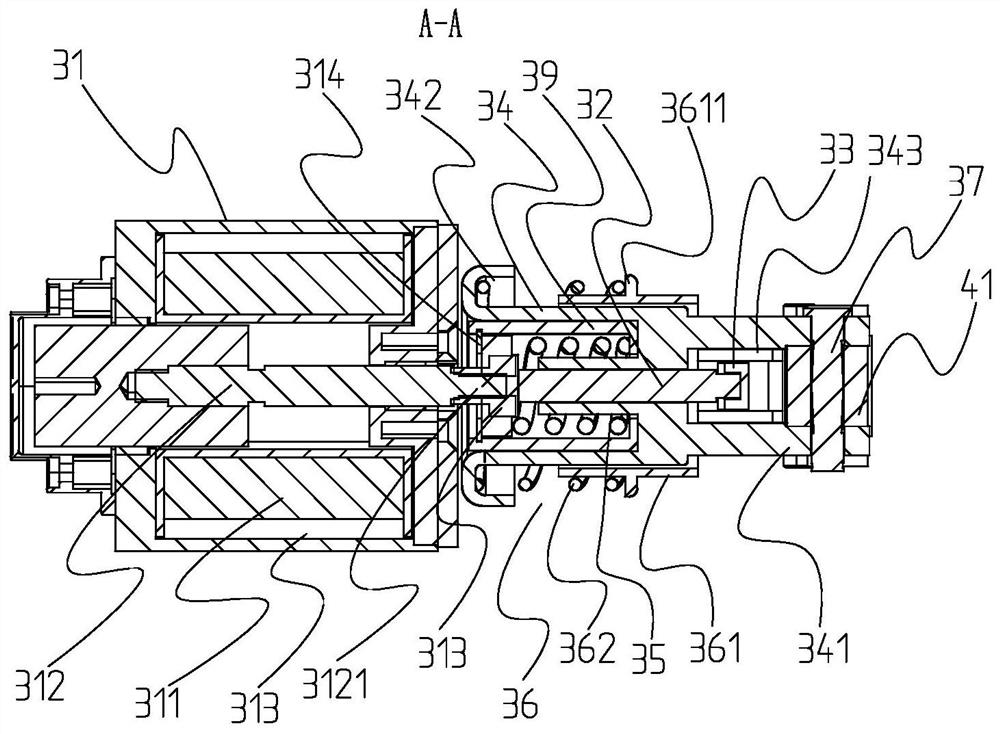

PendingCN112713059AReduce volumeIncrease working currentElectric switchesElectromagnetic relay detailsEngineeringContactor

The invention discloses an electromagnetic contactor. The electromagnetic contactor comprises a movable contact, a static contact, a movable auxiliary contact and a static auxiliary contact, wherein the contact attraction assembly comprises an electromagnetic power assembly, a push rod, a swing rod, a movable sleeve and a first compression spring, the end of an iron core of the electromagnetic power assembly makes contact with one end of the push rod, the end, away from the iron core, of the push rod is hinged to the swing rod, one end of the swing rod is hinged to the electromagnetic contactor body, and a movable auxiliary contact is fixedly arranged at the other end; the movable contact is connected to the end, away from the electromagnetic power assembly, of the movable sleeve, the end, away from the movable contact, of the movable sleeve extends towards the iron core and then makes contact with one end of the first compressed spring, and the other end of the first compressed spring makes contact with a supporting part on the iron core; the iron core pushes the push rod to move towards the end where the movable contact is located, pushes the swing rod to rotate around the hinged shaft of the push rod and the electromagnetic contactor body, drives the movable auxiliary contact to move towards the static auxiliary contact and then makes contact with the static auxiliary contact, and meanwhile the iron core extrudes the first compressed spring so that the movable sleeve can drive the movable contact to make contact with the static contact.

Owner:JIAXING SAITIELONG ELECTRIC

Solid welding wire for unplating welding use

InactiveCN1233498CImprove arc striking effectWelding/cutting media/materialsSoldering mediaPotassiumCopper

A plating-free solid wire for welding of the present invention contains C: 0.04 to 0.12 mass%. Si: 0.5 to 1.1 mass%, Mn: 1.0 to 1.7 mass%, Ti: not more than 0.03 mass%, and remainder Fe. In addition, the expression: Si + Mn + ( 10 x Ti) ≤ 2.5 is satisfied, where Si, Mn, and Ti denote the contents of respective elements in the wire. The tensile strength of the wire is 900 to 1300 (N / mm2). A potassium compound is present in an amount of 2 to 10 ppm in terms of potassium; MoS2, 0.01 to 0.5 g per 10 kg of the wire; and an oil containing polyisobutene, 0.3 to 1.5 g per 10 kg of the wire, on the surface and / or immediately under the surface of the non-plated wire. With such a constitution, it is possible to improve both the wire feedability and the arc start characteristics.

