Arc striking device of electric welding machine and arc striking method thereof

A technology of arc striking device and electric welding machine, which is applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problem that electric wires cannot strike arc smoothly, and achieve the effect of improving welding effect, reducing production cost and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

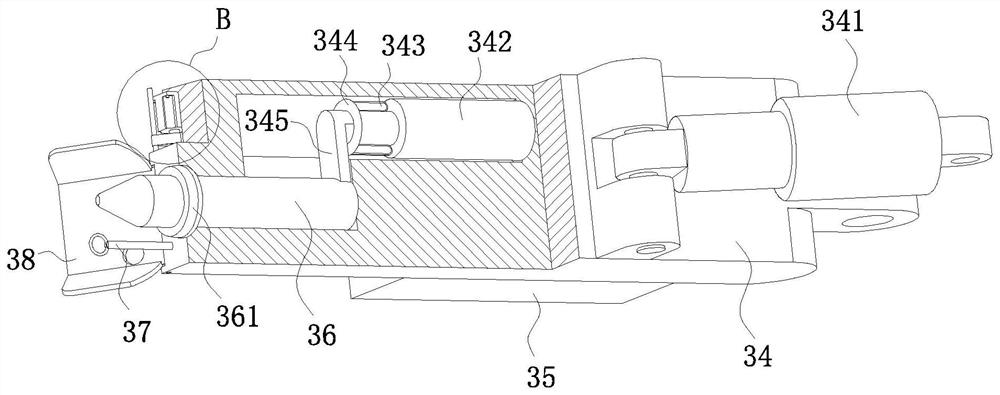

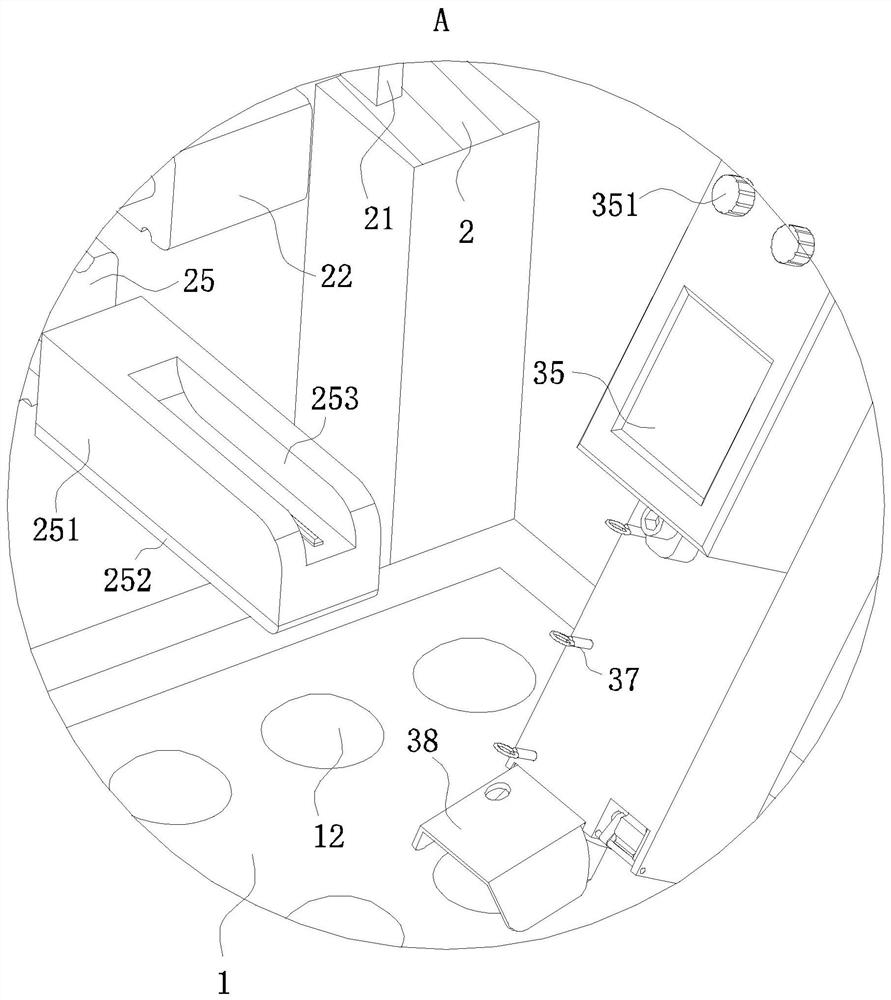

[0035] As an embodiment of the present invention, a protective plate 38 is installed on the end of the second movable plate 34 away from the first movable plate 33; the protective plate 38 is C-shaped and surrounds the vicinity of the tungsten pole 36; the protective plate 38 The interior is hollow; the surface of the protective plate 38 facing the tungsten electrode 36 is provided with evenly arranged micropores; the micropores communicate with the interior of the protective plate 38; the internal hollow space of the protective plate 38 is connected to the external inert gas source Connected through the pipeline; the protective plate 38 is equipped with a rotating shaft 381; the rotating shaft 381 is installed on the second moving plate 34; the protective plate 38 can rotate freely; the second moving plate 34 is installed away from one end of the moving plate one 33 There is a motor 382; the output shaft of the motor 382 is connected to the rotating shaft 381 through a synchro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com