Device and method for preparing AZO transparent conducting film through magnetron sputtering

A technology of transparent conductive film and magnetron sputtering, applied in sputtering plating, ion implantation plating, metal material coating process, etc., can solve the problems of low ionization rate of argon gas, and the photoelectric performance of film formation needs to be improved. , to achieve the effect of lowering the surface barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

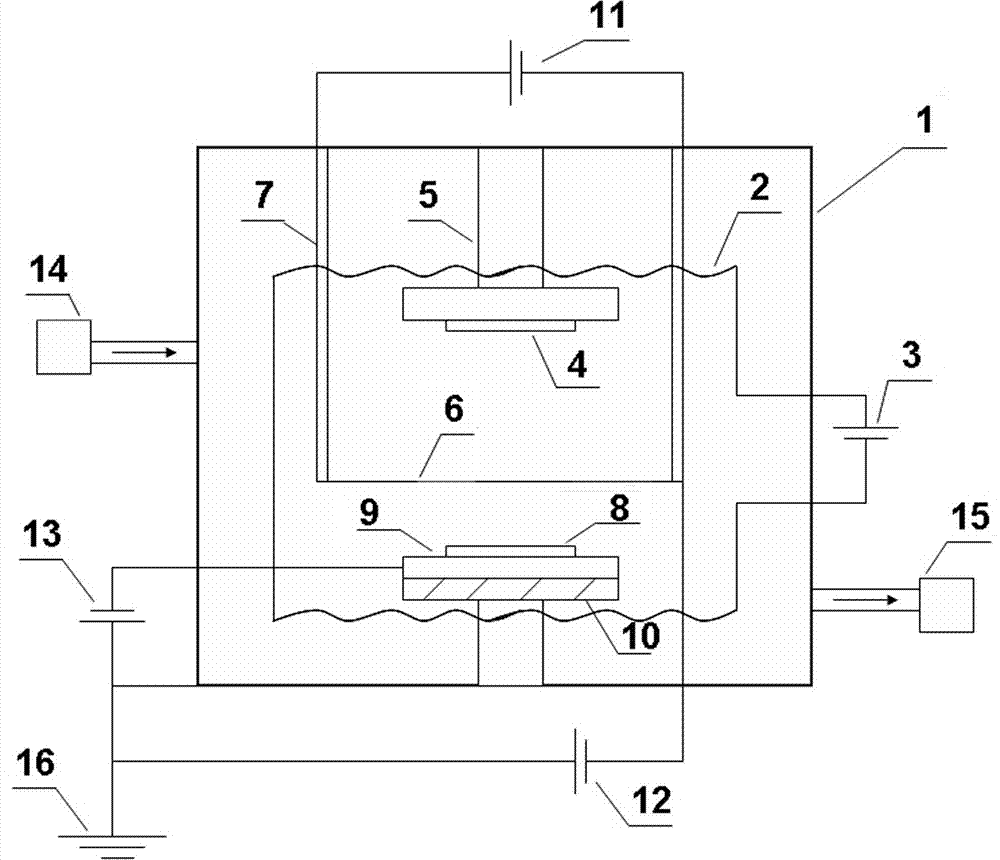

Image

Examples

Embodiment 1

[0020] Utilize the flow control system to control the flow rate of argon to be 200 sccm, utilize the vacuum pump group to control the process pressure to be 5Pa, the voltage of the stainless steel substrate power supply 13 is 750V, and control the current through the tungsten wire to be 25A by adjusting the voltage of the tungsten wire heating power supply 11, and pass Adjust the voltage of the coil power supply 3 to control the current through the electromagnetic coil 2 to 80A, the number of turns of the electromagnetic coil 2 to 60 turns, the substrate heating temperature to 200°C, and the composition of the AZO target: ZnO: Al 2 o 3 =98%: 2% (wt.%). Under the above process parameter conditions, the sputtering time was 30 minutes, and the AZO film was prepared with a resistivity of 5×10 -4 ohm. cm, and the average transmittance in visible light wavelengths is 86%.

Embodiment 2

[0022] Utilize the flow control system to control the flow rate of argon gas to be 200 sccm, utilize the vacuum pump group to control the process pressure to be 10Pa, and the voltage of the stainless steel base power supply 13 is 800V, and the current through the tungsten wire is controlled to be 30A by adjusting the voltage of the tungsten wire heating power supply 11, and the Adjust the voltage of the coil power supply 3 to control the current through the electromagnetic coil 2 to 90A, the number of turns of the electromagnetic coil 2 to 70 turns, the substrate heating temperature to 200°C, and the composition of the AZO target: ZnO:Al 2 o 3 =98%: 2% (wt.%). Under the conditions of the above process parameters, the sputtering time was 30 minutes, and the AZO film was prepared with a resistivity of 4.7×10 -4 ohm. cm, and the average transmittance within the visible wavelength is 86.8%.

Embodiment 3

[0024] Utilize the flow control system to control the flow rate of argon to be 200 sccm, utilize the vacuum pump group to control the process pressure to be 8Pa, the voltage of the stainless steel base power supply 13 is 600V, and control the current passing through the tungsten wire to be 20A by adjusting the voltage of the tungsten wire heating power supply 11. Adjust the voltage of the coil power supply 3 to control the current through the electromagnetic coil 2 to 60A, the number of turns of the electromagnetic coil 2 to 80 turns, the substrate heating temperature to 200°C, and the composition of the AZO target: ZnO: Al 2 o 3 =98%: 2% (wt.%). Under the conditions of the above process parameters, the sputtering time was 30 minutes, and the AZO film was prepared with a resistivity of 4.7×10 -4 ohm. cm, and the average transmittance in visible light wavelengths is 87.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com