Owner:KOBE STEEL LTD

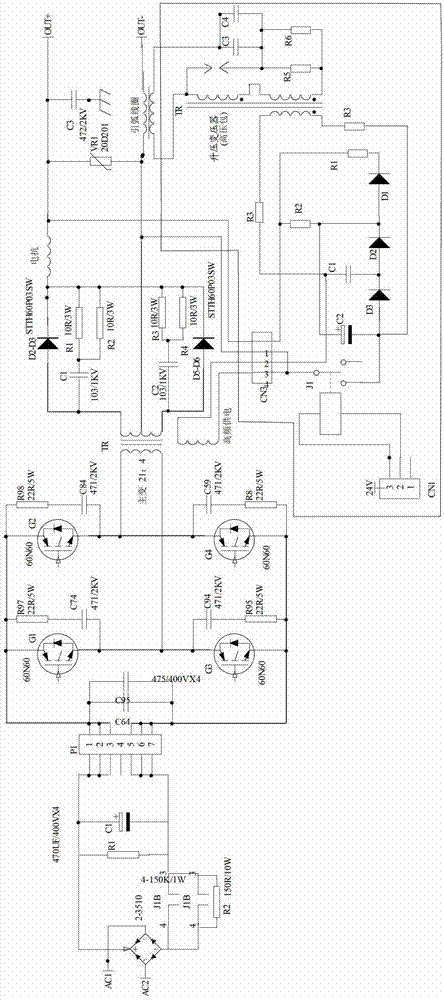

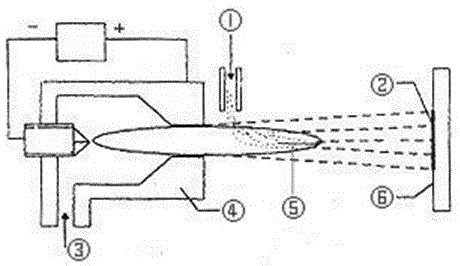

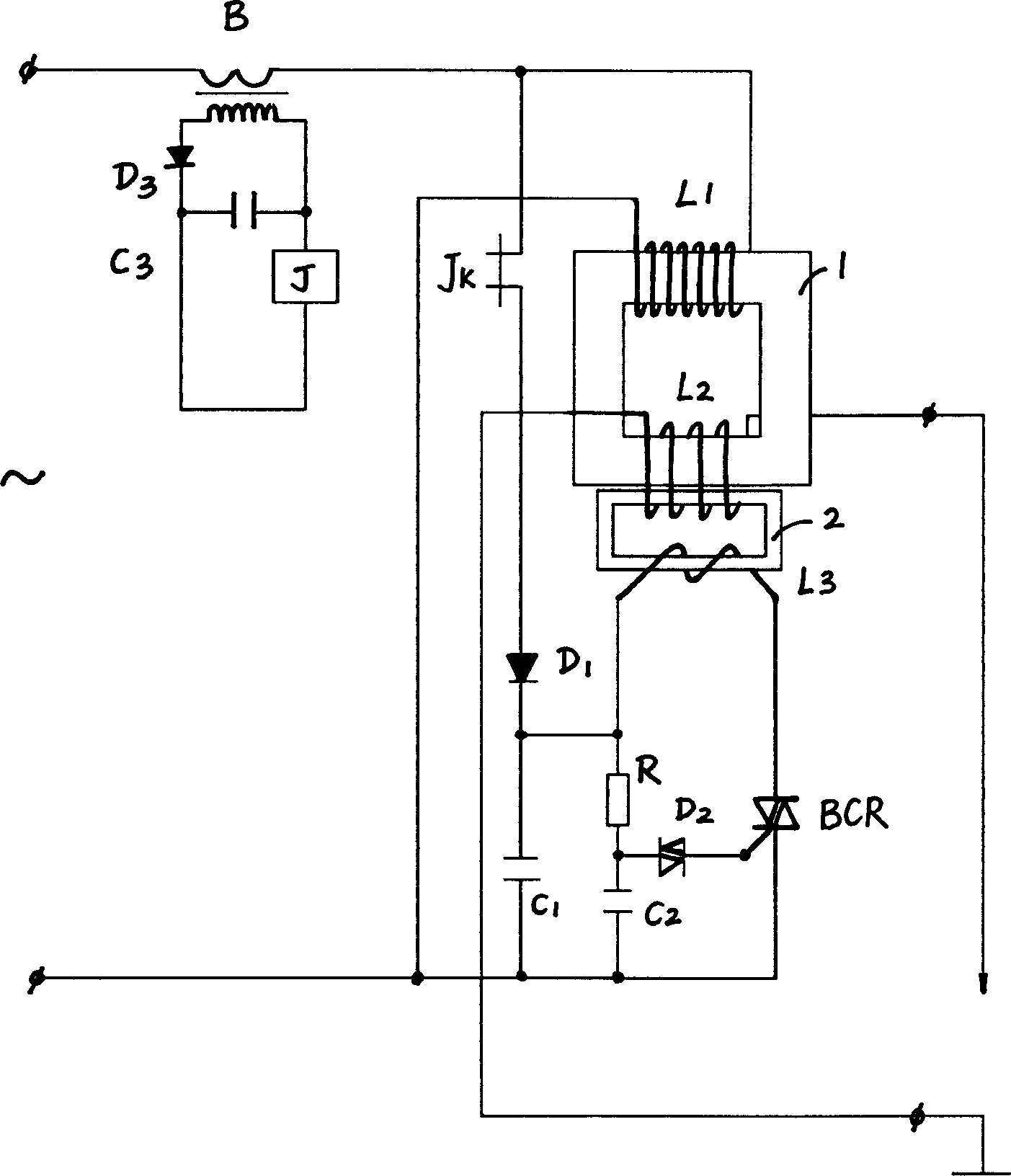

High-voltage arc strike electric welding machine

InactiveCN1775445AEasy to generate high voltage dischargeImprove arc striking effectArc welding apparatusCapacitanceElectricity

The present invention discloses a high-voltage arc-striking welder. It includes main coil and secondary coil which are winded on the iron core, the main coil is connected with power supply input terminal, the secondary coil is connected with welding output terminal, the iron core is formed from main iron core and auxiliary iron core. The main coil is winded on the main iron core, the secondary coil is winded on the coincident portion of main iron core and auxiliary iron core, on the auxiliary iron core an auxiliary coil is set, said auxiliary coil is connected with capacitor discharge oscillating circuit, and can be used as discharge coil of said circuit. Said invention also provides its working principle for producing high-voltage discharge.

Owner:陈欢

Arc-extinguishing device suitable for switch cabinet

The invention discloses an arc-extinguishing device suitable for a switch cabinet. The arc-extinguishing device suitable for the switch cabinet is characterized by comprising a supporting insulator, an arc-extinguishing grid frame, arc-extinguishing grid sheets, a spindle and a wafer, wherein the arc-extinguishing grid frame is fixedly arranged on the supporting insulator by screws; the arc-extinguishing grid frame is provided with a plurality of clamping troughs; the bottom ends of the arc-extinguishing grid sheets are inserted into the clamping troughs to be fixed; at least one of the ends of the arc-extinguishing grid sheets is not tidily arranged; the wafer and the spindle are movably connected. The arc-extinguishing device suitable for the switch cabinet, which is disclosed by the invention, has the beneficial effects that the arc-extinguishing grid sheets are fixed by the clamping troughs, so distance among the arc-extinguishing grid sheets is reduced, the amount of the arc-extinguishing grid sheets is increased, the arc-extinguishing capability can be enhanced, and installation is firmer; the arc striking capability is increased by untidy arrangement of the ends of the arc-extinguishing grid sheets.

Owner:YIHE ELECTRIC GRP

High frequency arc ignition circuit with direct current voltage output

InactiveCN103111719BEasy breakdownIncrease success rateArc welding apparatusEngineeringHigh pressure

