Golden fragrant nut and preparation method thereof

A technology of nuts and equipment, which is applied in the field of Jinxiang nuts and its preparation, can solve the problems of difficult removal of waste residue, increase of labor force, long baking or long baking time, etc., so as to ensure the consistency of appearance, improve the compactness of texture, Uniform wrapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

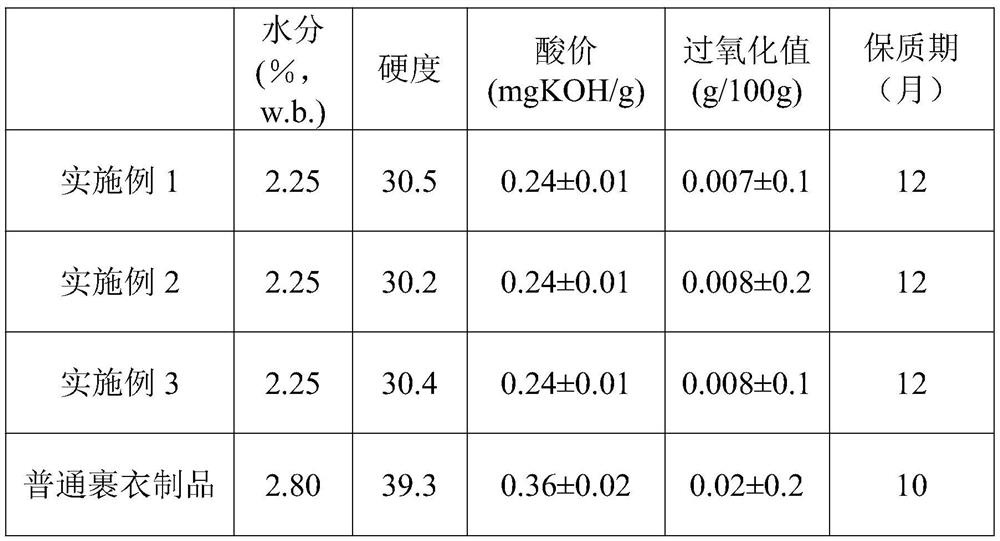

Examples

Embodiment 1

[0043] The nut product selects nut kernels, and the preparation method of Jinxiang nut kernels specifically includes the following steps:

[0044] (1) Baking: put 2kg of nut raw materials into an oven at a temperature of 105°C and bake for 2 hours;

[0045] (2) Cooling: Use rapid cooling equipment to cool the freshly baked nuts to room temperature. The temperature of the cold air is 5°C and the wind speed is 10 m / s. cool down;

[0046] (3) Prepare the coating solution: prepare the coating solution according to the mass percentage of nuts at 5%, and the coating solution is composed of: 60g of water, 1g of xanthan gum, 8g of maltose syrup, and 31g of white granulated sugar according to the mass ratio of the solution;

[0047] (4) Prepare the pre-powder: prepare the pre-powder according to the mass percentage of nuts at 15%. The chili powder of 100g, the cinnamon powder of 0.9g, the yeast extract of 9g are mixed and stirred evenly to make the front powder;

[0048] (5) Garment...

Embodiment 2

[0055] The nut product selects nut kernels, and the preparation method of Jinxiang nut kernels specifically includes the following steps:

[0056] (1) Baking: put the nut raw material into an oven with a temperature of 107°C and bake for 2 hours;

[0057] (2) Cooling: Use rapid cooling equipment to cool the freshly baked nuts to room temperature. The temperature of the cold air is 7°C, and the wind speed is 15 m / s. cool down;

[0058] (3) Prepare coating liquid: prepare coating liquid according to the mass percentage of nuts at 5%, and the coating liquid is composed of: 57g of water, 1.2g of xanthan gum, 9g of maltose syrup, and 32.8g of white granulated sugar;

[0059] (4) Prepare the pre-powder: prepare the pre-powder according to the mass percentage of nuts at 15%. The pre-powder is composed of: 245.4g of powdered sugar, 36g of salt powder, 3.9g of onion powder, 3g of garlic powder, 1.8 The chili powder of 100g, the cinnamon powder of 0.9g, the yeast extract of 9g are mi...

Embodiment 3

[0067] The nut product selects nut kernels, and the preparation method of Jinxiang nut kernels specifically includes the following steps:

[0068] (1) Baking: Put 2kg of nut raw materials into an oven at a temperature of 110°C and bake for 2 hours;

[0069] (2) Cooling: use rapid cooling equipment to cool the freshly baked nuts to room temperature. The temperature of the cold air is 10°C and the wind speed is 25 m / s. cool down;

[0070] (3) Prepare coating liquid: prepare coating liquid according to the mass percentage of nuts at 5%, and the coating liquid is composed of: 55g of water, 1.5g of xanthan gum, 9.5g of maltose syrup, and 34g of white granulated sugar;

[0071] (4) Prepare the pre-powder: prepare the pre-powder according to the mass percentage of nuts at 15%. The pre-powder is composed of: 240g of powdered sugar, 39g of salt powder, 4.5g of onion powder, 3.6g of garlic powder, 2.1 The chili powder of 1g, the cinnamon powder of 1.2g, the yeast extract of 9.6g are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com