High-voltage arc strike electric welding machine

An electric welding machine and high-voltage technology, which is applied in the field of electric welding machines with arc striking devices, can solve the problems of poor arc striking effect, large current loss, and low inductive reactance of secondary coils, etc., and achieve good arc striking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

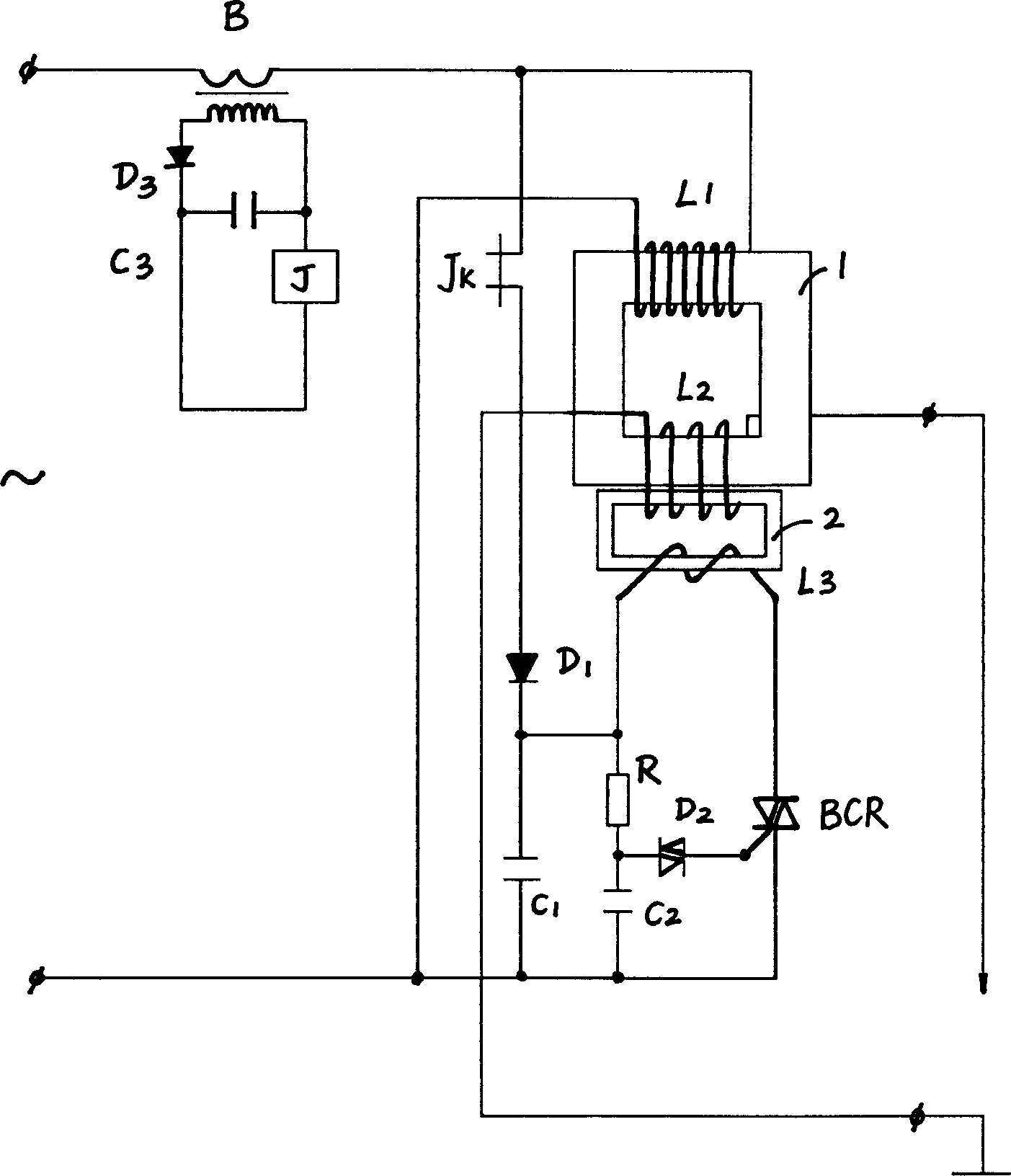

[0011] The high-voltage arc ignition welding machine of the embodiment includes a main coil L1 and a secondary coil L2 wound on the iron core, the main coil L1 is connected to the power input terminal, the secondary coil L2 is connected to the welding output terminal, and the iron core is composed of the main iron core 1 Composed of the auxiliary iron core 2, the two iron cores partially overlap, the main coil L1 is wound on the main iron core 1, the secondary coil L2 is wound on the overlapping part of the main iron core 1 and the auxiliary iron core 2, and the auxiliary iron core 2 is set There is an auxiliary coil L3, and the auxiliary coil L3 is connected to the capacitive discharge oscillating circuit as a discharge coil of the circuit.

[0012] The capacitive discharge oscillating circuit is composed of capacitors C1, C2, diode D2, bidirectional trigger diode D3, silicon controlled rectifier BCR, and a discharge coil that is an auxiliary coil L3. This circuit uses capaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com