The invention relates to a high frequency arc ignition circuit with direct current voltage output. The high frequency arc ignition circuit with direct current voltage output comprises a high frequency signal source, a relay, a high frequency voltage booster circuit and a voltage doubling circuit. The high frequency signal source is respectively connected with the input end of the voltage doubling circuit and the input end of the high frequency voltage booster circuit through the relay. The output end of the voltage doubling circuit outputs direct current voltage to secondary positive and negative electrodes of a welding machine main circuit. The high frequency voltage booster circuit produces high frequency high voltage signals and the high frequency high voltage signals are coupled to the secondary negative electrode of the welding machine main circuit and outputted. With the aid of the voltage doubling circuit, the direct current voltage is added to the high frequency arc ignition circuit with direct current voltage output on the condition of high frequency arc starter, air can be punctured more easily at the time of high frequency arc starter, arcing is easier, and success rate of arcing and arcing performance of the welding machine can be improved.

Owner:广东世博科焊接工程技术有限公司

An arc extinguishing chamber and a DC contactor using the arc extinguishing chamber

The invention relates to an arc extinguish chamber and a direct current contactor adopting the arc extinguish chamber. The direct current contactor comprises a moving contact assembly and a stationary contact assembly, wherein an upper arc guide angle assembly bent upwards is arranged beside a moving contact of the moving contact assembly, a lower arc guide angle assembly bent downwards is arranged beside a stationary contact of the stationary contact assembly, the arc extinguish chamber is arranged between the upper arc guide angle assembly and the lower arc guide angle assembly, arc guide pieces are alternatively arranged in the arc extinguish chamber in a layering mode, an arc guide port is formed in one end of each arc extinguish piece, a plurality of arc extinguish ribs facing the interior of the arc extinguish chamber are arranged at the other end of each arc extinguish piece at intervals, and a metal piece connected in a bending mode is arranged at least on one arc extinguish rib. The arc extinguish chamber and the direct current contactor adopting the arc extinguish chamber resolve the problems in the prior art that the motion time of the electric arc in the arc extinguish chamber is too long, and the arc extinguish chamber is large in loss and short in service life under the conditions that currents are too strong or too weak, can rapidly pull the electric arc to the maximum, timely and effectively extinguishes the electric arc and is safe and durable.

