Arc start control method in consumable electrode arc welding

A technology of arc welding and melting electrodes, which is applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as prone to deposition, and achieve the effects of arc ignition, high-quality arc ignition, and suppression of instantaneous arc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

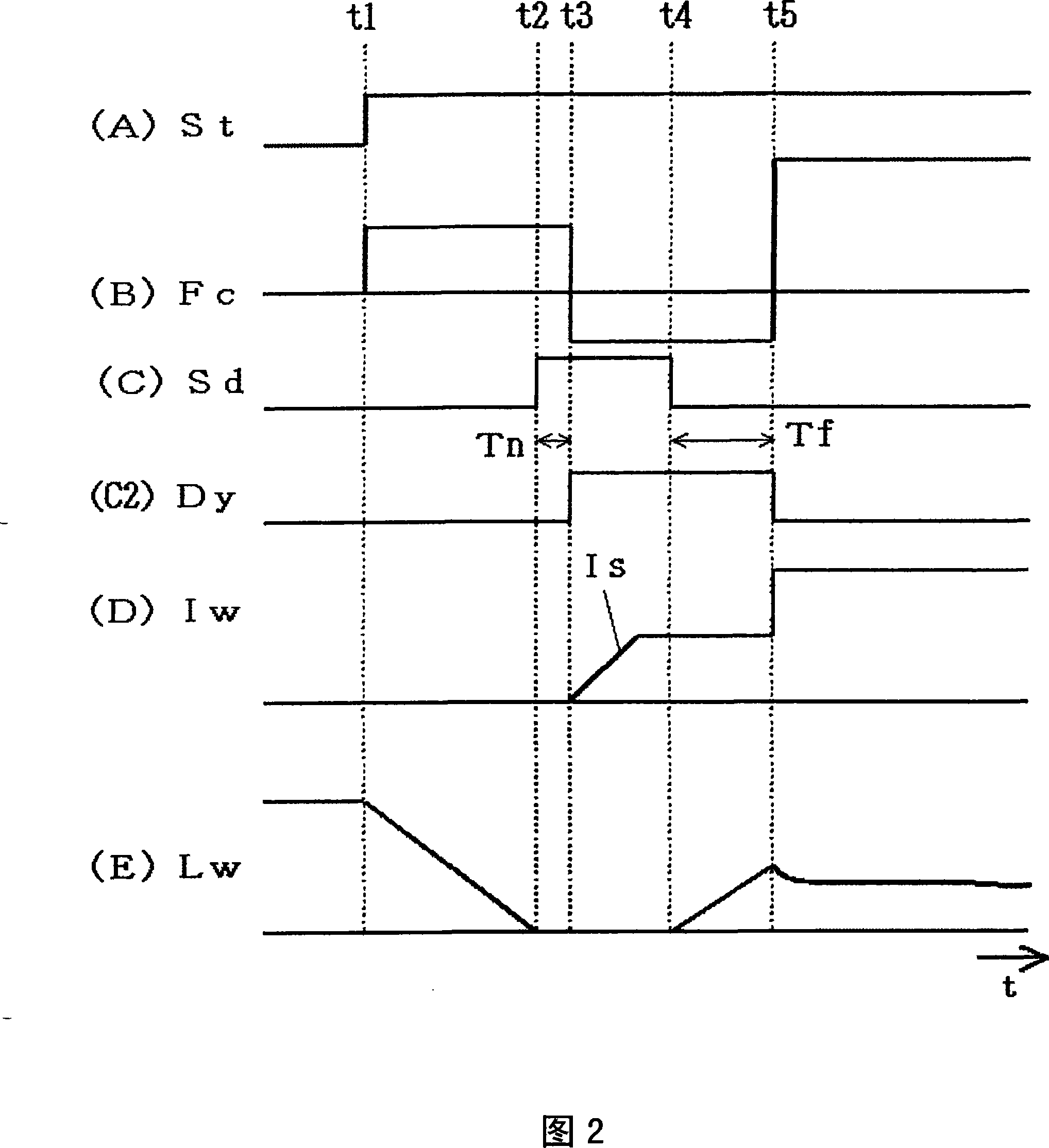

[0033] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

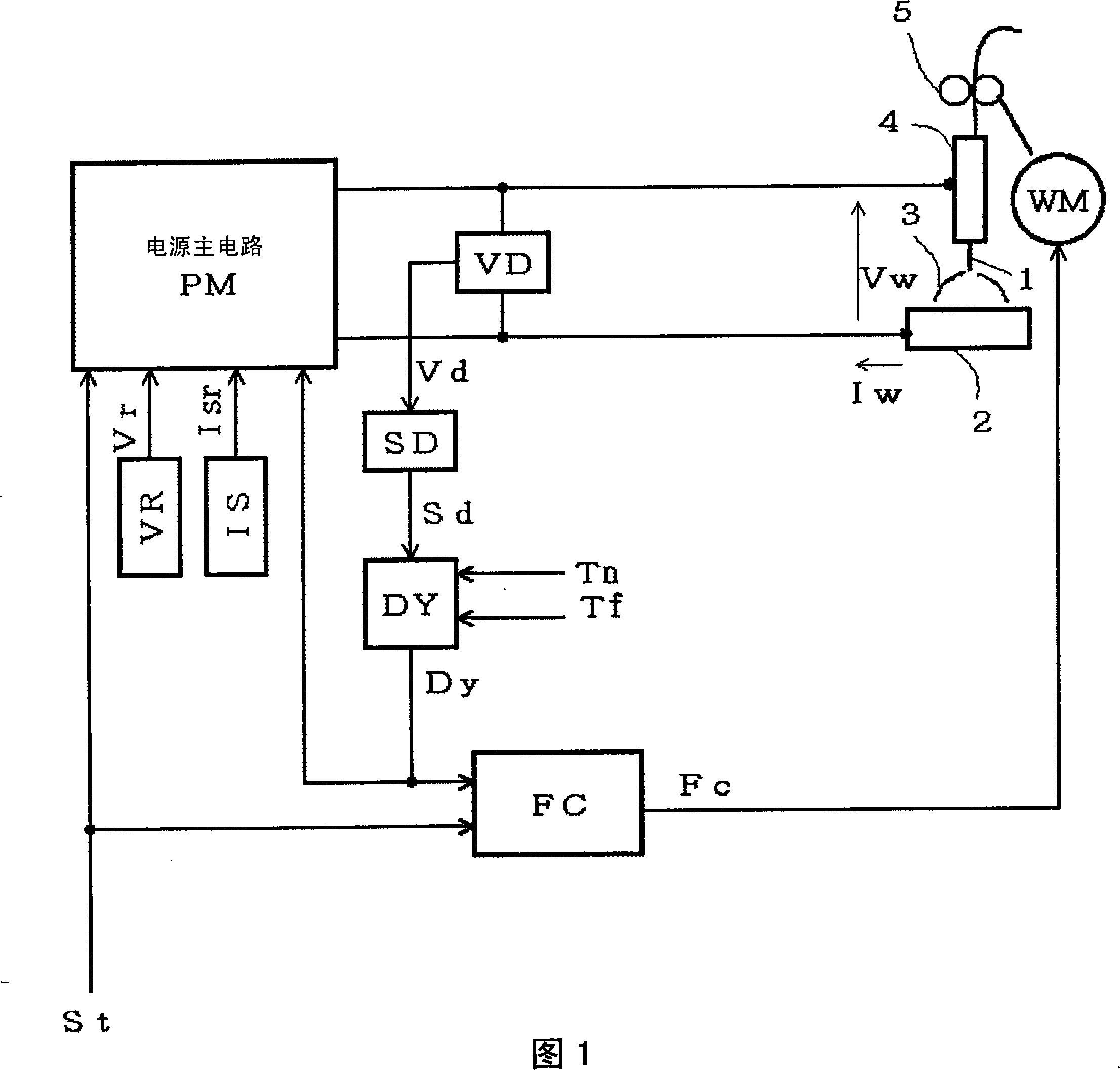

[0034] FIG. 1 is a block diagram of a welding power source PS for implementing an arc ignition control method related to molten electrode arc welding according to an embodiment of the present invention. As a welding apparatus, it is the same as that of FIG. 4 mentioned above, but the welding power supply PS is replaced with the welding power supply of this figure. Hereinafter, each functional block will be described with reference to this figure.

[0035]The voltage setting circuit VR outputs a predetermined voltage setting signal Vr. The initial current setting circuit IS outputs a predetermined initial current setting signal Isr. The power supply main circuit PM takes commercial power such as three-phase 200V as input, and performs output control such as inverter control based on the voltage setting signal Vr when the start signal St is at a high level, and outputs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com