Electrode fused arc welding machine

A technology for arc welding machines and melting electrodes, which is applied to arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of limiting arc ignition performance and insufficient rise of starting current, so as to improve arc ignition performance and prevent arcing Effect of cutting, preventing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

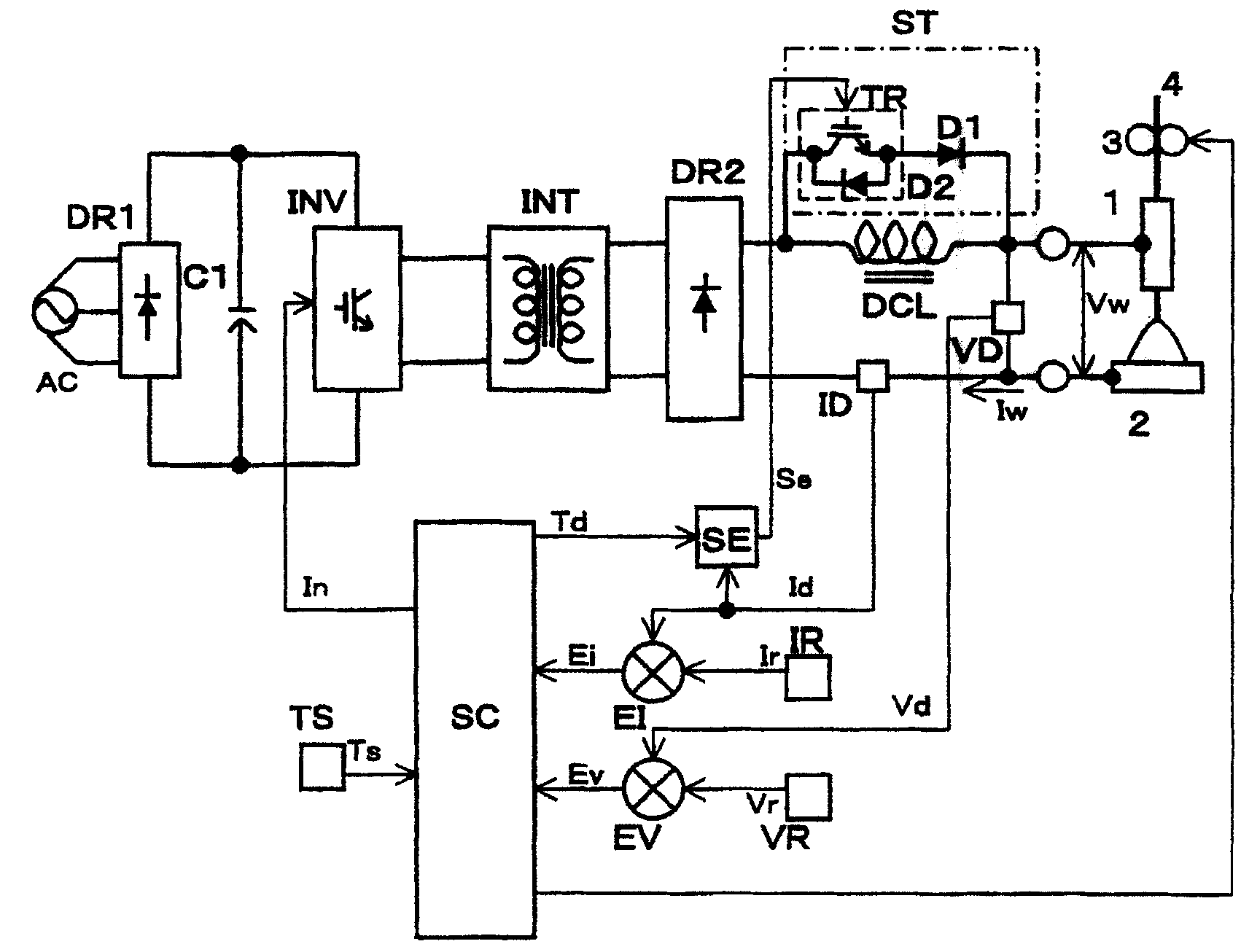

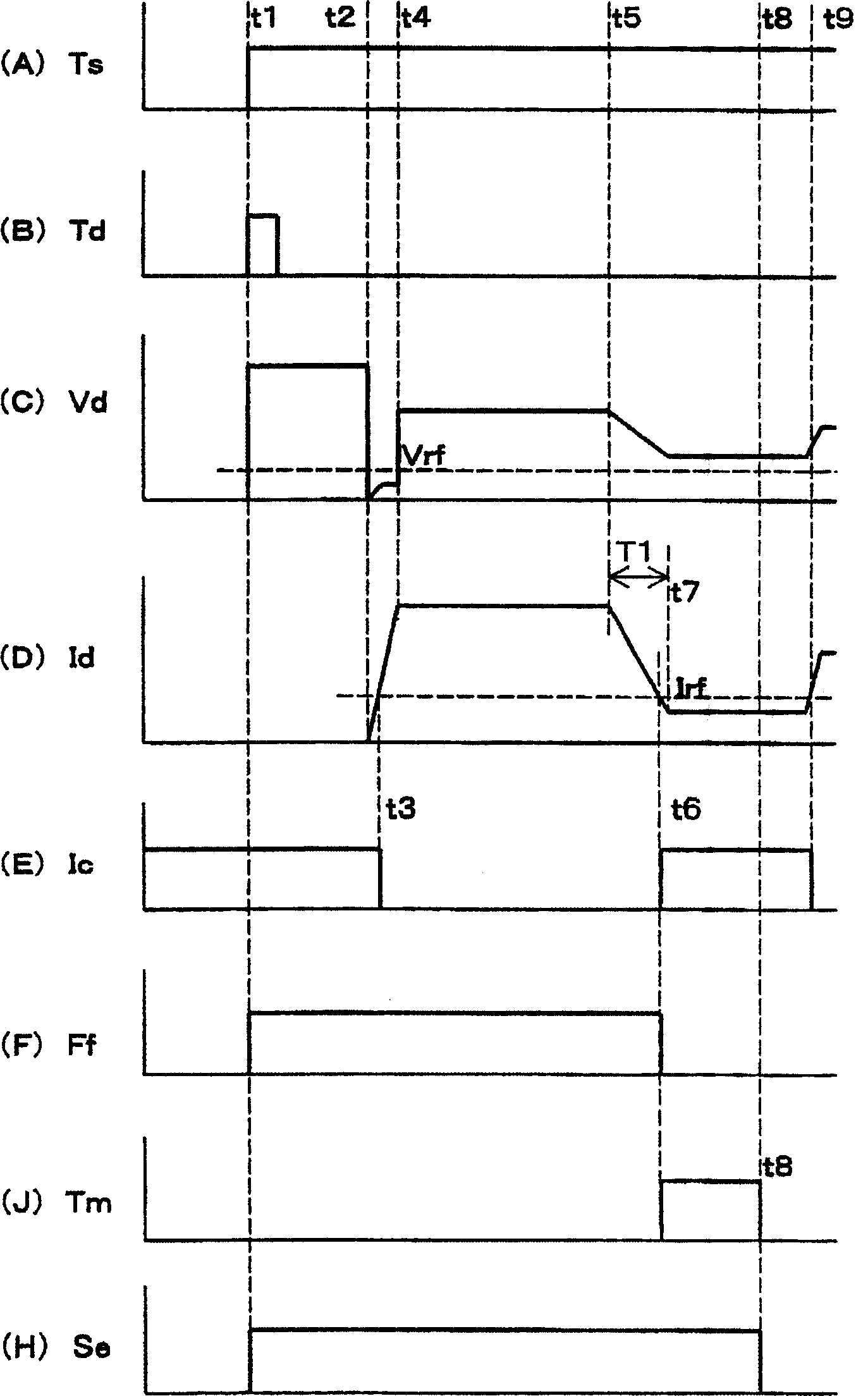

[0038] figure 1 It is an electrical connection diagram of the fusion electrode type arc welding machine according to Embodiment 1 of the present invention. In this figure, with Figure 6 The structural components with the same symbols in the electric connection diagram of the prior art fusion electrode arc welding machine shown in FIG.

[0039] exist figure 1 In the electrical connection diagram of the molten electrode arc welding machine shown, the arc starting circuit ST is formed by a switching element (such as an IGBT) TR and a diode D1, the input terminal of the reactor DCL is connected to the drain side of the switching element TR, and the output terminal Connect to the cathode side of diode D1. In addition, since the withstand voltage of the reverse voltage of the switching element (IGBT) is low, the protection diode D2 is generally provided inside the module. The reactor DCL is short-circuited or released only by the switching element TR, and the energy charged t...