Owner:ANDELI GRP

A method for metallizing glass surfaces using plasma technology

A method of performing glass surface metallization by utilization of a plasma technology is disclosed. Direct-current arc laminar plasma beams adopting Ar and N2 as working gases are adopted as a heat source. Two intermediate coatings are successively sprayed onto the surfaces of a glass substrate and firmly combined to the glass. By adoption of the method of performing glass surface metallization, large-scale mass production in the atmospheric environment can be achieved, the production efficiency is high, and the powder material utilization rate is high. The produced metallization coatings largely adjust the coefficient of linear expansion of sealing joints so that the sealing joints and metals with a unmatched coefficient of linear expansion can be subjected to metal solder braze welding, the joints are firm and reliable and good in gas tightness.

Owner:CHENGDU PLASMAJET SCI & TECH

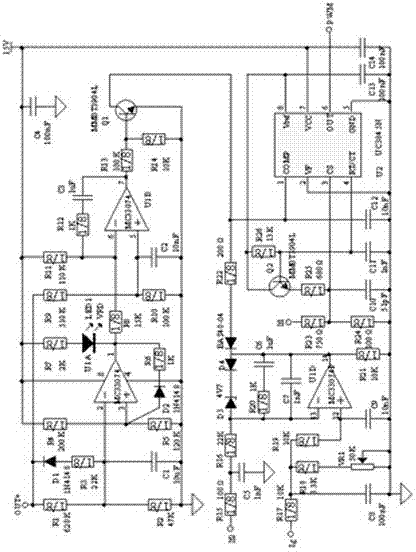

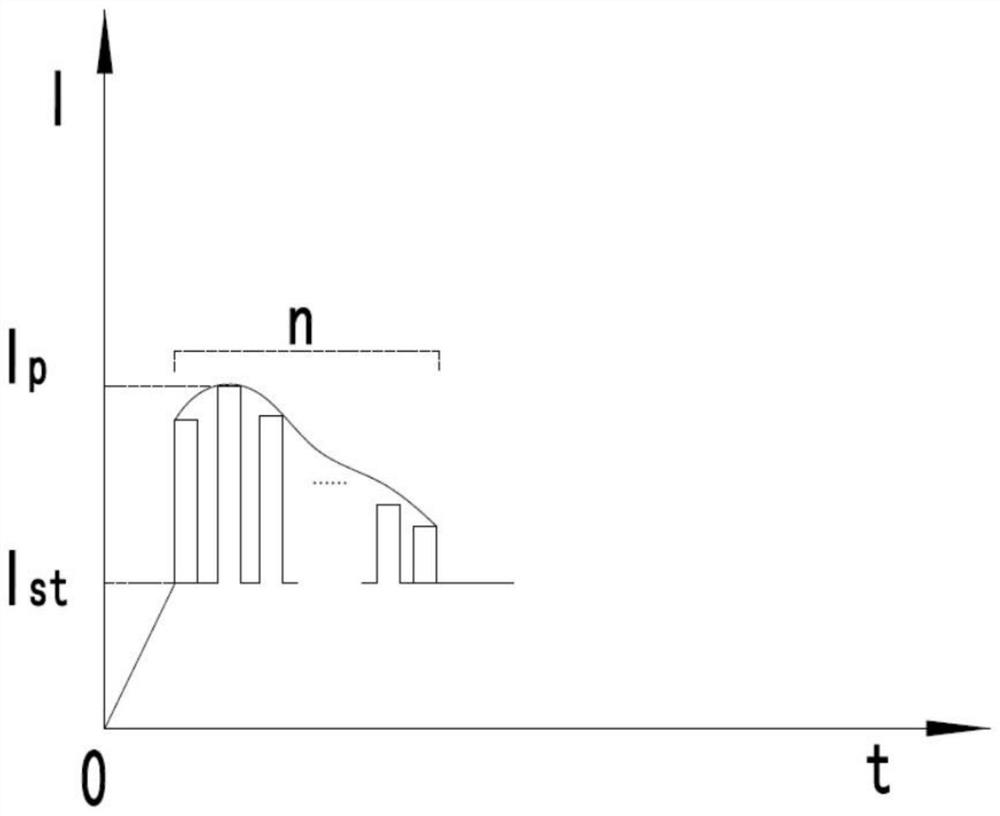

A control method and control system for arc ignition of an inverter manual arc welding machine

