Arc extinguish chamber and direct current contactor adopting same

A DC contactor and arc-extinguishing chamber technology, applied in the field of arc-extinguishing chamber, can solve the problems of large loss of arc-extinguishing chamber, short life, long arc movement time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

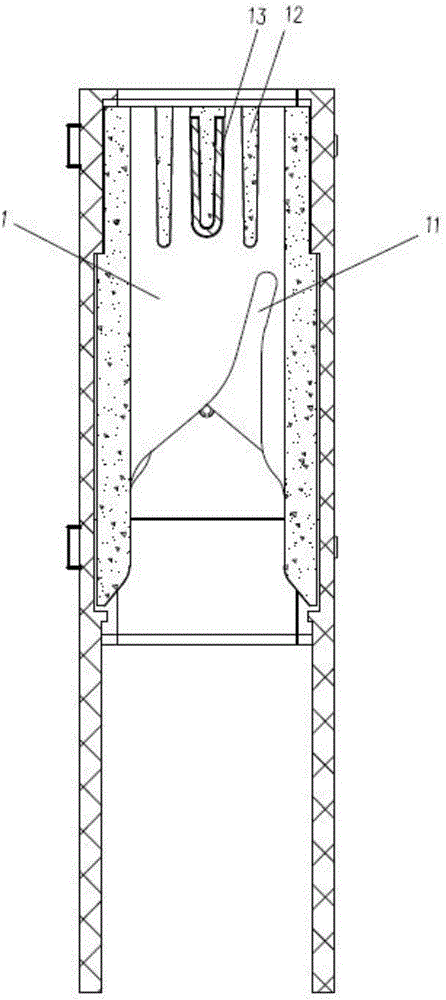

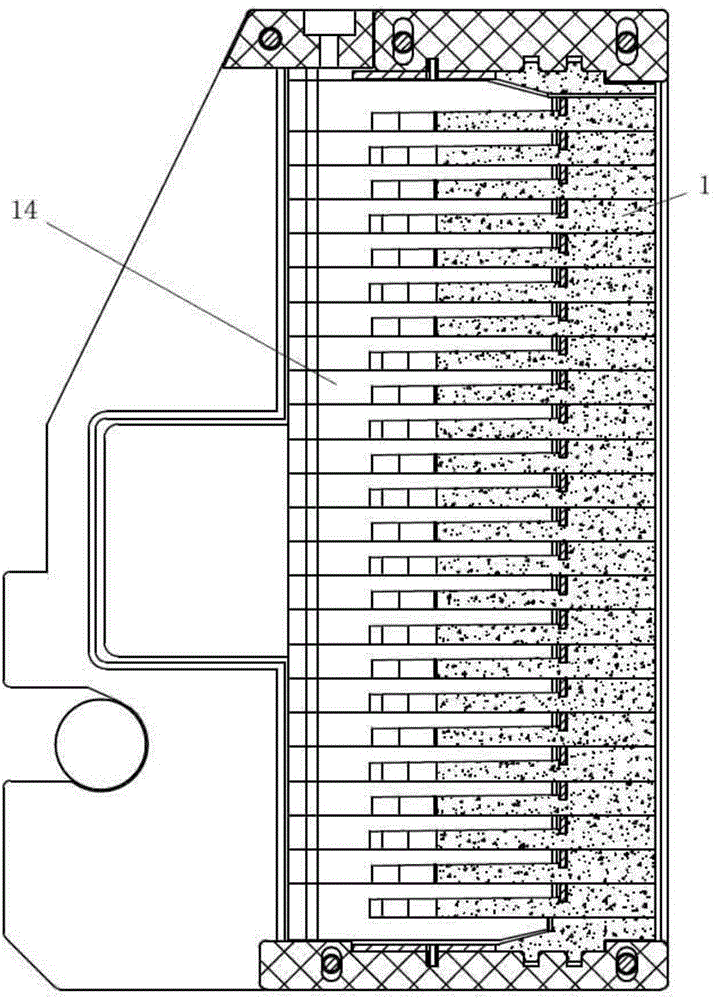

[0042] The structure of an arc extinguishing chamber according to the present invention is as follows: figure 2 As shown, in the arc extinguishing chamber 14, 26 arc extinguishing plates 1 are alternately arranged in layers. Except for the top arc extinguishing plate 1 and the bottom arc extinguishing plate 1, the arc extinguishing plate 1 in the middle position has an arc guide opening at one end. 11. The other end is provided with three arc extinguishing ribs 12 facing the arc extinguishing chamber 14 at intervals, and a bent and connected metal sheet 13 is arranged on the arc extinguishing rib 12 at the middle position. In this embodiment, the bent and connected The metal sheet 13 is U-shaped, and its opening direction faces the wall of the arc extinguishing chamber. The arc extinguishers 1 located at the top and bottom, in order to prevent arc leakage, are not provided with an arc guide port 11, and its structure is as follows Figure 3A with Figure 3B As shown, two pr...

Embodiment 2

[0046] On the basis of the arc extinguishing chamber 14 described in Embodiment 1, arc guide openings 11 are provided on the layered arc extinguishing plates 1 except for the top and bottom arc extinguishing plates 1 . The arc guide opening 11 is arranged on one side of the center line of the arc extinguishing plate 1 , and the positions of the arc guide openings 11 of two adjacent arc extinguishing plates 1 are staggered. In this embodiment, the arc guide opening 11 starts from one end of the arc extinguishing plate 1 and gradually shrinks to end at one side of the center line of the arc extinguishing plate 1 . exist Figure 5B As shown, as on one layer of arc extinguishing sheet 1, the arc guide port 11 gradually shrinks to the right side, then in the adjacent upper and lower layer of arc extinguishing sheet 1, as Figure 5A As shown, the arc guide openings 11 are gradually shrunk to the left side, so that the arc guide openings 11 on each layer of arc extinguishing plates ...

Embodiment 3

[0050] A DC contactor such as Figure 4 As shown, it includes a moving contact assembly 3 and a static contact assembly 5, an upwardly bent upper arc angle assembly 2 is arranged beside the moving contact of the moving contact assembly 3, and an Next to the static contact is a downwardly bent lower arc-guiding angle assembly 6, and an arc-extinguishing chamber 14 is arranged between the upper arc-guiding angle assembly 2 and the lower arc-guiding angle assembly 6, and the upper and lower arc-guiding angles The assembly 6 can guide the arc more quickly and stably into the arc extinguishing chamber 14, avoiding the free movement of the arc to damage other structures in the contactor; the arc extinguishing chamber 14 is alternately arranged with 26 pieces of arc extinguishing plates 1, such as figure 2 As shown, in addition to the top arc extinguishing plate 1 and the bottom arc extinguishing plate 1, the arc extinguishing plate 1 in the middle position has an arc guide port 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com