Embodiment approach 2

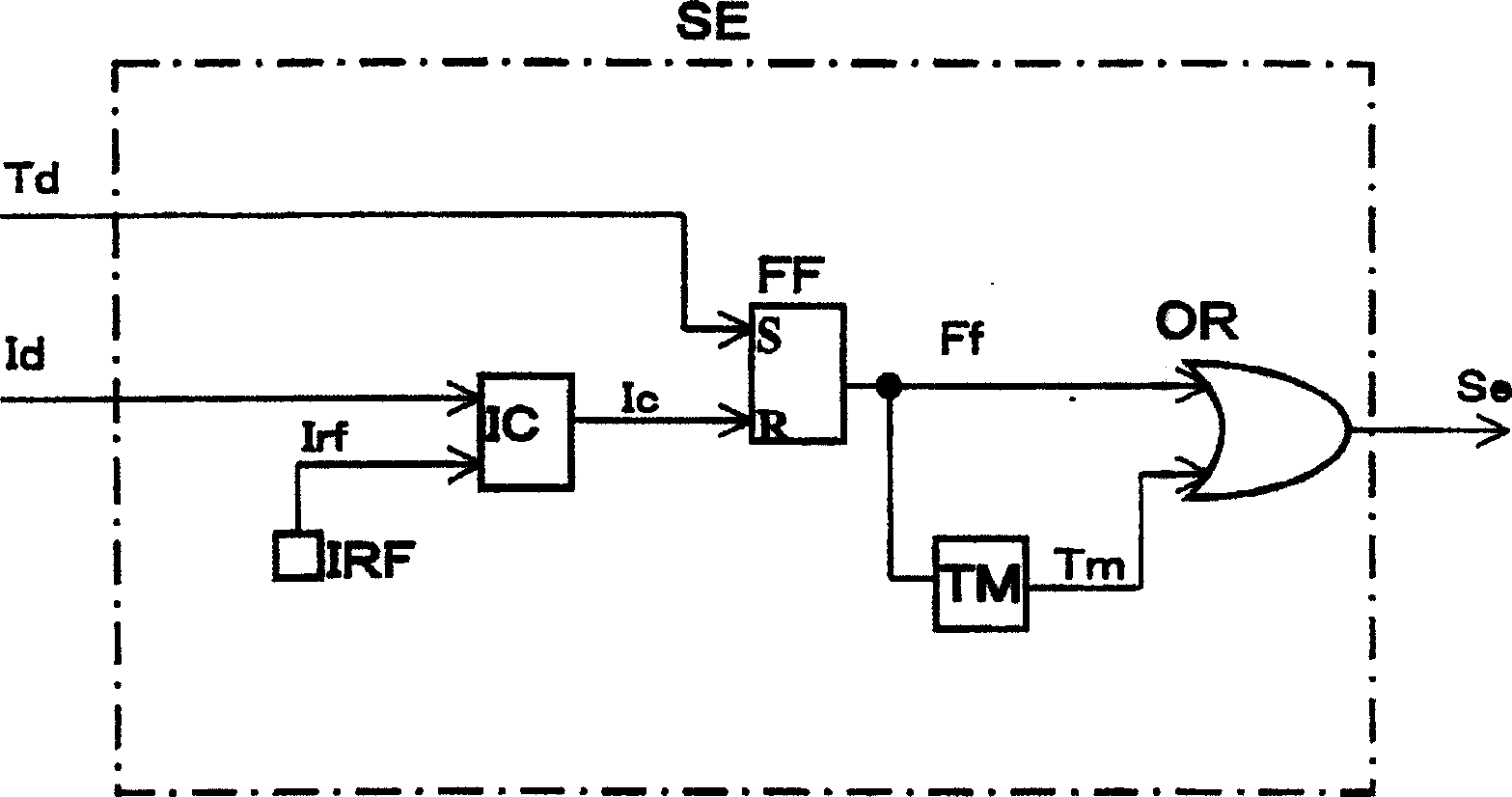

[0055] Figure 4 It is a detailed diagram of the second arc striking control circuit SE2 related to Embodiment 2, in which, and figure 2 In the shown arc start control circuit SE of Embodiment 1, components with the same reference numbers operate in the same manner, and thus description thereof will be omitted, and only components with different reference numbers will be described.

[0056] Figure 4 The second arc striking control circuit SE2 shown in is composed of flip-flop circuit FF, current comparison circuit IC, reference current setting circuit IRF, second flip-flop circuit FF2, second current comparison circuit IC2, and second reference current setting The circuit IRF2 and the OR logic circuit OR are formed.

[0057] The second current comparison circuit IC2 compares the predetermined reference current setting value Irf2 with the welding current detection signal Id, and if it is higher than the second reference current setting value Irf2, the second current compari...

Embodiment approach 3

[0071] Figure 6 Electrical connection diagram of a molten electrode arc welding machine for AC pulsed MIG welding. In this figure, with figure 1 In the electrical connection diagram of the fusion electrode arc welding machine according to Embodiment 1 of the present invention shown, components with the same symbols operate in the same way, so descriptions are omitted, and only components with different symbols will be described.

[0072] Figure 6 The shown secondary-side inverter circuit INV2 is installed on the output side of the reactor DCL, so that the output smoothed to DC by the secondary rectification circuit DR2 and the reactor DCL operates at a low frequency (for example, 50 to 200 Hz) necessary for the AC pulse MIG , generating an AC arc.

[0073] Circuit configurations other than the secondary-side inverter circuit INV2 shown above, and figure 1 The electric connection diagram of the fusion electrode type arc welding machine related to Embodiment 1 shown has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com