ActiveCN110877137BImprove arc striking effectImprove the success rate of arc strikingArc welding apparatusControl systemThin slab

The present invention relates to a control method and control system for arc ignition of an inverter manual arc welding machine. The welding current of the welding power supply becomes the pulse square wave arc ignition current. After the arc ignition of the inverter manual arc welding machine power supply is successful, the pulse thermal arc ignition signal is turned off, and the normal welding current is restored, and the arc burns normally. strike the arc. The invention is suitable for welding plates of different thicknesses, especially suitable for manual arc welding of thin plates, and has the characteristics of easy arc starting, high arc starting success rate, good welding shape, difficult welding deformation and high welding strength.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

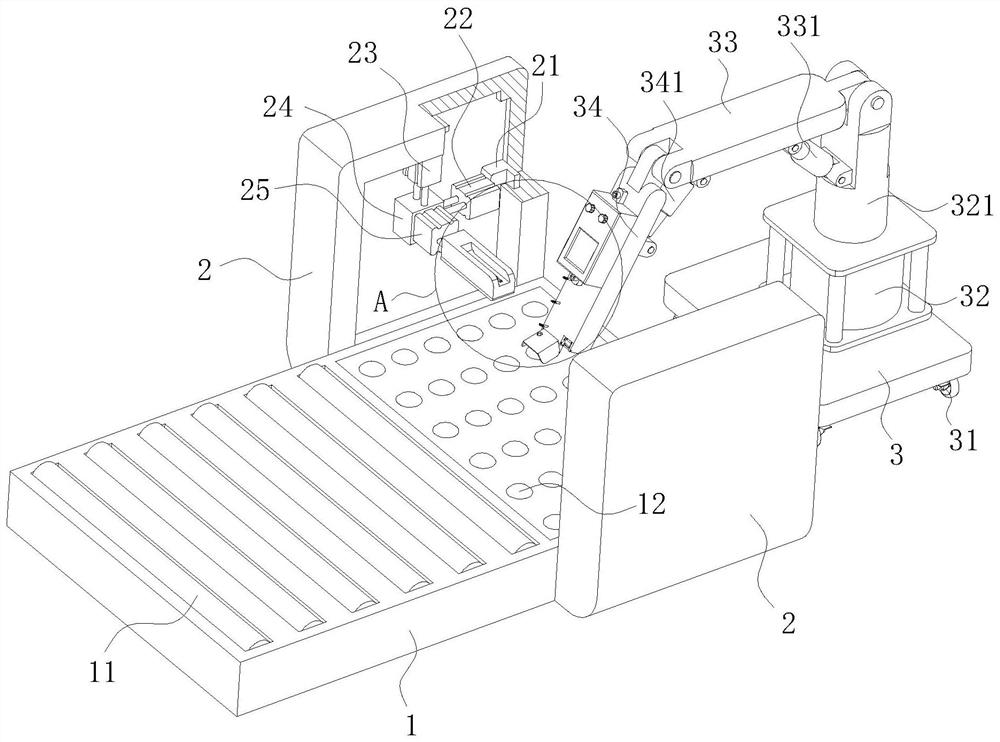

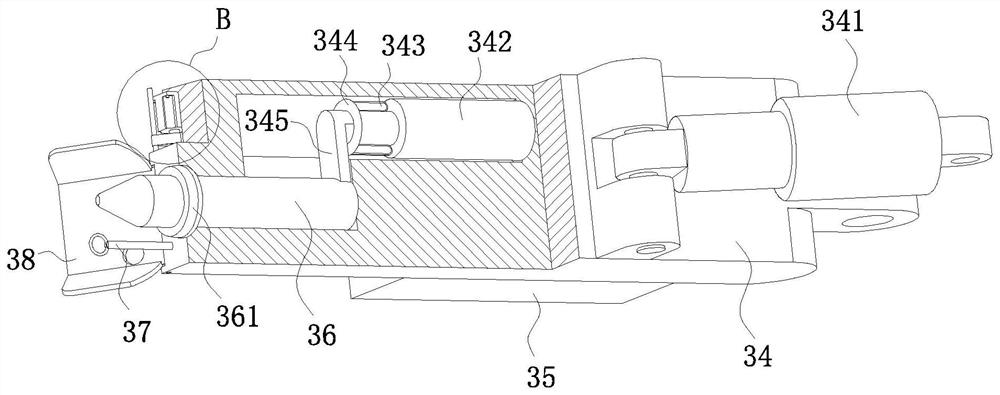

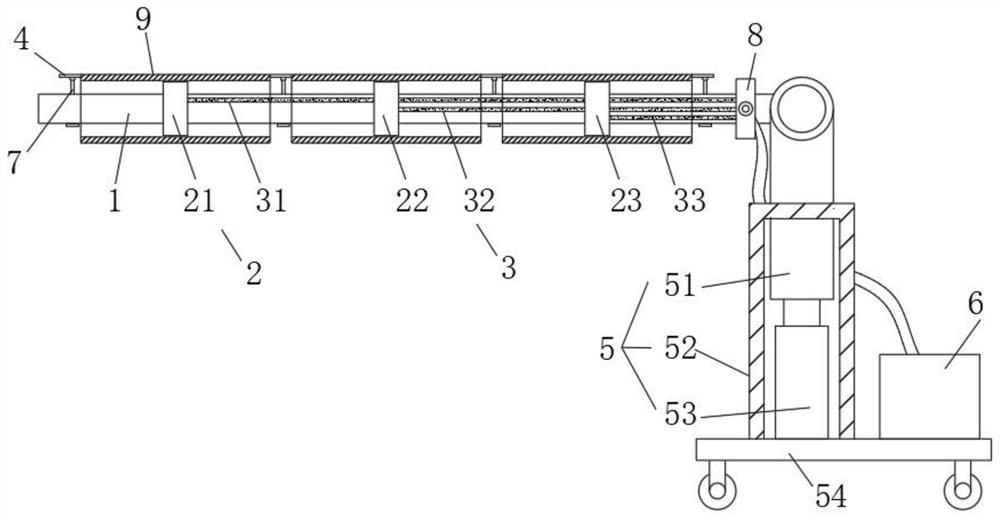

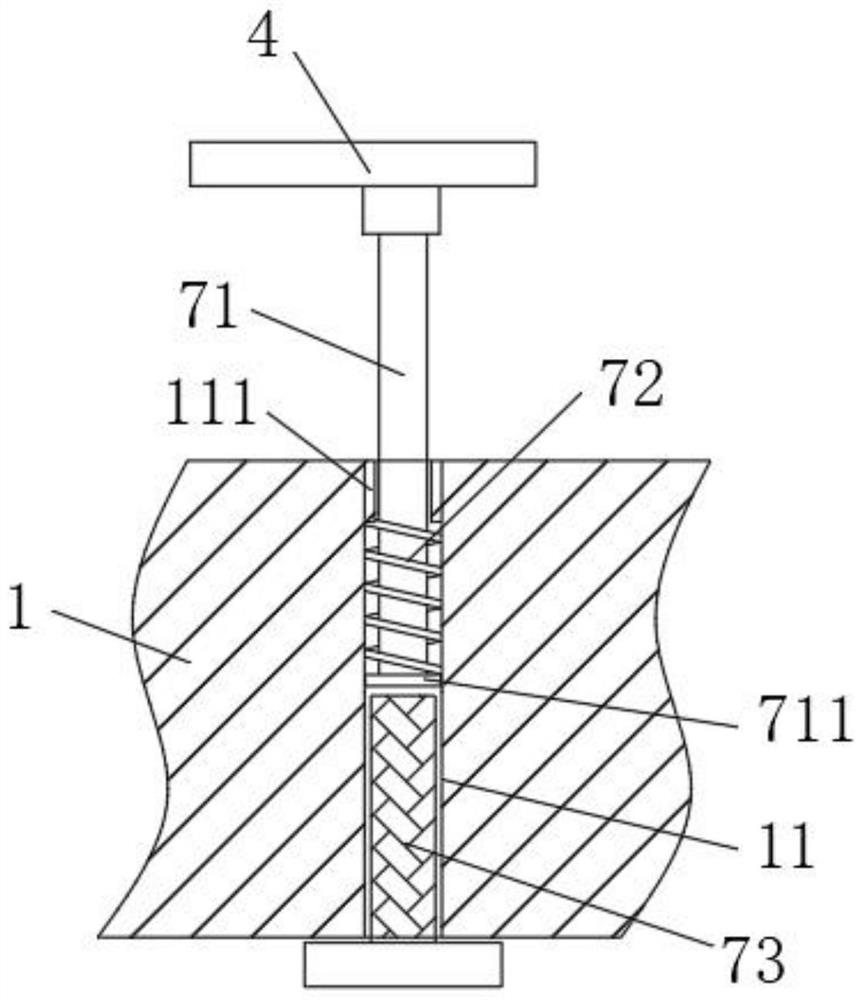

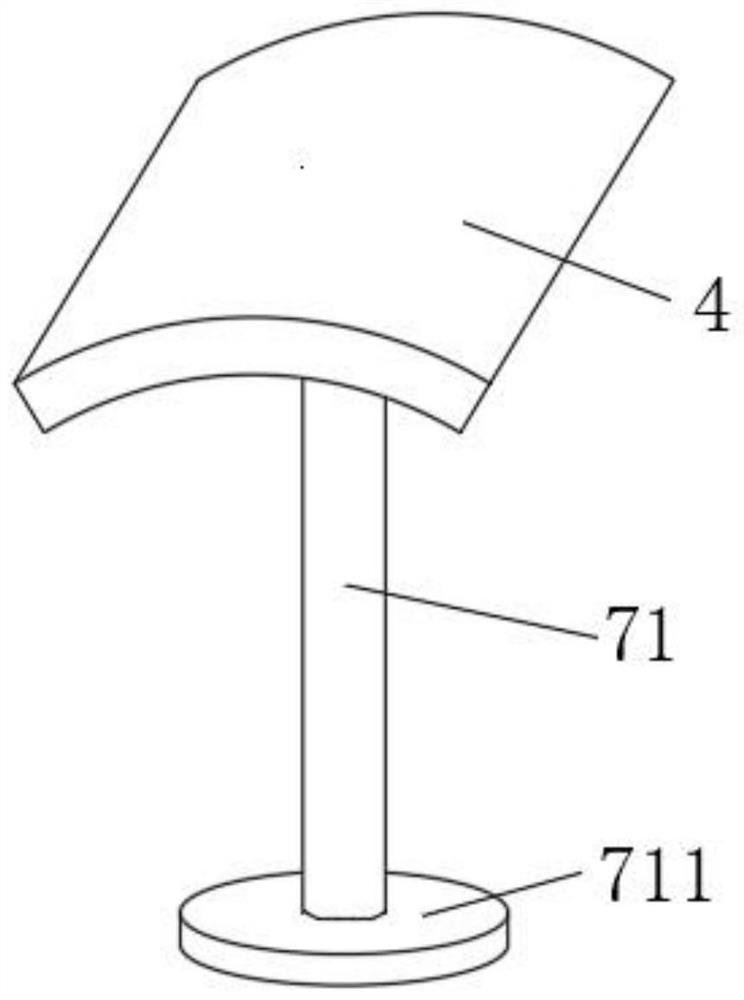

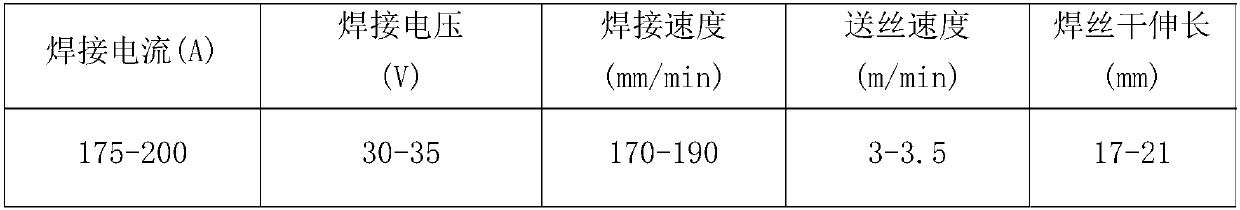

An auxiliary device for welding the cylinder body of a gas storage cylinder

ActiveCN111571018BImprove processing efficiencyEasy to moveLaser beam welding apparatusEngineeringWeld seam

Owner:四川丰科汽车部件有限公司

A self-shielded flux-cored wire for all-position underwater wet welding in deep water environments

ActiveCN106964918BMeet weldingEasy arc startWelding/cutting media/materialsSoldering mediaSlagRare earth

The invention belongs to the technical field of welding materials and discloses a self-protective flux-cored wire for all-position underwater wet welding in a deep water environment. The self-protective flux-cored wire comprises a metal skin and a flux core. The metal skin is formed by rolling an N6 nickel strip. The basic slag system of the flux core is an alkaline calcium fluoride-aluminum-magnesium slag system. The N6 nickel strip comprises, by weight, no smaller than 99.5% of Ni and Co in total, no larger than 0.06% of Cu, no larger than 0.10% of Fe, no larger than 0.05% of Mn, no larger than 0.10% of C, no larger than 0.10% of Si and no larger than 0.005% of S. The flux core comprises, by mass, 52-67% of fluoride, 14-20% of aluminum-magnesium alloy powder, 5-10% of calcium carbonate, 5-15% of ferromanganese, 3-10% of chromium, 4-10% of titanium and 1.5-5% of rare earth. The filling rate of the flux core in the flux-core wire is 24-32%. According to the scheme provided by the invention, the self-protective flux-cored wire can be used for welding under water by 100-200 meters, arcing is easy during welding, arc burning is stable, no arc blowout or breaking phenomenon occurs, an obtained welding seam is attractive in forming, the tensible strength of deposited metal after welding is larger than 500 MPa, and the self-protective flux-cored wire has good impact toughness and meets the all-position welding requirements of medium and low carbon steel and low alloy high strength steel in the deepwater environment.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Electrode fused arc welding machine

ActiveCN101036956BReduce the inductance valueInhibit deteriorationArc welding apparatusWelding power supplyEngineering

A consumable electrode-type arc welder supplies output between a consumable electrode and an object to be welded by a reactor provided in an output path in a welding power resource. The consumable electrode-type arc welder is provided with: an arc striking circuit which is series-connected with a source side of a switch member and an anode side of a diode, wherein an input terminal of the reactoris connected to the source side of the switch member, and an output terminal of the reactor is connected to a cathode side of the switch member; and an arc striking control circuit which turns on theswitch member when a welding start signal is inputted, and by which a large start current is passed between the consumable electrode and the object to be welded in a predetermined time, and then if electrification of the start current is finished, the start current is transfered to a small initial current, the switch membem is turned off when the initial current is passed. Thereby, even if an inductance of the reactor provided in the output path in the welding power resource is a big value, an arc striking performance is good.

Owner:DAIHEN CORP

Arc-extinguishing device of control and protection switch

Owner:RADIN ELECTRIC TECH

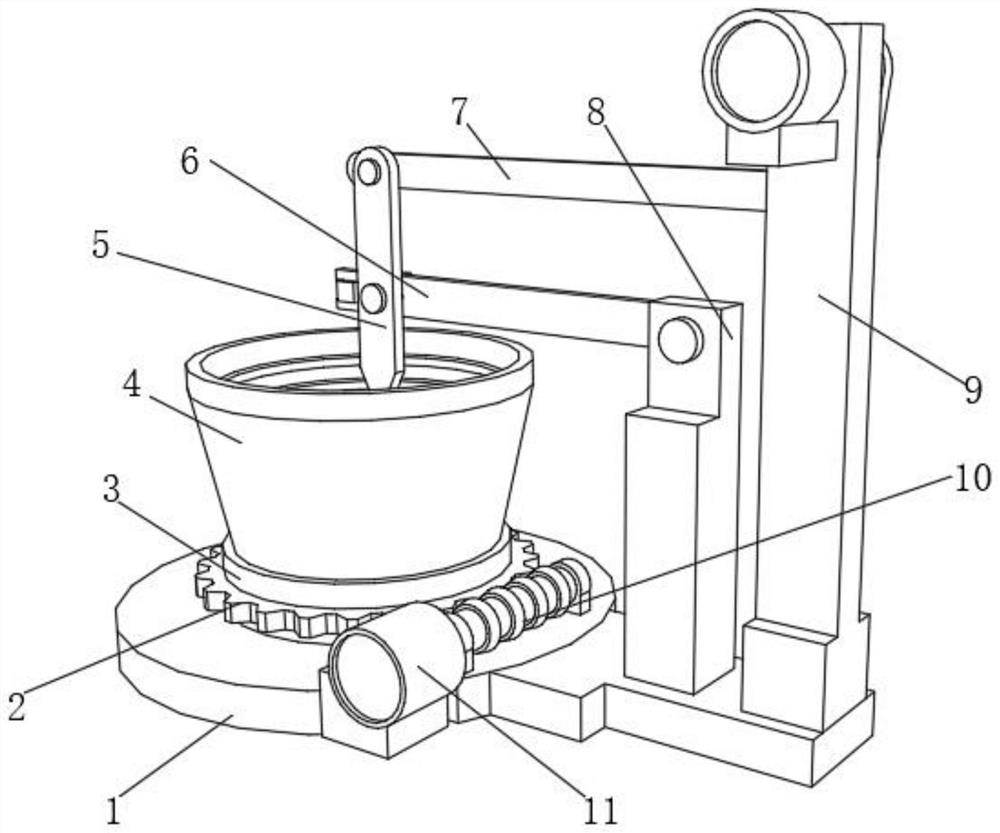

Welding material and production device thereof

ActiveCN112276415AImprove arc striking effectWell formed weldRotating receptacle mixersTransportation and packagingGrain Boundary SlidingGrain boundary migration

The invention discloses a welding material and a production device thereof, relates to the technical field of welding materials, and aims to solve the problem of high-temperature plastic loss cracks.The production device specifically comprises a base, a mounting groove is formed in the outer wall of one side of the top of the base, a first motor is fixed to the inner wall of one side of the mounting groove through a supporting plate, a worm is fixed to the output end of the first motor through a coupler, the two ends of the worm are fixed to the top of the base through bearing pedestals correspondingly, a driving gear is fixed to the outer wall of the top circle center of the base through a supporting shaft and engaged with the worm, a first mounting base and a second mounting base are fixed to the outer wall of one side of the base through bolts, a second motor is fixed to the outer wall of one side of the second mounting base through a supporting plate, and a mounting plate is fixedto the outer wall of the top of the driving gear through threads. Gathering of lattice defects can be blocked, grain boundary sliding and grain boundary migration are prevented from occurring at thesame time and meeting, and then high-temperature plastic loss cracks are avoided.

Owner:东安县双龙焊剂新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com